Oil cooling low consumption external rotor permanent magnetic motor

A permanent magnet motor and outer rotor technology, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of insufficient use of thermal conductivity, increased motor oil friction loss, decreased power density, etc., to achieve harmonic reduction, The effect of increasing the oil intake and improving the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

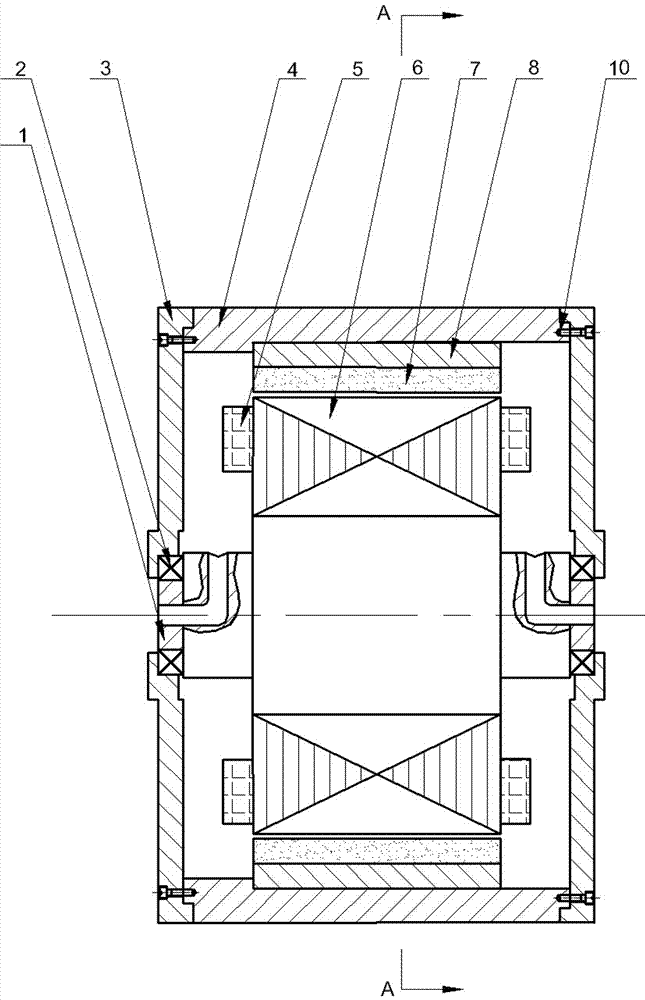

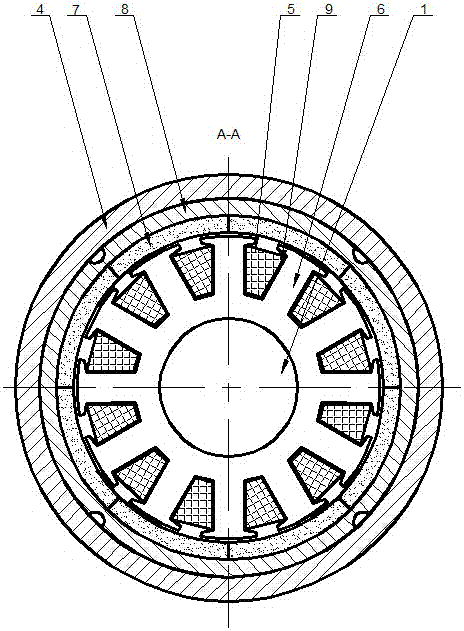

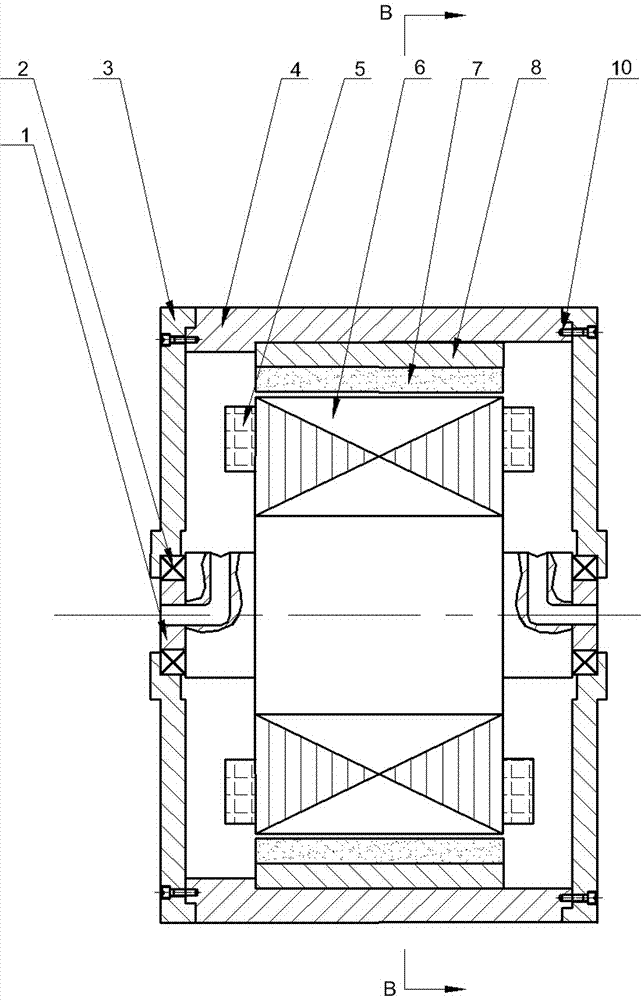

[0029] Specific implementation mode one: as Figure 1~Figure 13 As shown, this embodiment describes an oil-cooled, low-consumption external rotor permanent magnet motor, which includes a stator and a rotor. The stator includes a stator shaft 1, a stator core 6, an insulating layer 9 and a plurality of stator coils 5; the rotor includes a casing 4, a rotor yoke 8, two bearings 2, a plurality of magnetic steel 7 and two end covers 3; the rotor yoke 8 is fixed on the inner surface of the casing 4, The inner surface of the rotor yoke 8 is located on the same circumference, and a plurality of magnetic steels 7 are closely arranged in sequence. The two ends of the stator shaft 1 are respectively connected to the two end covers 3 through a bearing 2. The casing 4 rings are set On the outside of the plurality of magnetic steels 7, the housing 4 and the two end covers 3 are detachably fixedly connected by screws 10, and the inner ring of the plurality of magnetic steels 7 is fitted wit...

specific Embodiment approach 2

[0031] Specific implementation mode two: as Figure 5~Figure 9 As shown, this embodiment further describes the specific embodiment 1. The chamfered inner corners 11 of the plurality of magnetic steels 7 and the inner circular surface of the rotor yoke 8 form a plurality of axial channels 12 .

specific Embodiment approach 3

[0032] Specific implementation mode three: as Figure 10 and Figure 11 As shown, this embodiment will further explain the specific embodiment 1. The described screw-in drainage groove 7-1 is a left-handed or right-handed screw-in drainage groove 7-1, and the described left-handed or right-handed screw-in drainage groove 7-1 The setting principle of 7-1 is: when the rotor is placed upright on a horizontal plane, the screw-in drainage groove 7-1 rotates and rises in the counterclockwise direction, which is the left-handed screw-in drainage groove 7-1; Rotating upward in the clockwise direction is the right-handed spiraling drainage groove 7-1, wherein the cross-sectional shape of the spiraling drainage groove 7-1 is rectangular, semicircular, triangular or trapezoidal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com