Circulating oil-cooling type electric-magnetic iron remover

A technology of electromagnetic iron remover and circulating oil cooling, which is applied in the direction of circuits, magnetic separation, magnetic objects, etc., can solve the problems that are not suitable for large-scale super-strong electromagnetic iron remover, the heat dissipation effect is not very ideal, and the external structure size is increased, etc., to achieve Reduce local overheating, improve the utilization rate of magnetic potential, and improve the effect of magnetic attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

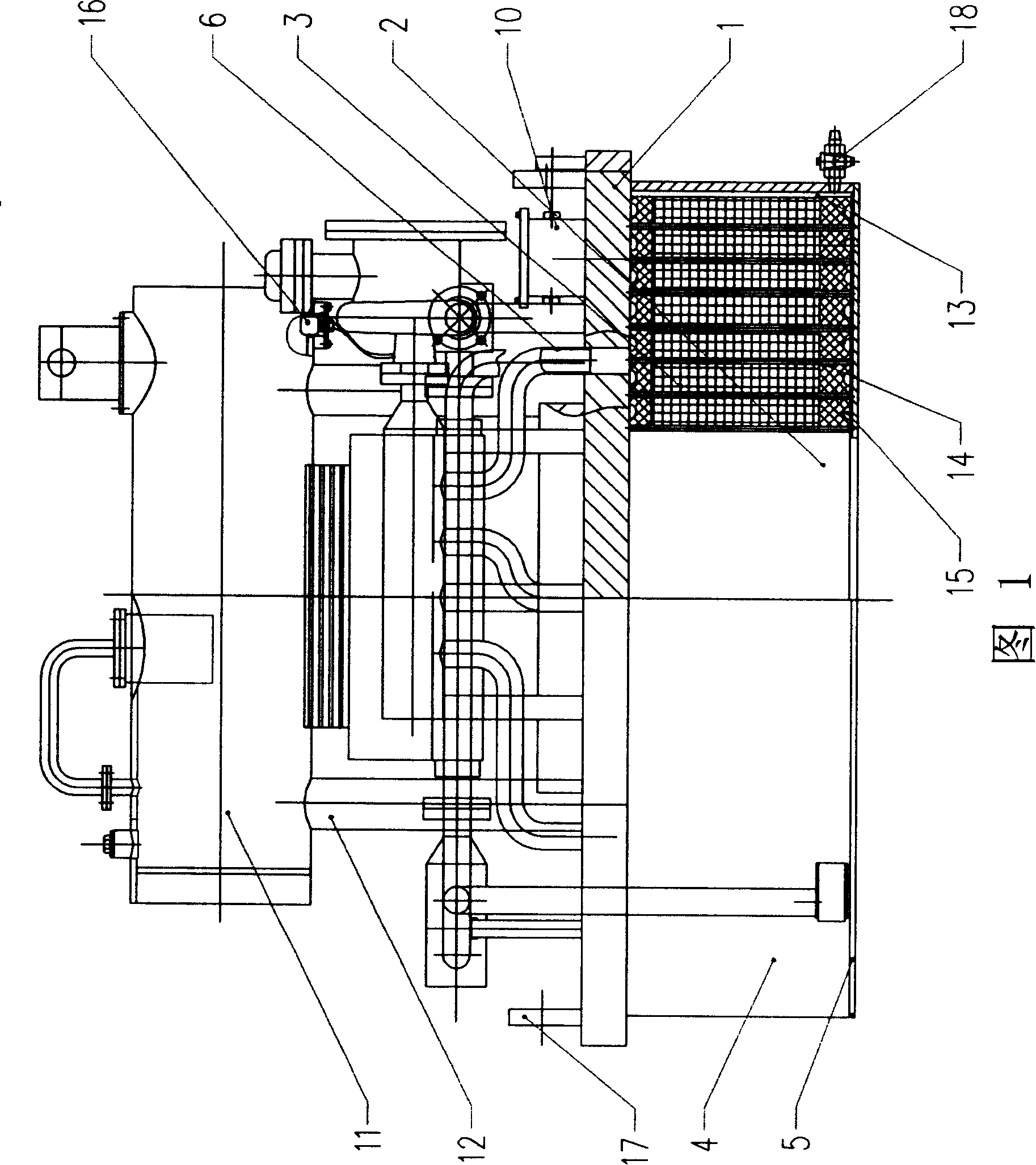

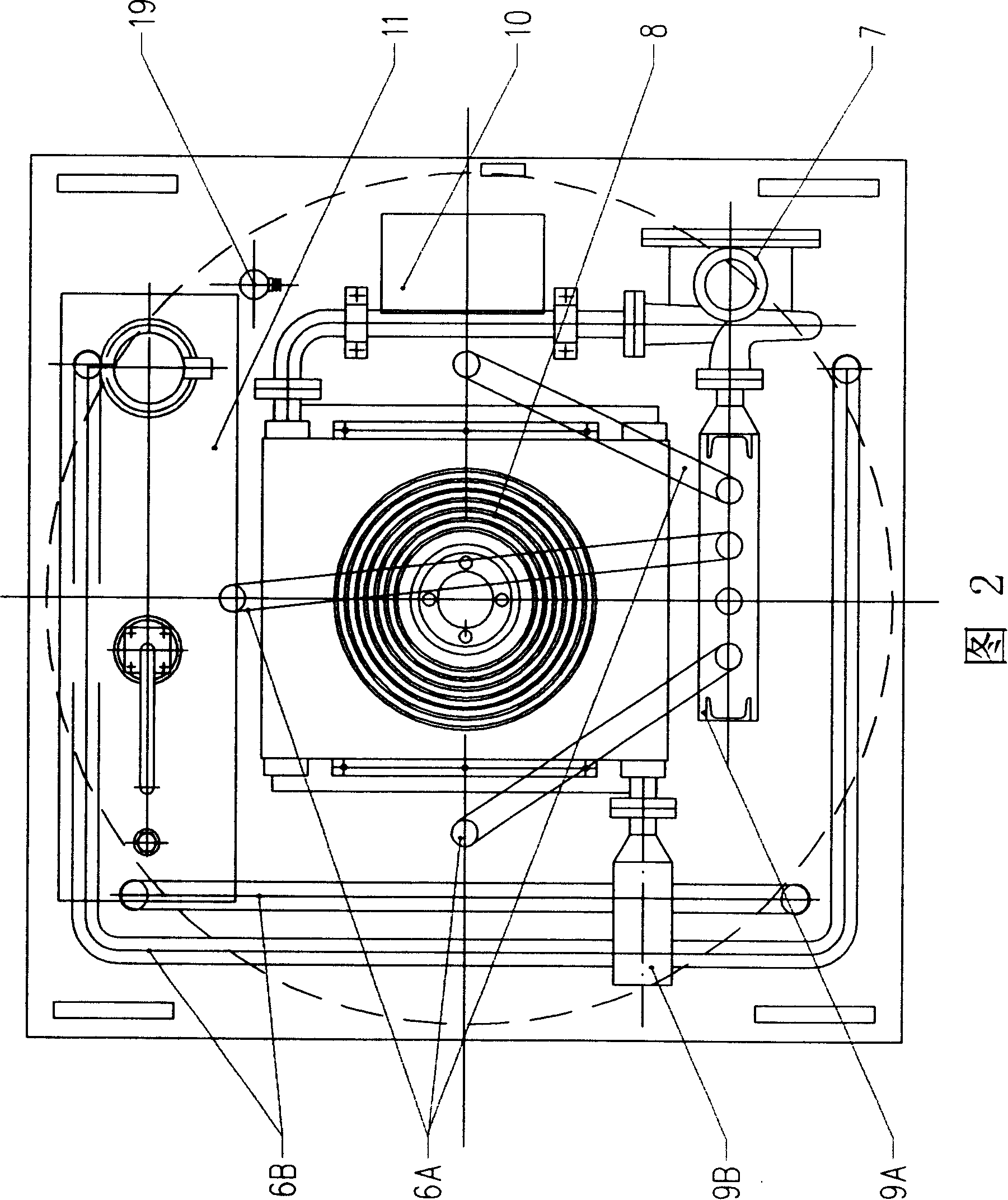

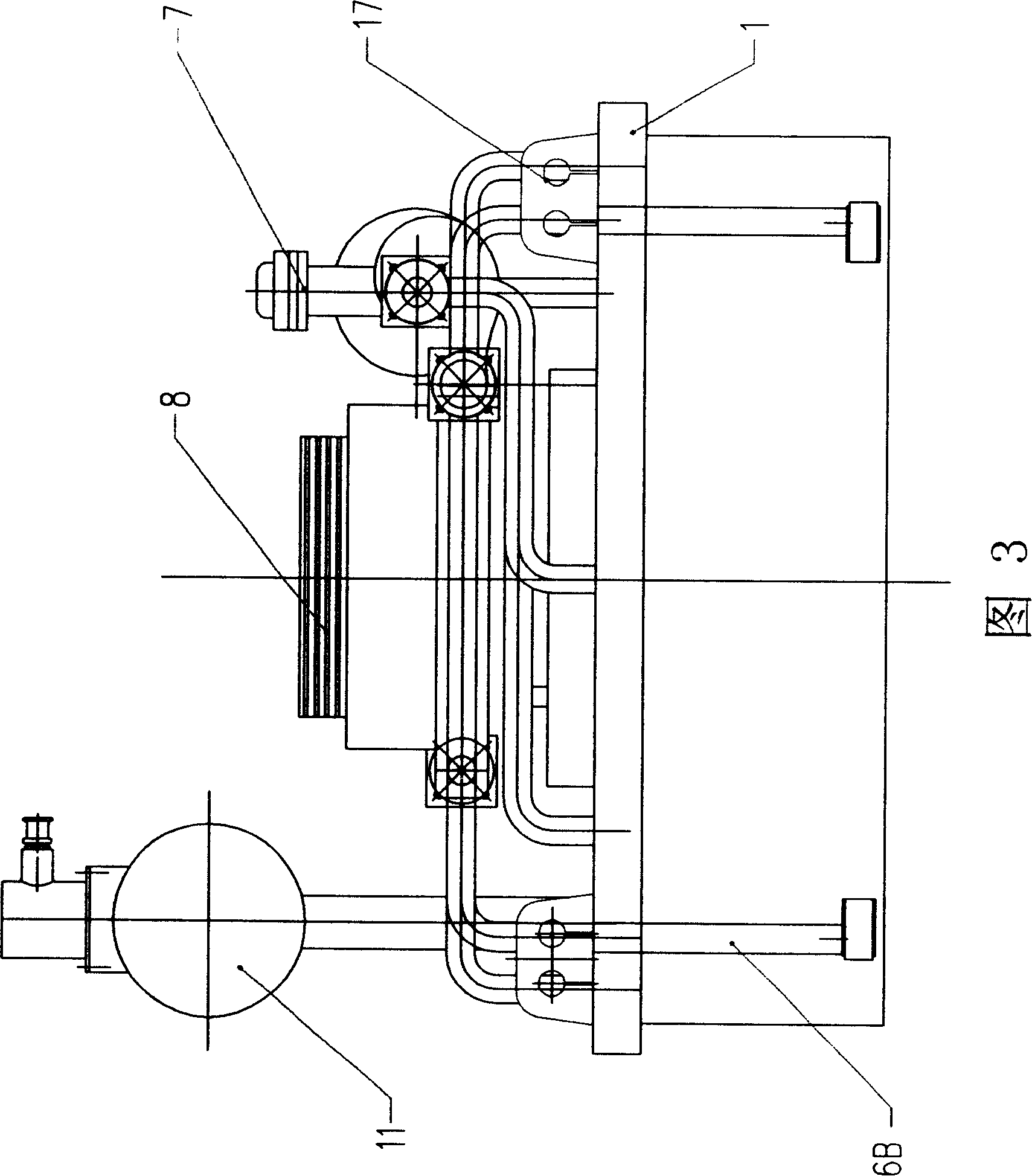

[0009] As shown in Figures 1 to 3, the iron remover of the present invention consists of an oil conservator 11, an internal and external circulation cooling system and an oil-cooled magnetic system. The oil conservator 11 has an oil injection port, an outlet port and an oil passage 12, through which two oil passages 12 provide a cooling medium 13 for the oil-cooled magnetic system. The cooling medium 13 is selected from transformer oil with good insulation performance and fluidity performance. An oil level alarm 16 is also installed on the oil conservator 11 . The wires connected to the excitation coil 2 of the oil-cooled magnetic system are led out from the outlet port through the oil channel 12 on one side and connected to the junction box 10, and the junction box 10 is fixed on the oil-cooled magnetic system. Oil temperature alarm 19 is installed on the oil-cooled magnetic system. The oil-cooled magnetic system adopts a fully enclosed shell welded by yoke plate 1, magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com