Walking wheel mechanism of suspended cover manipulator

An uncapping machine and suspension type technology, which is applied in the direction of wheel hubs, vehicle parts, mechanical equipment, etc., can solve the problems of deflection and falling off of running wheels and loosening of running wheels, so as to increase the axial force, prevent deflection and falling off, and increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be explained in detail in conjunction with the accompanying drawings and specific embodiments.

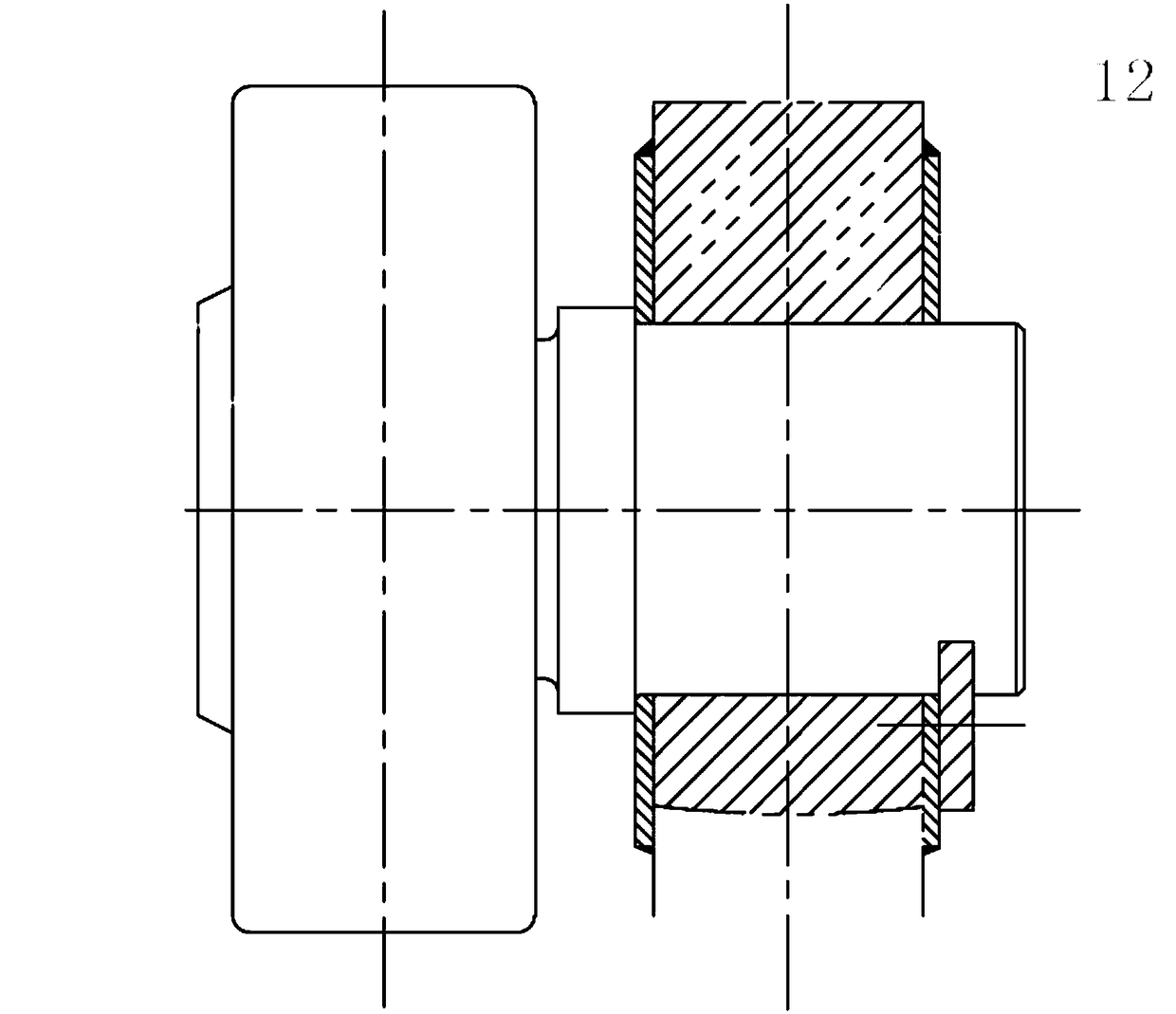

[0029] Such as figure 1 Shown is that wheel 1 is installed on the vehicle frame of suspended type uncovering machine body 12, and four groups of wheels are installed on every suspended type uncovering machine body 12.

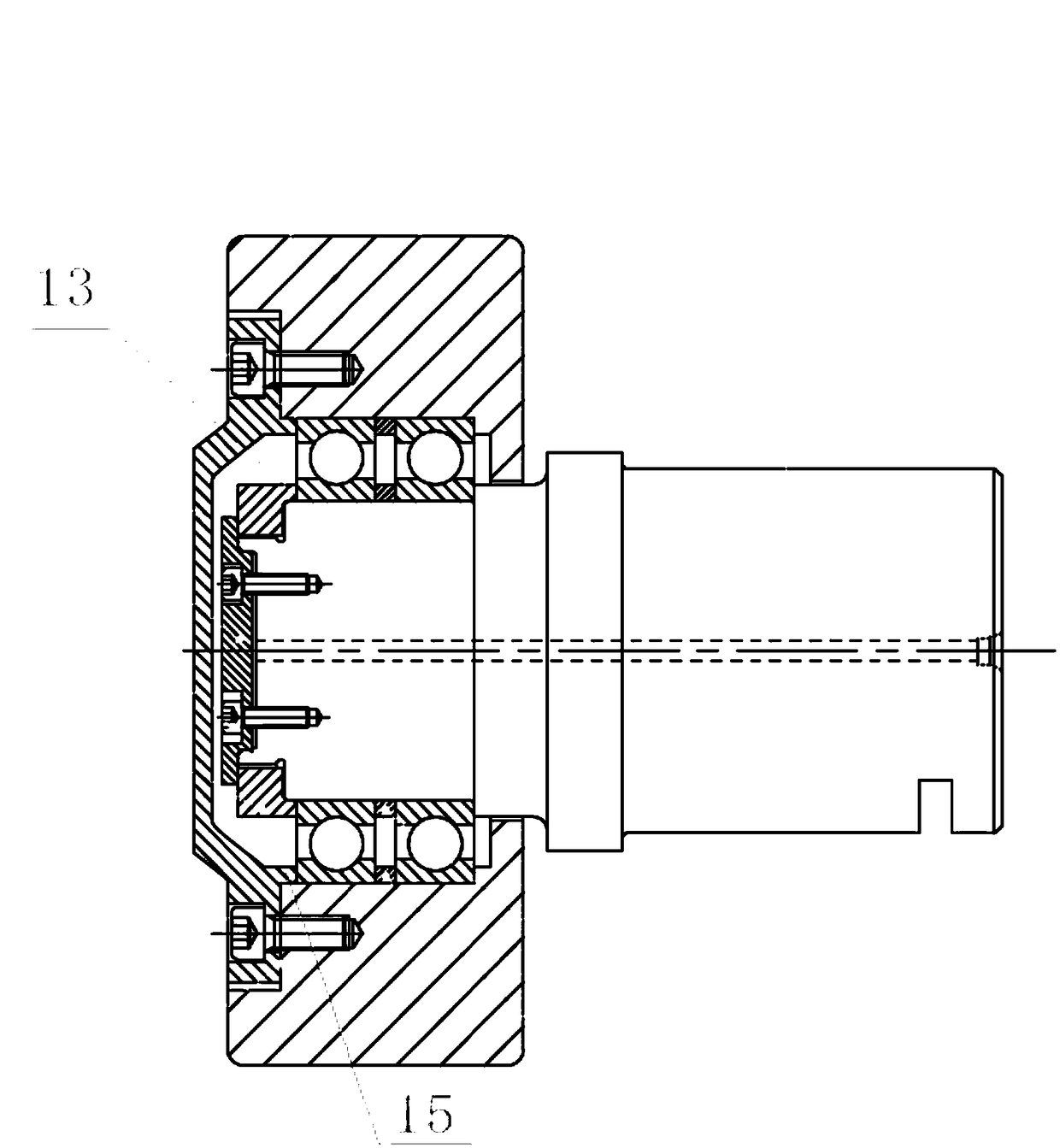

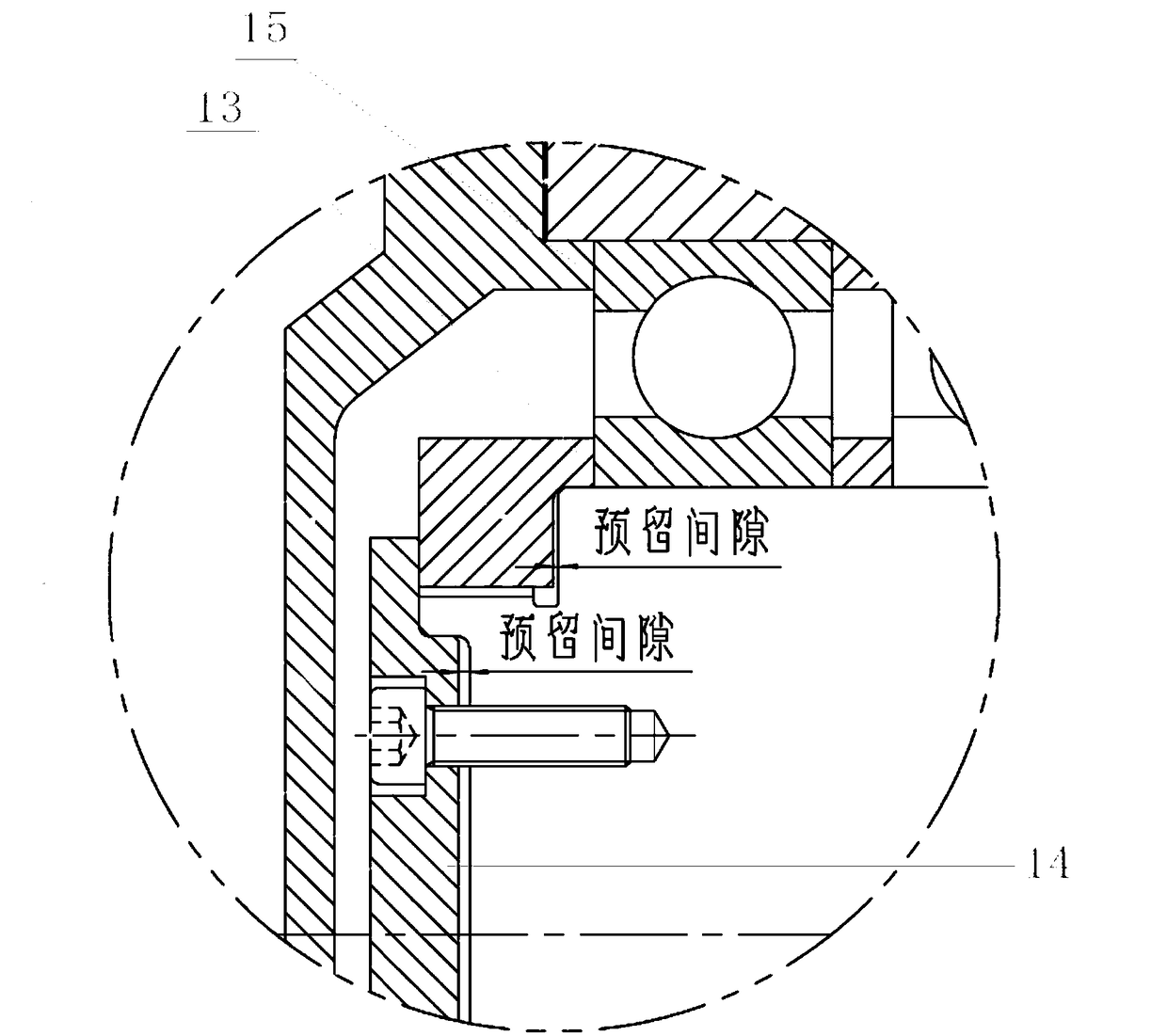

[0030] Such as figure 2 Shown, the present invention comprises wheel 1, bearing 2, stuffy cover 3, gland 4, first screw 5, nut 6, second screw 7, inner retaining ring 8, outer retaining ring 9 and wheel shaft 10, wheel shaft 10 It is a stepped axle, and the wheel axle 10 includes a first stepped axle section, a second stepped axle section and a third stepped axle section in sequence from the end, and the diameter of the first stepped axle section is smaller than the diameter of the second stepped axle section, and the second stepped axle section The diameter of the stepped shaft section is smaller than the diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com