Static-pressure direct drive rotating table

A technology of rotary table and direct drive, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing static pressure bearing resistance, shaking of rotating disk surface, electromagnetic interference of direct drive motor, etc. The effects of increasing bearing capacity, increasing axial stiffness, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

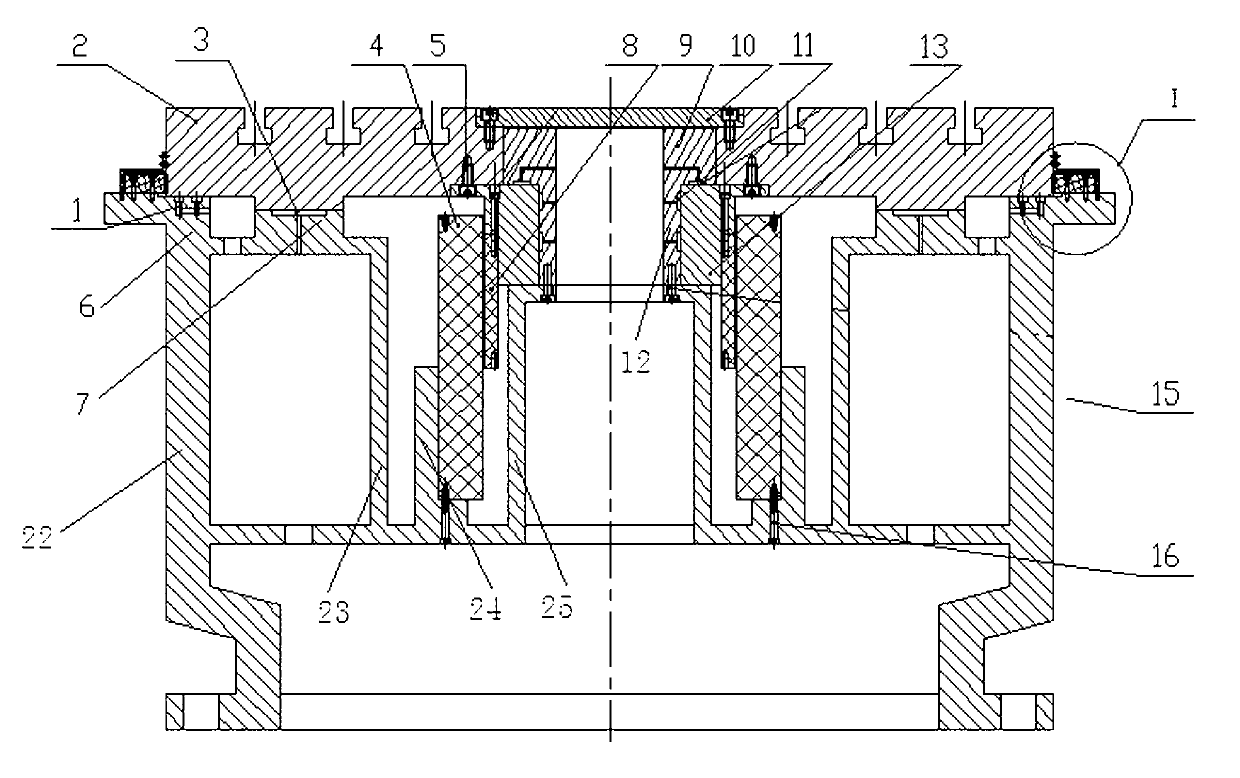

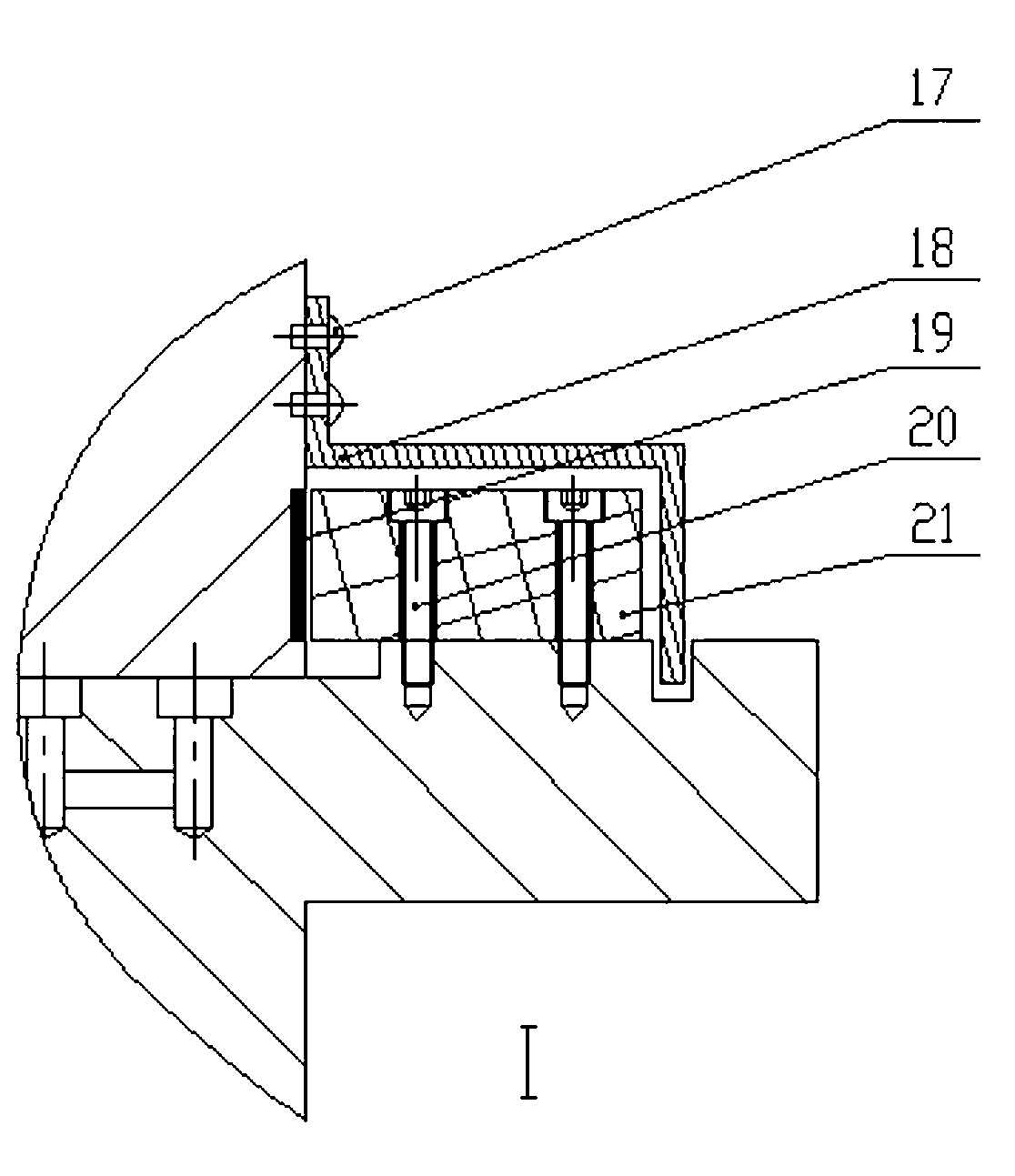

[0018] An embodiment of a static pressure direct drive rotary table Figure 1~2 As shown: it includes a base 15, a direct drive motor, a hydrostatic bearing, and a turntable 2 whose axis extends in the up-down direction. The base includes a peripheral casing 22 and a middle support arranged in the peripheral casing. The vertical connecting plate and the bearing mounting seat 25, the motor mounting seat 24 and the guide rail setting seat 23 arranged concentrically on the connecting plate from the inside to the outside in turn, the bearing mounting seat, the motor mounting seat, the guide rail setting seat and the peripheral shell are all hollow Sleeve structure, the stator 4 of the direct drive motor is fixedly assembled on the motor mounting base 24 by the first screw 16, and the upper end of the rotor 8 of the direct drive motor is fixed on the bottom of the rotary table by the second screw 5; the bearing fixed of the hydrostatic bearing The ring 12 is fixedly assembled on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com