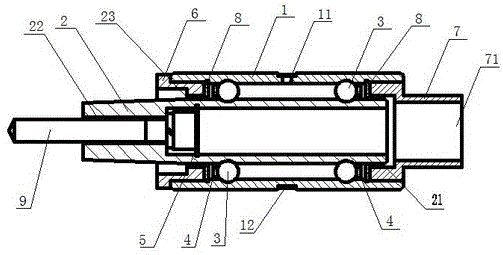

Drawing leather roller sleeve bearing

A technology for sleeve bearings and top rollers, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of unstable sliver quality, heavy maintenance workload, and high heat generation, so as to ensure the sealing performance and solve the problem of hair loss. The effect of high heat and reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0011] like figure 1 As shown, a drawing roller sleeve bearing, which includes: a bearing shell 1, a bearing mandrel 2 and a screw 9; the outer circle of the bearing shell 1 is provided with an annular groove, and an oil filling hole 11 is arranged in the annular groove, and an elastic ring 12 Embedded in the annular groove and block the oil filling hole 11, the inner hole of the bearing shell 1 is provided with two R-shaped inner channels, and one end of the bearing mandrel 2 is provided with a cone outer circle, the taper and size of the cone outer circle are the same as the top roller mandrel The inner taper hole of the bearing housing 1 is matched, and the non-tapered outer circle of the bearing mandrel 2 is provided with two R-shaped outer channels. The position of the outer channels matches the R-shaped inner channel of the bearing shell 1, and there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com