Modified glass fiber cloth, preparation method of modified glass fiber cloth, solid ammonia storage device and automobile

A kind of glass fiber cloth and modification technology, applied in the direction of muffler device, exhaust device, mechanical equipment, etc., can solve the problems of hindering ammonia filling of ammonia tank, obstacles, etc., to improve thermal conductivity, process stability, improve bonding performance and The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] One embodiment of the present invention provides a preparation method of modified glass fiber cloth, comprising the following steps:

[0041] Arrange the glass fiber base in the suspension for dipping and pulling, and then heat treatment;

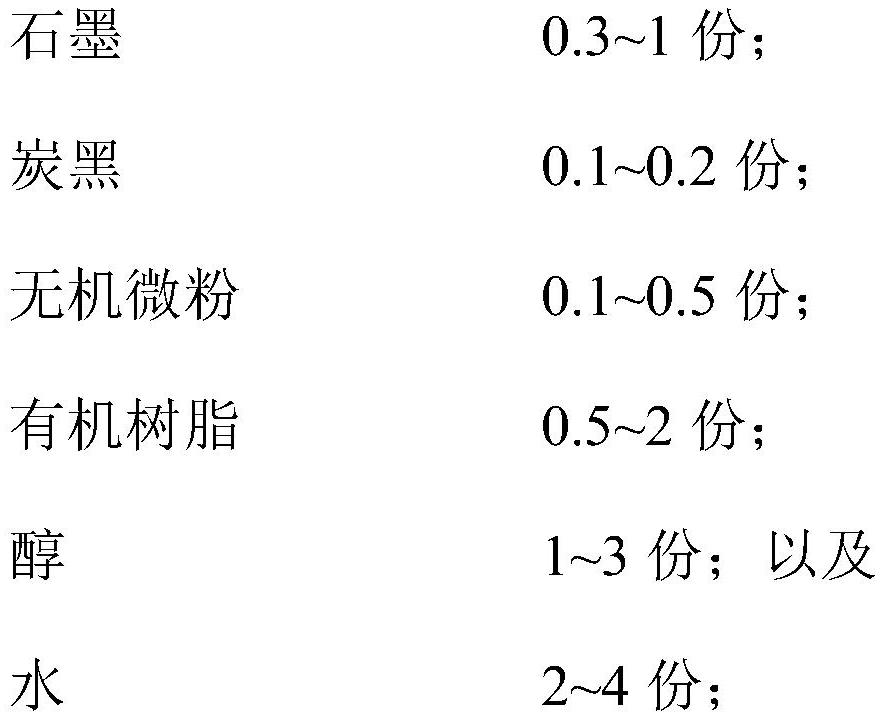

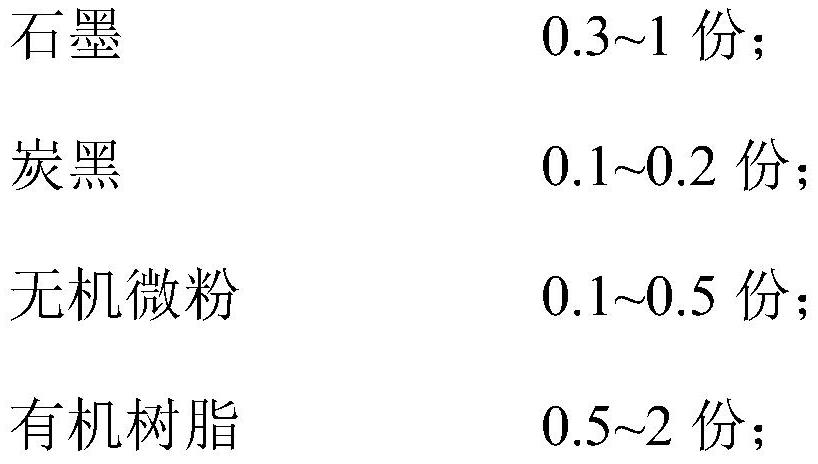

[0042] Wherein, the suspension comprises the following components in parts by mass:

[0043]

[0044] The inorganic fine powder is selected from at least one of alumina fine powder and magnesium oxide fine powder, and the organic resin is phenolic resin.

[0045] Correspondingly, the present invention provides a modified glass fiber cloth, which can be prepared by the above preparation method. The modified glass fiber cloth includes a glass fiber base cloth and a surface modification layer formed on the glass fiber base cloth; the surface modification The active layer includes the following components in parts by mass: 0.3-1 parts of graphite, 0.1-0.2 parts of carbon black, 0.1-0.5 parts of inorganic fine powder, 0.5-2 parts of o...

specific Embodiment

[0098] Below according to glass fiber cloth bag of the present invention and preparation method thereof and solid ammonia storage device, automobile example, can be understood that glass fiber cloth bag of the present invention and preparation method thereof and solid ammonia storage device, automobile are not limited to following implementation example.

[0099] The phenolic resins used in Examples and Comparative Examples are all commercially available industrial products, for example, phenolic resin 2123#.

Embodiment 1

[0101] (1) Preparation of suspension

[0102] Prepare raw materials: 0.6 parts of graphite with a D50 of 100-200 μm, 0.15 parts of carbon black with a D50 of 10-39 μm, 0.3 parts of alumina micropowder with a D50 of 0.6-10 μm, 1 part of phenolic resin, 2 parts of ethanol and 3 parts of water;

[0103] Graphite, carbon black, inorganic micropowder, organic resin, ethanol and water were mixed and ball milled with a centrifugal ball mill at a rotational speed of 250 rpm and a milling time of 25 minutes to obtain a suspension.

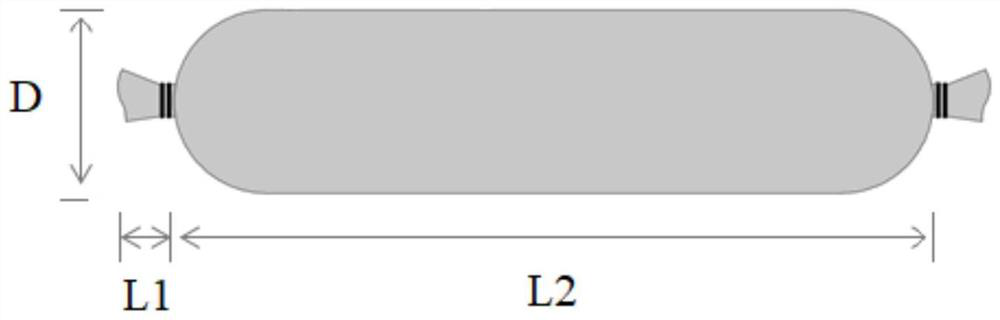

[0104] (2) glass fiber filter cotton is prepared into a bag-like structure with a diameter of 52 mm, which is placed in the suspension prepared in step (1) to impregnate, pulled up and down 3 times, taken out, and compressed air is used to blow off excess liquid, Squeeze the impregnated glass fiber filter cotton once with a pair of rollers, set the gap between the upper and lower rollers of the pair of rollers to 60% of the sum of the thickness of the two l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com