A single degree of freedom magnetic bearing

A magnetic bearing and degree of freedom technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of small axial bearing capacity, large magnetic leakage of magnetic bearings, low critical speed, etc., to ensure rigidity, reduce weight, The effect of shortening the axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

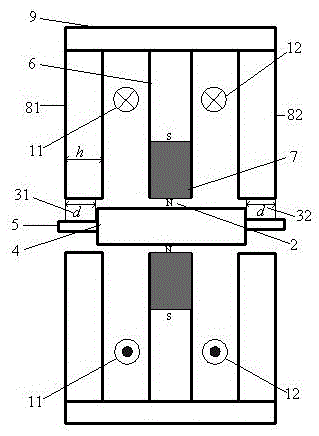

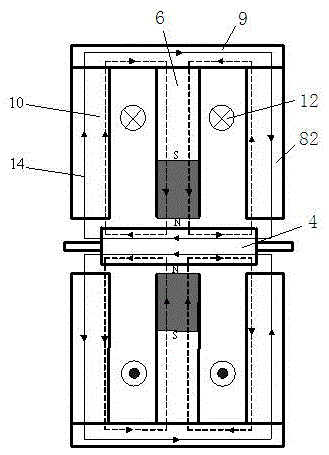

[0015] like figure 1 , 2 As shown, the present invention includes a rotor 4 and a permanent magnet 7. The rotor 4 is sleeved on the rotating shaft 5 and is formed by laminating silicon steel sheets. The outermost periphery is the axial stator cylinder 9, which is coaxially sleeved outside the rotor 4, the left end of the axial stator cylinder 9 is connected to the axial stator disk 81, and the right end of the axial stator cylinder 9 is connected to the axial The stator disc 82, the axial stator discs 81, 82 and the axial stator cylinder 9 are made of electrical pure iron to ensure good magnetic conductivity, low hysteresis, and minimize eddy current loss and hysteresis loss. The two outer end surfaces of the axial stator discs 81 and 82 are respectively flush with the left and right end surfaces of the axial stator cylinder 9 . The outer edges of the axial stator disk 81 and the axial stator disk 82 are fixedly connected to the inner wall of the axial stator cylinder 9 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com