Friction plate hollow rivet

A hollow rivet and friction plate technology, applied in rivets and other directions, can solve the problems of reduced strength of the connected parts, insufficient riveting, low strength, etc., and achieve the effects of reducing stress concentration, good riveting quality and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

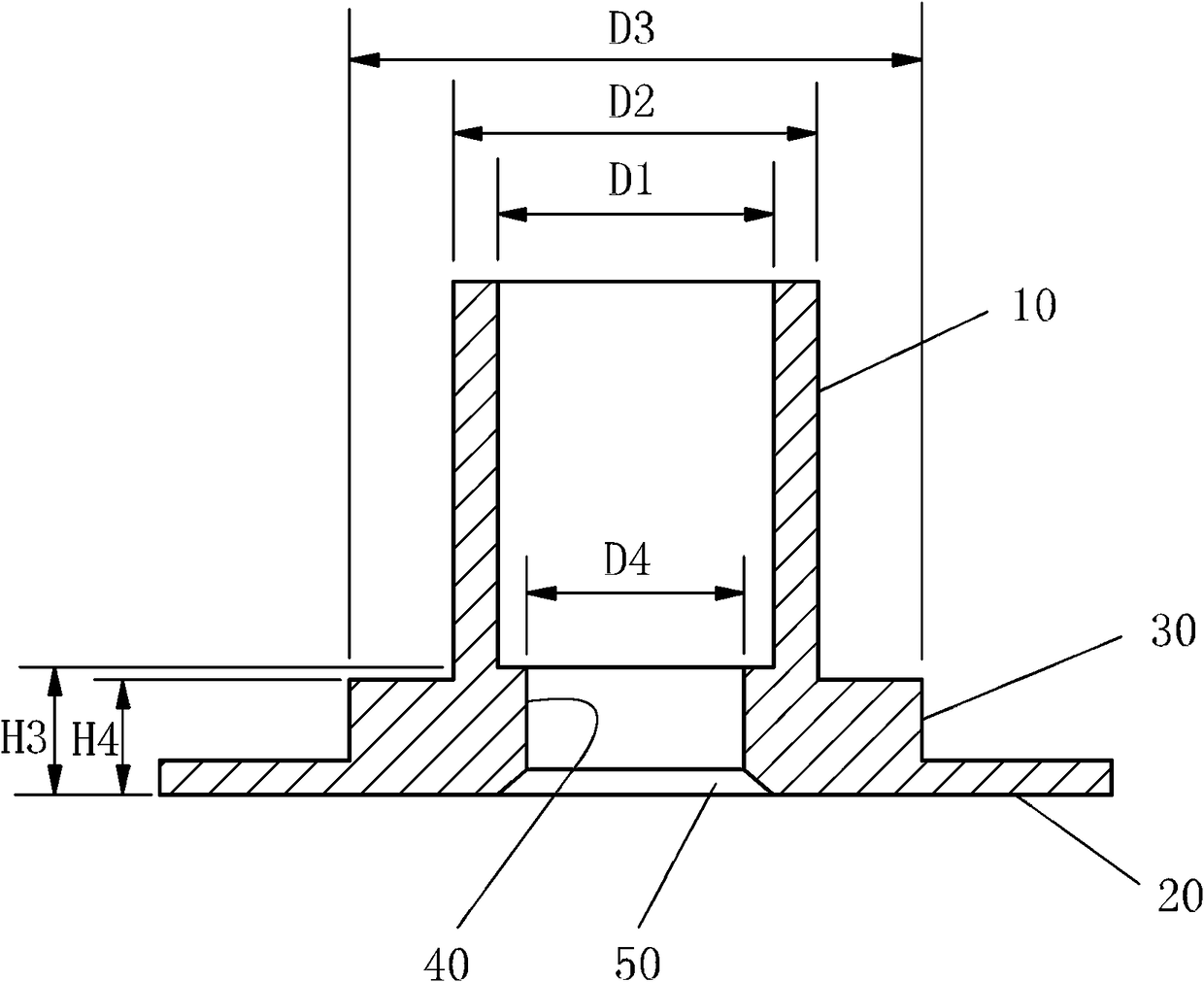

[0014] The present invention will be further described below with specific embodiment, see figure 1 :

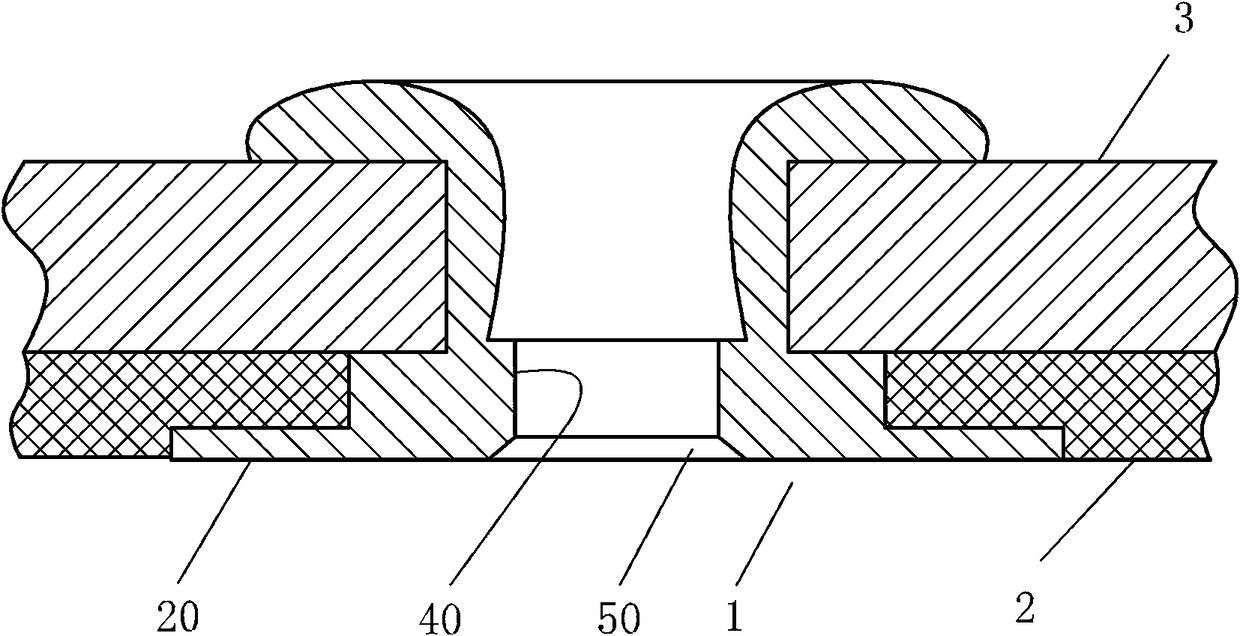

[0015] The hollow rivet of the friction plate has a base 20 extending outward from one end of the hollow cylinder 10, and the lower part of the outer surface of the hollow cylinder 10 is provided with an annular outer ring larger than the outer diameter D2 of the hollow cylinder 10 from the upper plane of the base 20 outward. Boss 30, the lower part of the inner surface of hollow cylinder 10 is provided with an annular inner boss 40 smaller than the inner diameter D1 of the hollow cylinder inwardly from the bottom plane of base 20, and the corner of annular inner boss 40 and base 20 is provided with Chamfer 50.

[0016] Measured upward from the bottom plane of the base 20 : the height H4 of the annular outer boss 30 ≤ the height of the annular inner boss H3 .

[0017] The hollow rivets of the above-mentioned friction discs are made of aluminum or aluminum alloy.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com