Pressing rivet die for hoist nameplate

A gourd and nameplate technology, which is applied in the field of gourd nameplate pressure riveting molds, can solve the problems of gourd loss of indication function, uneven riveting quality, and detachment of gourd nameplate, so as to improve the qualified rate of riveting, complete and consistent molding, and high consistency of riveting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

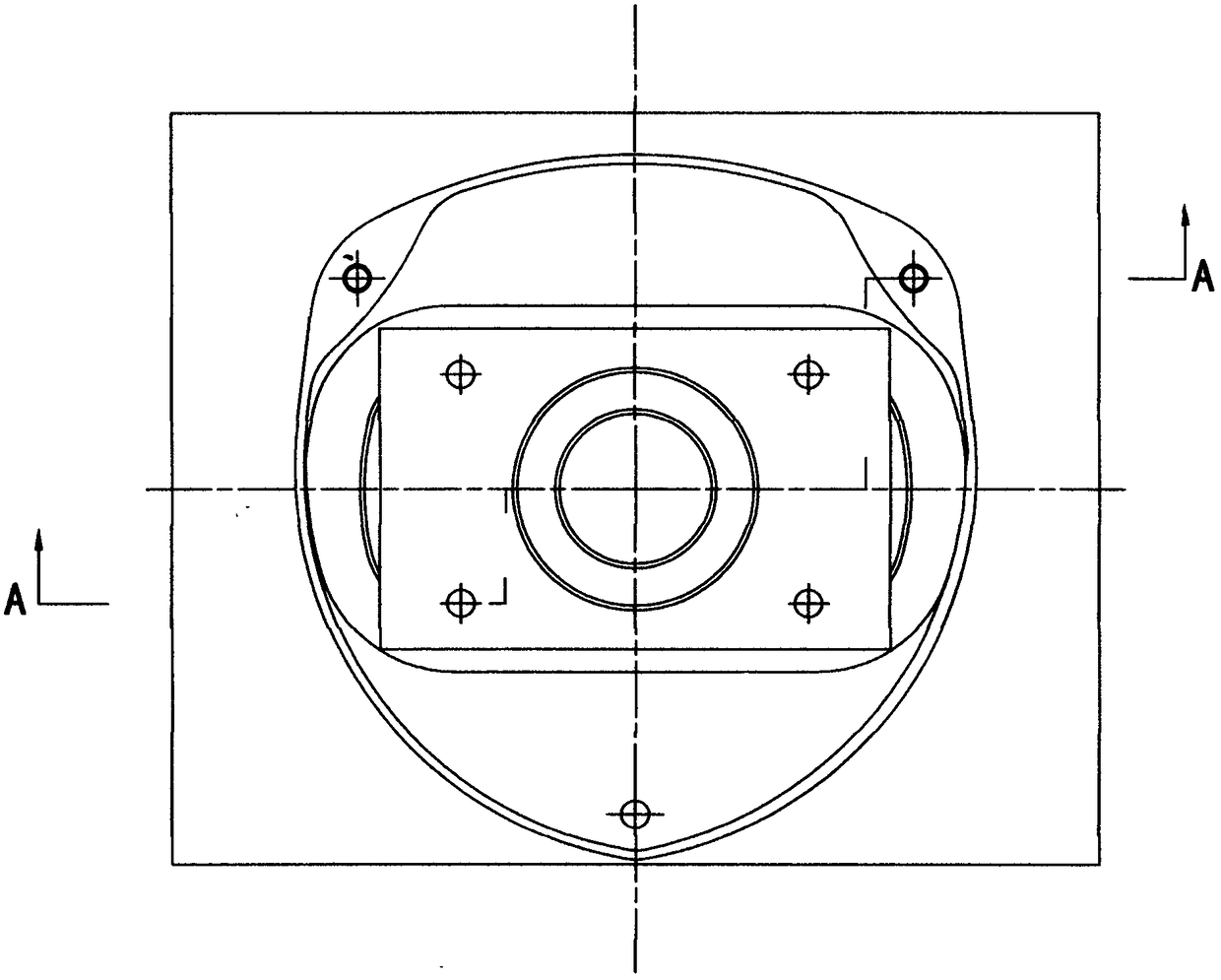

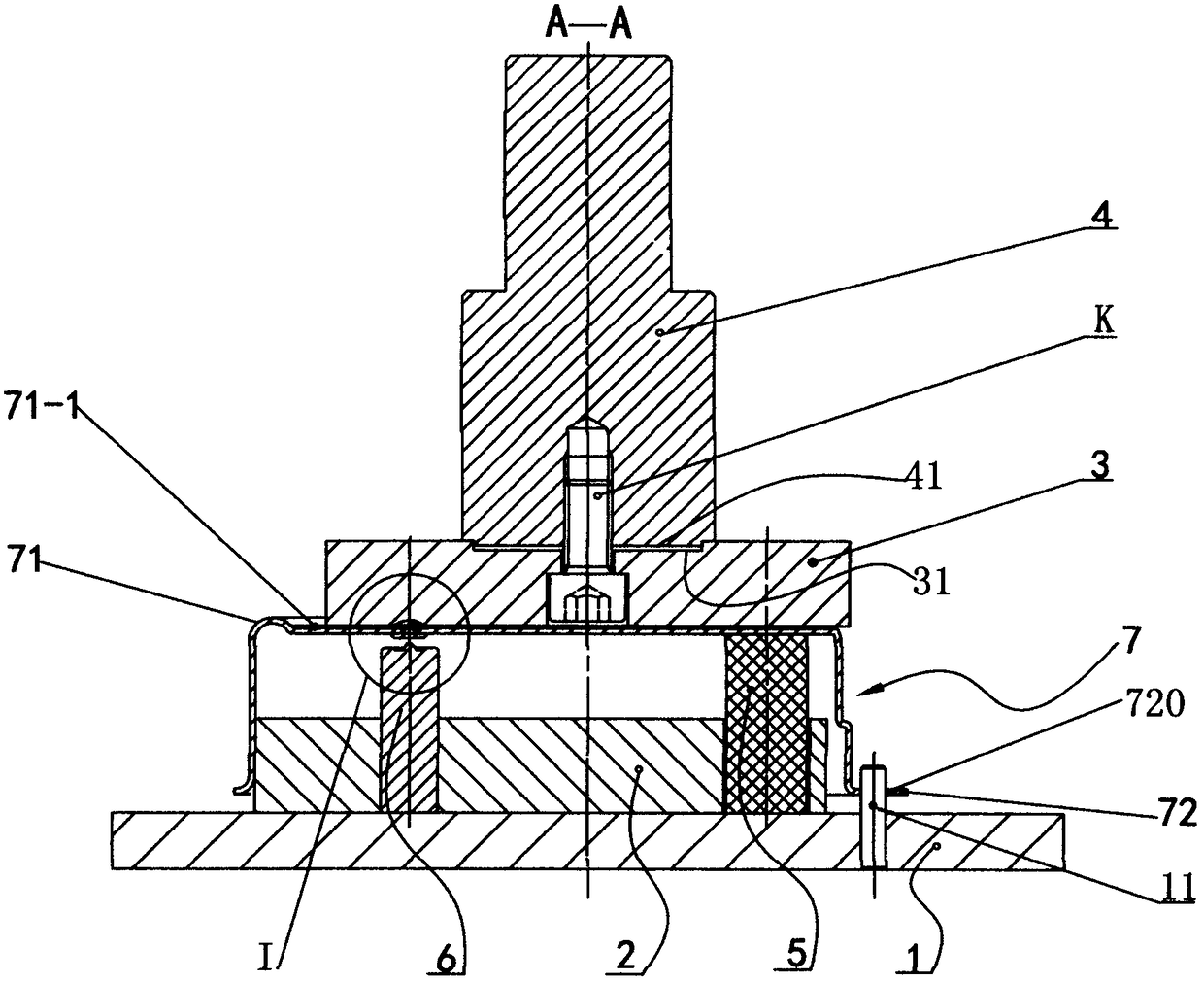

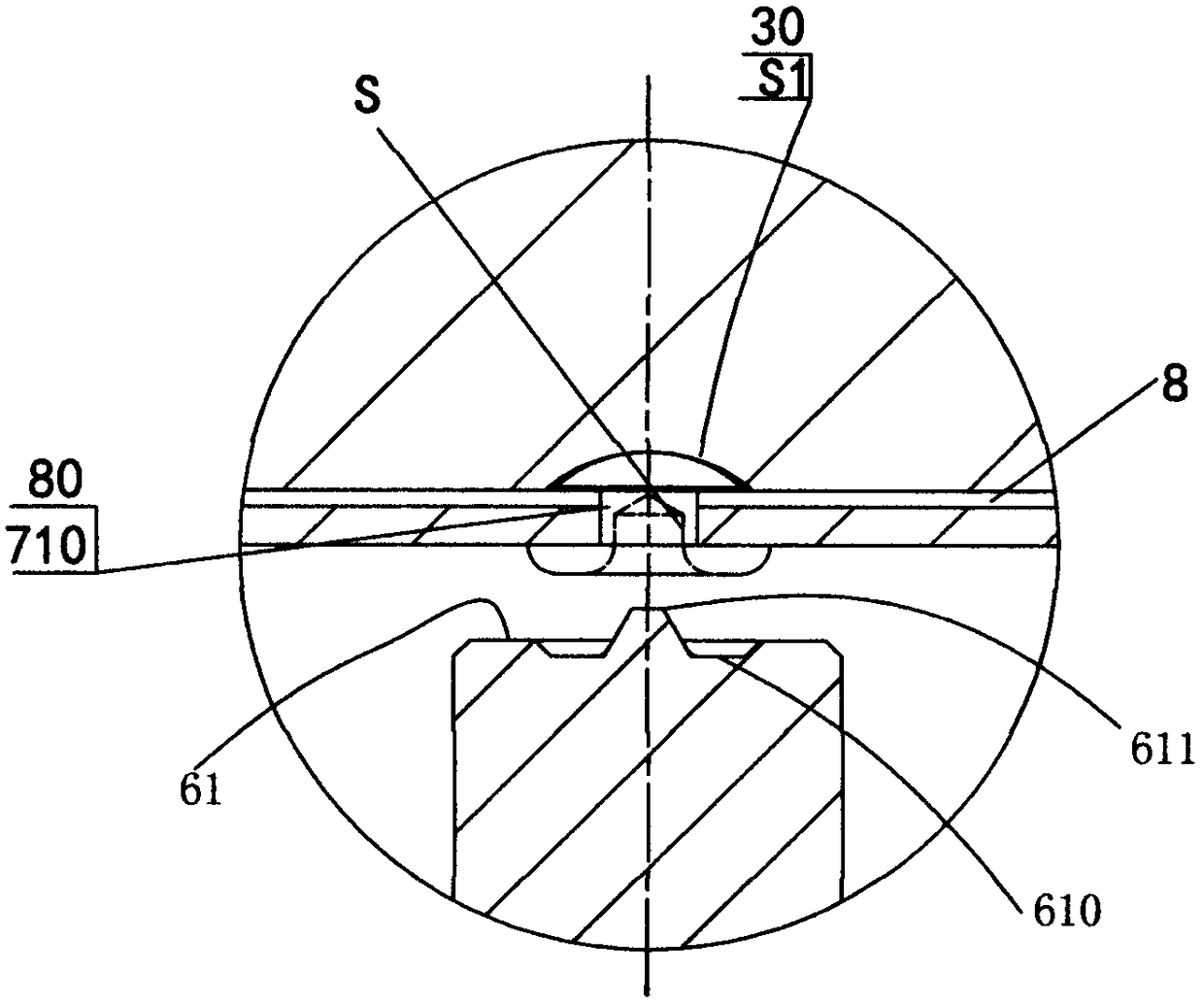

[0020] See figure 1 , 2 As shown in and 3, a mold for riveting a gourd nameplate includes a bottom plate 1, a positioning plate 2 fixed on the bottom plate 1 for the gourd cover 7 to cover, an upper mold 3 arranged on the top of the positioning plate 2, and the upper mold 3 The die handle 4 fixedly connected, the gourd case 7 has a case end face 71 and a case brim 72 provided with a pin hole 720, and a nameplate groove 71- for the gourd nameplate 8 is formed on the outer wall of the case end face 71 1. The bottom plate 1 is provided with a positioning pin 11 for the positioning of the pin hole 720. On the positioning plate 2, two elastic ejector rods 5 (only one is visible in the figure) are arranged symmetrically along its length direction to support the gourd cover 7. At least two riveting rods 6 are symmetrically arranged on the positioning plate 2, and the height of the riveting rods 6 is lower than that of the two elastic ejector rods 5, and each riveting rod 6 axially e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com