Blade and fan blade applying same

A blade and leeward technology, which is applied in the field of ventilation equipment, can solve the problems of screw wing vibration, lower production efficiency, uneven thickness of welds, etc., and achieve the effects of reducing vibration amplitude, improving rigidity, and riveting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

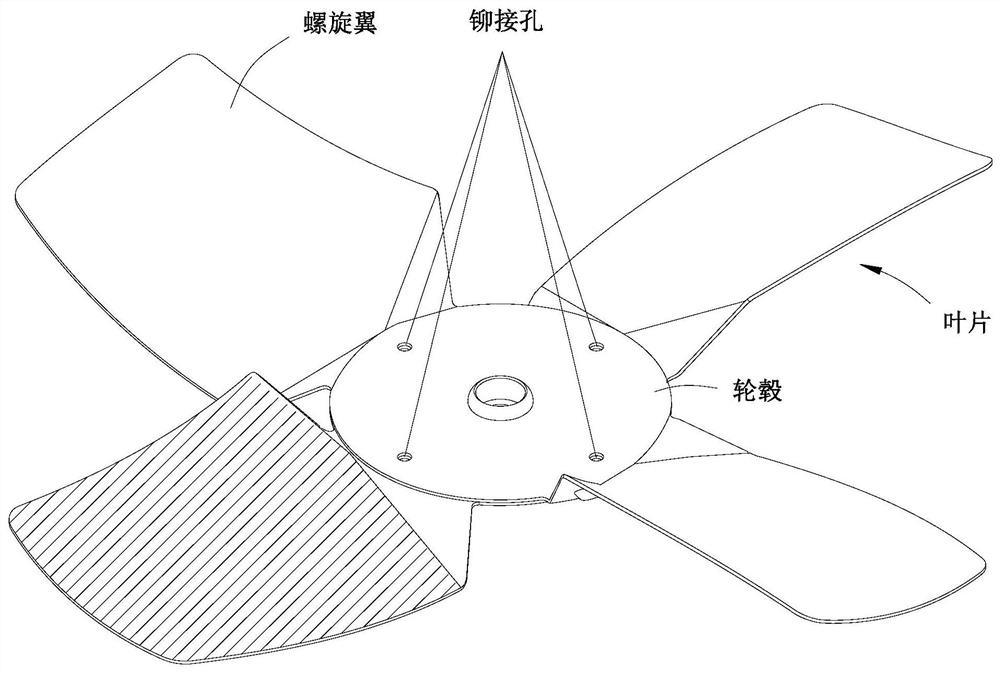

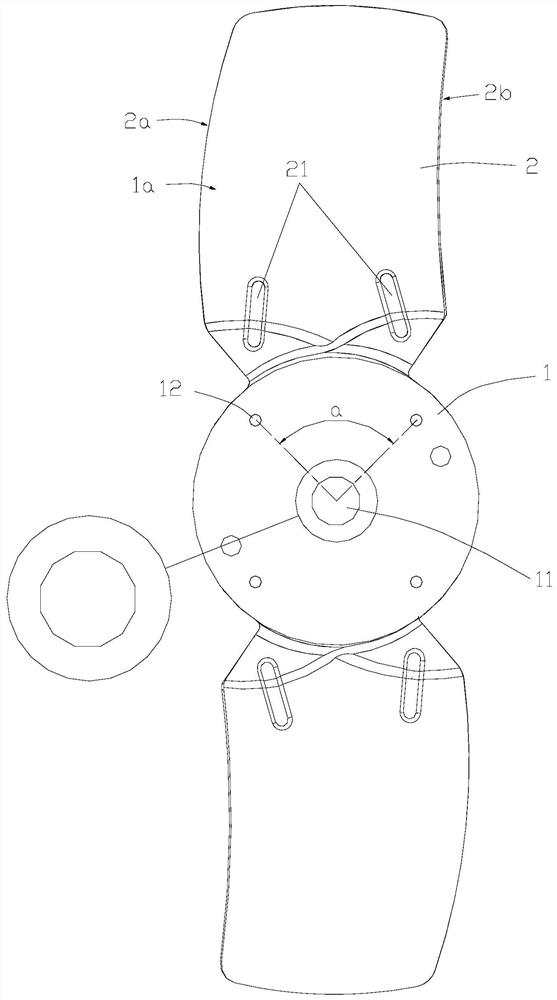

[0031] see Figure 3 to Figure 8 , the present embodiment provides a blade applied on the fan blade, which includes a hub 1 and at least two helical wings 2 arranged on the outer periphery of the hub 1, a shaft hole 11 is provided in the middle of the hub 1, and the root of the helical wing 2 is connected to the hub. 1 connection, the hub 1 is provided with riveting holes 12 at least at the edge positions on both sides close to the root of each spiral wing 2, and the riveting holes 12 are used for passing through the rivets 3 to rivet the blades stacked on the upper and lower layers. 11 is used for inserting for axle sleeve 4. Preferably, the hub 1 and the helical wing 2 are integrally formed by stamping. This processing method has a simple process flow and is conducive to manufacturing. The integrally formed blade has good rigidity, and the blade rotates stably with little vibration.

[0032] One side of the blade is the windward side 1a, and the other side is the leeward si...

Embodiment 2

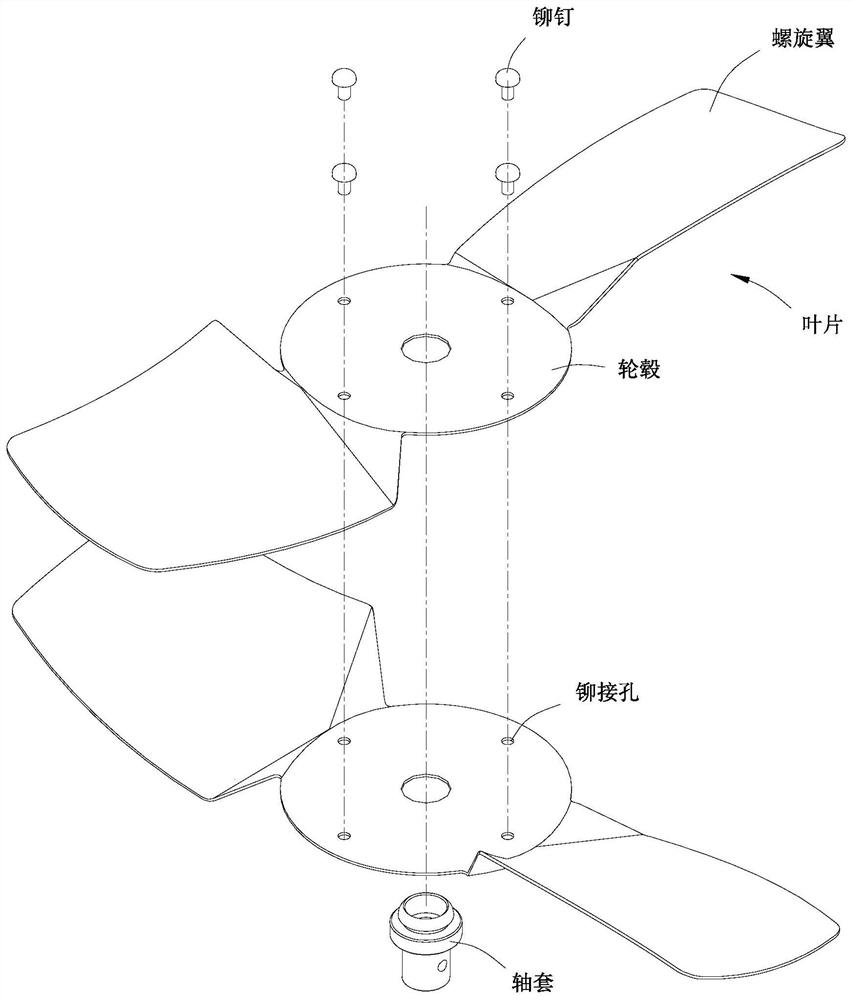

[0039] see Image 6 and Figure 8 , this embodiment provides a fan blade using the blade of Embodiment 1, which includes a bushing 4, a rivet 3 and two blades (101, 102) of Embodiment 1, and each blade (101, 102) is provided with two oppositely arranged A piece of spiral wing 2, two blades (101, 102) are stacked up and down at an angle of 90°, and include a first blade 101 on the upper layer, and a second blade 102 on the lower side, so that the two blades (101, 102) The riveting holes 12 are aligned, and the shaft holes 11 of the two blades (101, 102) are aligned, the rivet 3 penetrates the riveting holes 12 and the hub 1 of the riveting blades (101, 102), the upper end of the shaft sleeve 4 penetrates into the shaft hole 11 and is in the shaft hole Under the extrusion of the side of 11, plastic deformation occurs so as to be closely connected with the side of the shaft hole 11, and the two blades (101, 102) are riveted, thereby further preventing relative rotation between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com