Connector

A connector and riveting technology, which is applied in the direction of connection, two-part connection device, parts of connection device, etc., can solve problems such as connector enlargement and solder cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] An embodiment of the electrical connector of the present invention will be described below with reference to the drawings.

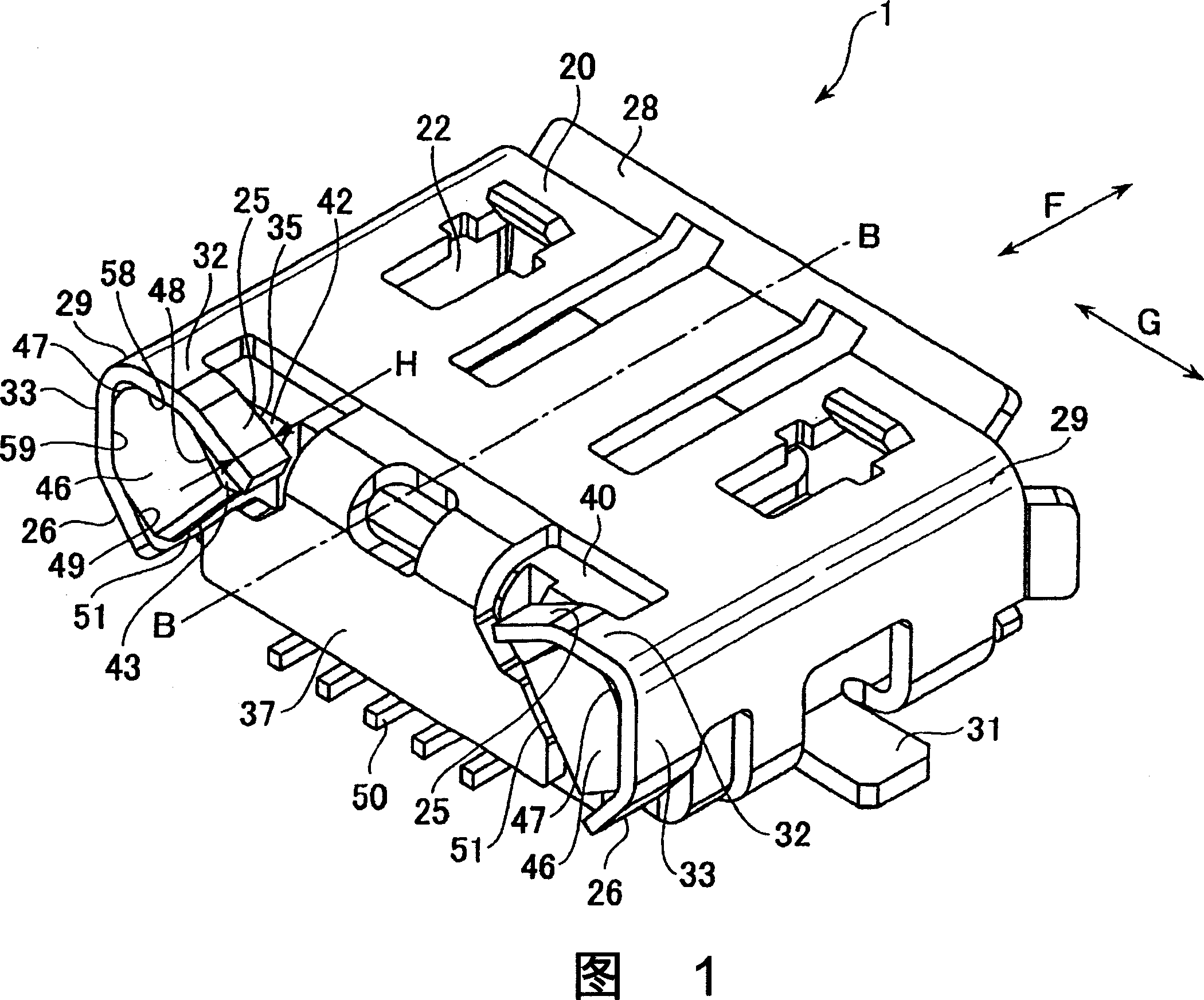

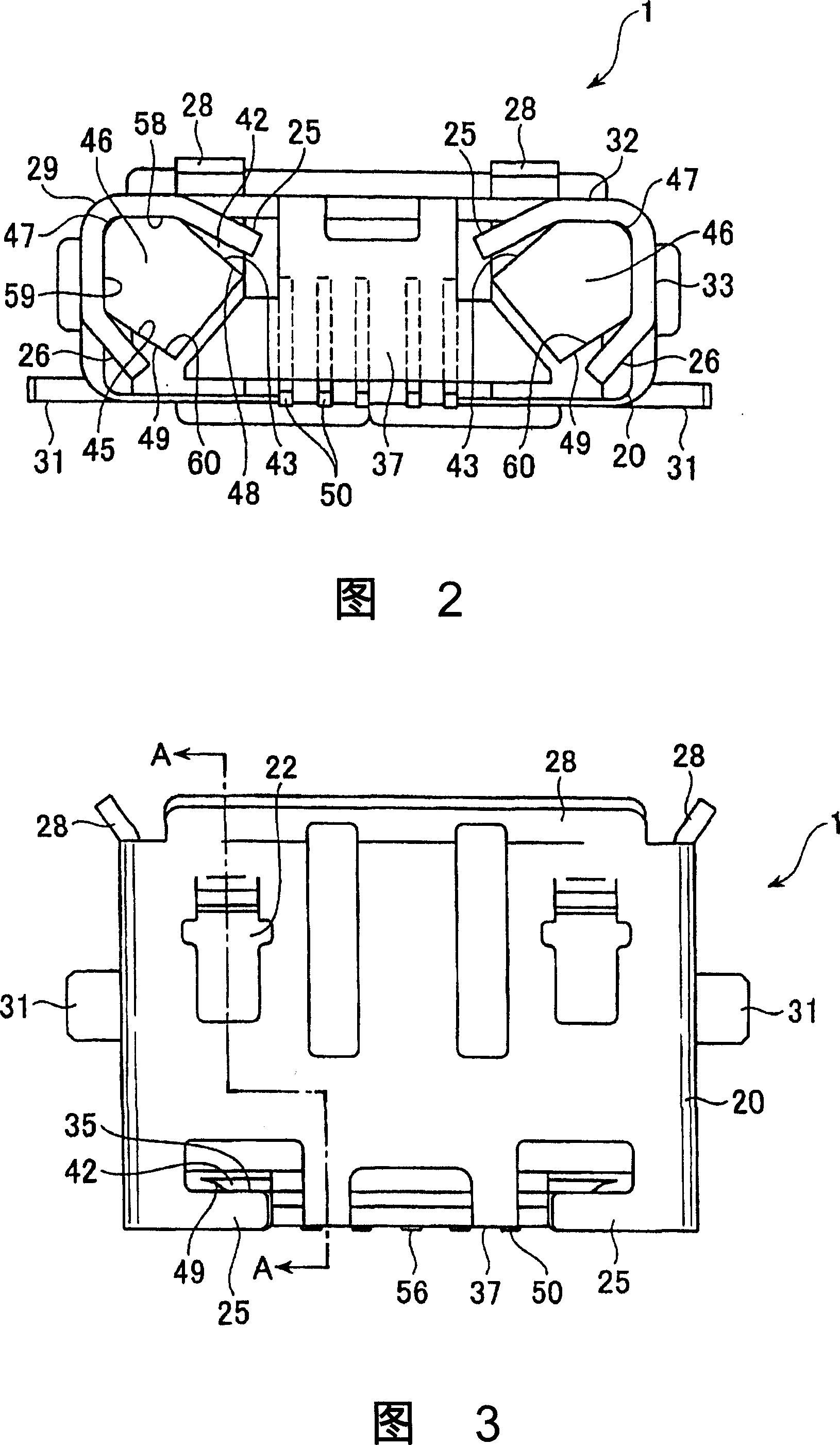

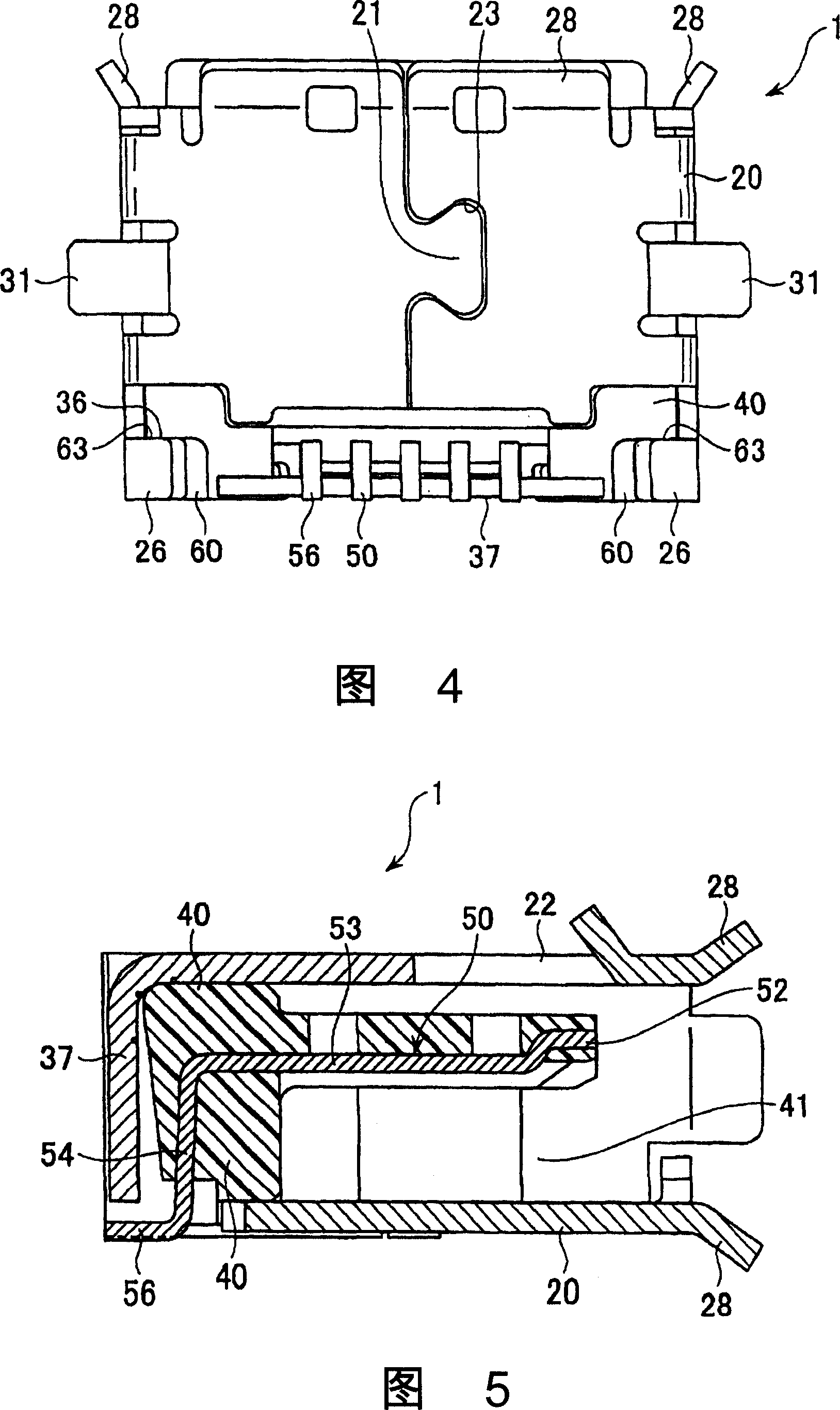

[0038] Fig. 1 is a rear perspective view of an electrical connector 1 of the present invention, Fig. 2 is a rear view thereof, Fig. 3 is a top view thereof, Fig. 4 is a bottom view thereof, Fig. 5 is a sectional view of the A-A line of Fig. 3 , Fig. 6 is a connection with the other side Centerline sectional view when the device is fitted. The electrical connector 1 is used as a so-called receptacle-side connector 1. As shown in FIG. 1 free plug and play.

[0039] The electrical connector 1 has a resin-molded housing 40 , a metal housing cover (Shell) 20 covering the outside of the housing 40 , and terminals 50 arranged in parallel inside the housing 40 at narrow pitches. The electrical connector 1 has a left-right symmetrical shape across a center line (line B-B) extending along the insertion / extraction direction of the mating connector 80 (arro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com