Special-shaped polygonal self-plugging rivet

A blind rivet and special-shaped technology, applied in rivets and other directions, can solve the problems of safety consequences, low safety and reliability of riveting, and cannot completely guarantee that no rotation will occur, so as to achieve the effect of firm riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

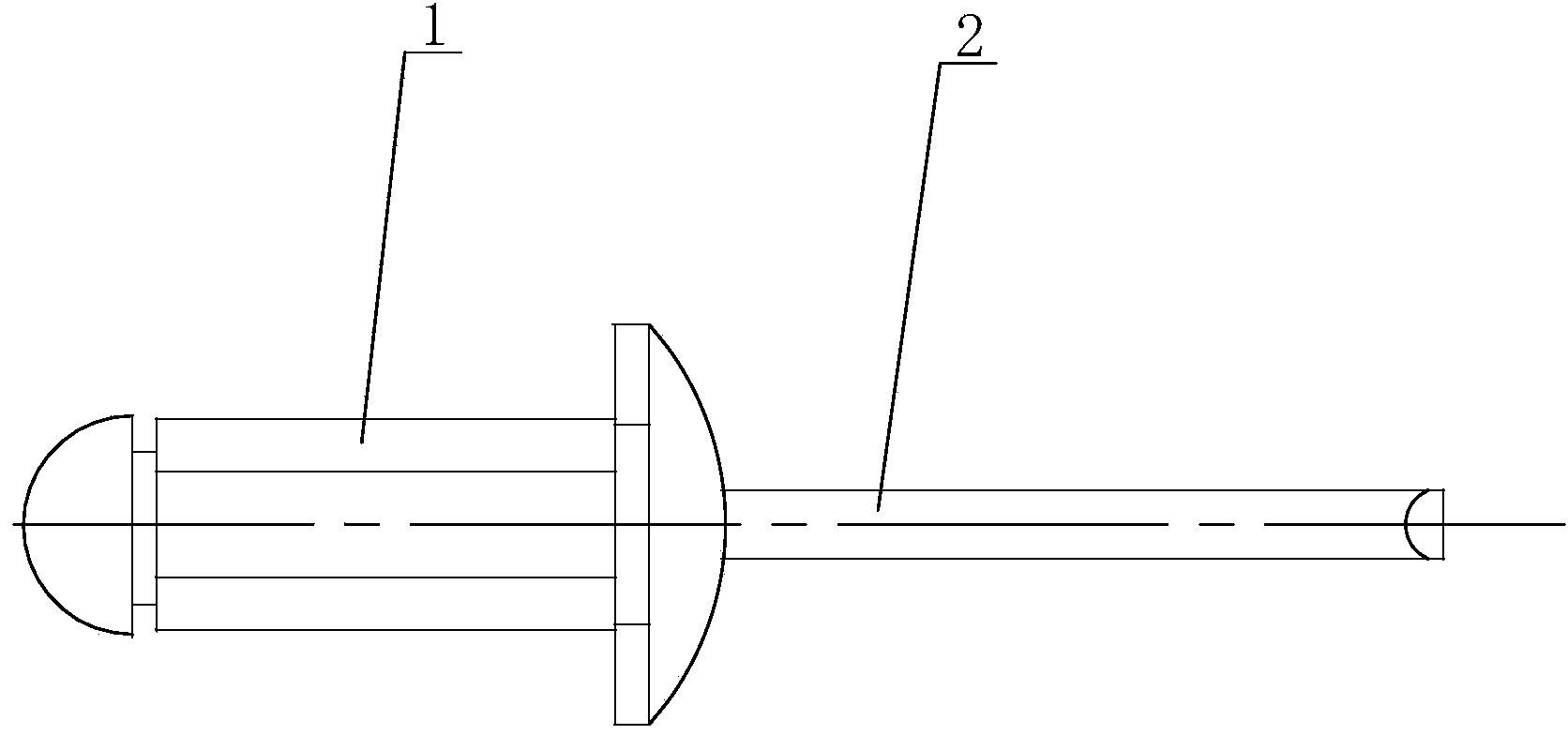

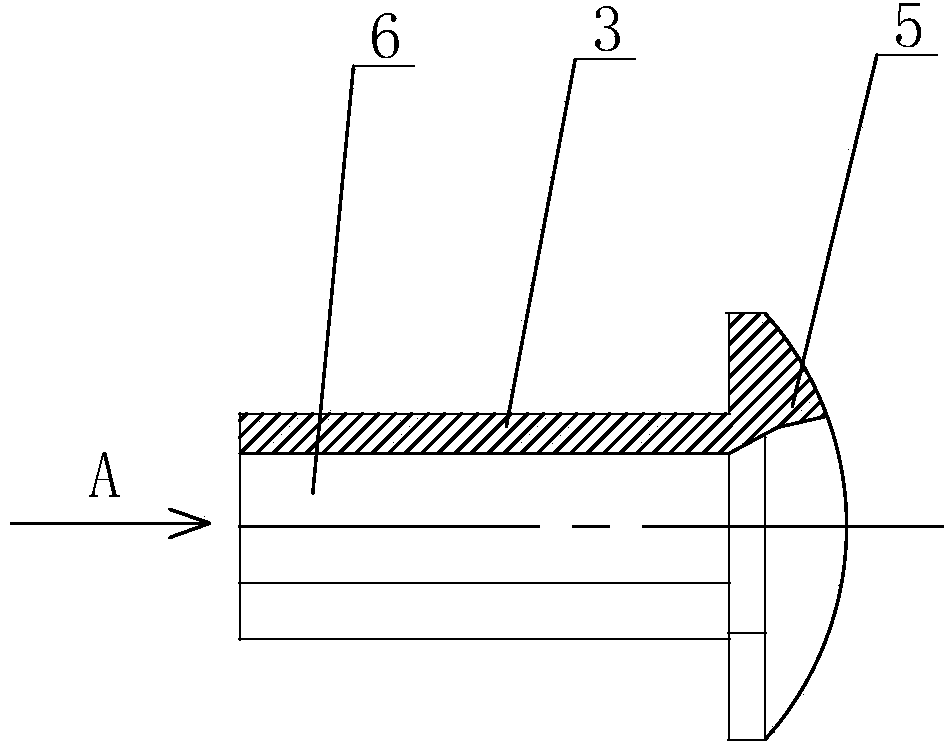

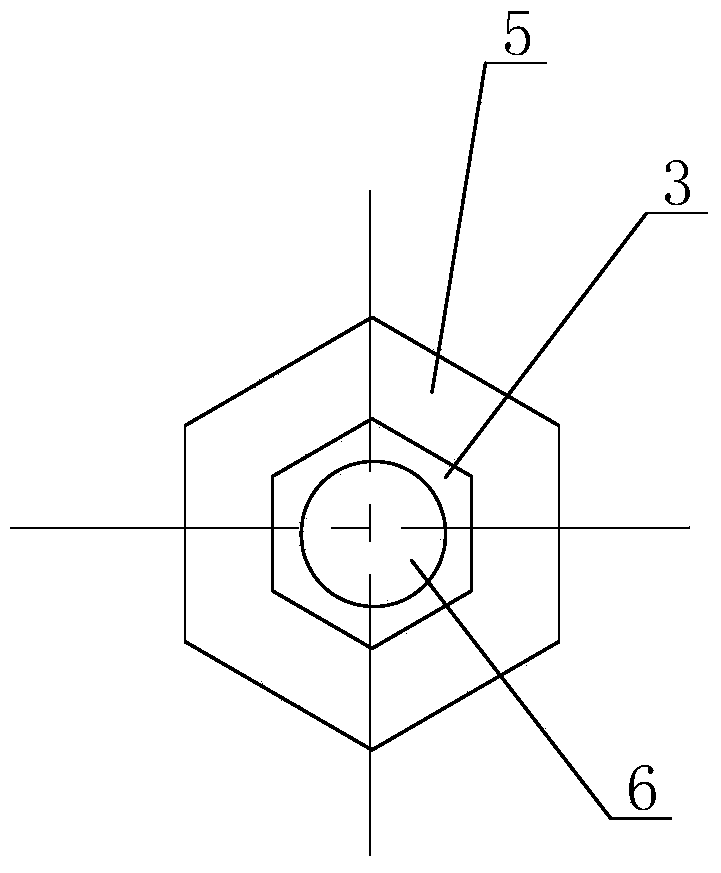

[0022] see Figure 1 to Figure 4 As shown, in this embodiment, a special-shaped polygonal blind rivet includes a nail body 1 and a nail mandrel 2, and the nail body 1 includes a tubular nail body body 3 having a central round hole 6, and the nail body body 3 The cross-section is a regular hexagonal structure, and one end of the nail body 3 is provided with a nail body head 5 with an outer diameter greater than the outer diameter of the nail body 3, and the nail body head 5 provides a good surface for the nail body 1 when riveting. positioning. And the head 5 of the nail body is a hexagonal semicircular structure, which is composed of a regular hexagonal part and a semicircular spherical part. This spherical shape looks better after the riveting is completed, especially the surface will be relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com