Pressing rivet structure of automobile engine wind shielding ring assembly

A technology of automobile engine and pressure riveting structure, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve the problems of low production efficiency, cumbersome vulcanization process, and low assembly efficiency of the windshield ring assembly, so that it is not easy to fall off , The riveting structure is convenient, and the riveting structure is firm and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

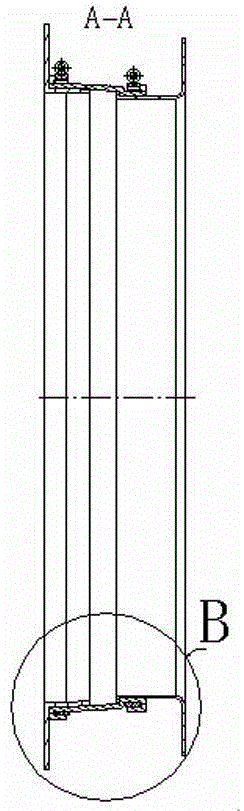

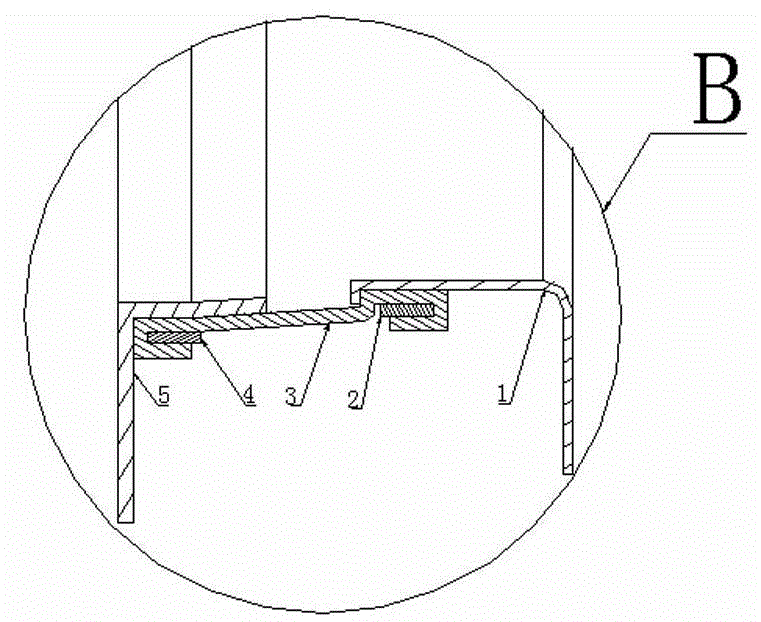

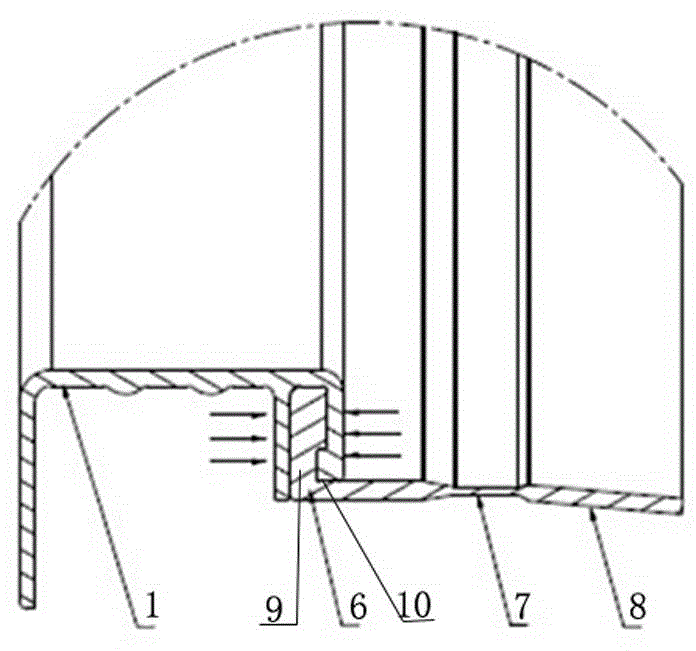

[0022] The present invention as image 3 , 4 , 5, 6, 7, 8, and 9.

[0023] The pressure riveting structure of the automobile engine wind protection ring assembly includes the wind protection ring 1, and an open pressure riveting structure is arranged on the outer wall or the inner wall of the journal of the wind protection ring 1, and the opening 9 of the open pressure riveting structure faces outward or inward.

[0024] The direction of the opening 9 of the open pressure riveting structure is any angle within the range of 0°-90° with the outer wall or inner wall of the journal of the wind protection ring.

[0025] There are one or two openings 9 of the open pressure riveting structure, and bosses 10 are provided on the inner wall of the opening.

[0026] The outer peripheral side 11 or the inner peripheral side 12 of the opening 9 of the open pressure riveting structure is folded upwards to form a semi-enclosed structure.

[0027] After the rubber sealing ring 6 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com