Riveting method for front and back plates used for package of high-voltage cable disc

A packaging board and high-voltage cable technology, applied in packaging and other directions, can solve the problems of the packaging board falling off, the packaging board and the side wall of the wire reel being not tightly pressed, and it is difficult to tightly combine the packaging board and the wire reel. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

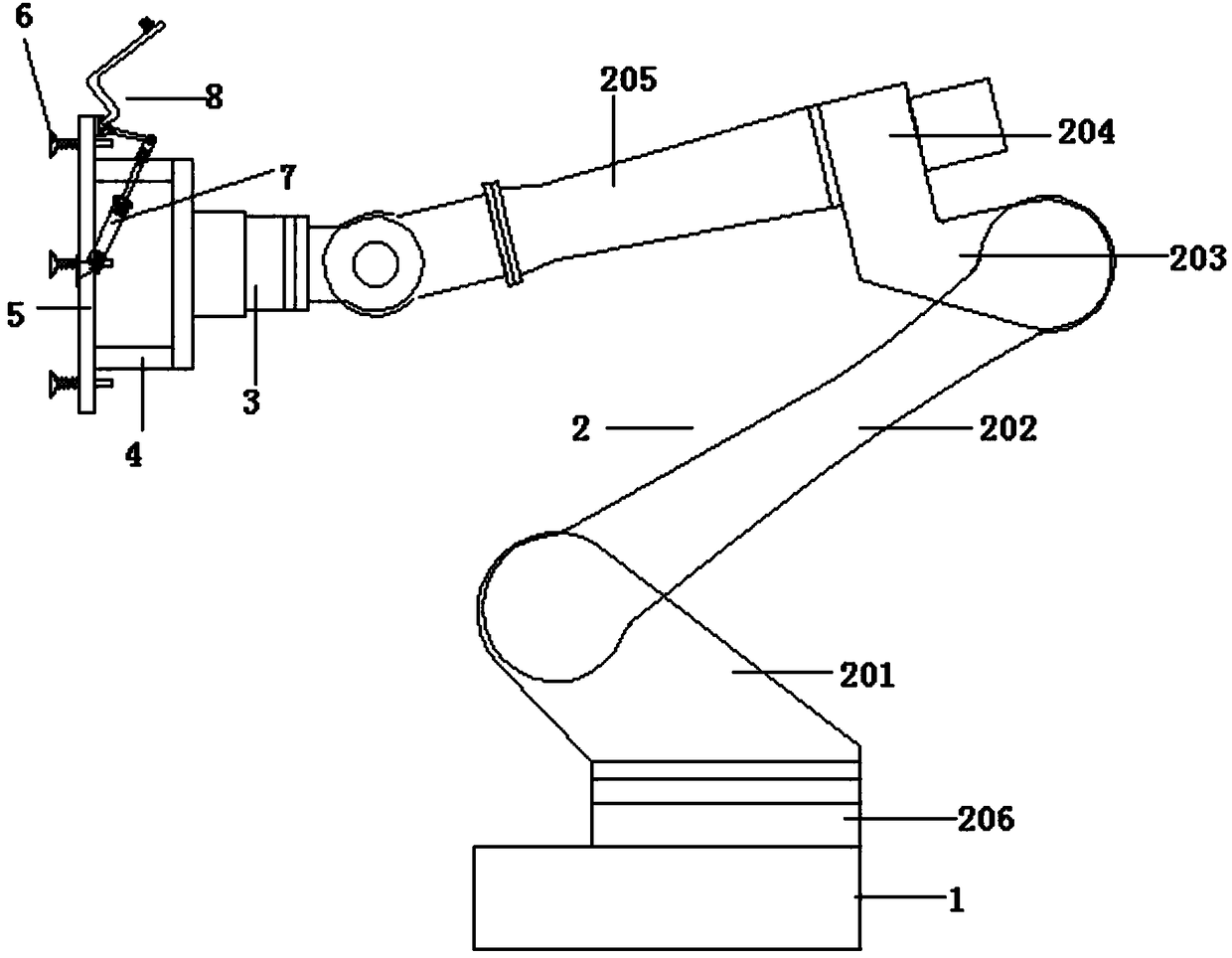

[0036] A method for riveting front and rear plates of high-voltage cable reel packaging, comprising the following steps:

[0037] Step 1: Make holes on the packaging board, the specific process is as follows:

[0038] S11: Placing the plate stack to a relatively fixed position;

[0039] S12: The grabbing device grabs the packaging board and puts it on the positioning tool, the board is automatically positioned by gravity, and the preliminary positioning of the packaging board is completed;

[0040] S13: The grabbing device grabs the plate, and cooperates with the hole-forming device to form holes in the corresponding plate according to the hole-forming file; the hole-forming device is a common punching device in the workshop;

[0041] Step 2: The grabbing device grabs the first packaging board, approaches the wire reel according to the calculated path, and controls the automatic riveting device to perform drilling and riveting at the joint between the first packaging board an...

Embodiment 2

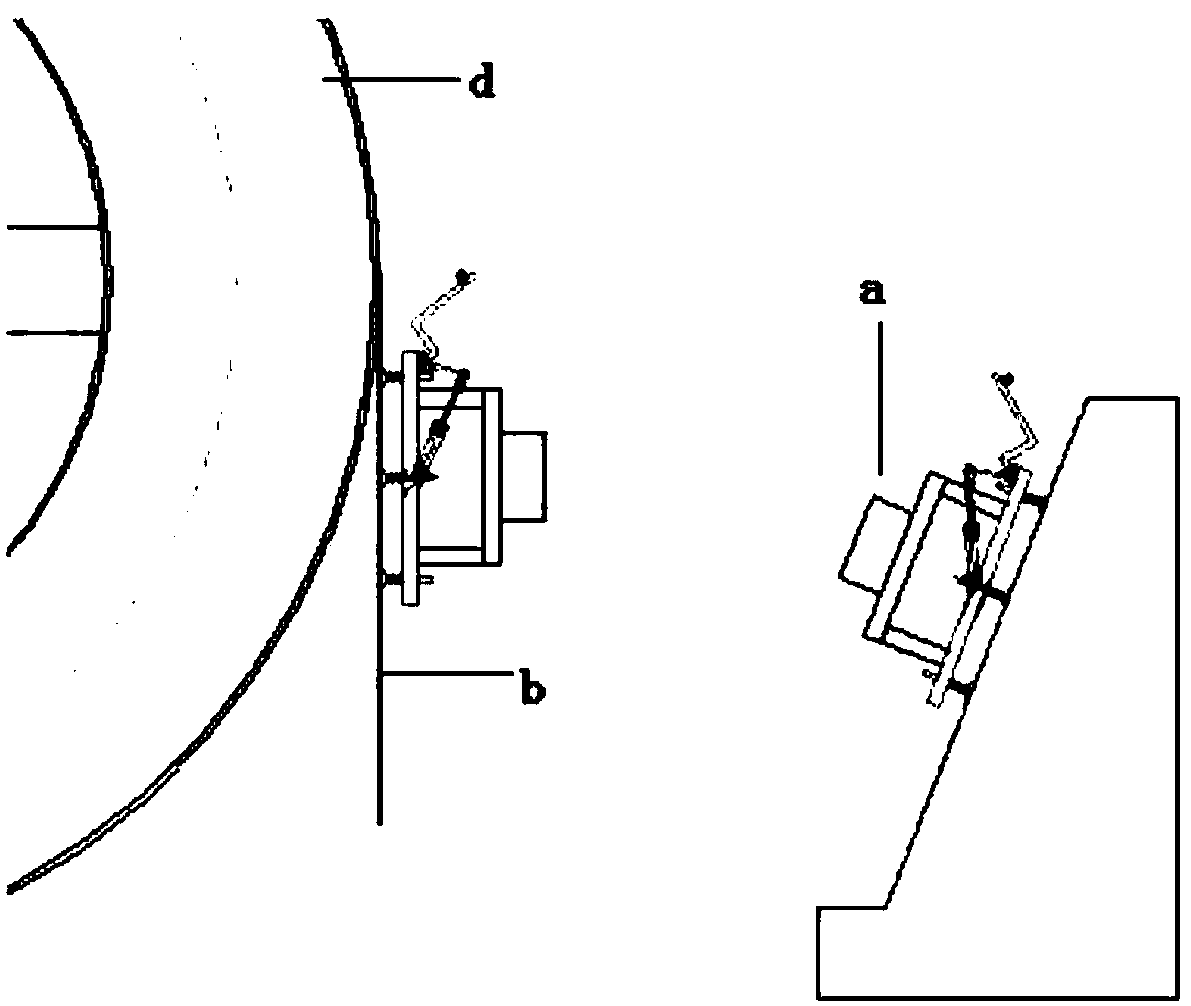

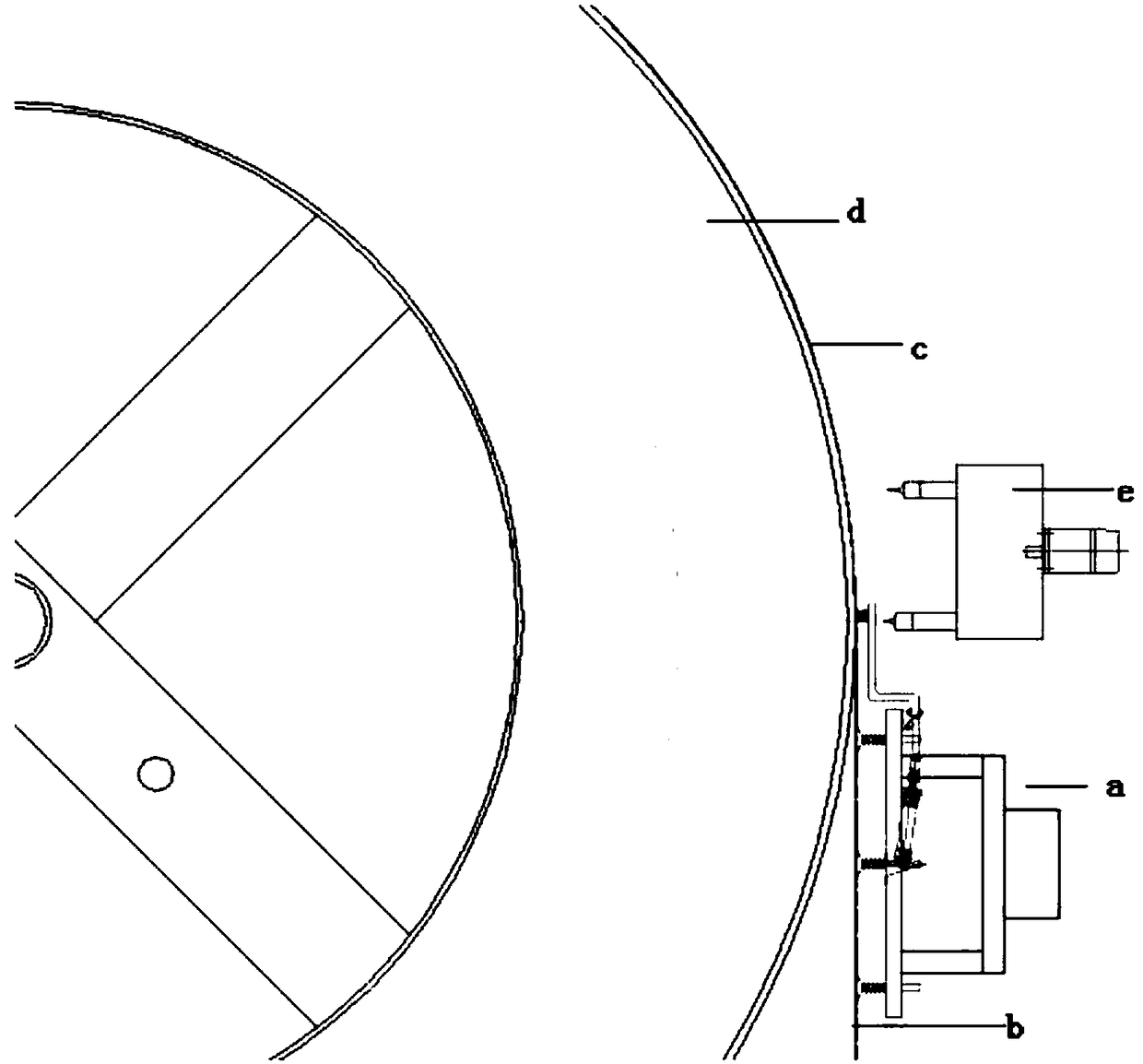

[0052] A riveting method for the front and rear panels of high-voltage cable drum packaging, such as figure 1 with figure 2 shown, including the following steps:

[0053] Step 1: The grabbing device a grabs the first packaging board b, approaches the wire reel according to the calculated path, and controls the automatic riveting device to perform drilling and riveting at the junction of the first packaging board b and the edge of the reel;

[0054] The specific riveting process of step 1 is as follows:

[0055] S101: After sucking the first packaging board b through the suction cup mechanism of the grabbing device a, move it to a designated position on the side of the wire reel according to the calculated path;

[0056] S102: Control the disk edge pressing mechanisms on both sides of the grabbing device to press one side of the first packaging board b to a designated position on the outer surface of the side wall of the wire reel, so that the distance between the first pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com