Auxiliary tool for self-plugging rivet and use method thereof

A core blind rivet and auxiliary tool technology is applied in the field of rivets to achieve the effects of convenient installation and removal, stable riveting and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

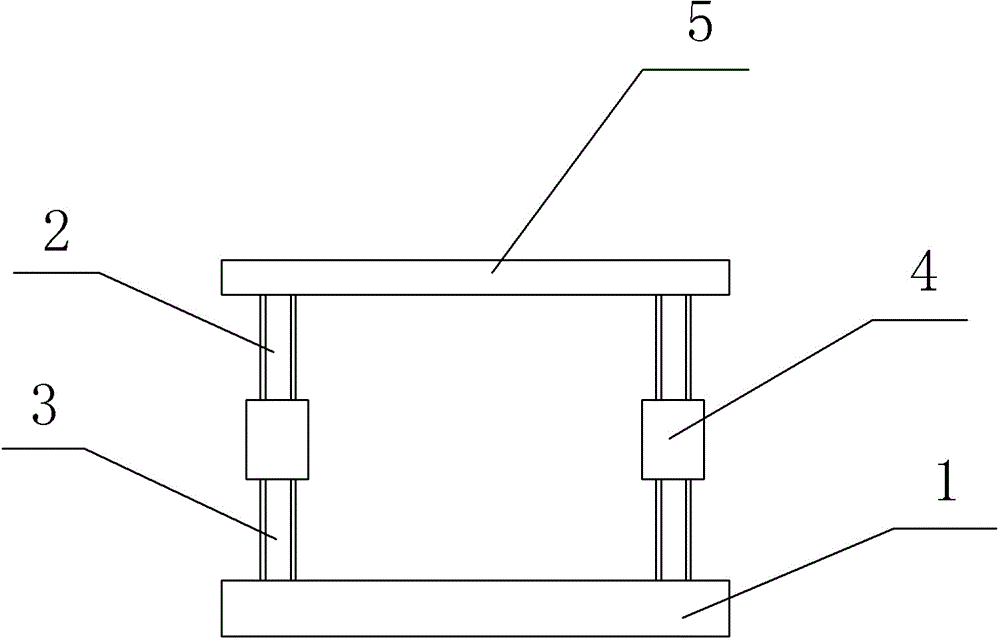

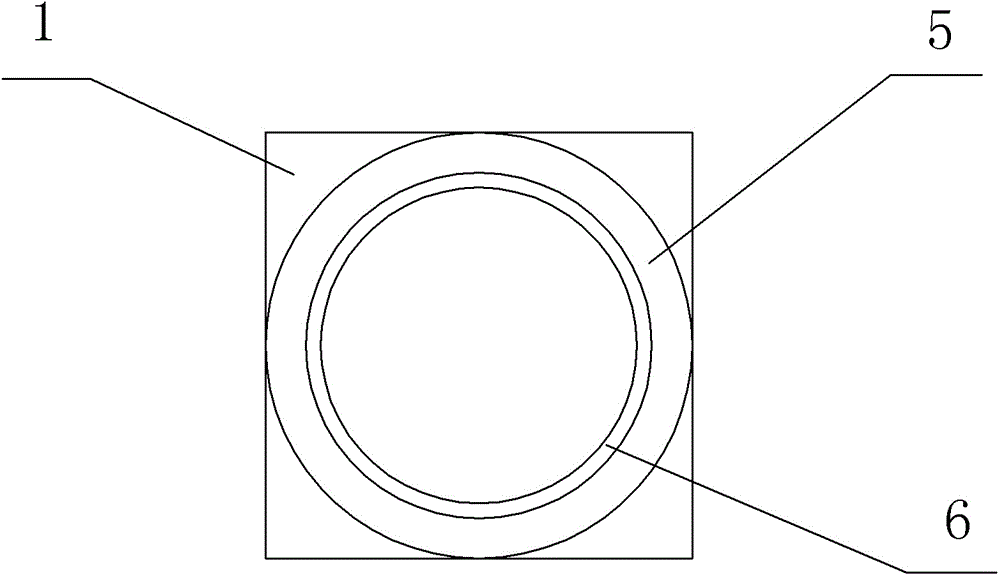

[0026] Such as figure 1 and figure 2 As shown, an auxiliary tool for blind rivets in this embodiment includes a base 1 , an adjusting rod and a fixing ring 5 . The quantity of adjusting rod is four, and adjusting rod is evenly distributed along the circumference of fixed ring 5, because adjusting rod is used for supporting fixed ring 5, adjusting rod 5 supports fixed ring up and down left and right, can make this structure more stable. The adjusting rod is mainly composed of a first screw 2, a second screw 3 and a sleeve 4, the sleeve 4 is threadedly connected to the lower end of the first screw 2 and the upper end of the second screw 3 respectively, and the upper end of the first screw 2 is connected to the base 1 Above, the lower end of the second screw rod 3 is connected to the back or outer edge of the fixing ring 5 . The inner edge of the fixed ring 5 is provided with a buffer pad 6, the inner diameter of the fixed ring 5 is less than the diameter of the deformable sec...

Embodiment 2

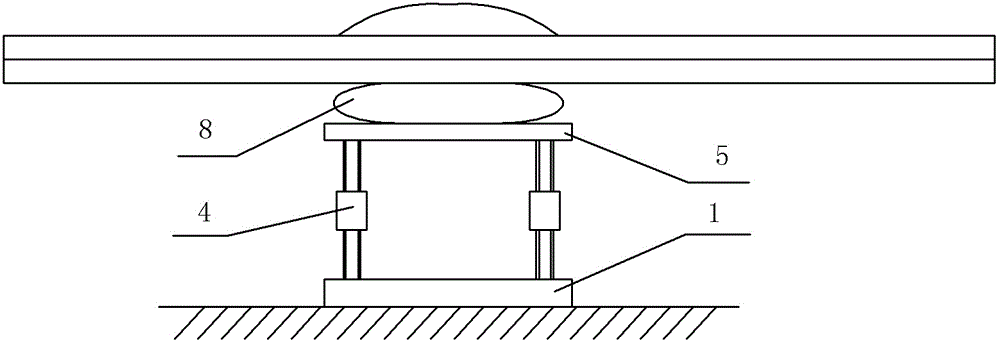

[0037] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that: the back of the base 1 is provided with a suction cup 7 . When there is a planar plate body on the other side of the riveting (that is, a narrow space), the suction cup 7 can be adsorbed on the plate body, which can make the structure more stable and less prone to deviation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com