Positioning device for blind nut hand tool

A positioning device and hand tool technology, applied in the field of positioning devices, can solve the problems of long assembly time, high processing cost, falling off of positioning steel ball 71, etc., achieve the effect of safe operation and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

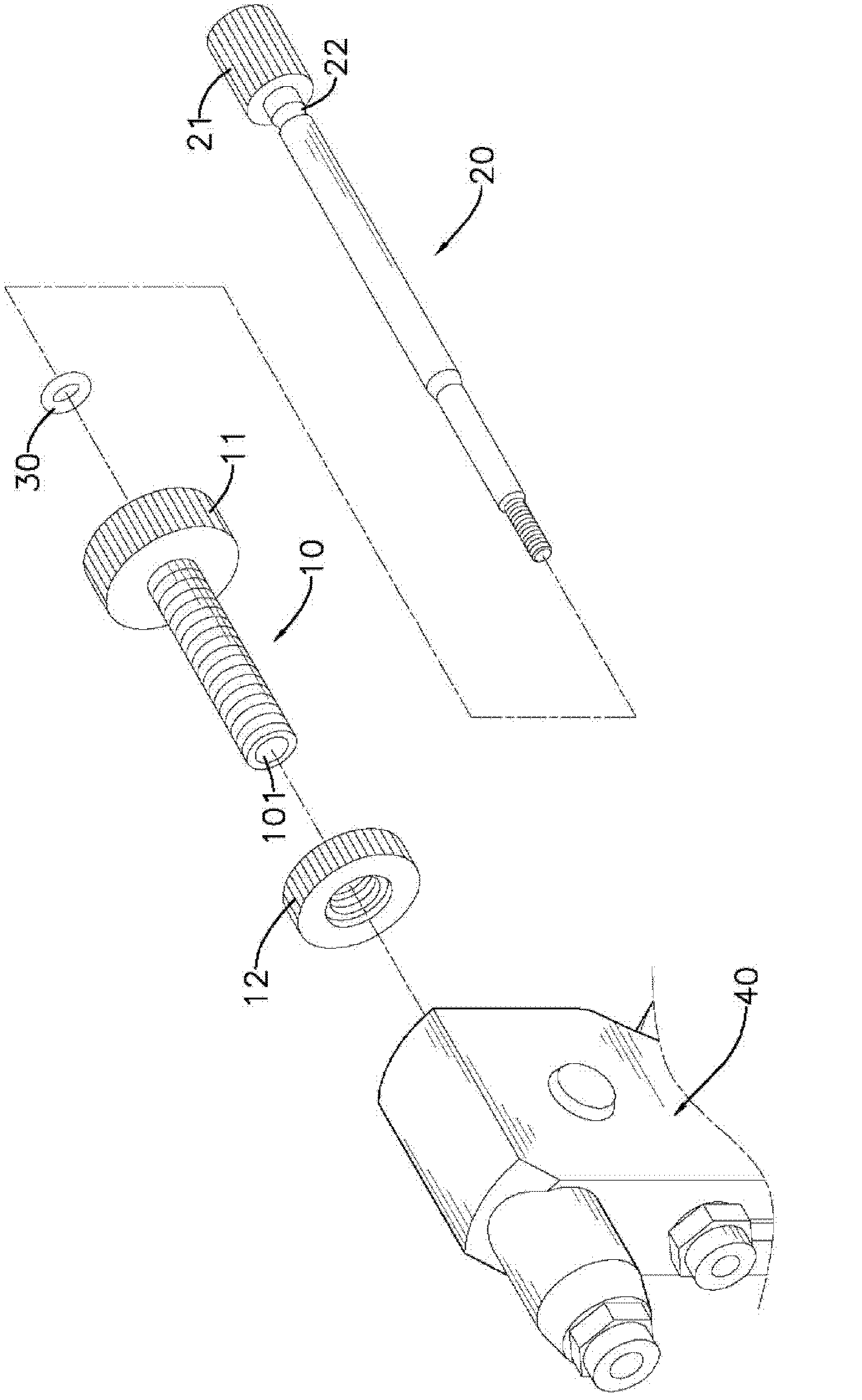

[0046] The present invention is a positioning device for a cap pulling hand tool, please refer to figure 1 As shown, it includes a rotating sleeve 10, a pull rod 20 and a positioning ring 30;

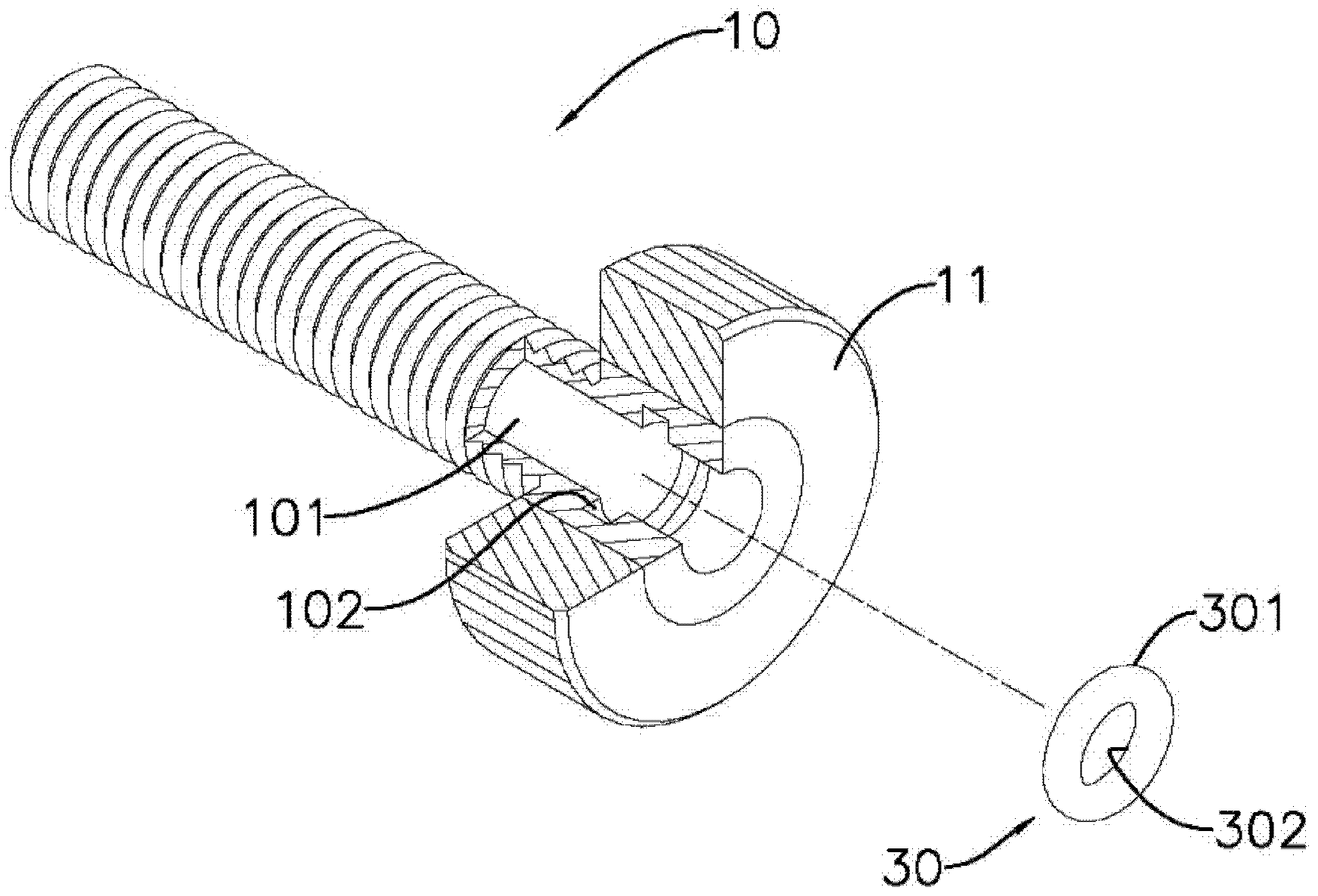

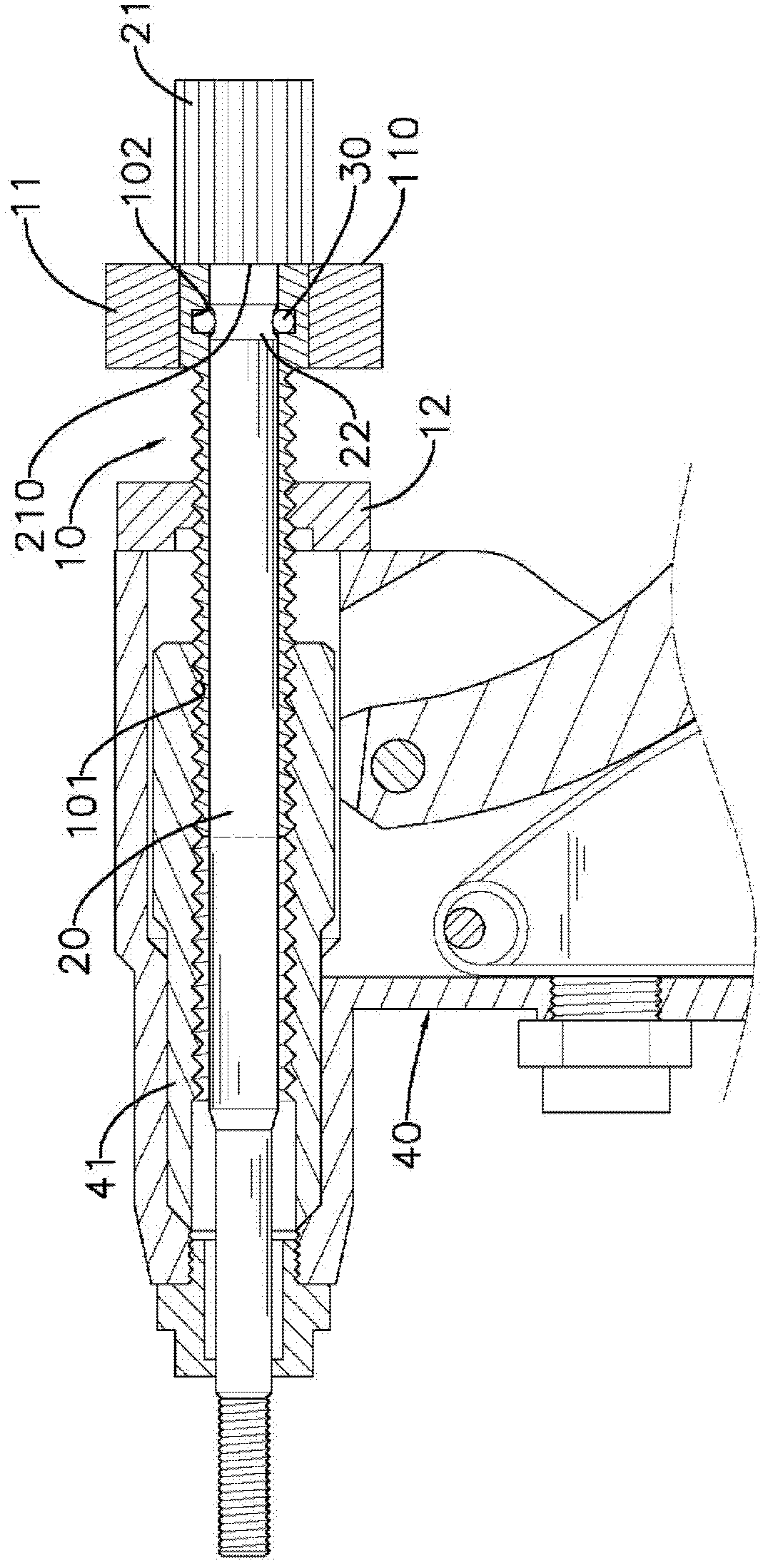

[0047] Please refer to figure 2 and image 3 As shown, the rotating sleeve 10 is a hollow tube with openings at both ends, and a rotating head 11 is sleeved on one end of the rotating sleeve 10. The outer pipe wall of the rotating sleeve 10 is provided with external threads. The inner tube wall of the sleeve 10 forms a through hole 101, and the inner hole surface at the end of the rotating head 11 is radially recessed with an annular mounting groove 102. In a preferred embodiment of the present invention, the mounting groove 102 is located at the The center of the axial position of the rotary head 11;

[0048] The pull rod 20 is a round rod. The outer diameter of the rod body is smaller than the aperture of the through hole 101. One end of the rod body is connected with a pull rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com