Patents

Literature

30results about How to "Eliminate penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

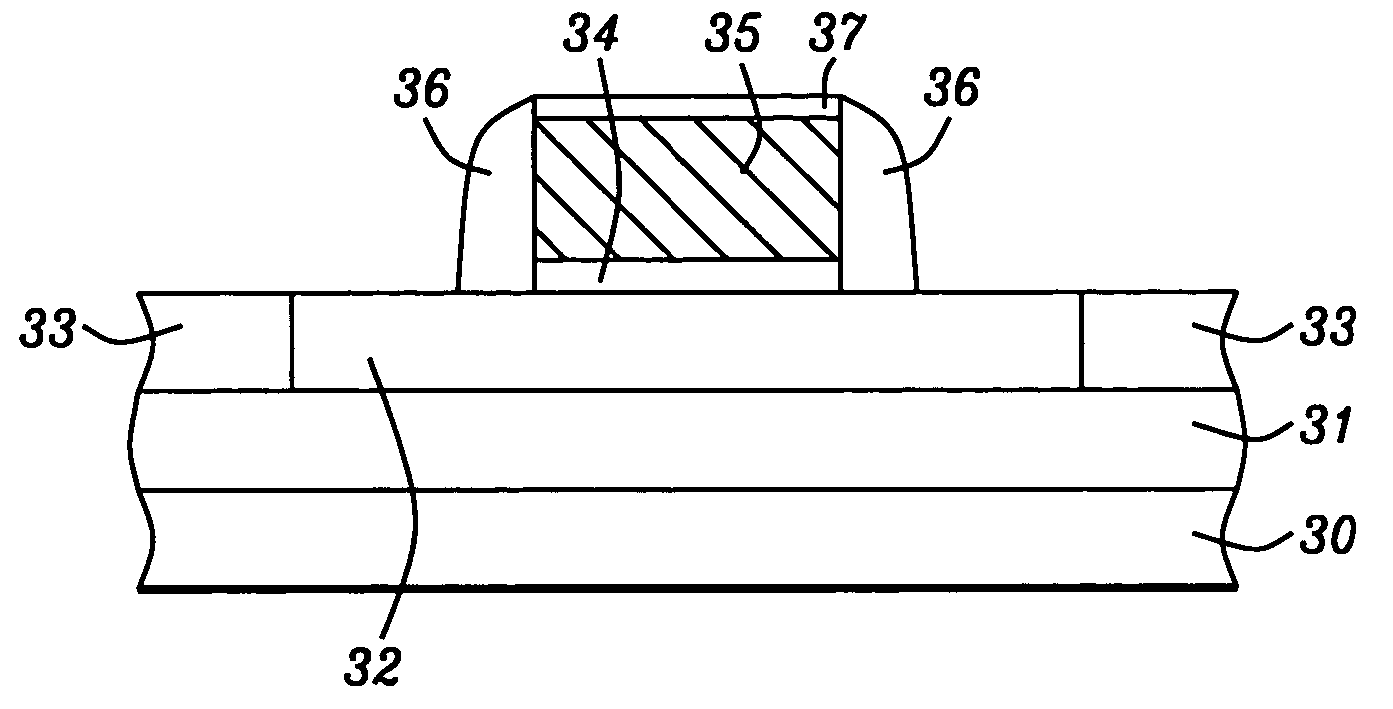

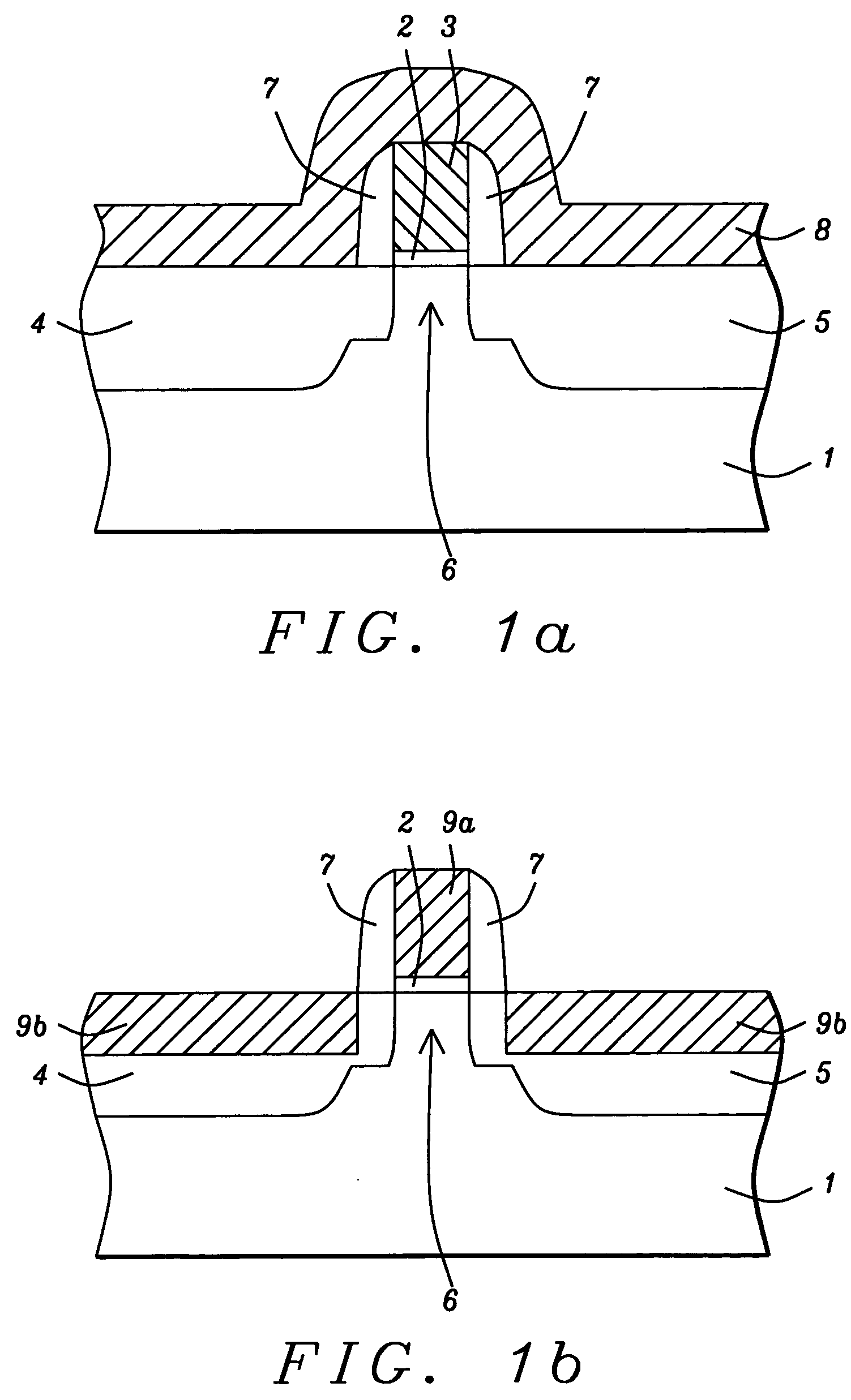

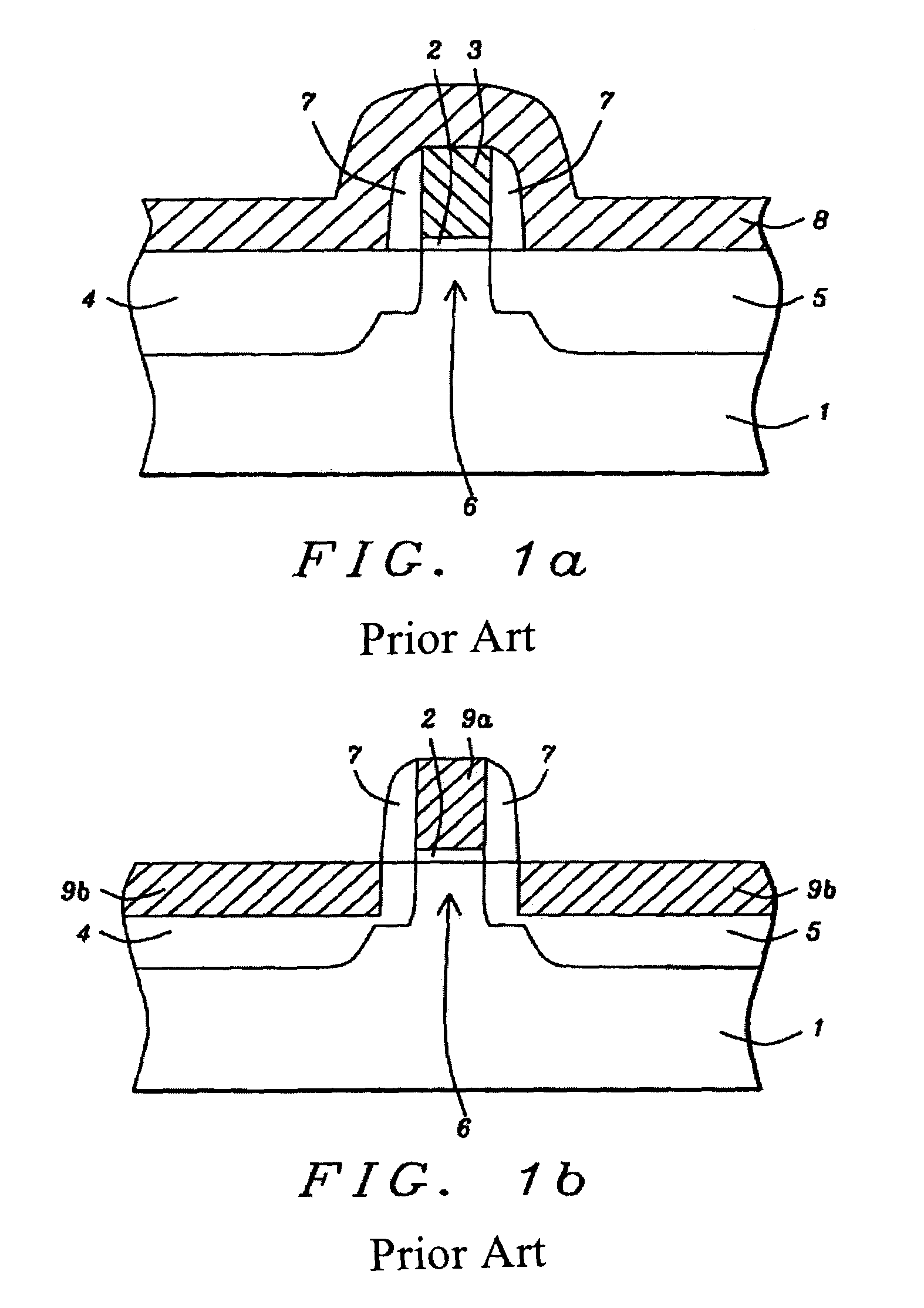

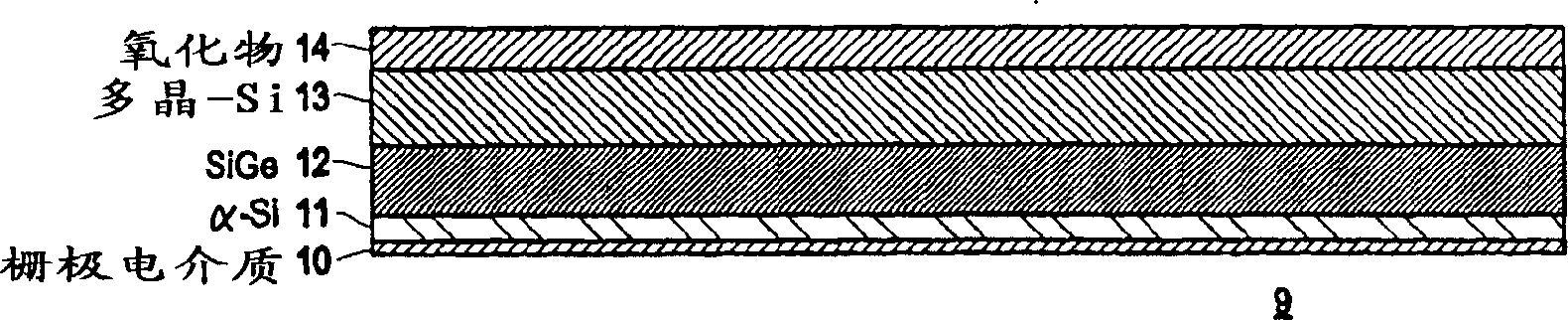

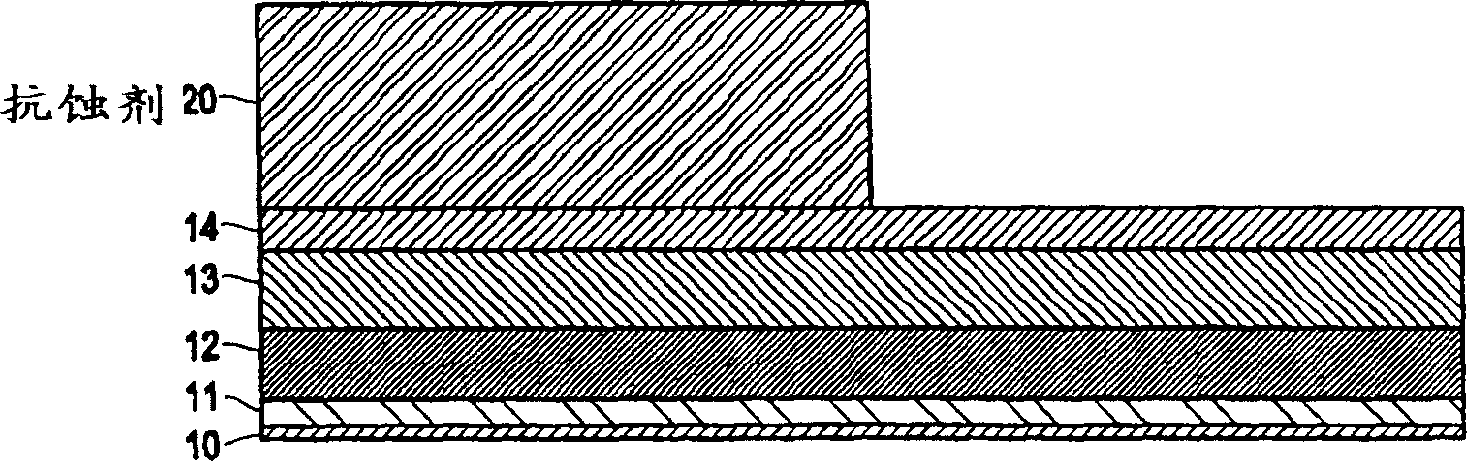

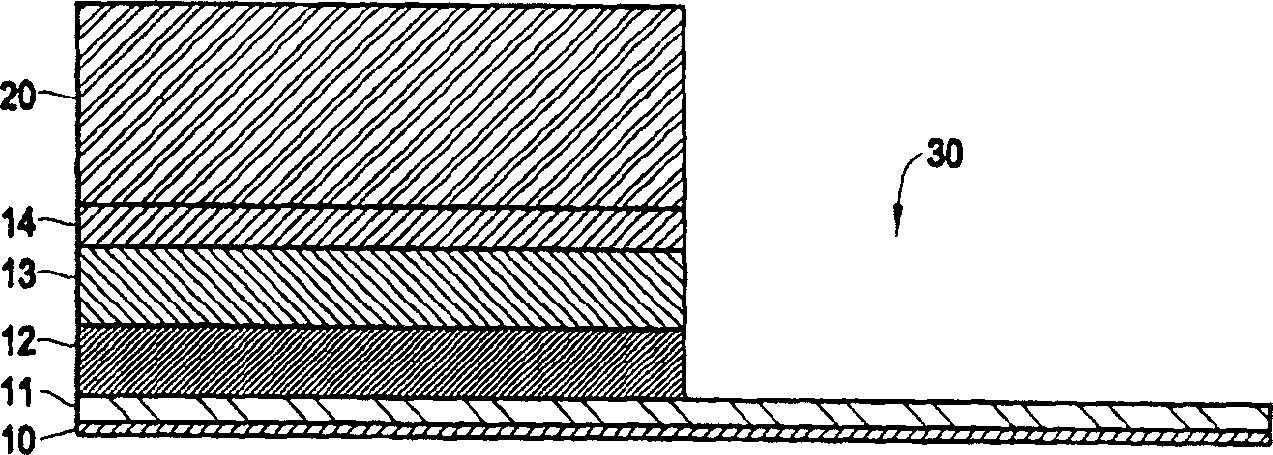

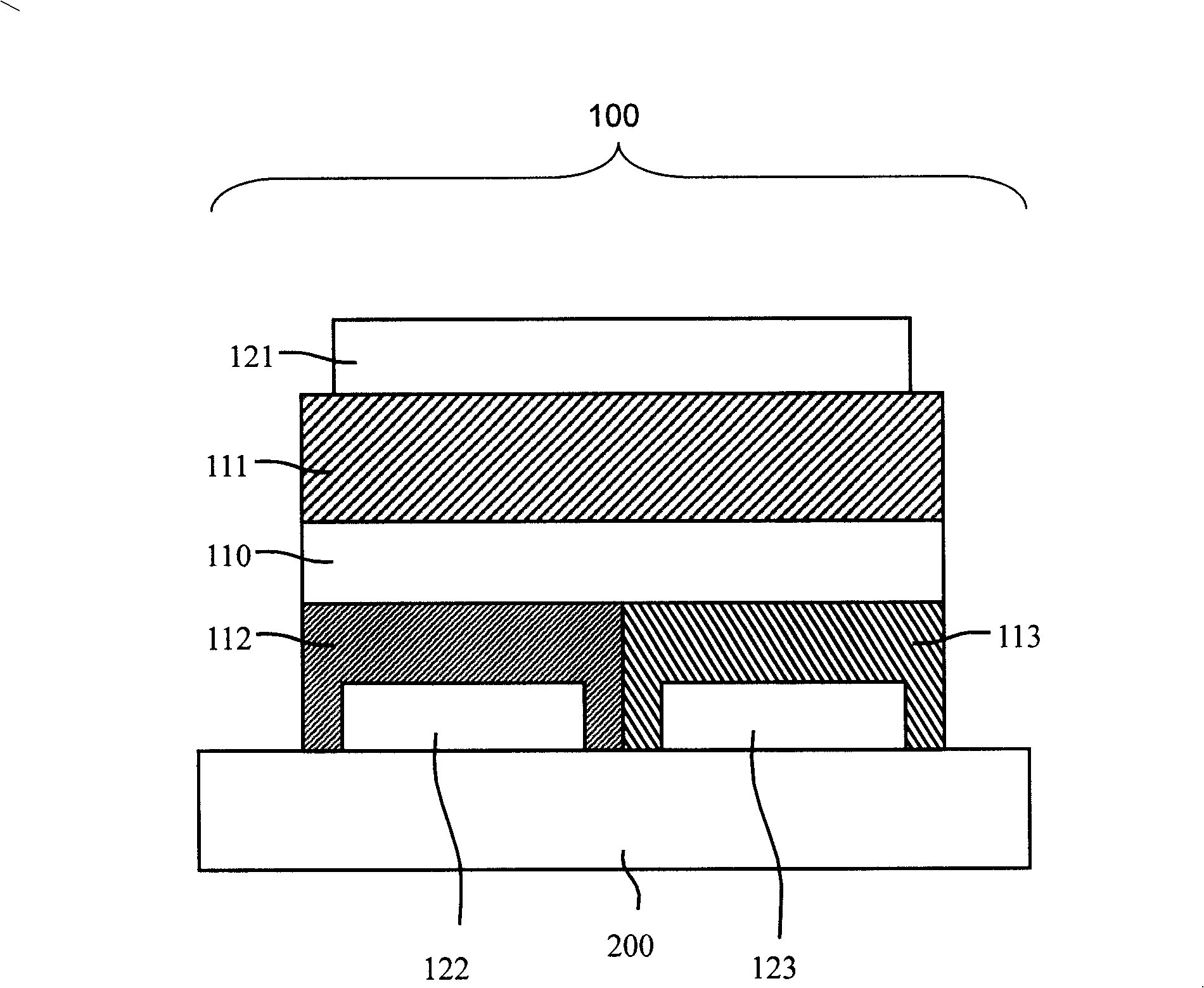

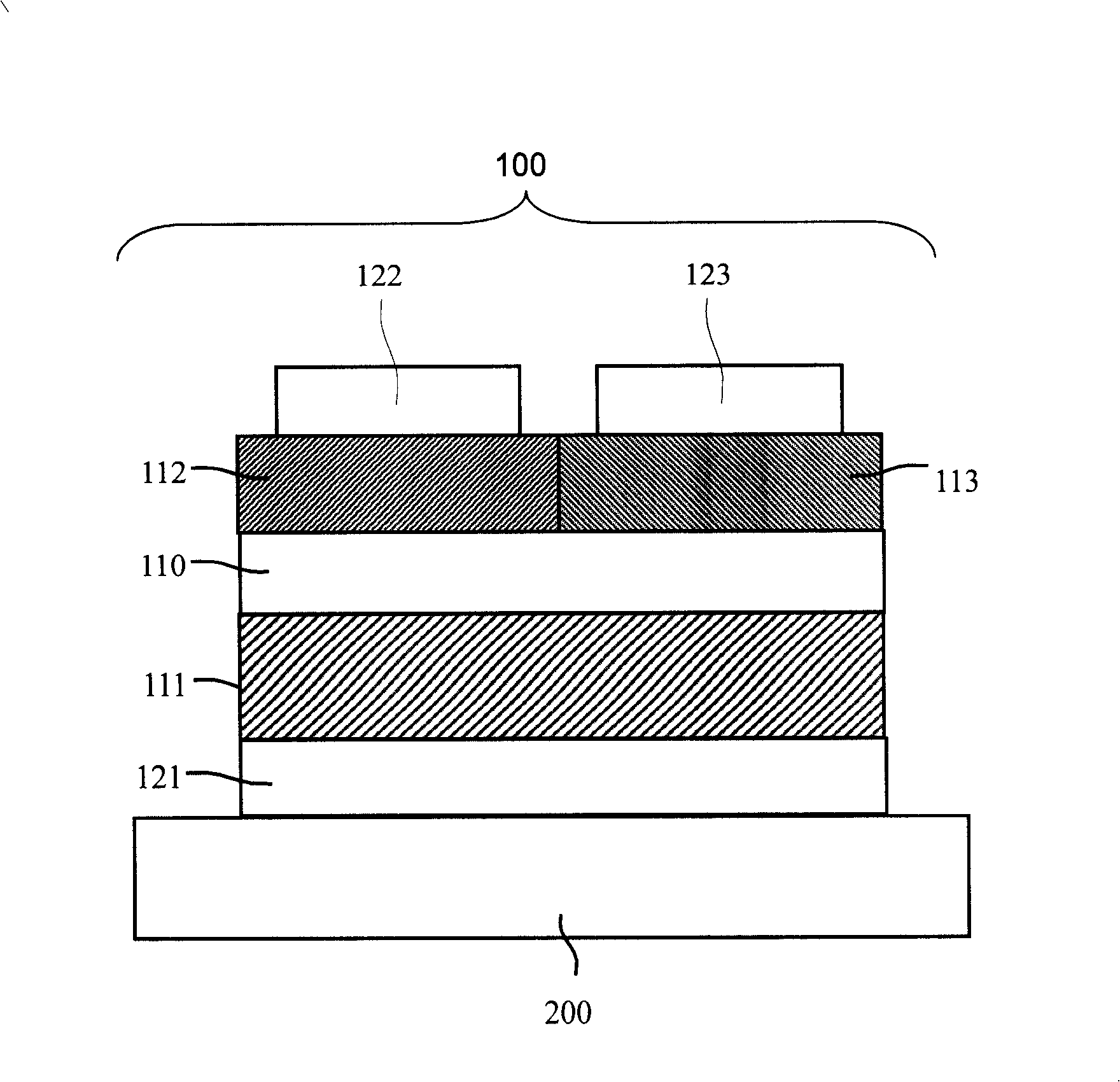

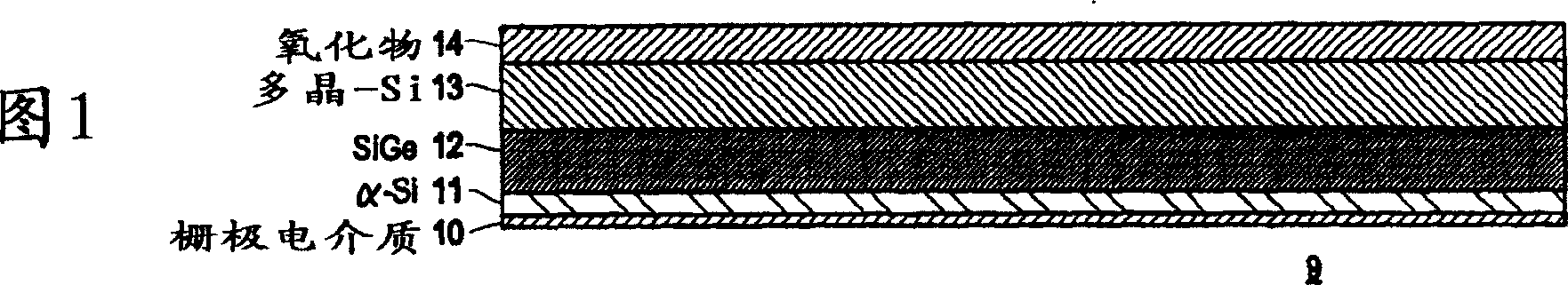

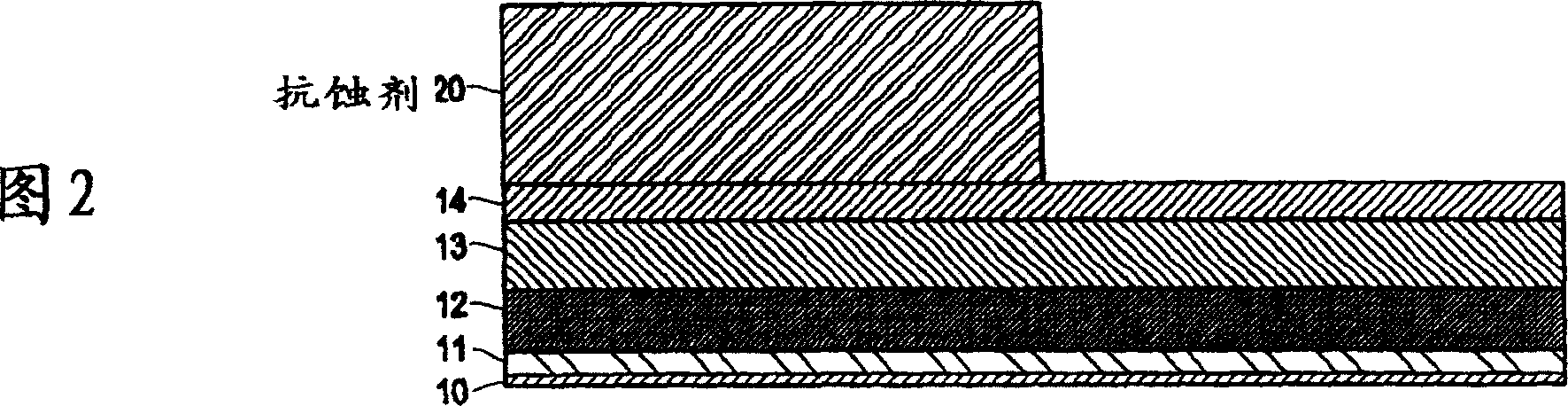

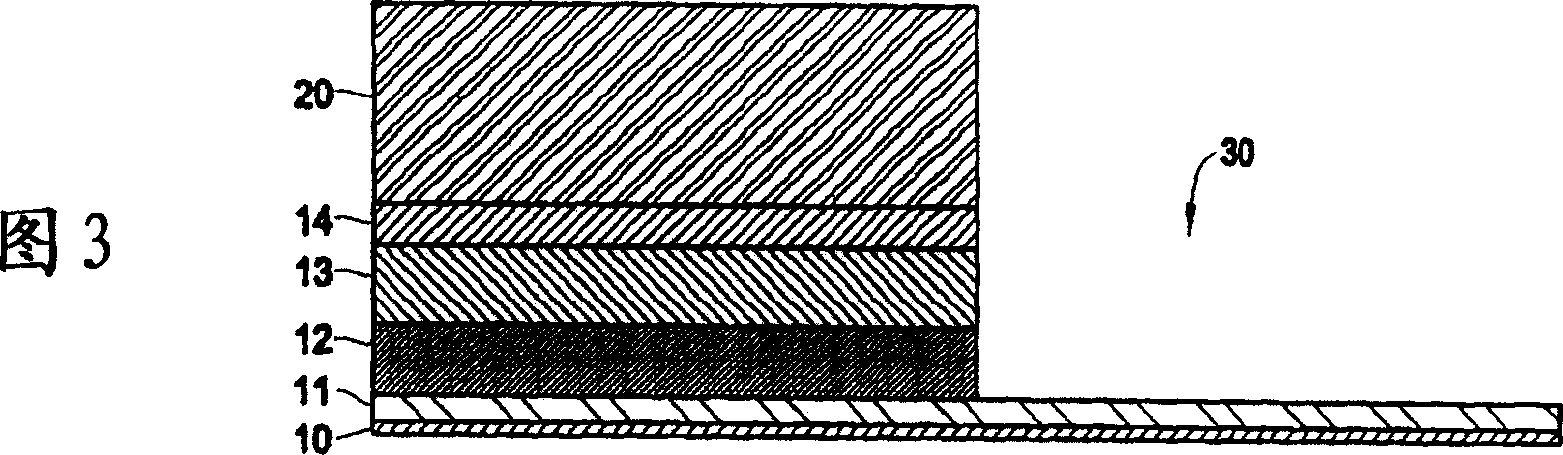

Silicide gate transistors and method of manufacture

InactiveUS20050156238A1Improve performanceEliminate depletionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMetal

A method in which a gate and raised source / drain (S / D) regions are fully silicided in separate steps to avoid degrading the resistance or junction leakage is described. A gate dielectric layer, gate, and spacers are formed over a semiconductor layer that is preferably Si, SiGe, or SiGeC on a buried insulator. Raised S / D regions are formed by selective epitaxy between spacers and isolation regions. The gate is protected with a mask while the raised S / D regions are covered with a first metal layer. A first anneal affords fully silicided S / D regions. A dielectric stack is deposited on the substrate and planarized to be coplanar with the top of the spacers. The mask is removed and a second metal layer is deposited. A second anneal yields a fully silicided gate electrode. The invention is also an SOI transistor with silicided raised S / D regions and a fully silicided and optionally recessed gate.

Owner:TAIWAN SEMICON MFG CO LTD

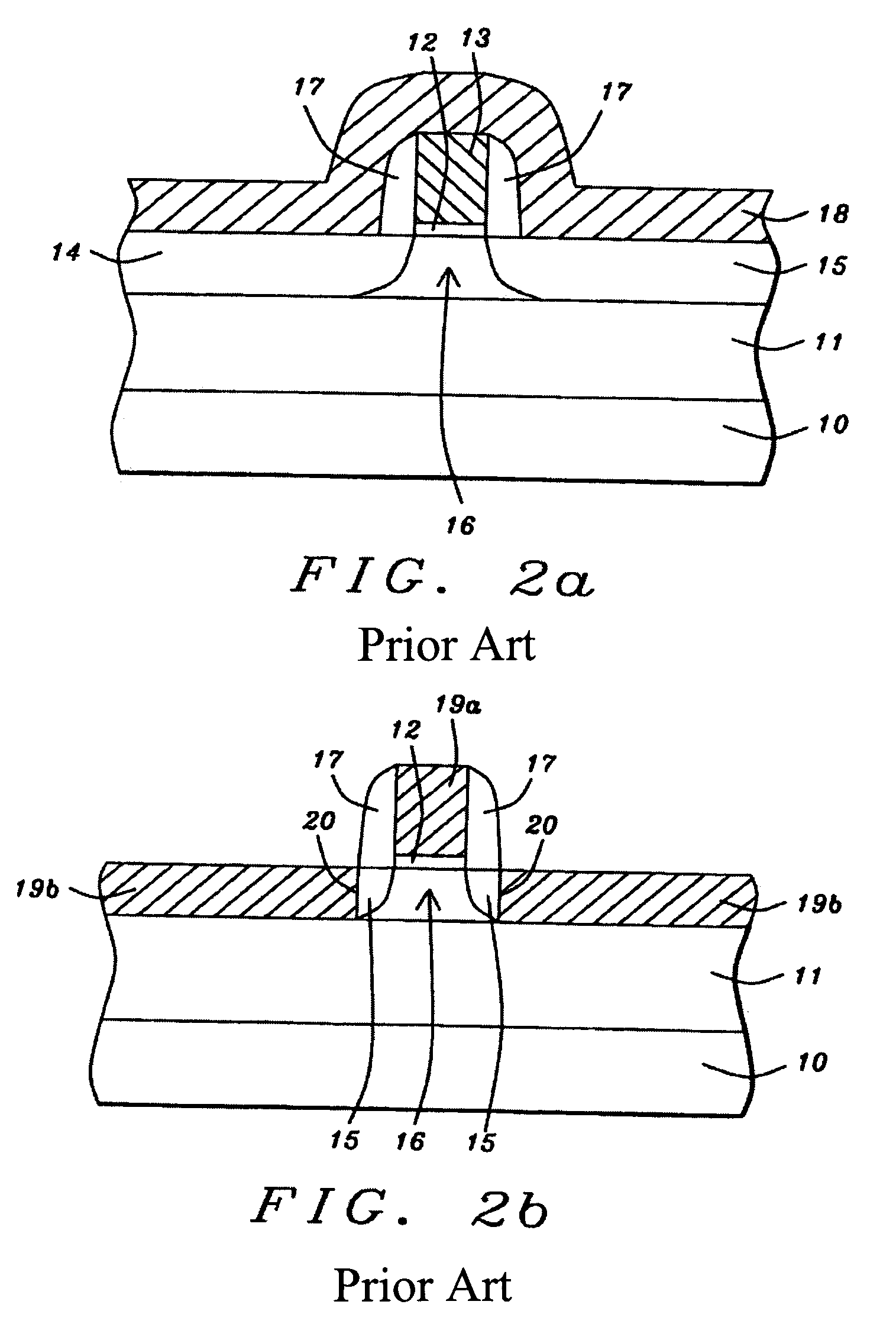

Silicide gate transistors and method of manufacture

InactiveUS7067379B2Improve performanceEliminate depletionSolid-state devicesSemiconductor/solid-state device manufacturingJunction leakageGate dielectric

A method in which a gate and raised source / drain (S / D) regions are fully silicided in separate steps to avoid degrading the resistance or junction leakage is described. A gate dielectric layer, gate, and spacers are formed over a semiconductor layer that is preferably Si, SiGe, or SiGeC on a buried insulator. Raised S / D regions are formed by selective epitaxy between spacers and isolation regions. The gate is protected with a mask while the raised S / D regions are covered with a first metal layer. A first anneal affords fully silicided S / D regions. A dielectric stack is deposited on the substrate and planarized to be coplanar with the top of the spacers. The mask is removed and a second metal layer is deposited. A second anneal yields a fully silicided gate electrode. The invention is also an SOI transistor with silicided raised S / D regions and a fully silicided and optionally recessed gate.

Owner:TAIWAN SEMICON MFG CO LTD

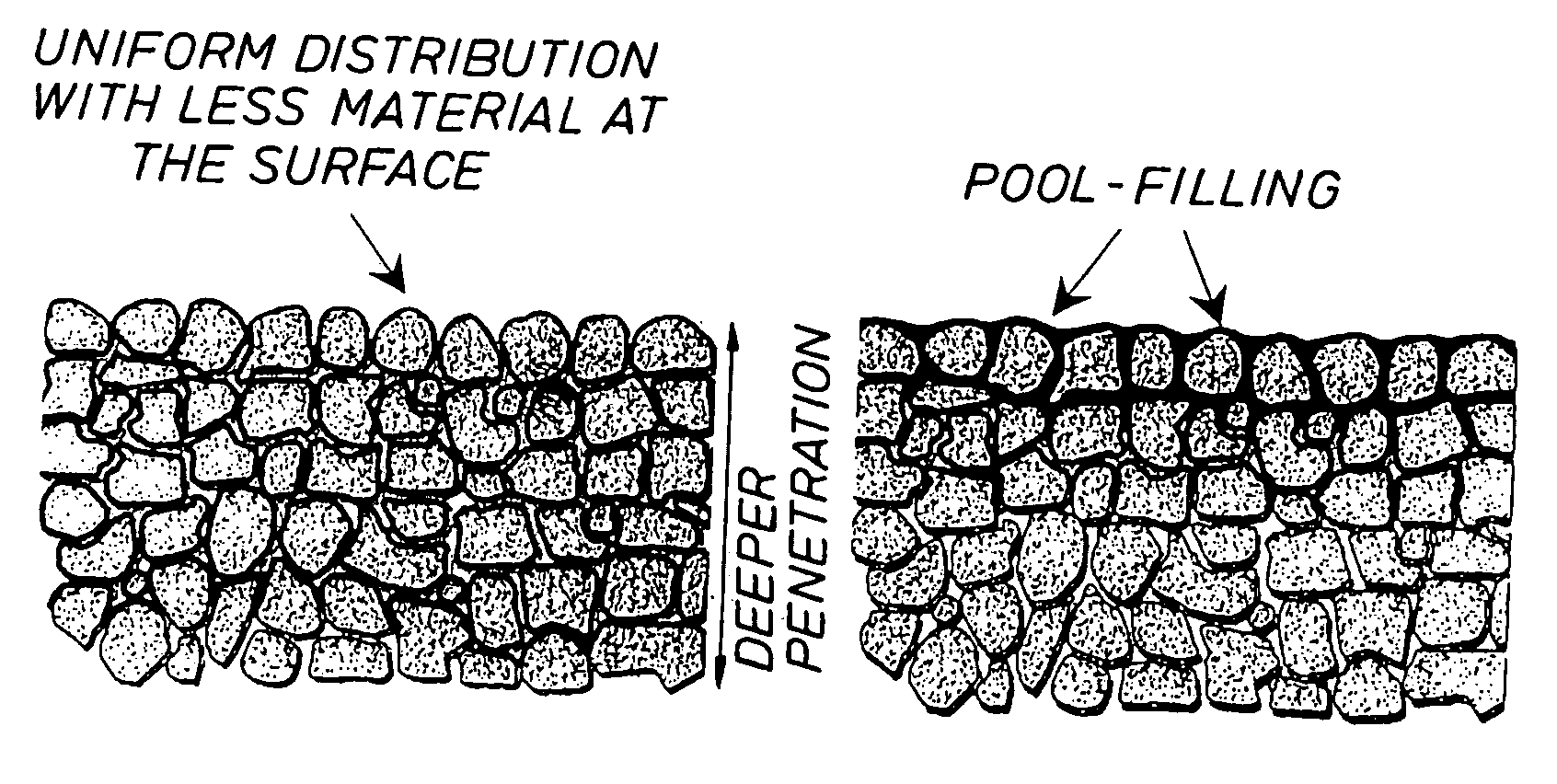

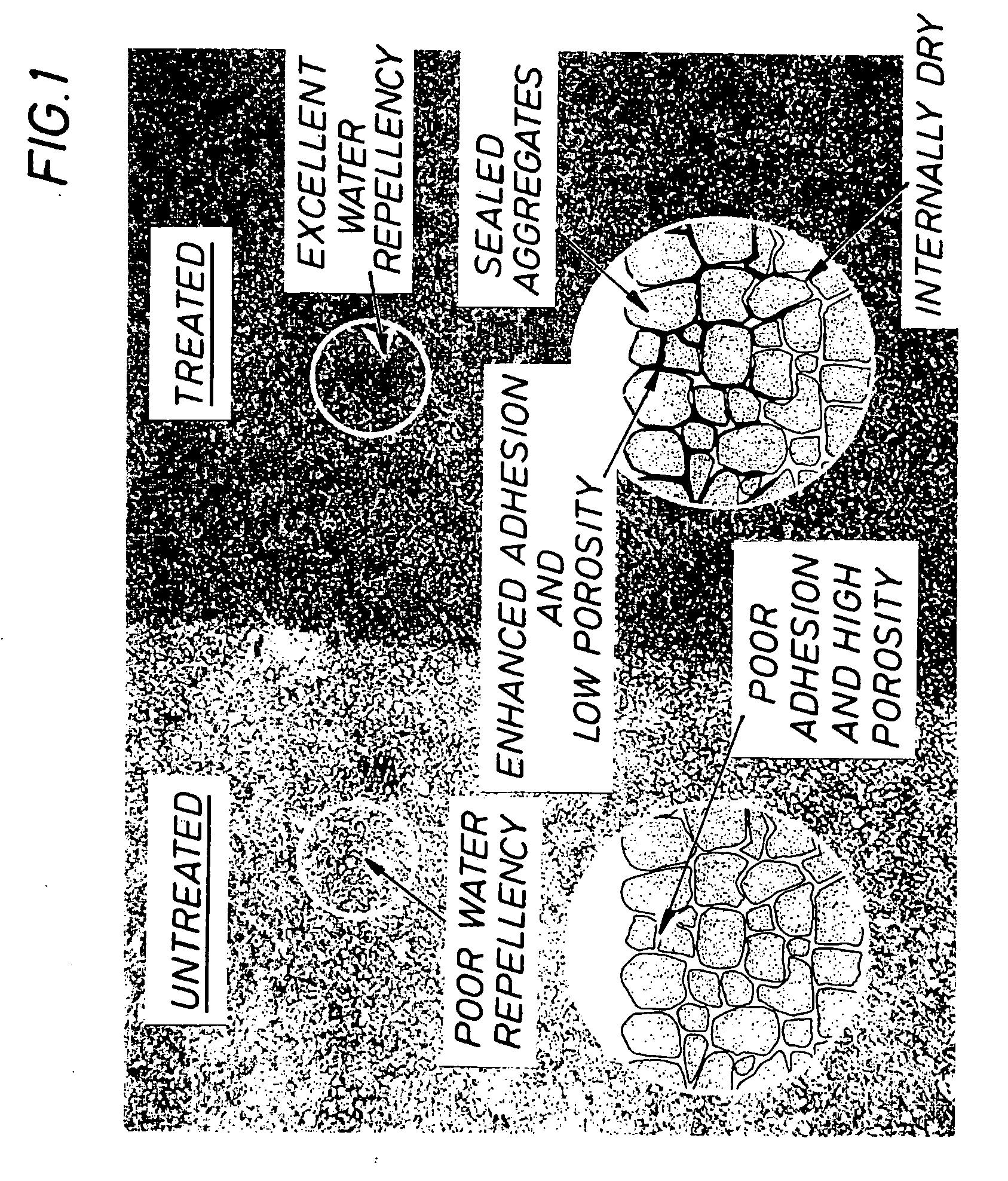

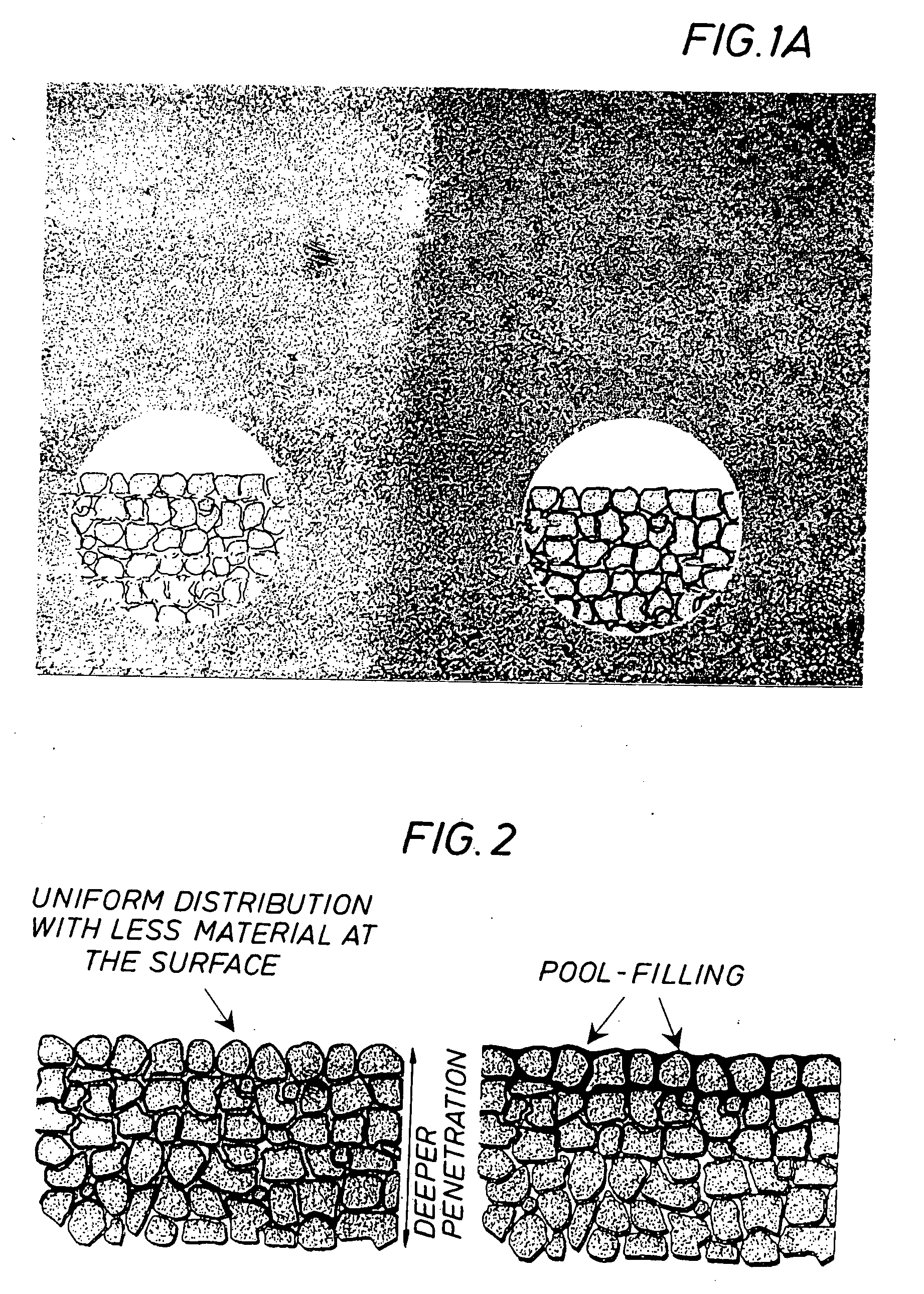

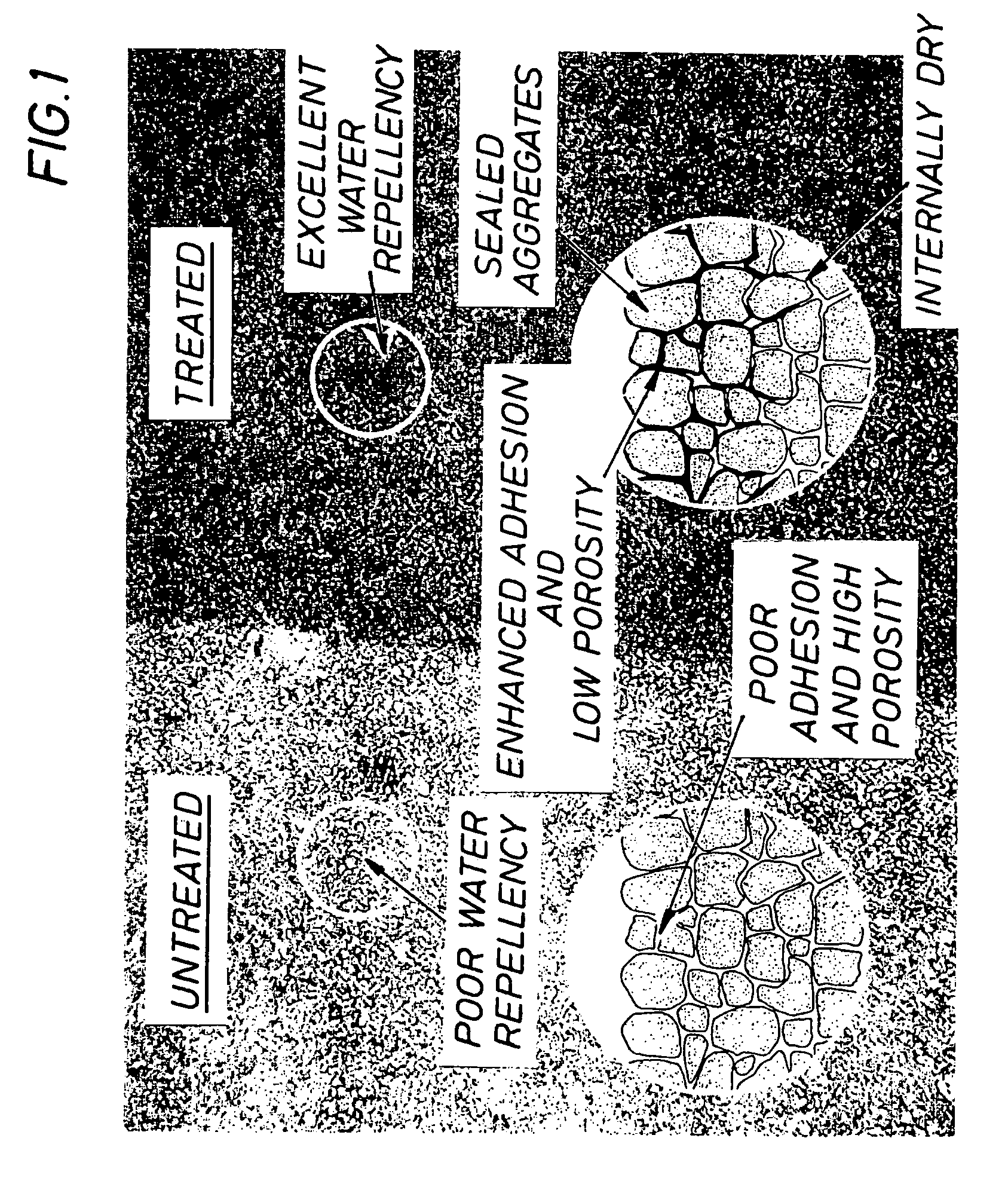

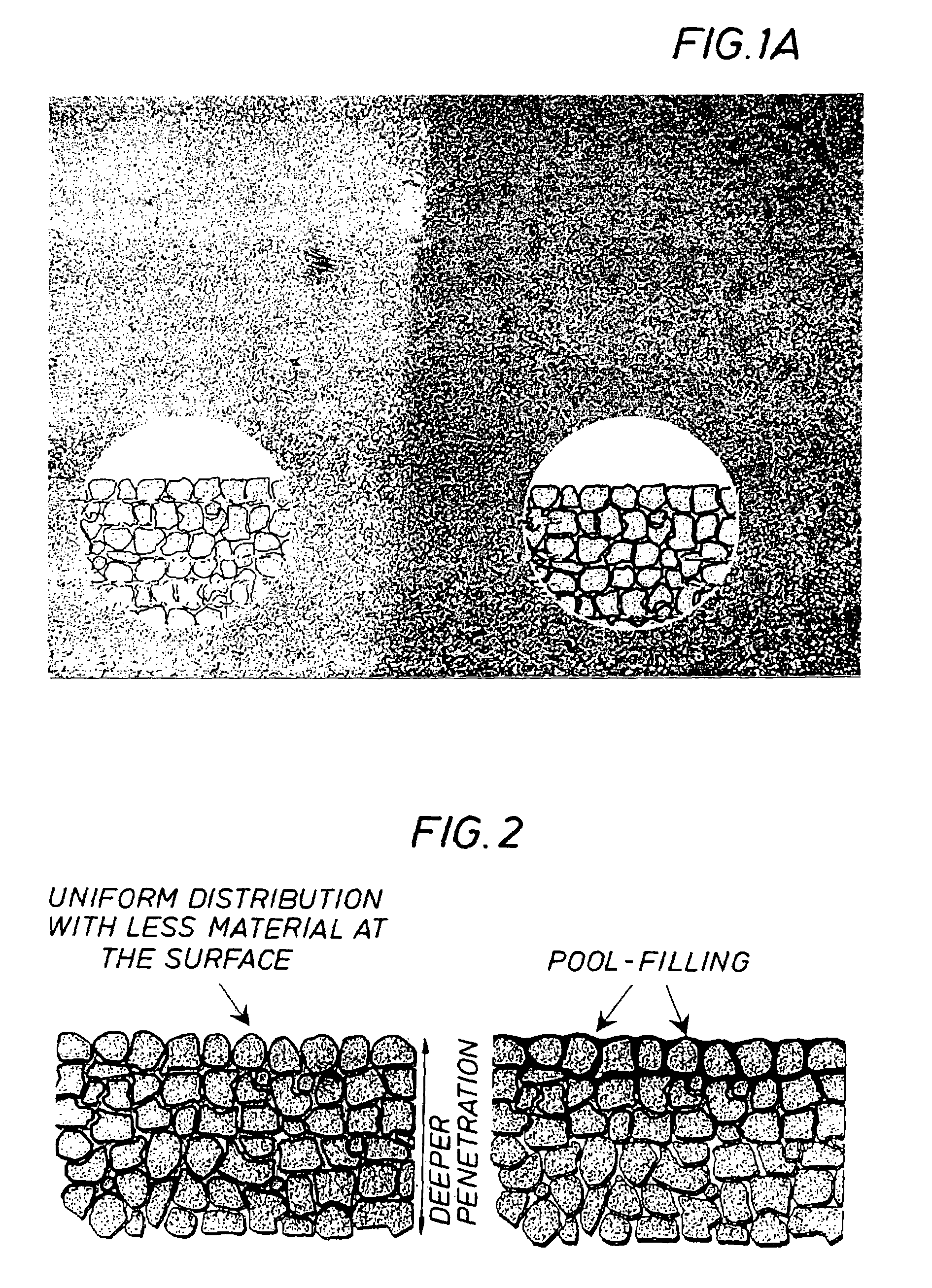

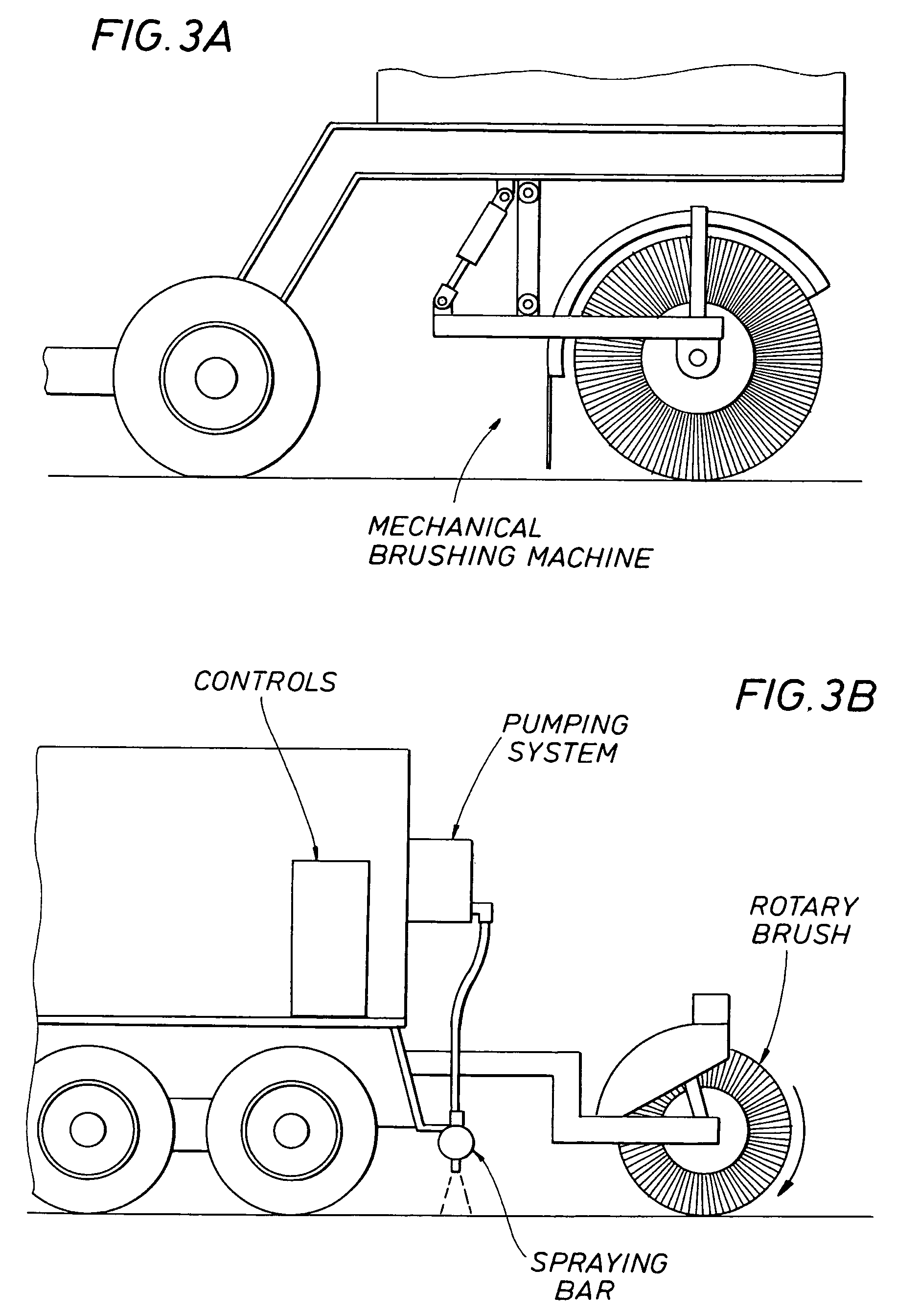

Low-viscosity, silicone-modified penetrating asphalt sealer to eliminate water associated problems in asphalt pavements

InactiveUS20050265784A1Eliminating water penetrationProlong asphalt service lifeIn situ pavingsPaving detailsEmulsionCompound (substance)

A solvent-based solution including methods of making and using for treating and protecting for heavy traffic asphalt pavement, particularly against water-associated problems, such as repeated freeze / thaw cycles, and damage caused by exposure to UV light. The mechanism of protection include an internal coating and partial internal sealing of voids and pores with a special blend of pre-oxidized asphalt emulsion that has been modified with moisture-insensitive silicone-based compounds and surfactants to enhance penetration depth and effectiveness. The sealer works from within the asphalt pavement as well as at the surface. A water-repelling function prevents water from penetrating from the surface while allowing vapor transmission across the pavement through connected voids and capillaries. The sealer should also enhance the bonding strength between asphalt coated particles, thus eliminate chipping. As a result, the sealer should prolong the life of exiting and of new asphalt pavement as well as reduce maintenance cost.

Owner:RASHED RADI AL

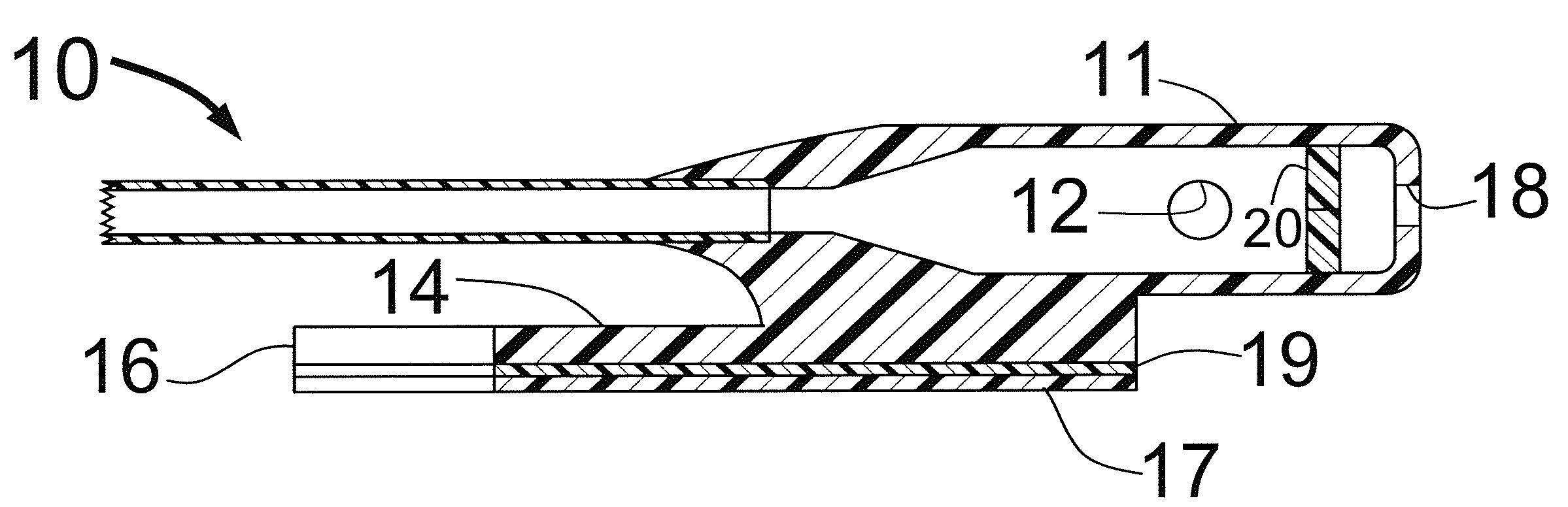

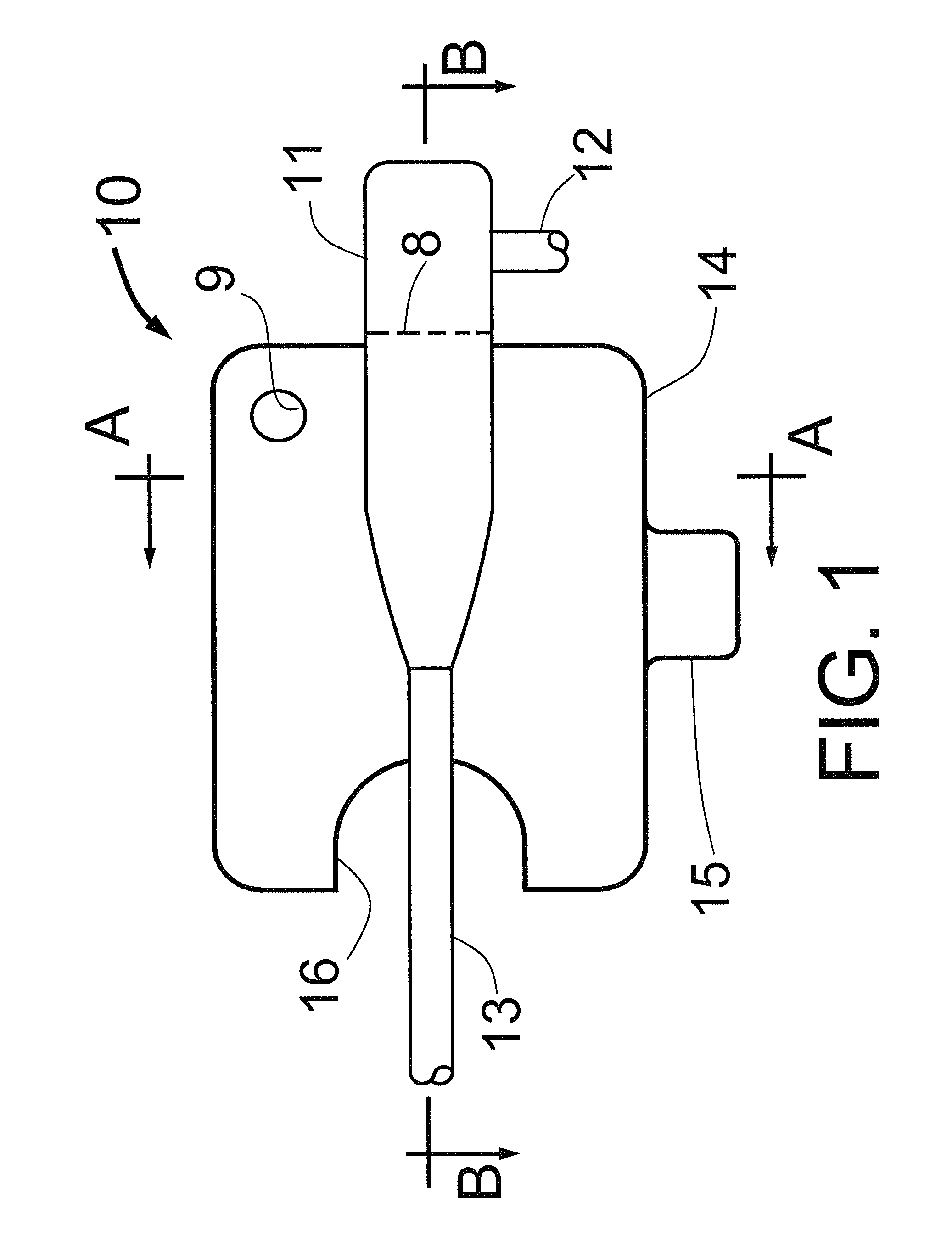

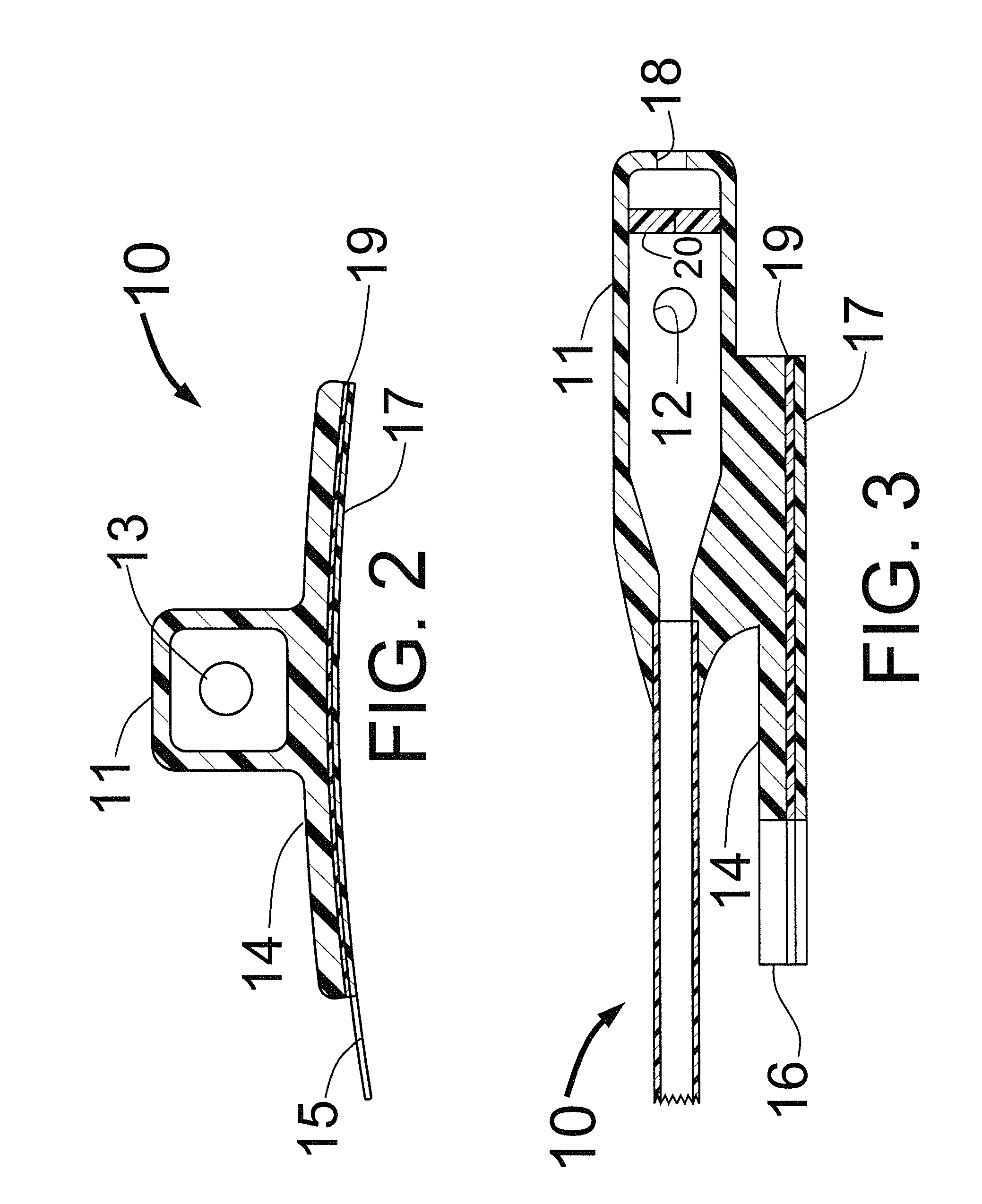

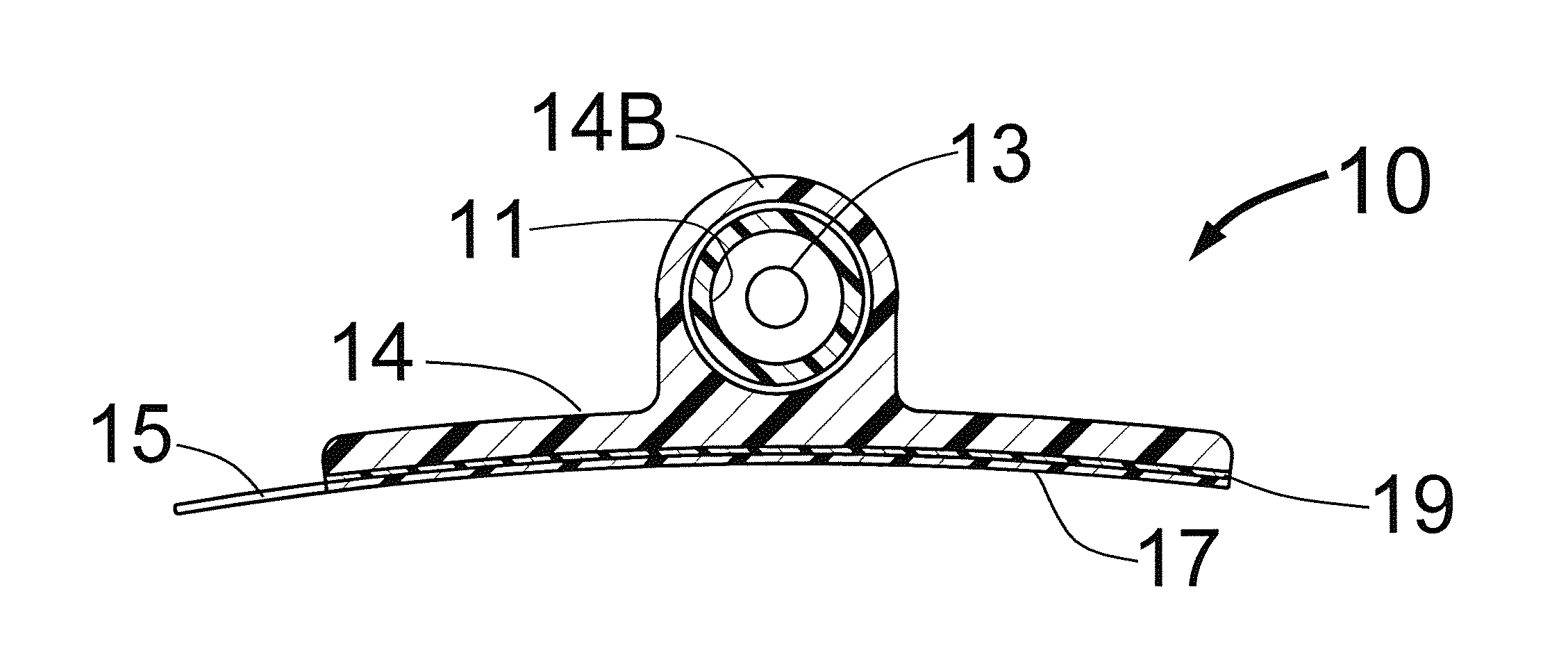

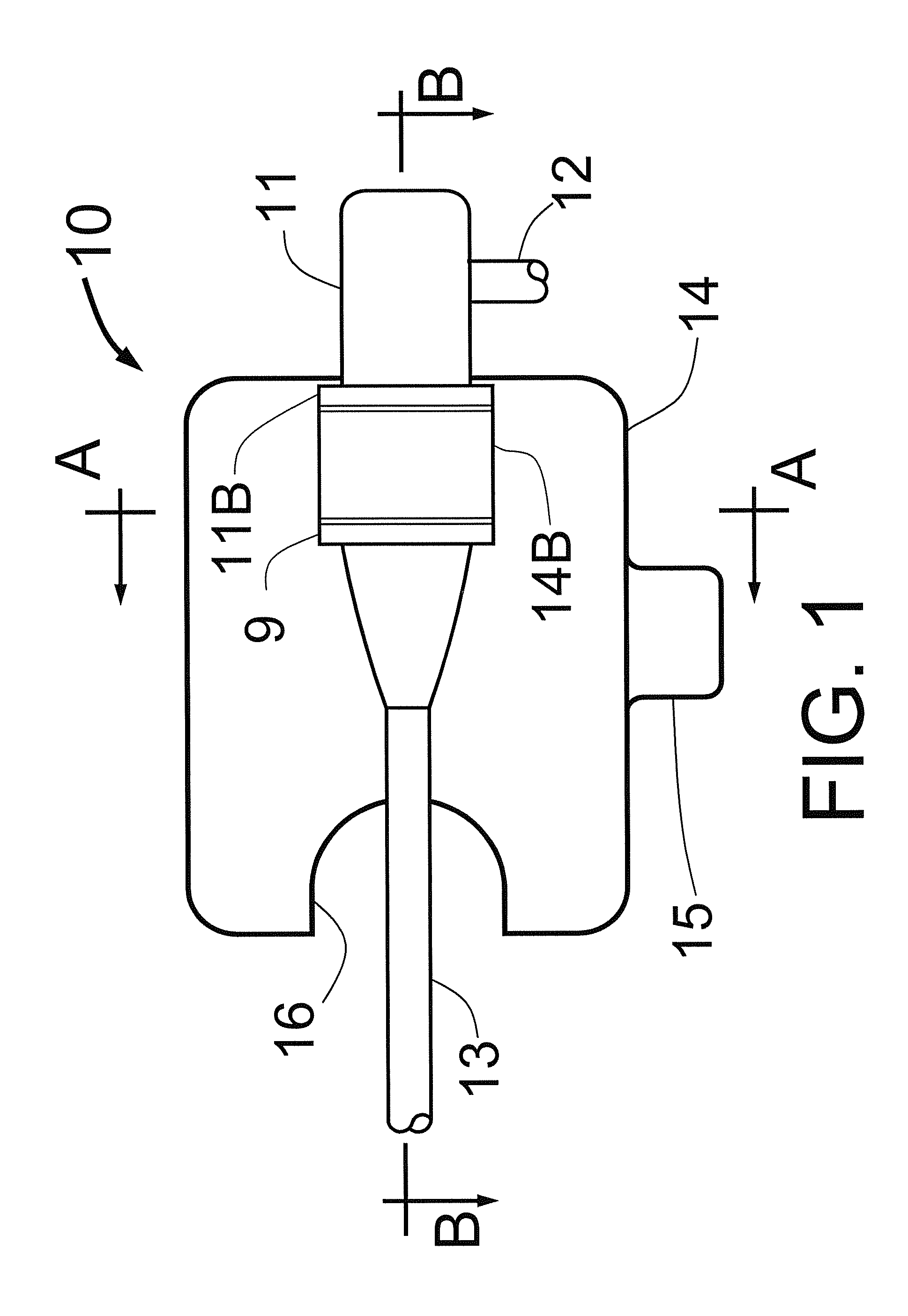

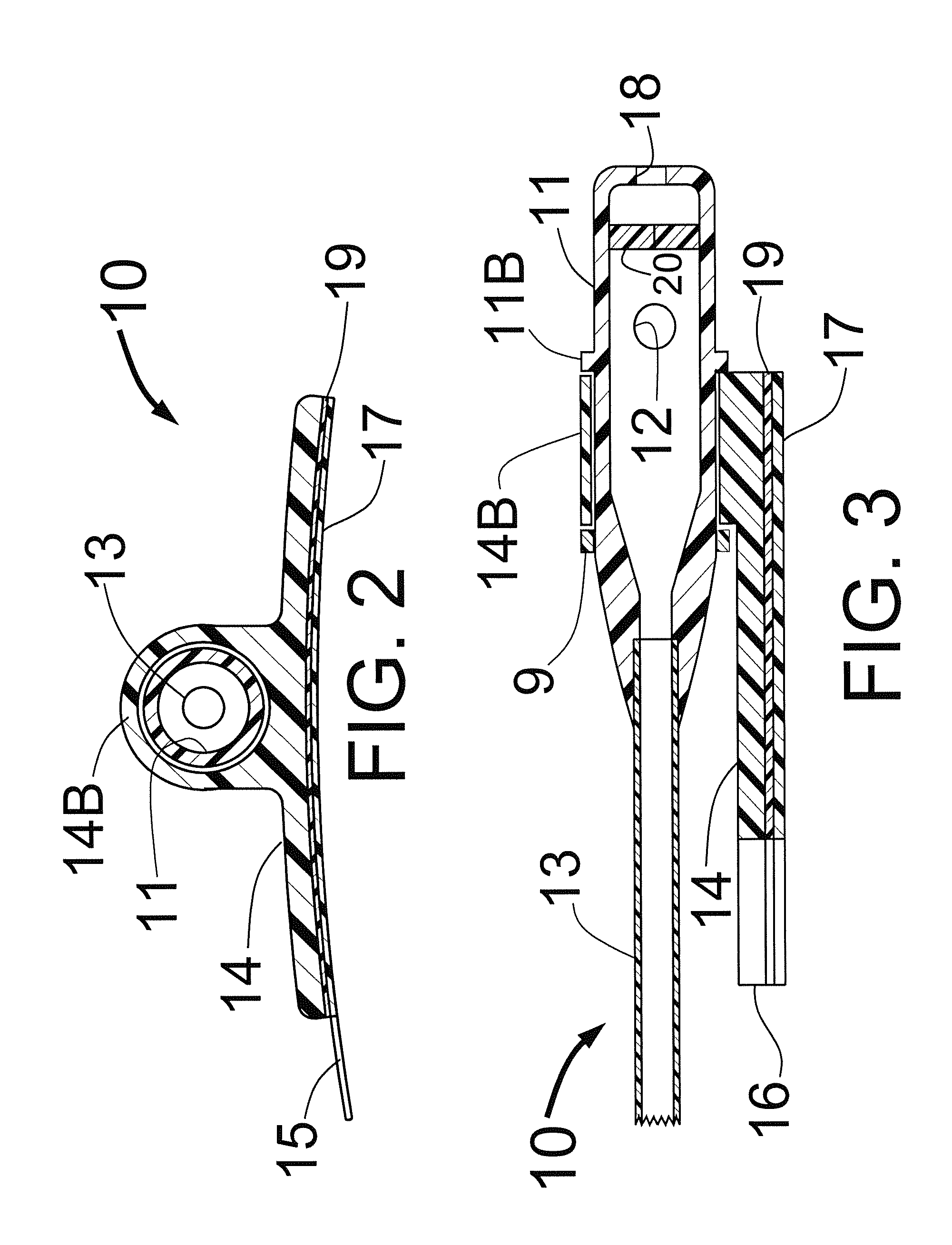

Introducer sheath having a hemostasis valve with an adhesive means for attachment to the skin

ActiveUS8262625B1Quick connectionFirmly attachedInfusion syringesCatheterHemostasis valveBlood vessel

An introducer sheath for placement of a tubular shaft into the vascular system of a human subject. The introducer sheath has a tubular shaft, a side arm, and a hemostasis valve placed at a proximal portion of the introducer sheath. The hemostasis valve has an adhesive pad formed integral with the shell of the hemostasis valve. The adhesive pad is designed to attach and detach a proximal section of the introducer sheath to and from the skin of the human subject.

Owner:FISCHELL INNOVATIONS

Introducer sheath with adhesive attachment means and a rotating side tube

The present invention is an introducer sheath that is improved by having an adhesive pad located near the sheath's proximal end that detachably attaches the introducer sheath to the patient's skin without requiring any additional parts that come from a separate sterile package such as a needle and a suture or a separate adhesive pad. The present invention also teaches a means to rotatingly connect the adhesive pad to the sheath's hemostasis valve so that the proximal portion of the hemostasis valve is free to rotate about the adhesive pad even after the adhesive pad is firmly attached to the patient's skin. This design allows the operator to position the side tube that is connected to the hemostasis valve at an optimum location relative to the patient's skin.

Owner:FISCHELL INNOVATIONS

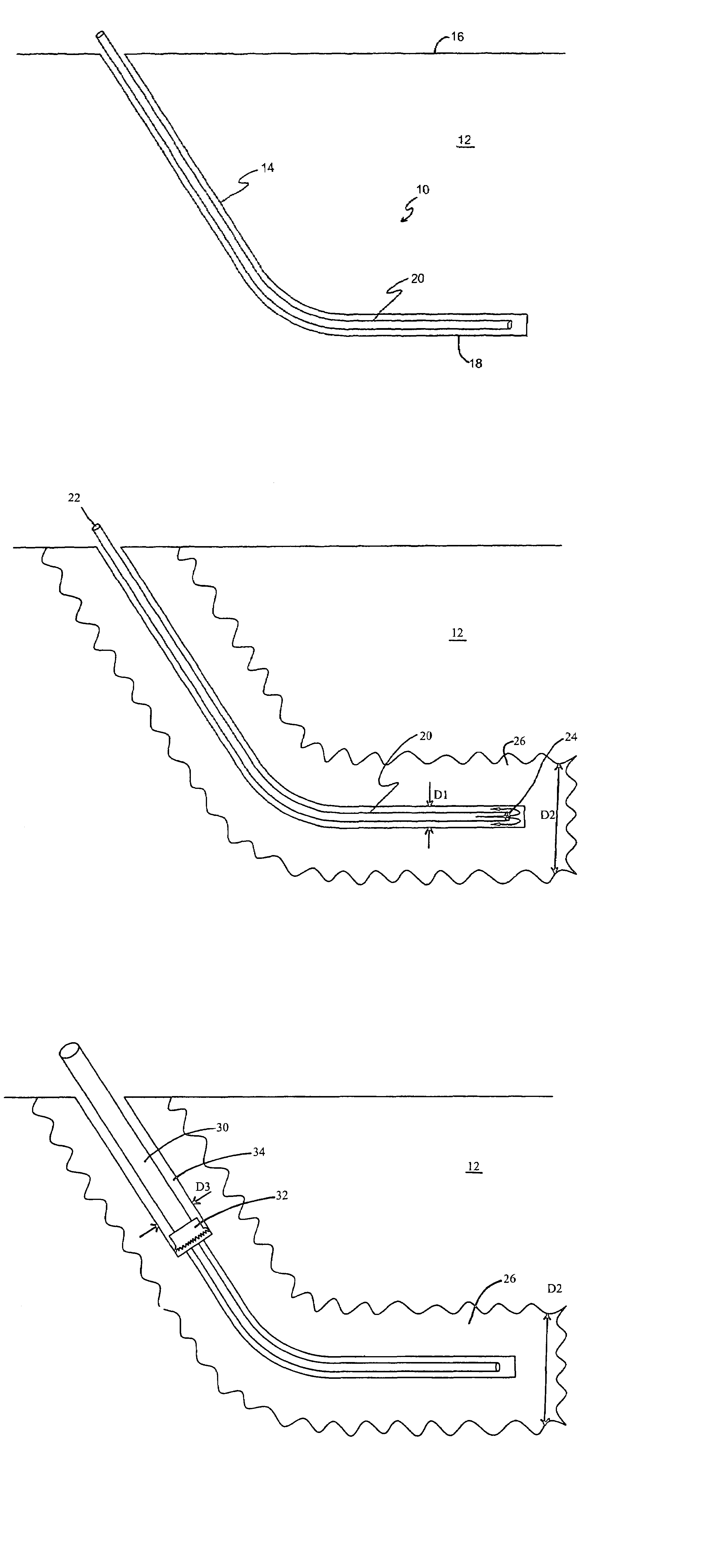

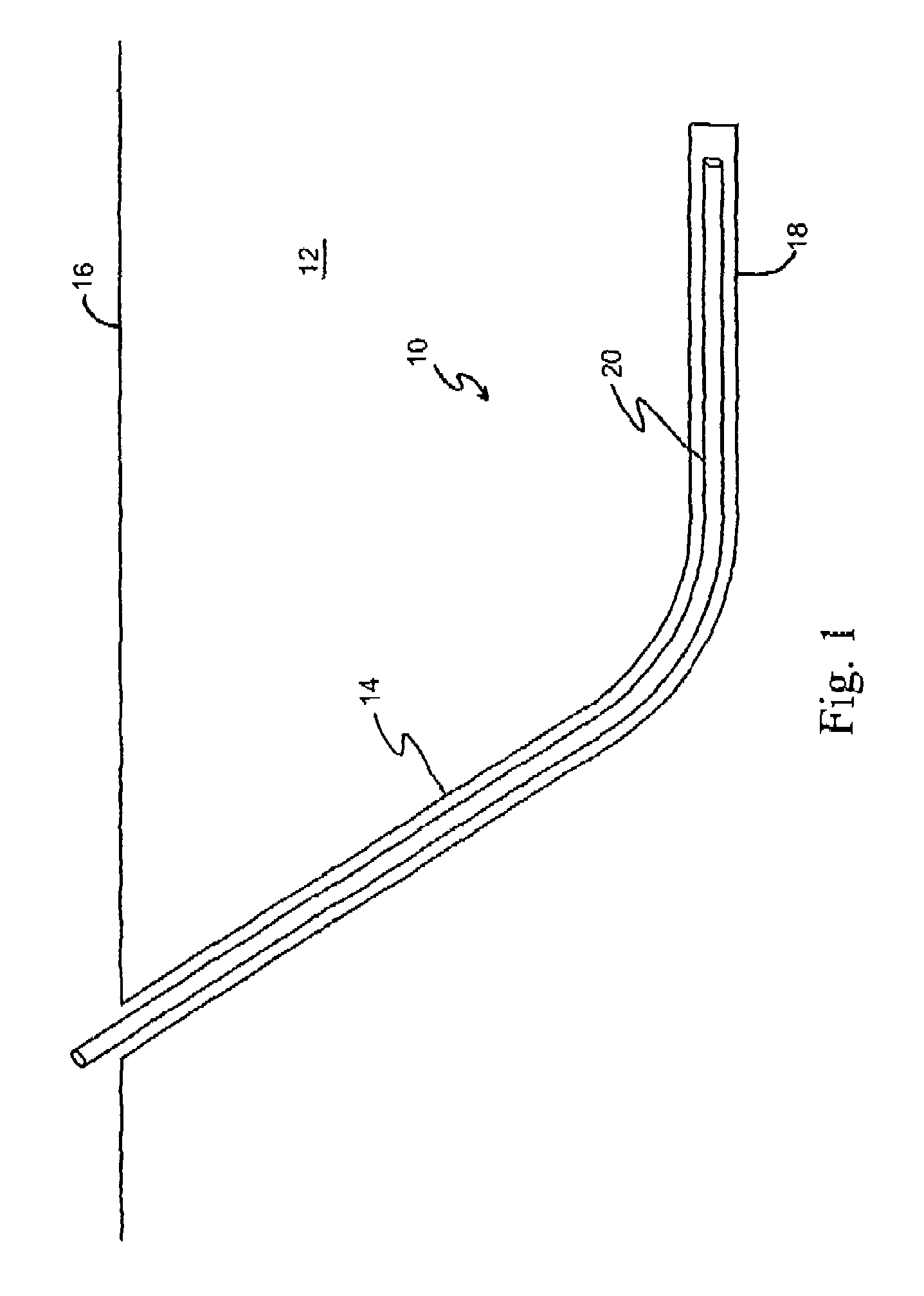

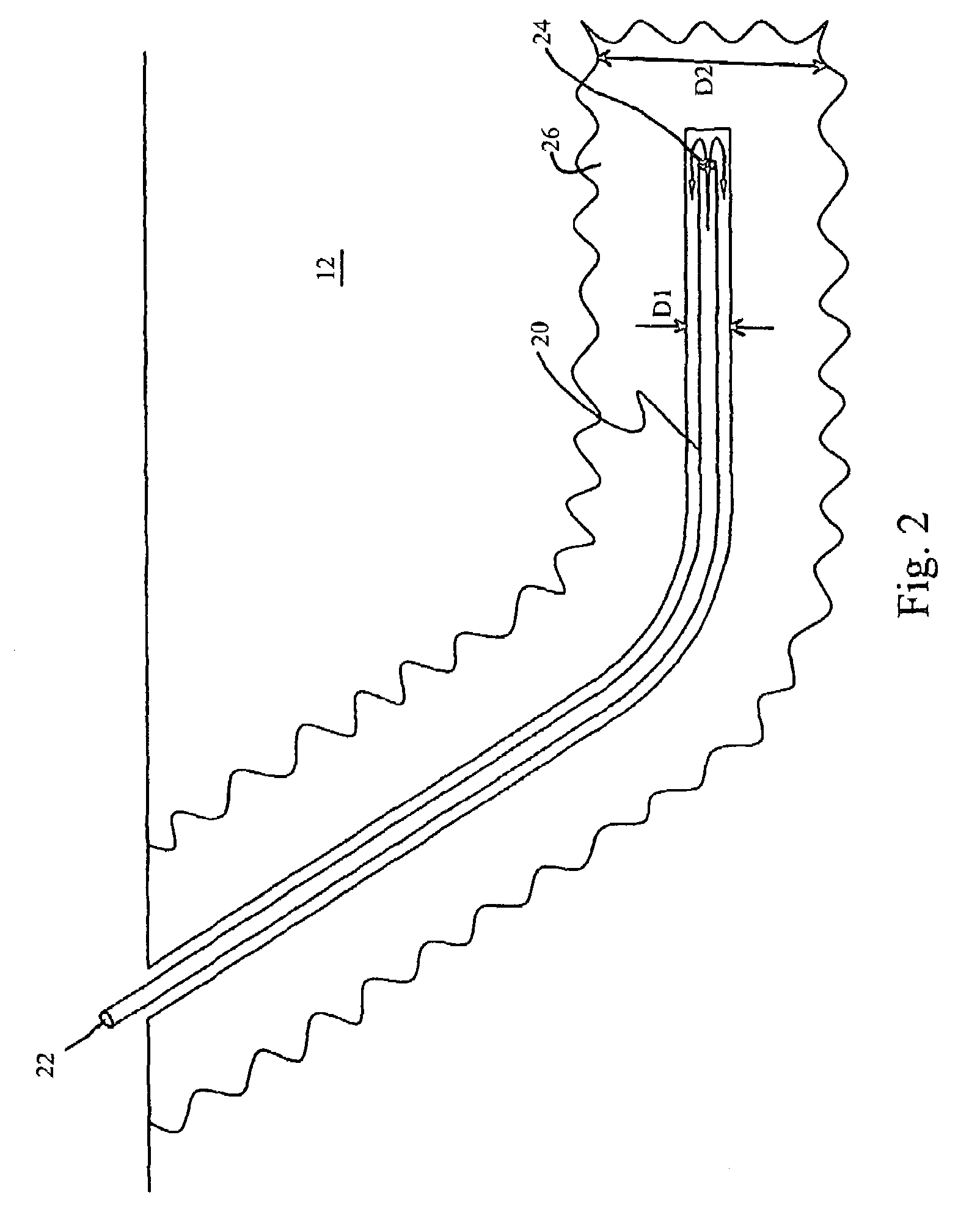

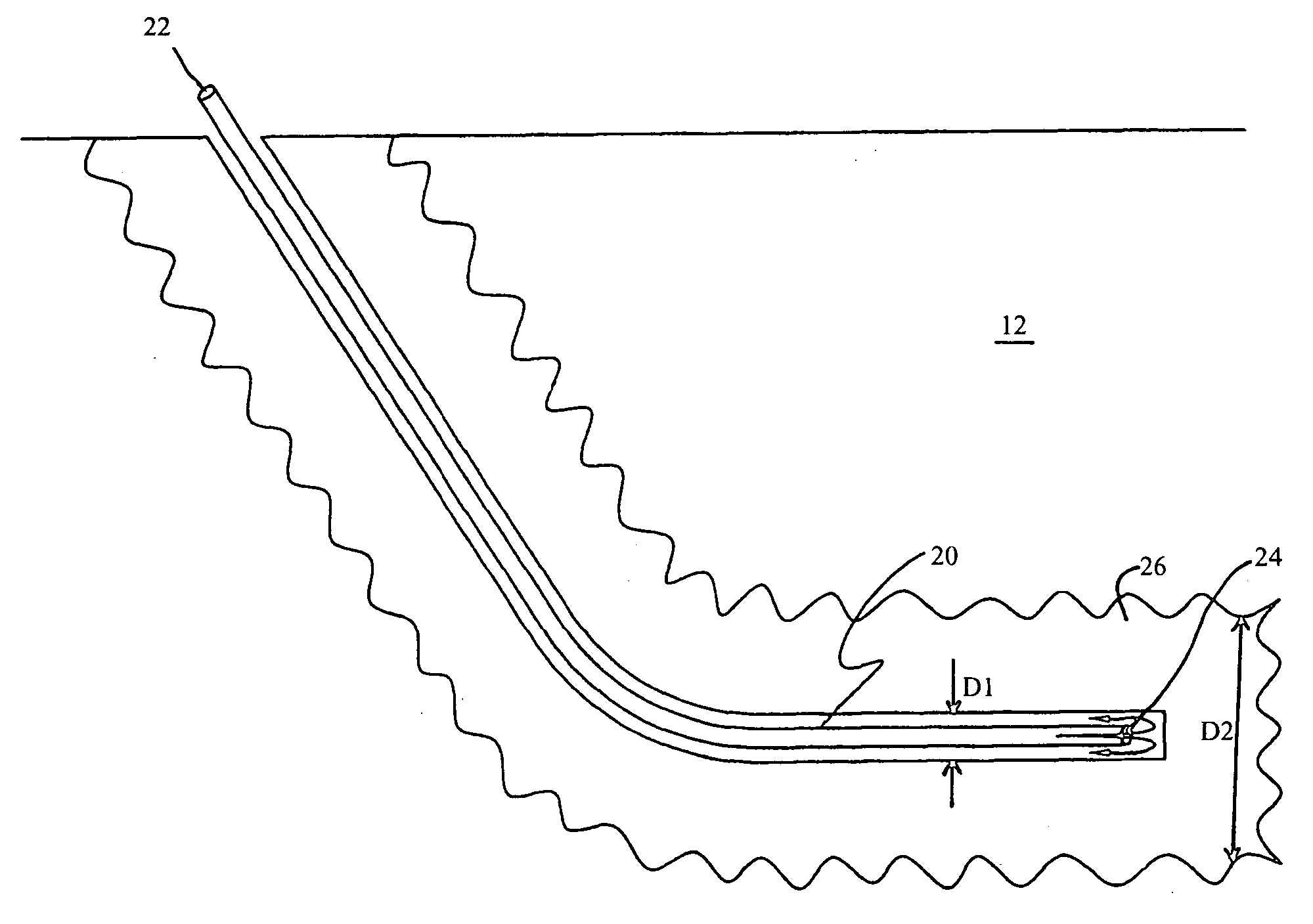

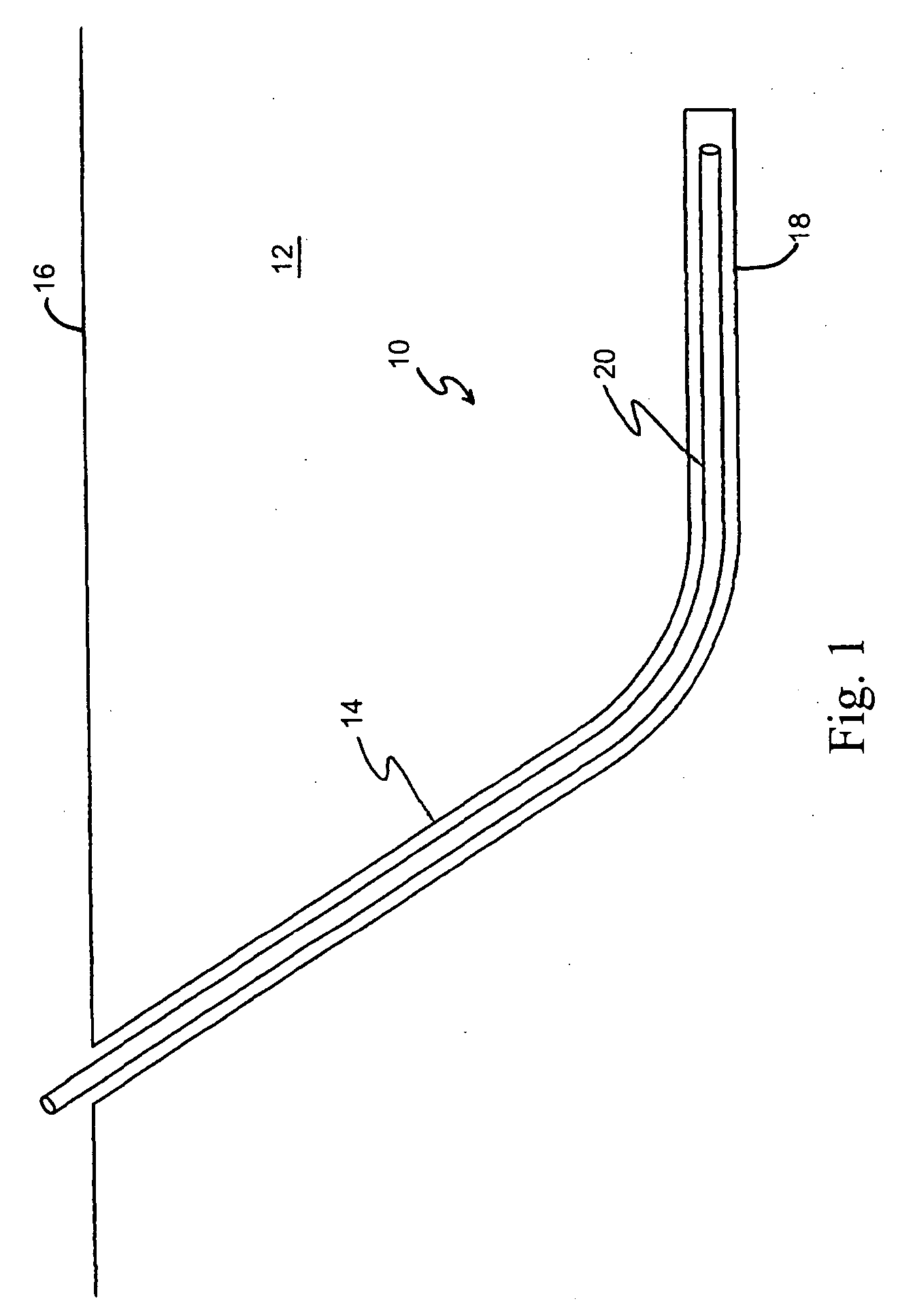

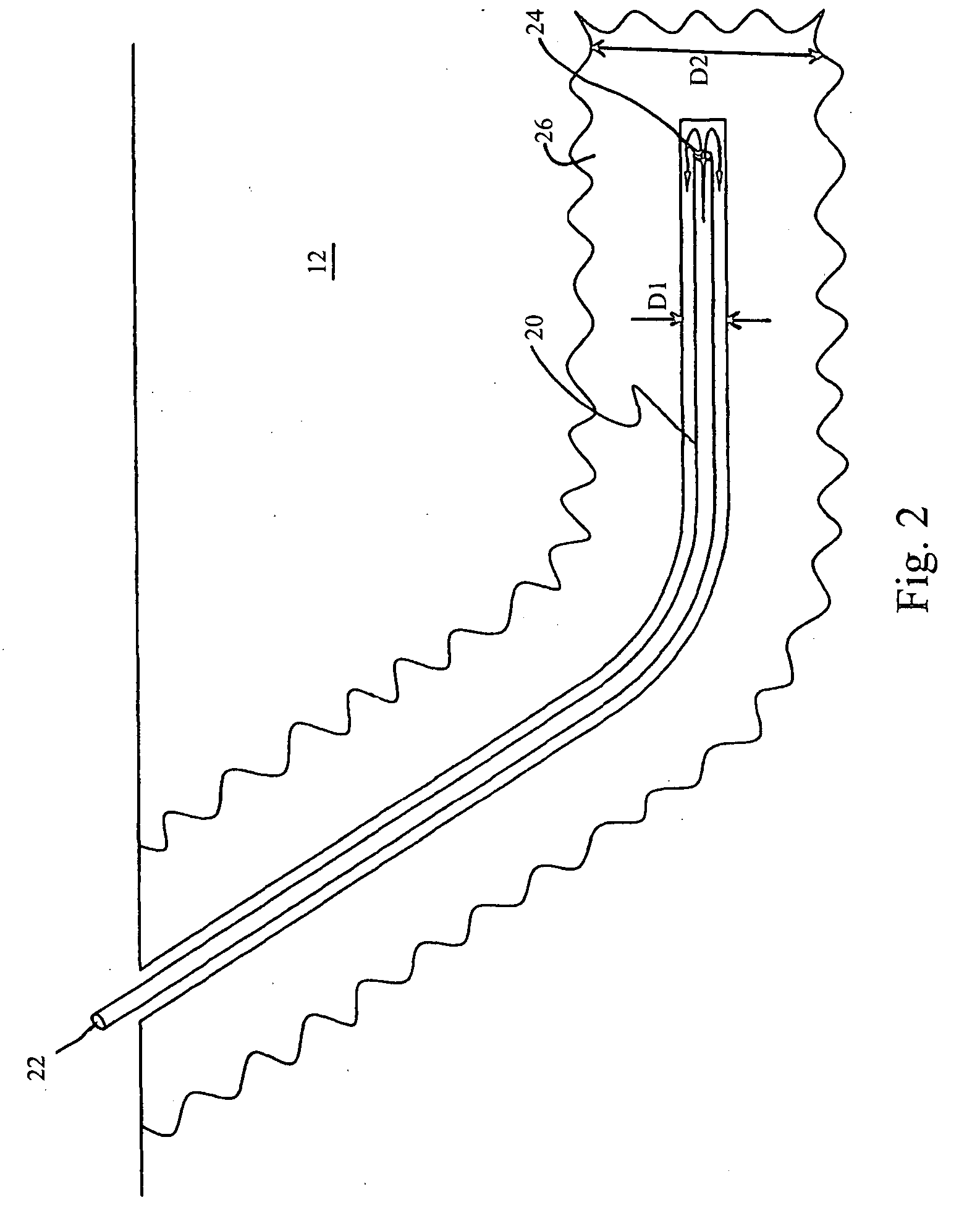

Horizontal bore cryogenic drilling method

ActiveUS7000711B2Prevent crashSufficient structural integrityArtificial islandsLighting and heating apparatusPilot holeEngineering

A horizontal bore cryogenic drilling method includes in a first embodiment forming a pilot hole of a first select diameter along a desired path of the horizontal bore. A grindable casing is inserted into the guide bore. A cryogenic fluid is flowed through the grindable casing to form a freeze zone of frozen moisture adjacent the grindable casing having a second select diameter. A primary bore is formed having a third select diameter greater than the first diameter and less than the second select diameter within the freeze zone along the desired path of the horizontal bore with the grindable casing in place. The second diameter is selected to be sufficiently greater than the third select diameter to prevent collapse of the freeze zone. Another embodiment of the invention is a method of forming a horizontal bore in an earth formation including providing a drill string having a conduit communicating with a cutting tool for engaging the earth formation. A cryogenic fluid is flowed through the conduit and the cutting tool to drive the cutting tool and remove cuttings from a bore formed by the cutting tool. The cutting tool is directed into an earth formation and a freeze zone is formed in the earth formation in advance of the cutting tool by the cryogenic fluid flowing through the cutting tool. The cutting tool is then advanced into the earth formation to form the horizontal bore at a rate enabling continuous formation of a freeze zone in advance of the cutting tool of sufficient diameter to prevent collapse of the bore as the cutting tool is advanced.

Owner:CH2M HILL +1

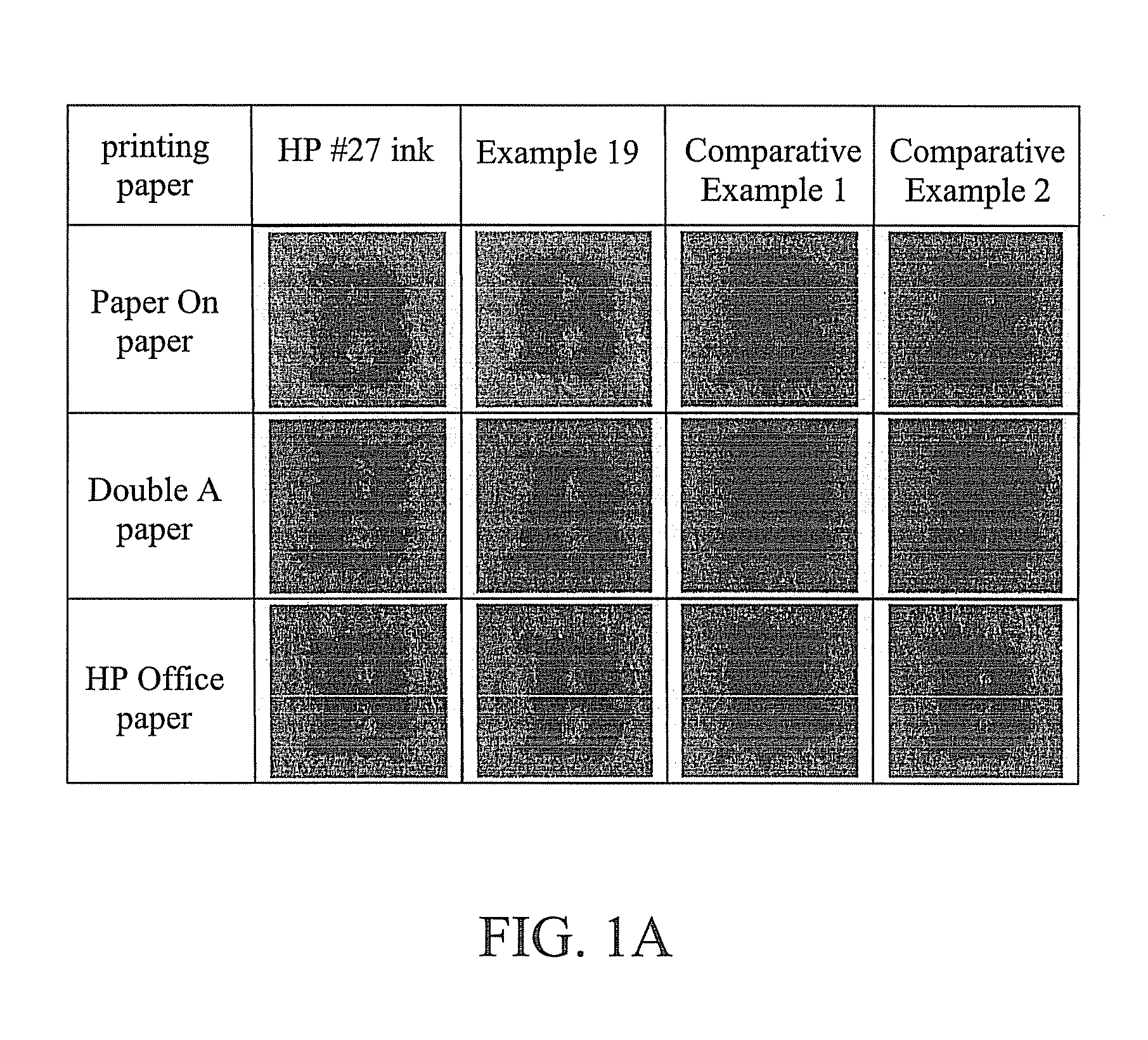

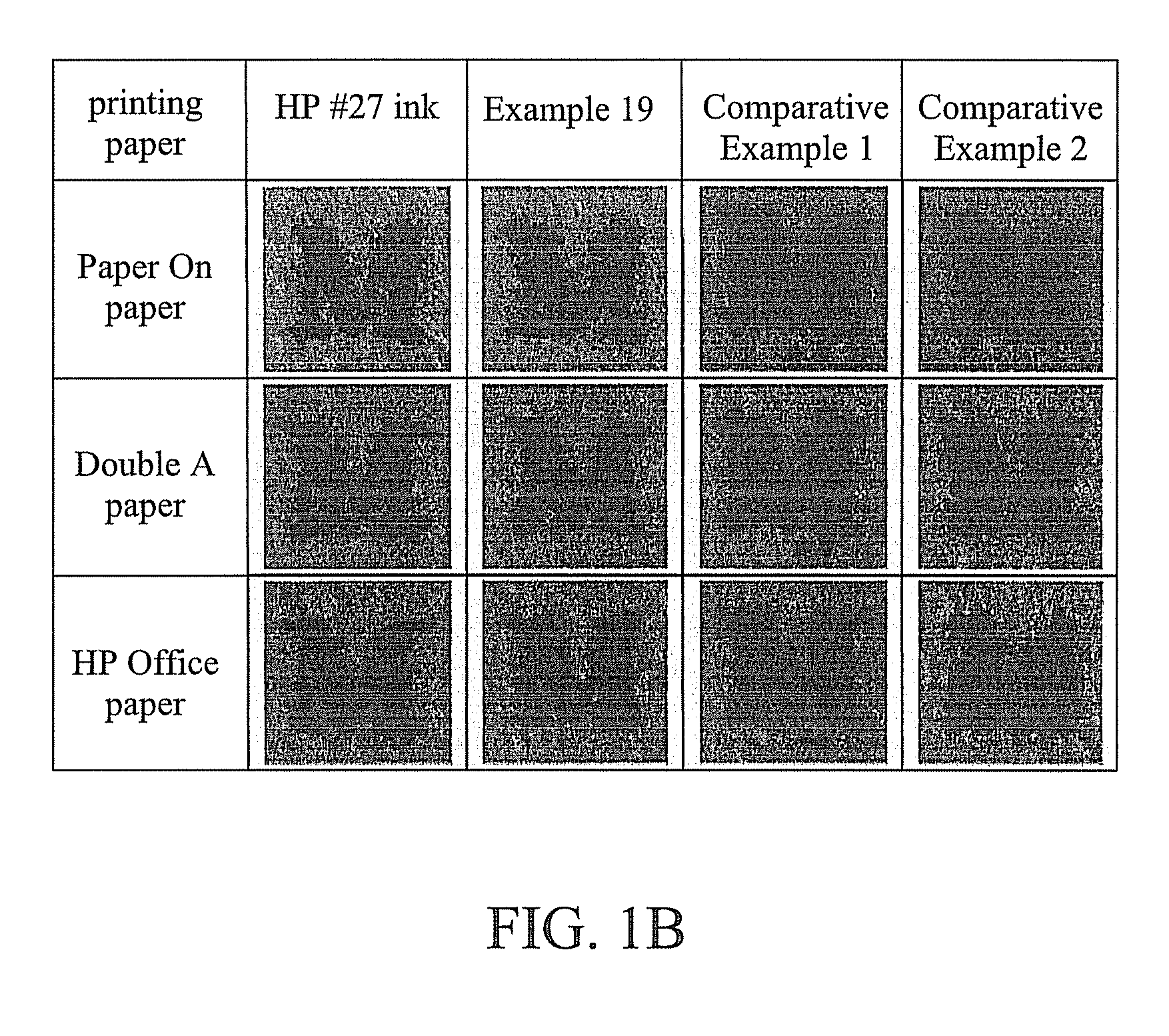

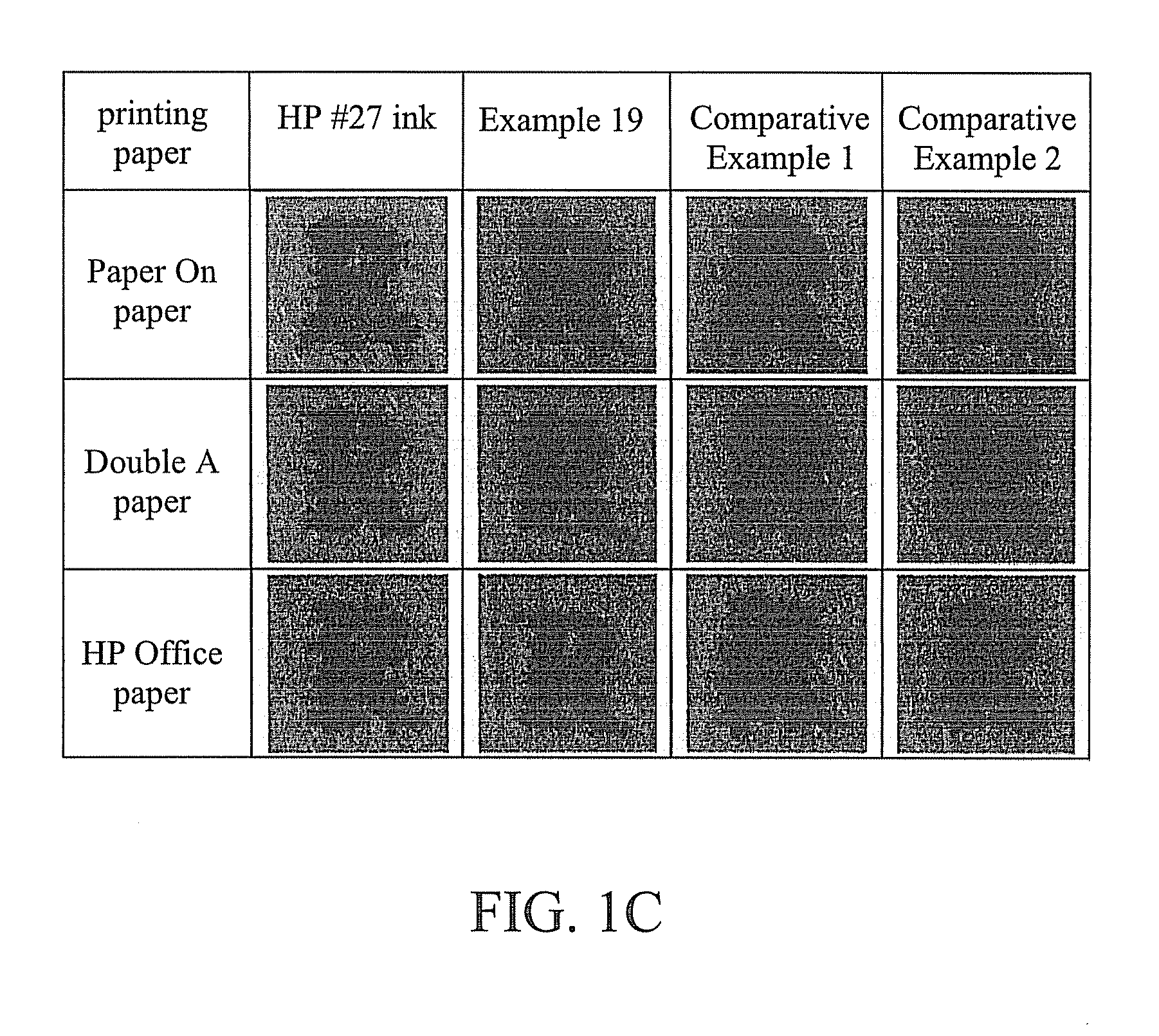

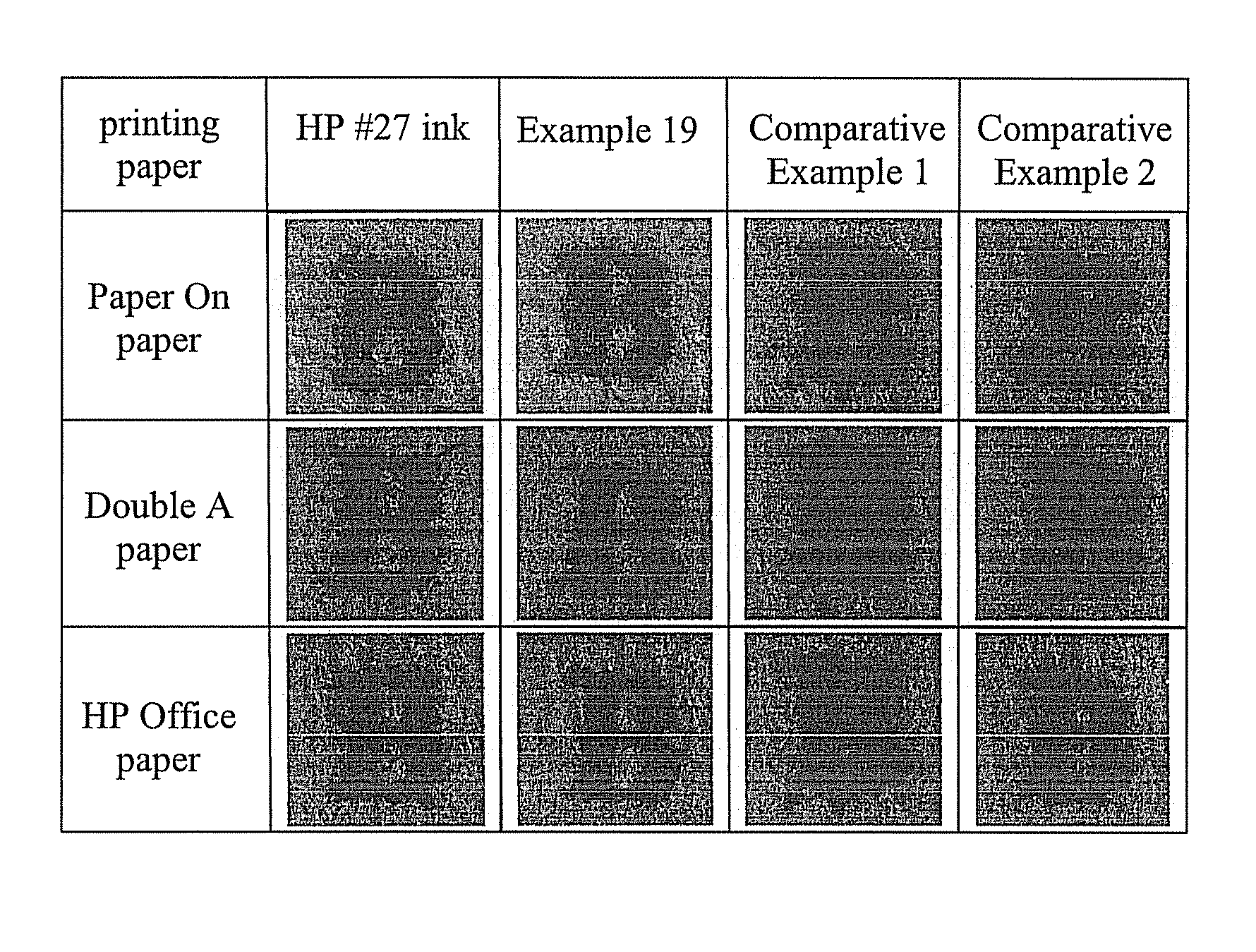

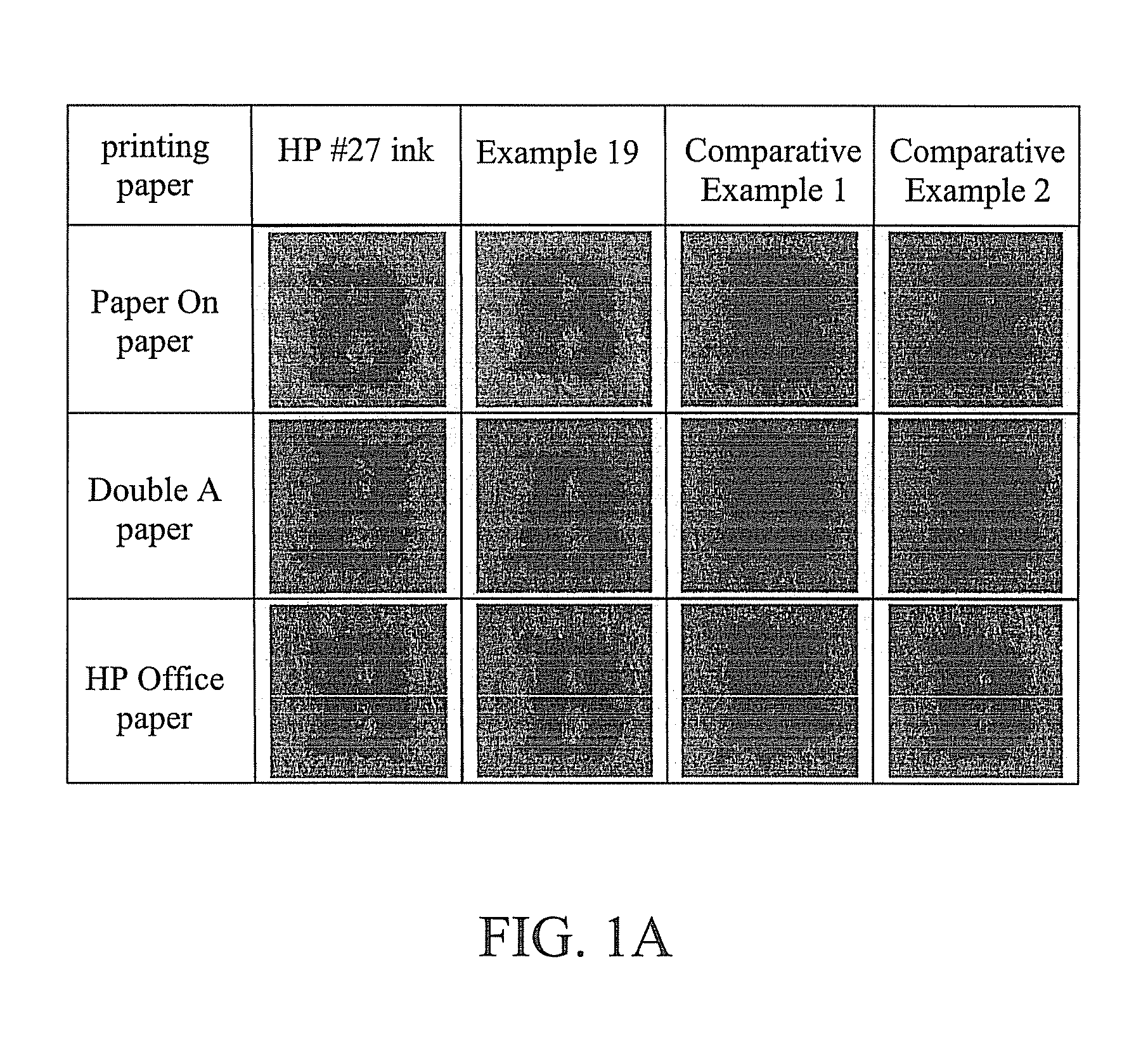

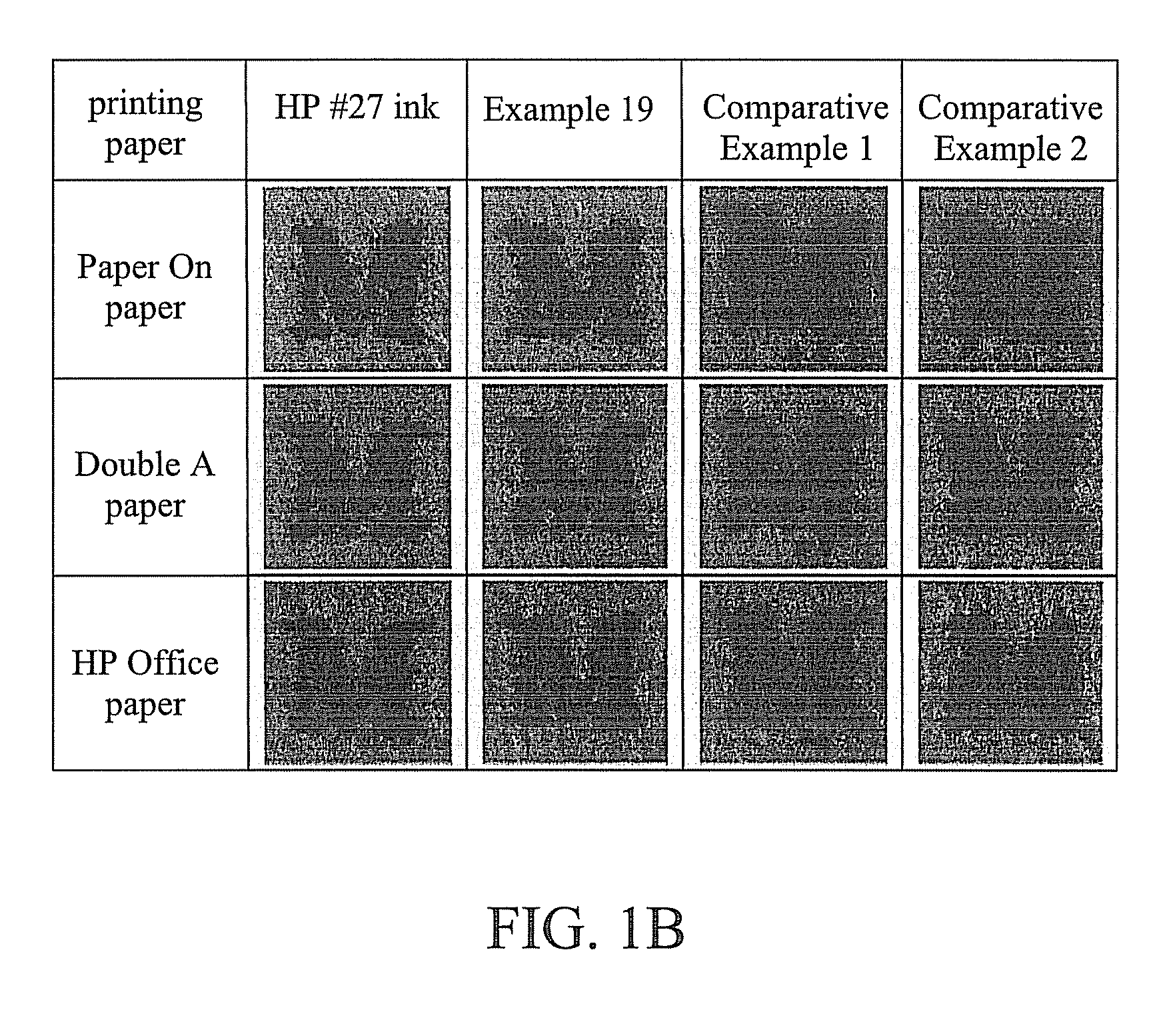

Black ink composition

InactiveUS20110297040A1Increase surface tensionEliminate over penetrationInksPrintingGlycol ethersSolvent

A black ink composition is provided. The black ink composition includes a dispersive black colorant; less than 1 wt % of a glycol ether compound based on total weight of the black ink composition; a solvent; and water. The black ink composition of the present invention is free of surfactants and has excellent compatibility with a nozzle, and thus provides good smoothness in printing and high-quality image.

Owner:EVERLIGHT USA INC

Horizontal bore cryogenic drilling method

ActiveUS20050173156A1Prevent crashSufficient structural integrityArtificial islandsLighting and heating apparatusPilot holeEngineering

A horizontal bore cryogenic drilling method includes in a first embodiment forming a pilot hole of a first select diameter along a desired path of the horizontal bore. A grindable casing is inserted into the guide bore. A cryogenic fluid is flowed through the grindable casing to form a freeze zone of frozen moisture adjacent the grindable casing having a second select diameter. A primary bore is formed having a third select diameter greater than the first diameter and less than the second select diameter within the freeze zone along the desired path of the horizontal bore with the grindable casing in place. The second diameter is selected to be sufficiently greater than the third select diameter to prevent collapse of the freeze zone. Another embodiment of the invention is a method of forming a horizontal bore in an earth formation including providing a drill string having a conduit communicating with a cutting tool for engaging the earth formation. A cryogenic fluid is flowed through the conduit and the cutting tool to drive the cutting tool and remove cuttings from a bore formed by the cutting tool. The cutting tool is directed into an earth formation and a freeze zone is formed in the earth formation in advance of the cutting tool by the cryogenic fluid flowing through the cutting tool. The cutting tool is then advanced into the earth formation to form the horizontal bore at a rate enabling continuous formation of a freeze zone in advance of the cutting tool of sufficient diameter to prevent collapse of the bore as the cutting tool is advanced.

Owner:CH2M HILL +1

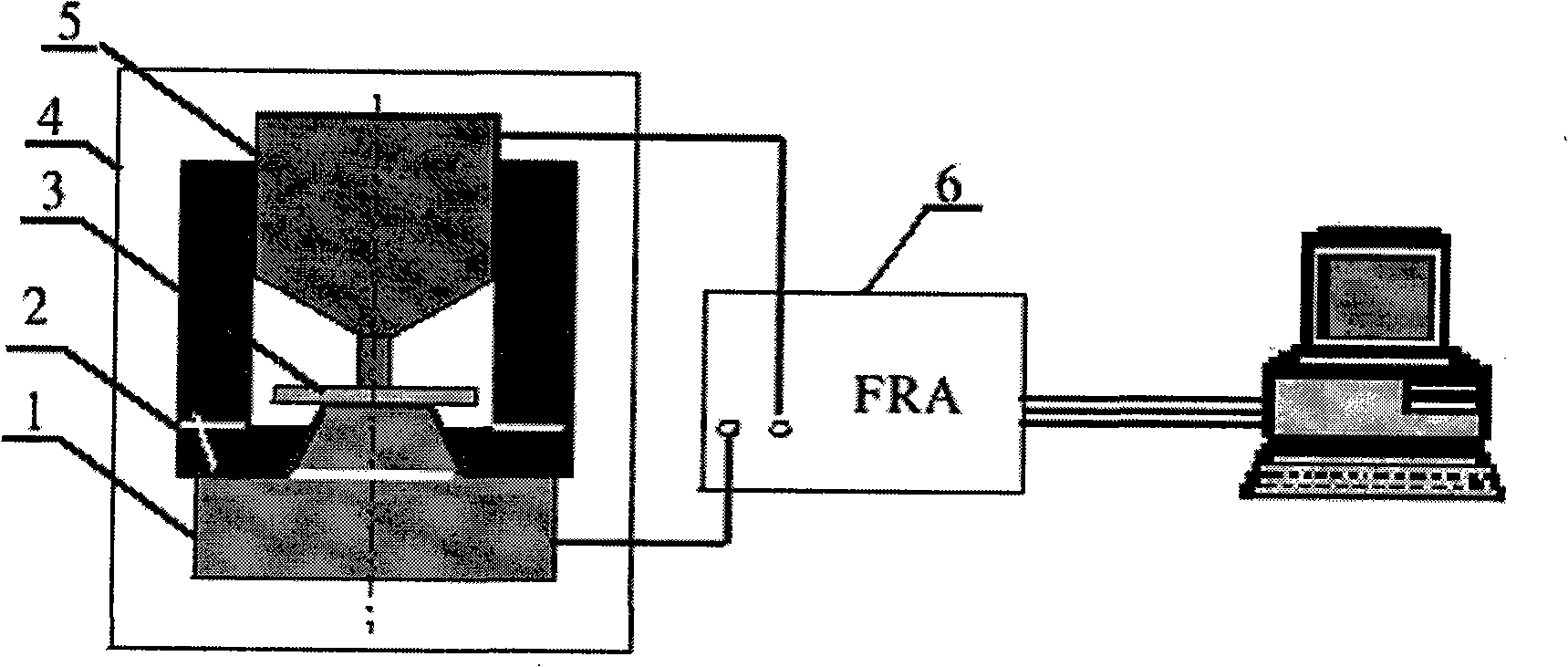

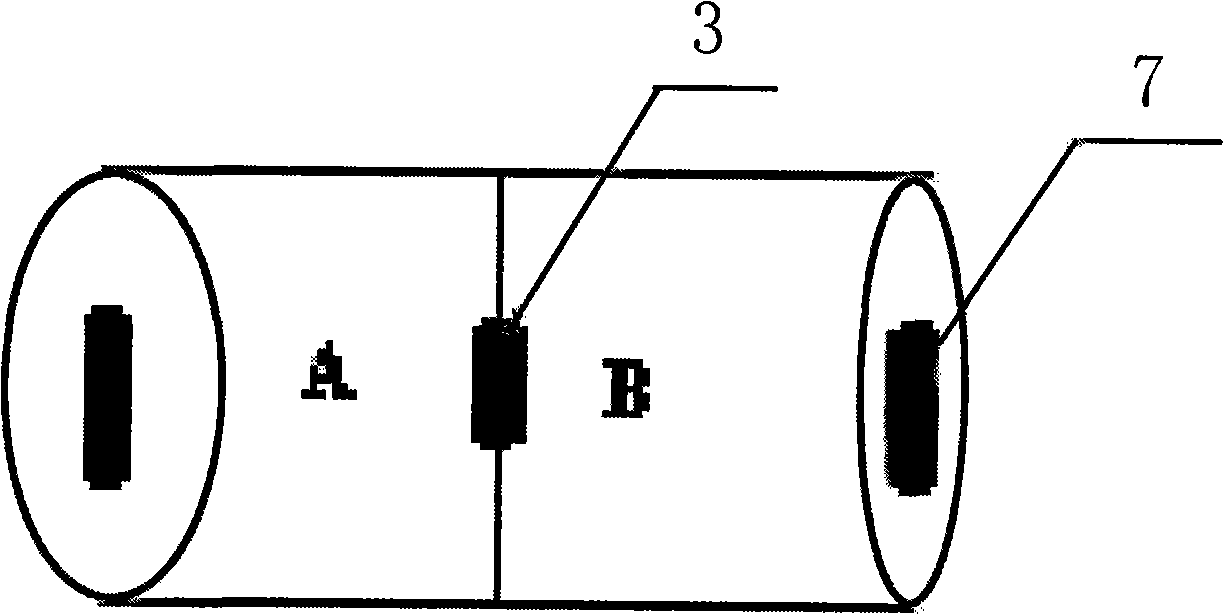

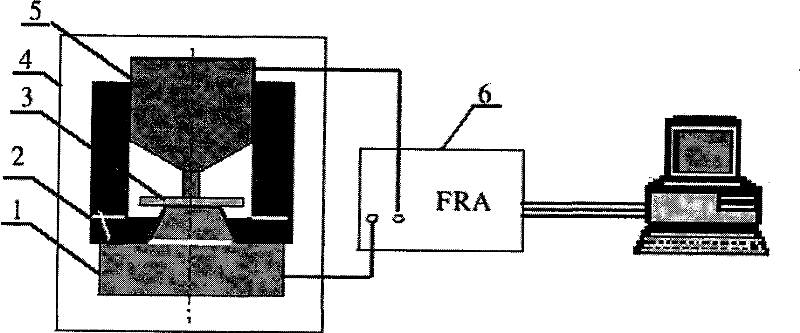

Use of pyridine quaternary ammonium salt type alkaline or alkalescent polymer membranous

InactiveCN101328275AIncrease the rate of oxidation reactionsEliminate penetrationFuel cell detailsPolymer scienceAlcohol fuel

The invention discloses a quaternary pyridine salt type alkaline or weak alkaline polymer membrane, which is used as a membrane material of a direct alcohol fuel cell. The quaternary pyridine salt type alkaline or weak alkaline polymer membrane is produced from polymer materials which are subjected to membrane formation, quaternization reaction and alkalization reaction. The polymer materials are polymer materials produced by pyridine quaternization and a blend prepared from the polymer materials and polyvinylidene fluoride, bisphenol A polyether sulfone, polyether-ether-ketone, polyether sulfone, polyethersulfoneketone, poly(phthalazinone ether ketone), poly(phthalazinone ether sulfone) or poly(phthalazinone ether sulfone ketone) and so on which are blended. A direct methanol fuel cell (AMDMFC) adopting the quaternary pyridine salt type alkaline or weak alkaline polymer membrane works under alkaline or weak alkaline conditions, has the advantages of improving the oxidation reaction rate of methanol, eliminating the methanol permeation caused by electric dragging, widening the selection range of catalysts (including the catalysts of anodes and cathodes) and cell materials, simplifying water management and so on.

Owner:SHANDONG UNIV OF TECH

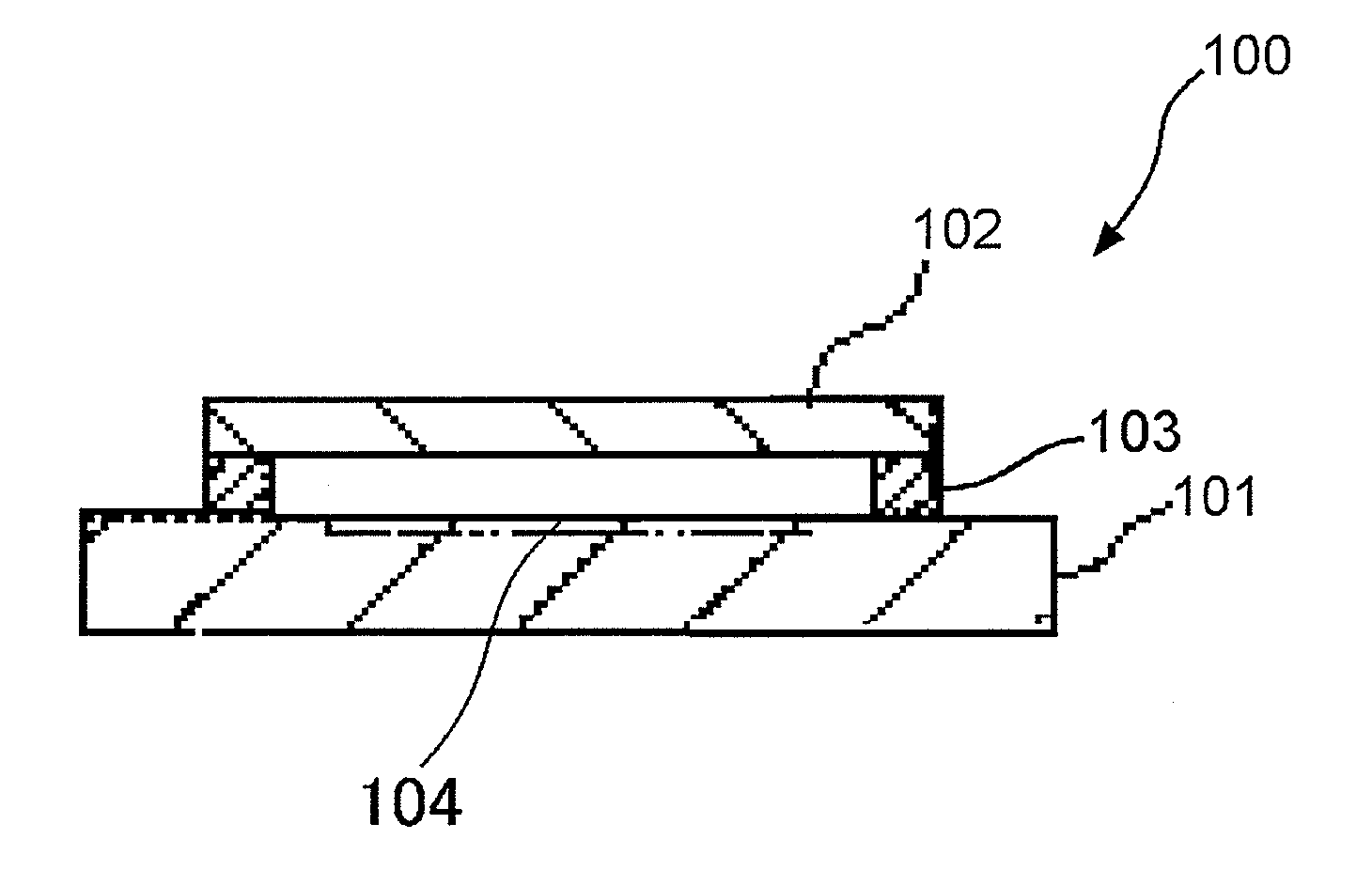

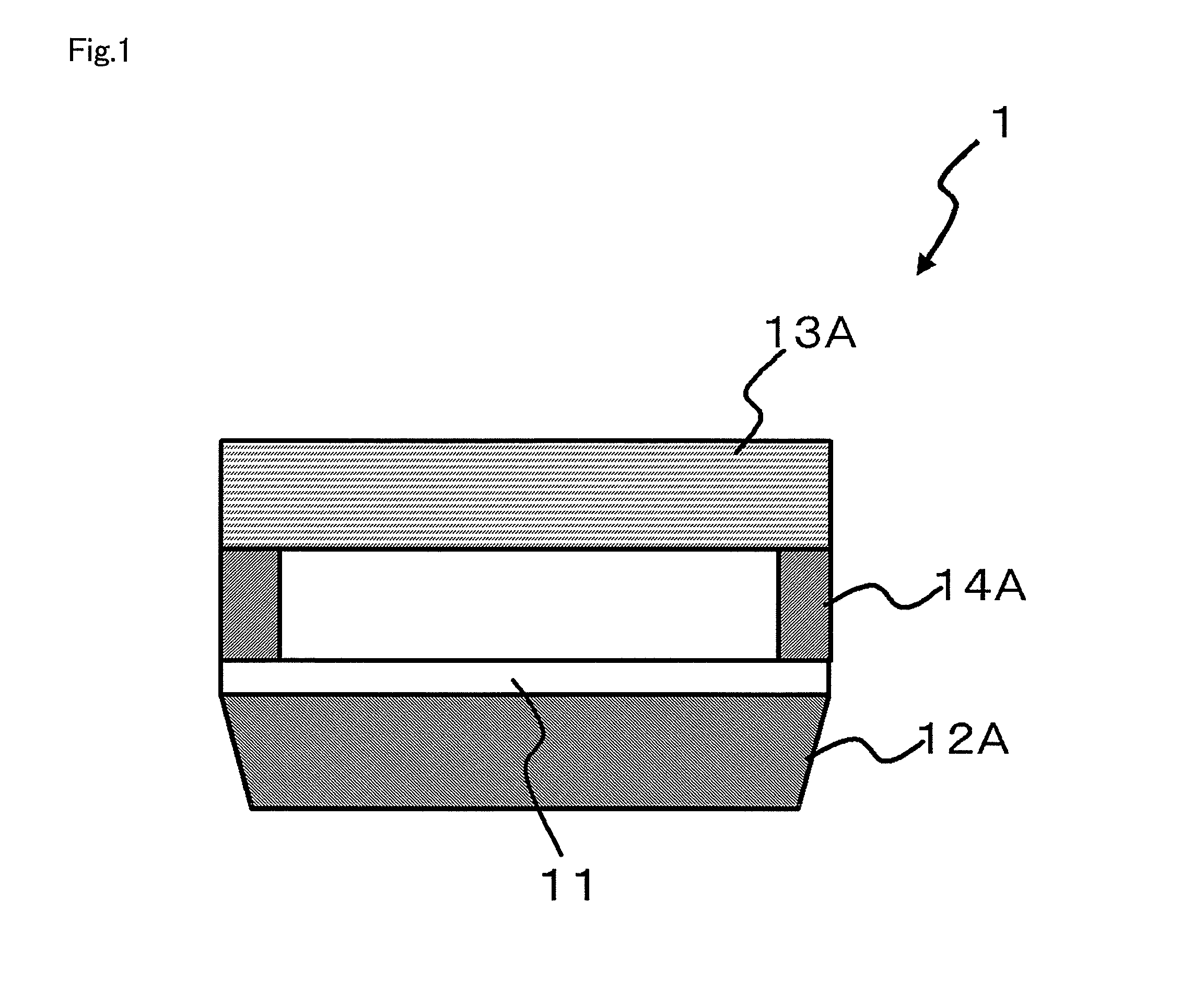

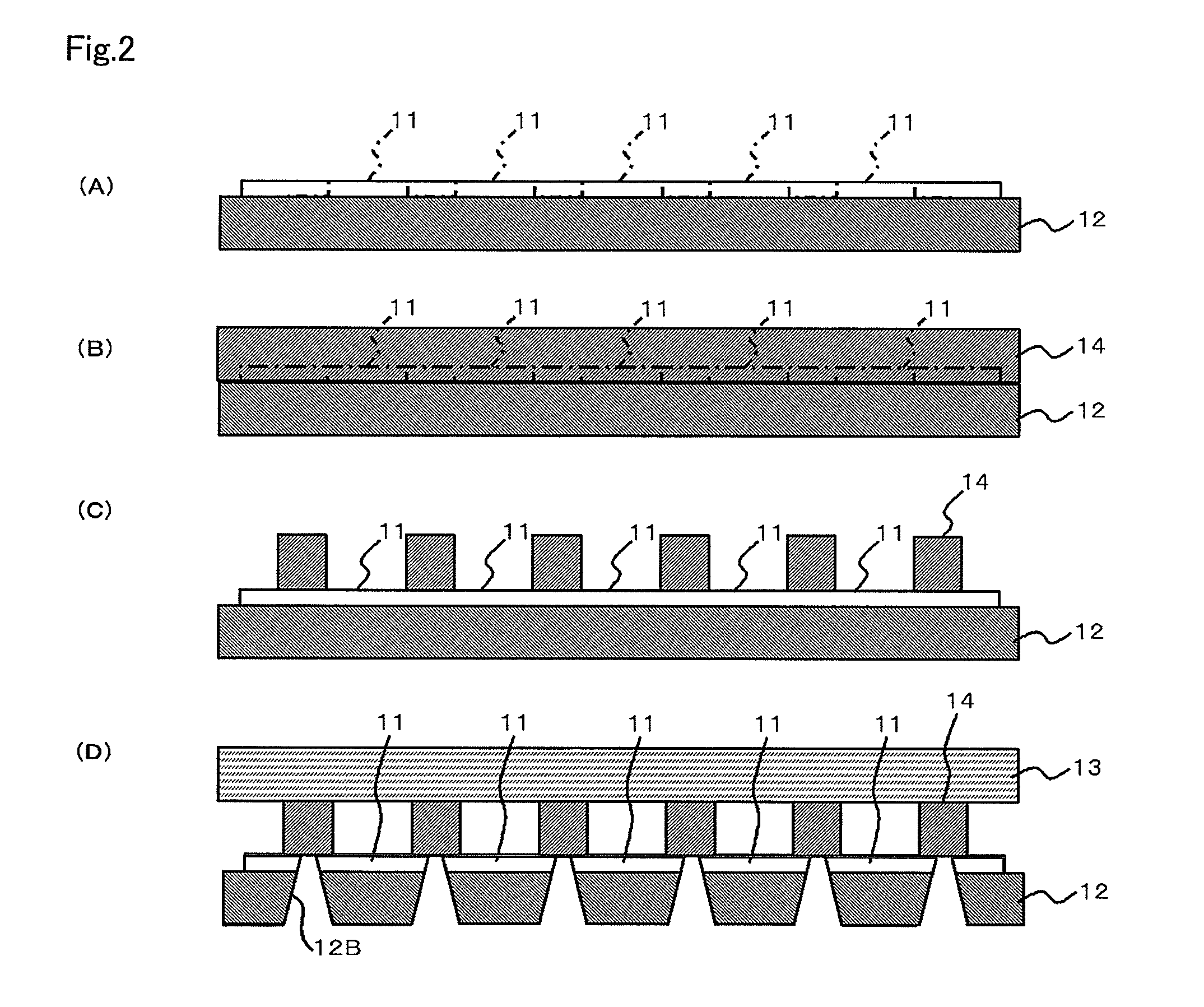

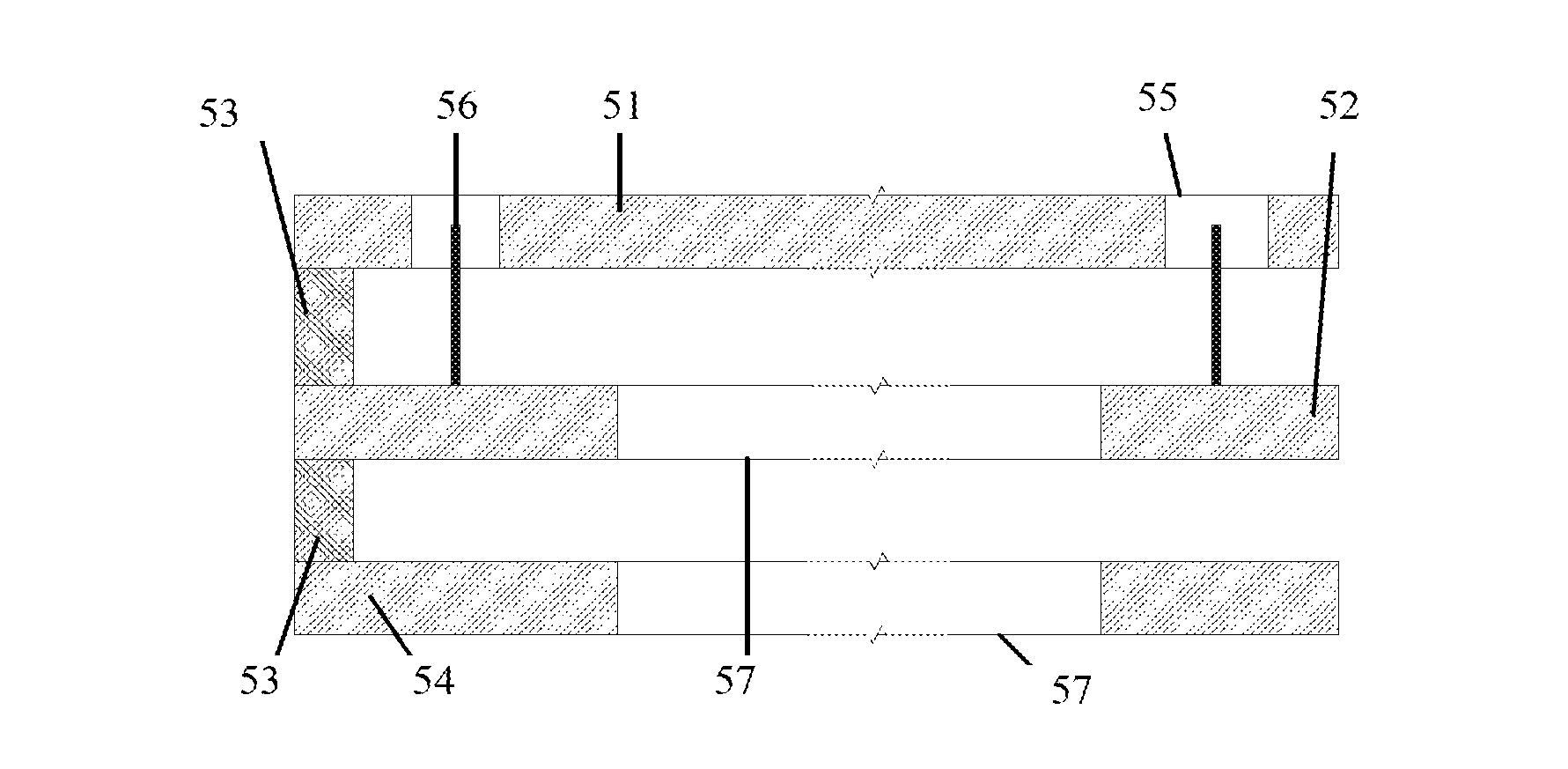

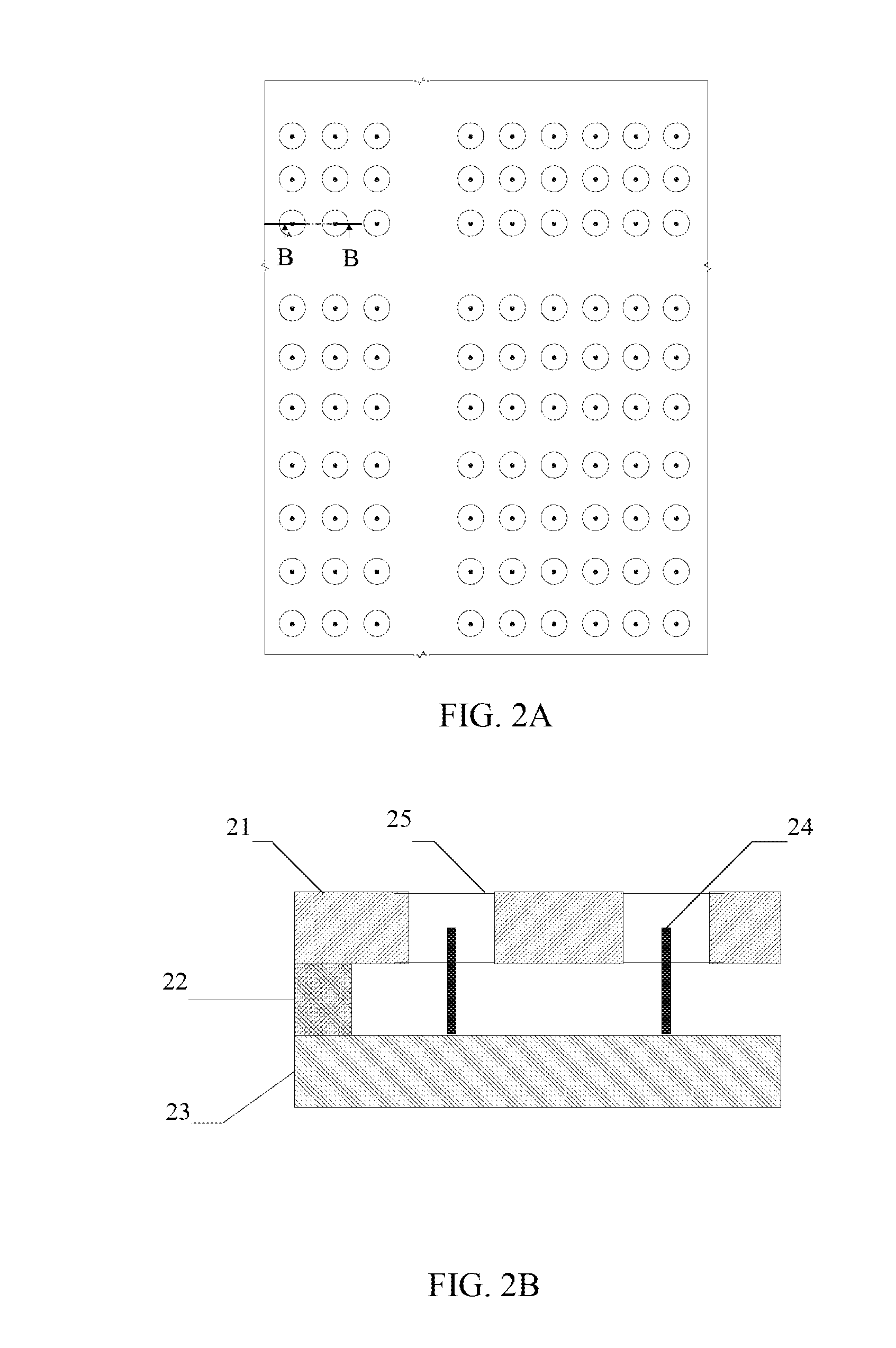

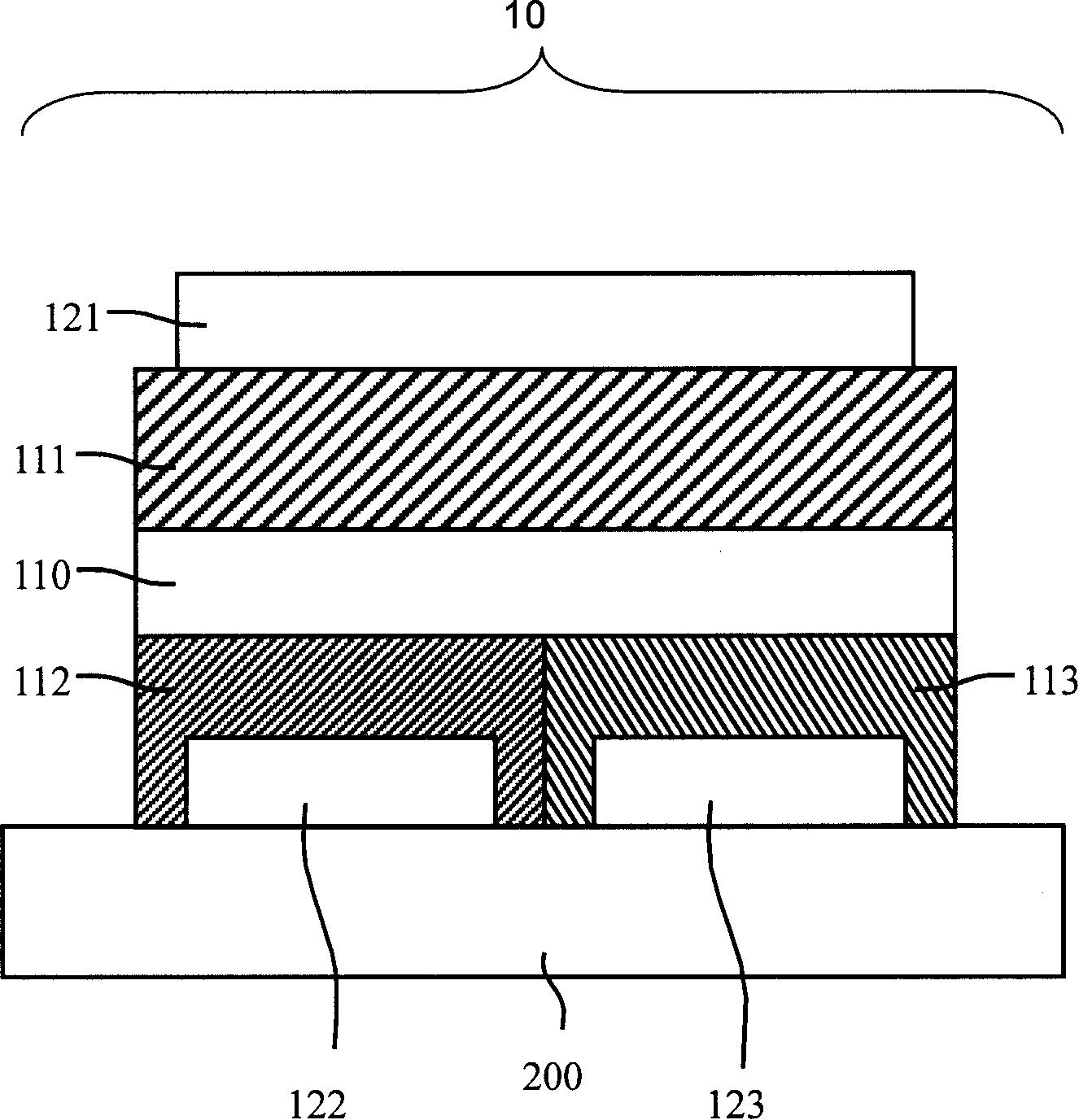

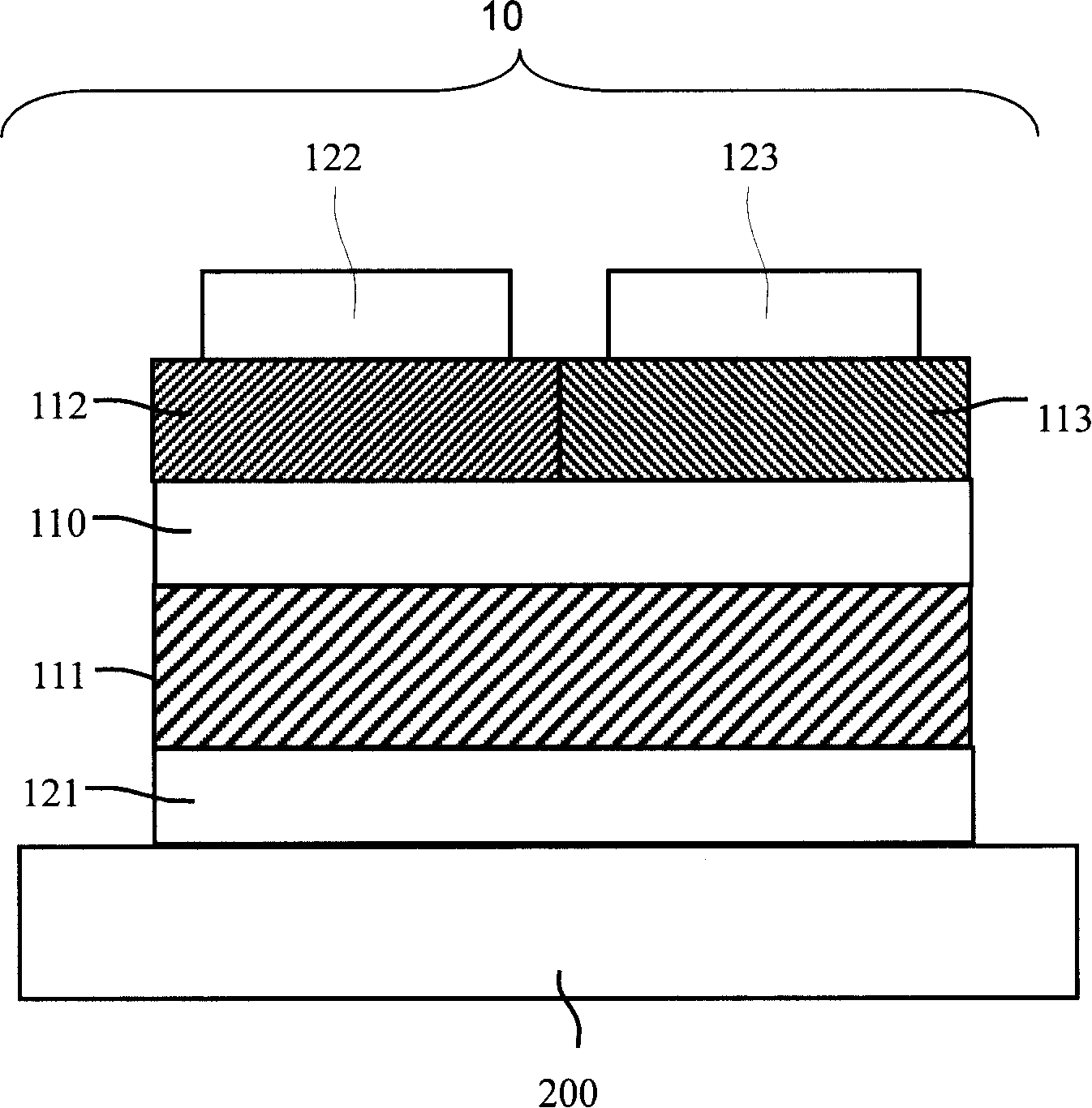

Light-receiving device and method of manufacturing the same

InactiveUS20110101484A1Reduce generationReduce undercuttingSolid-state devicesSemiconductor/solid-state device manufacturingMoisture permeabilityEngineering

There is provided a device including at least one light-receiving unit 11, a base substrate 12A provided with the light-receiving unit 11, a transparent base substrate 13A disposed facing the base substrate 12A and the light-receiving unit 11, and a frame member 14A disposed around the light-receiving unit 11 between the base substrate 12A and the transparent substrate 13A. The frame member 14A consists of a cured resin composition. The resin composition contains an alkali-soluble resin, a photopolymerizable resin and an inorganic filler in 9% or less by weight. The photopolymerizable resin contains an acrylic polyfunctional monomer. The frame member 14A has a moisture permeability of 12 [g / m2·24 h] or more and an elastic modulus of 100 Pa or more at 80 degrees C.

Owner:SUMITOMO BAKELITE CO LTD

Low-viscosity, silicone-modified penetrating asphalt sealer to eliminate water associated problems in asphalt pavements

InactiveUS7179017B2Eliminate penetrationEliminating the transmission of water through the asphalt pavementIn situ pavingsPaving detailsUltravioletEngineering

Owner:RASHED RADI AL

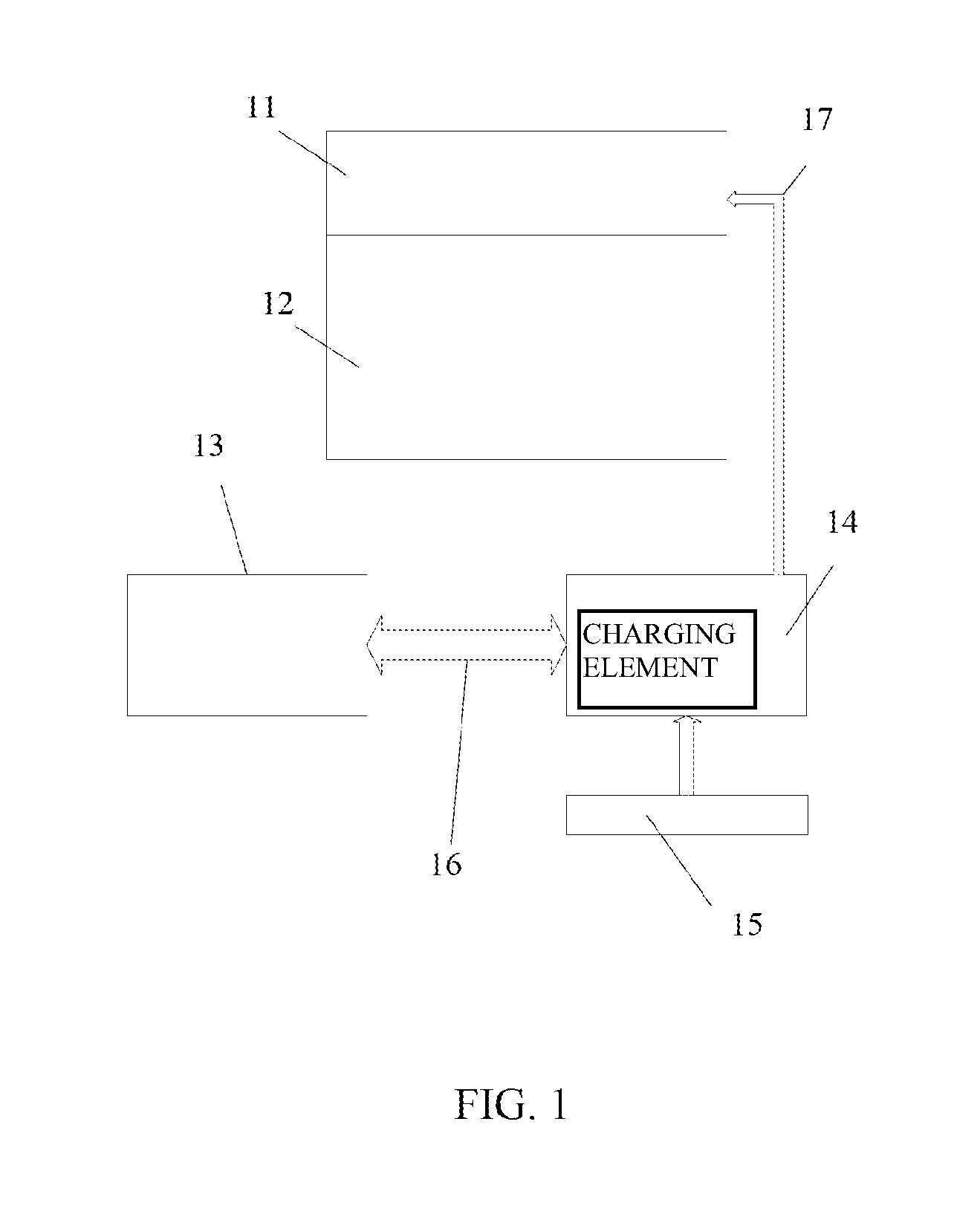

Electronically-controlled device for release of drugs, proteins, and other organic or inorganic chemicals

InactiveUS7981106B2Eliminate systemic side-effectsEliminate penetrationMaterial nanotechnologyElectrotherapyDrug reservoirInorganic Chemical

A device for drug release including a drug reservoir including a gate, wherein opening of the gate releases a drug stored in the drug reservoir, an electronic command and control (C & C) unit in communication with the gate that produces a gate bias voltage and time profile supplied to the gate for controlling opening of the gate, and a power source for supplying power to the electronic command and control unit.

Owner:GILAD PINCHAS

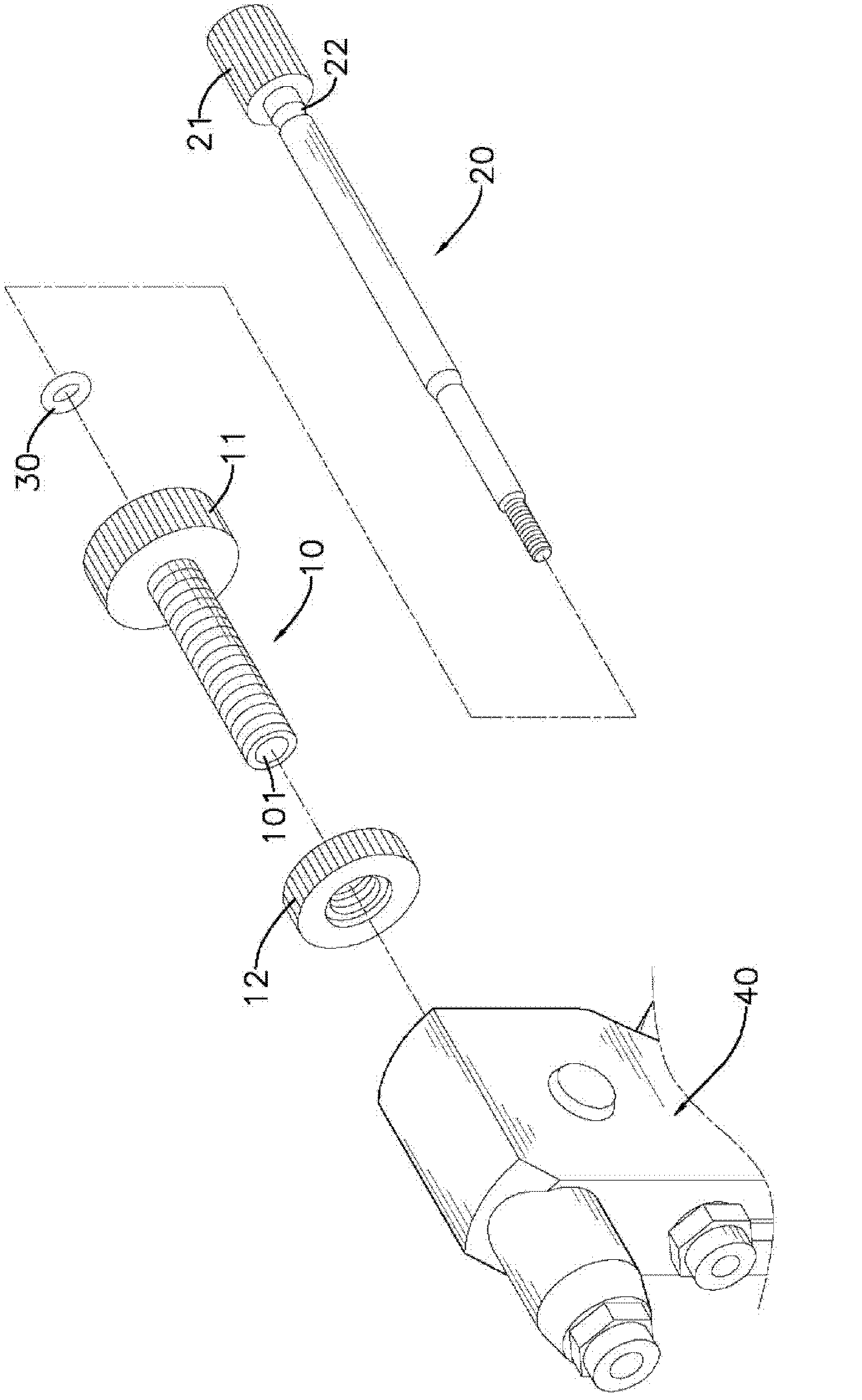

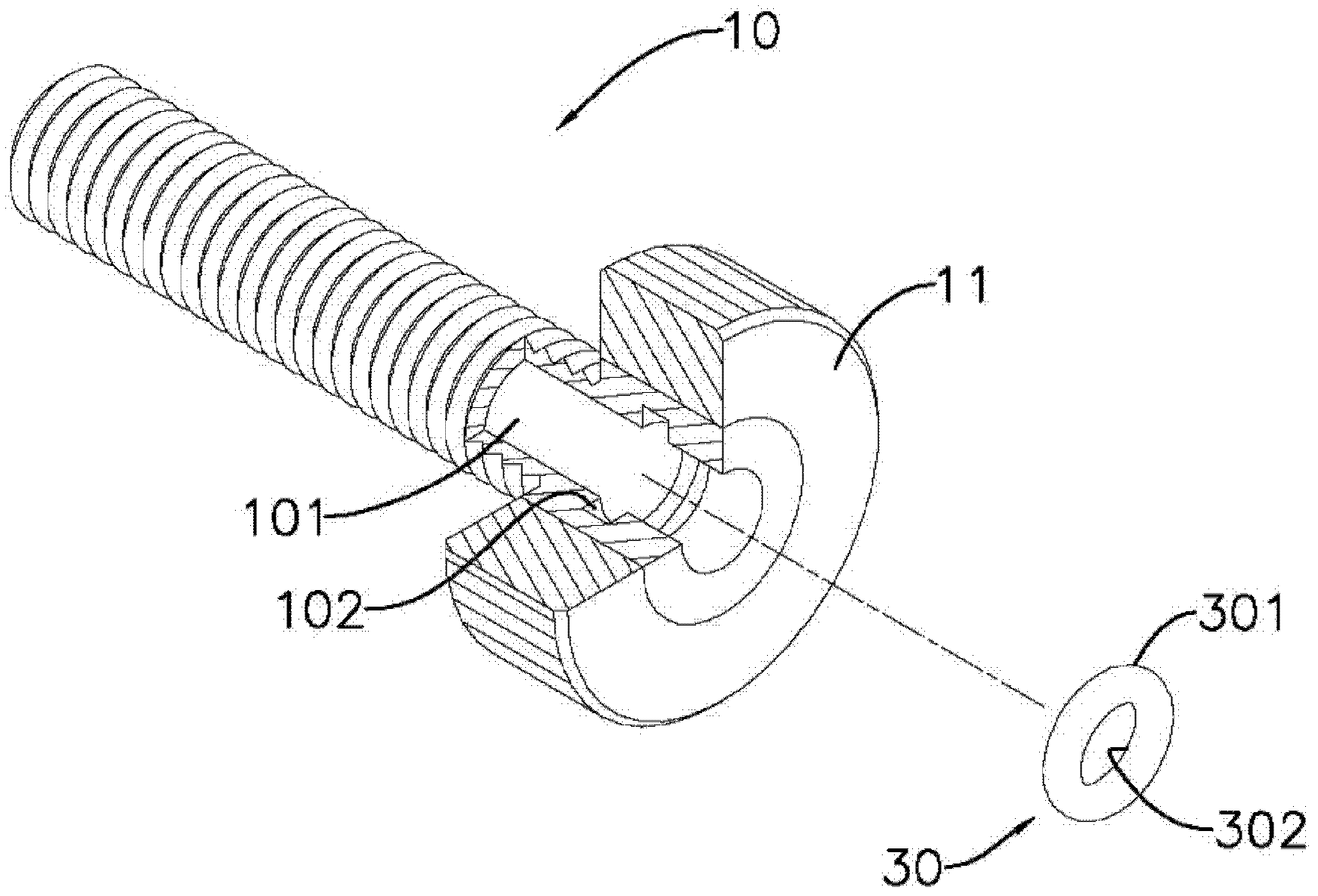

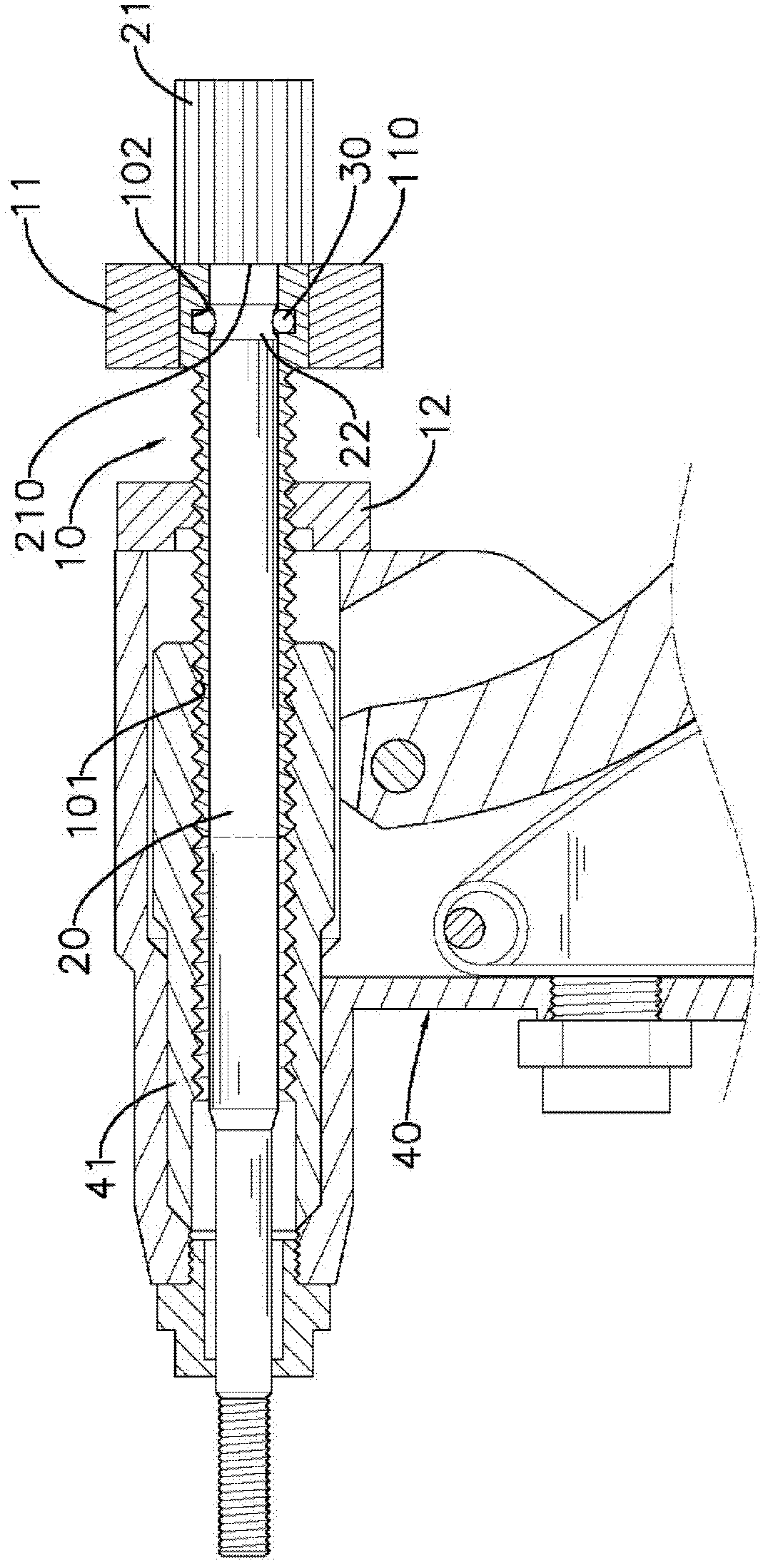

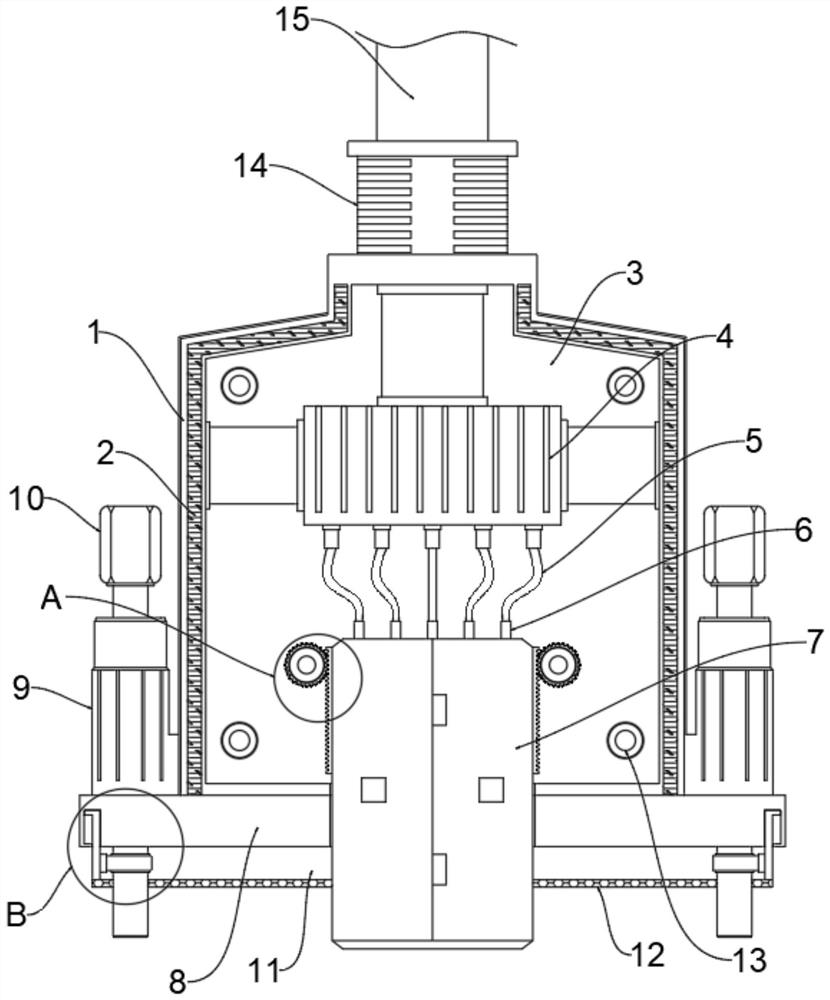

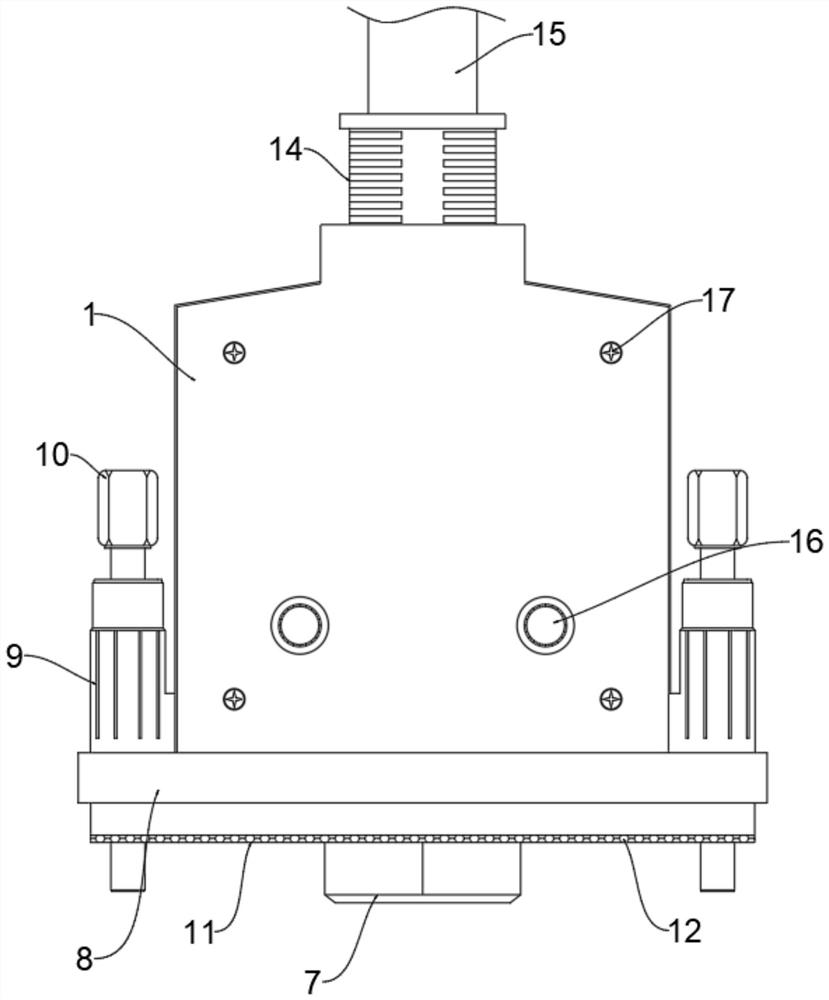

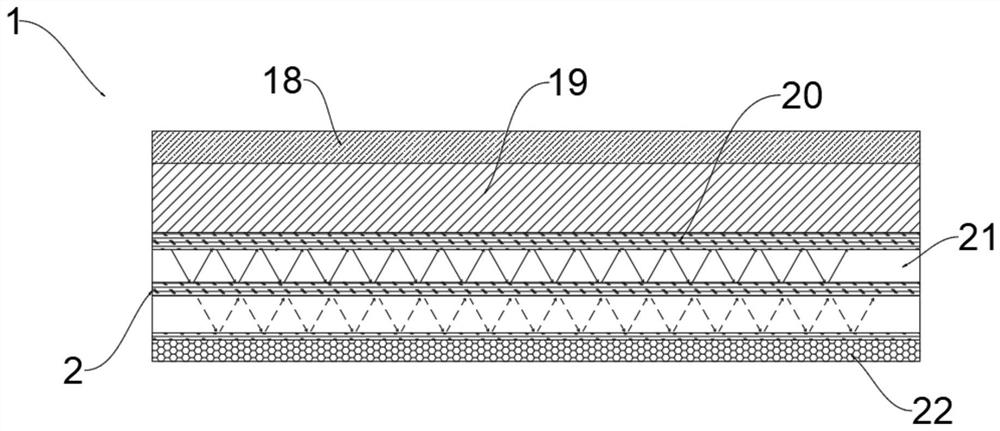

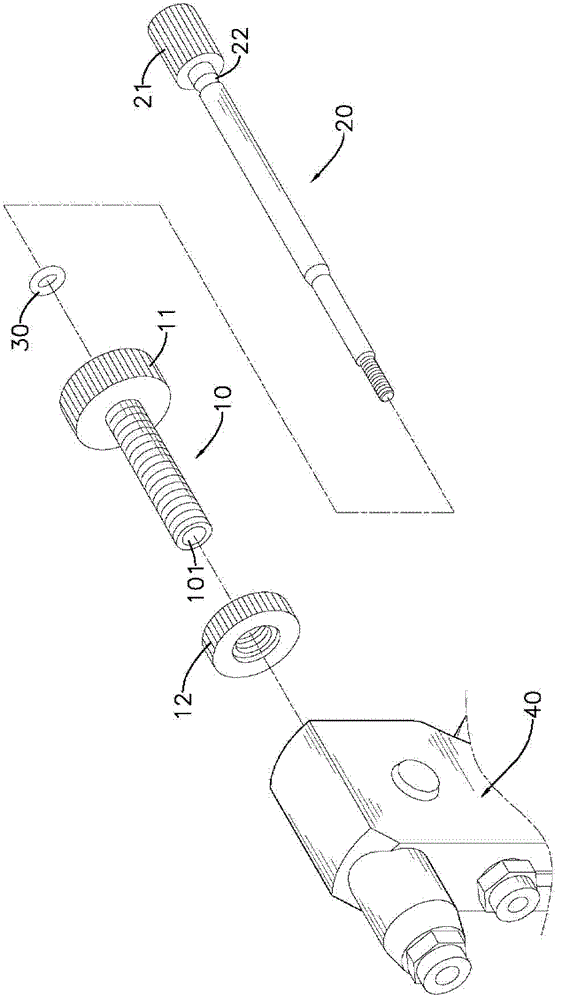

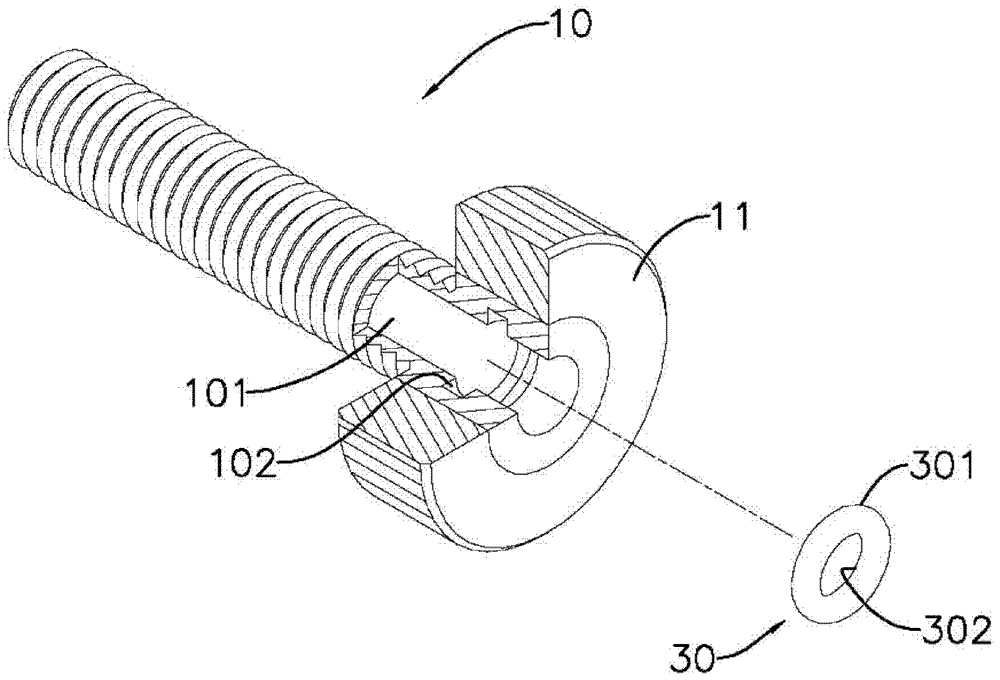

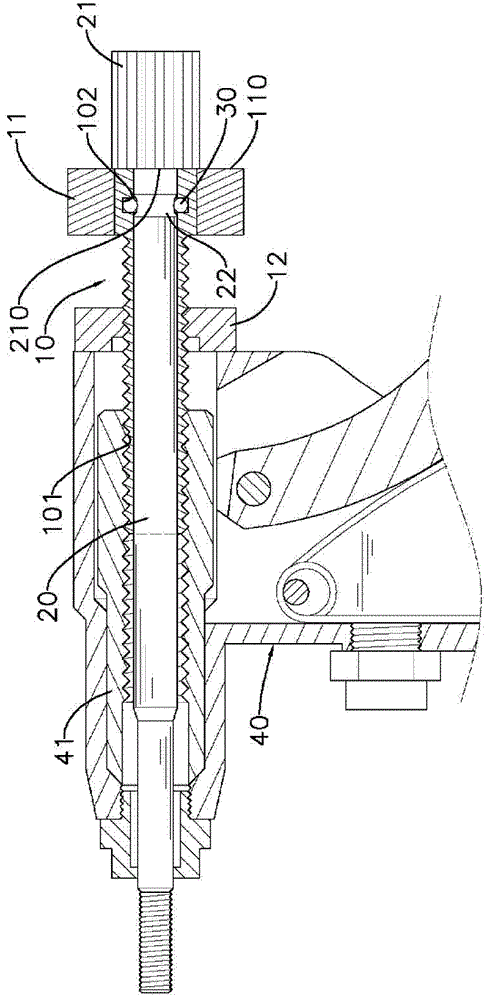

Positioning device for blind nut hand tool

The invention relates to a positioning device for a blind nut hand tool, which comprises a rotating sleeve, a pull rod and a positioning ring. An installation groove is formed inside a through hole at the position of a rotating head of the rotating sleeve; the positioning ring is arranged in the installation groove by an outer lateral ring surface; the pull rod is provided with a positioning groove corresponding to the positioning ring, and thus, when the pull rod moves to be inserted into the through hole, an inner lateral ring surface of the positioning ring is elastically sleeved on the positioning groove and a pull rod head can be surely positioned at a fixed position without shaking, so that the blind nut hand tool can stably rivet a blind nut on a workpiece. According to the device, by the technical means, a positioning device in the prior art is simplified, assembly labor hours and cost can be reduced and a better positioning effect is provided.

Owner:KARAT INDAL CORP

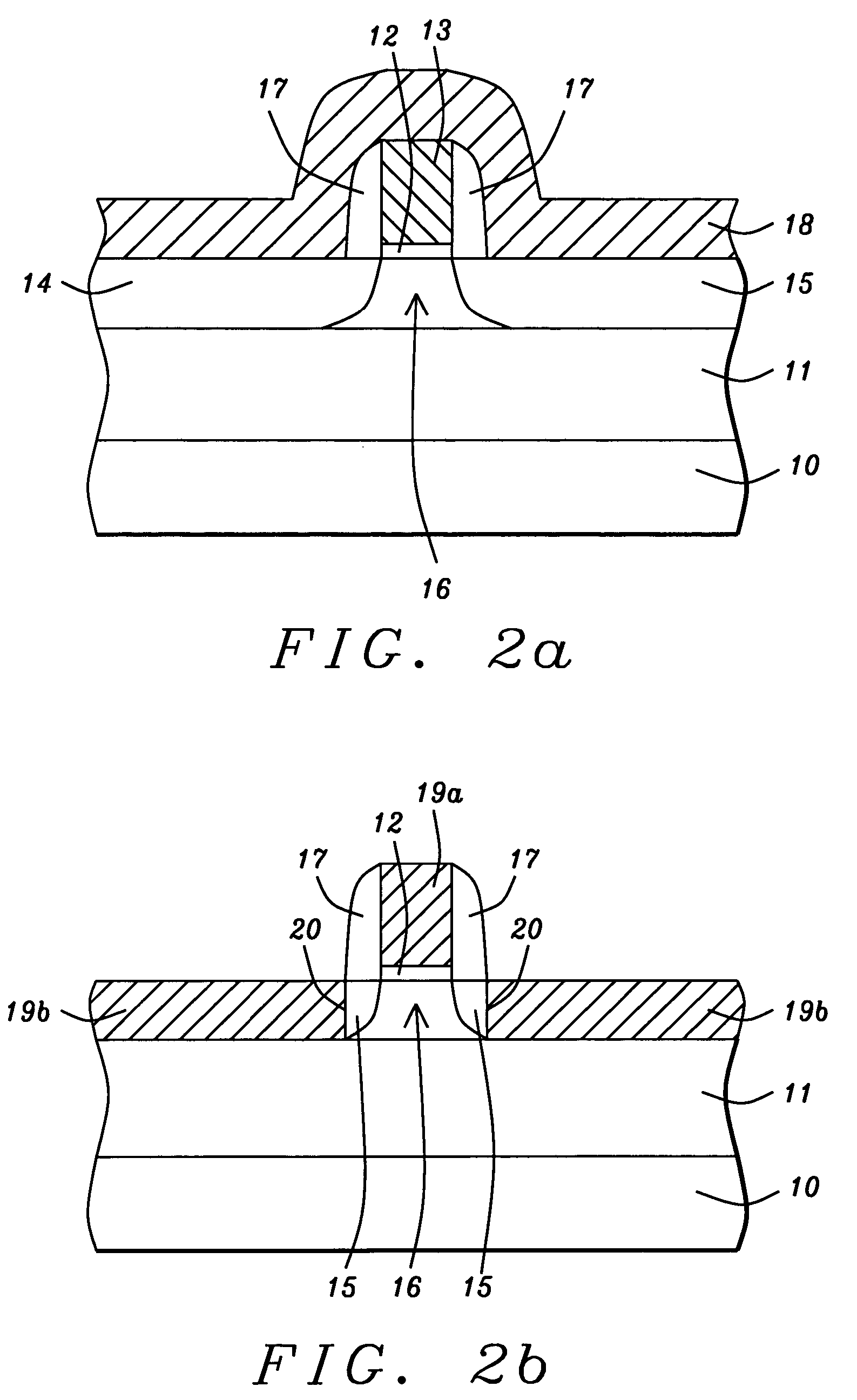

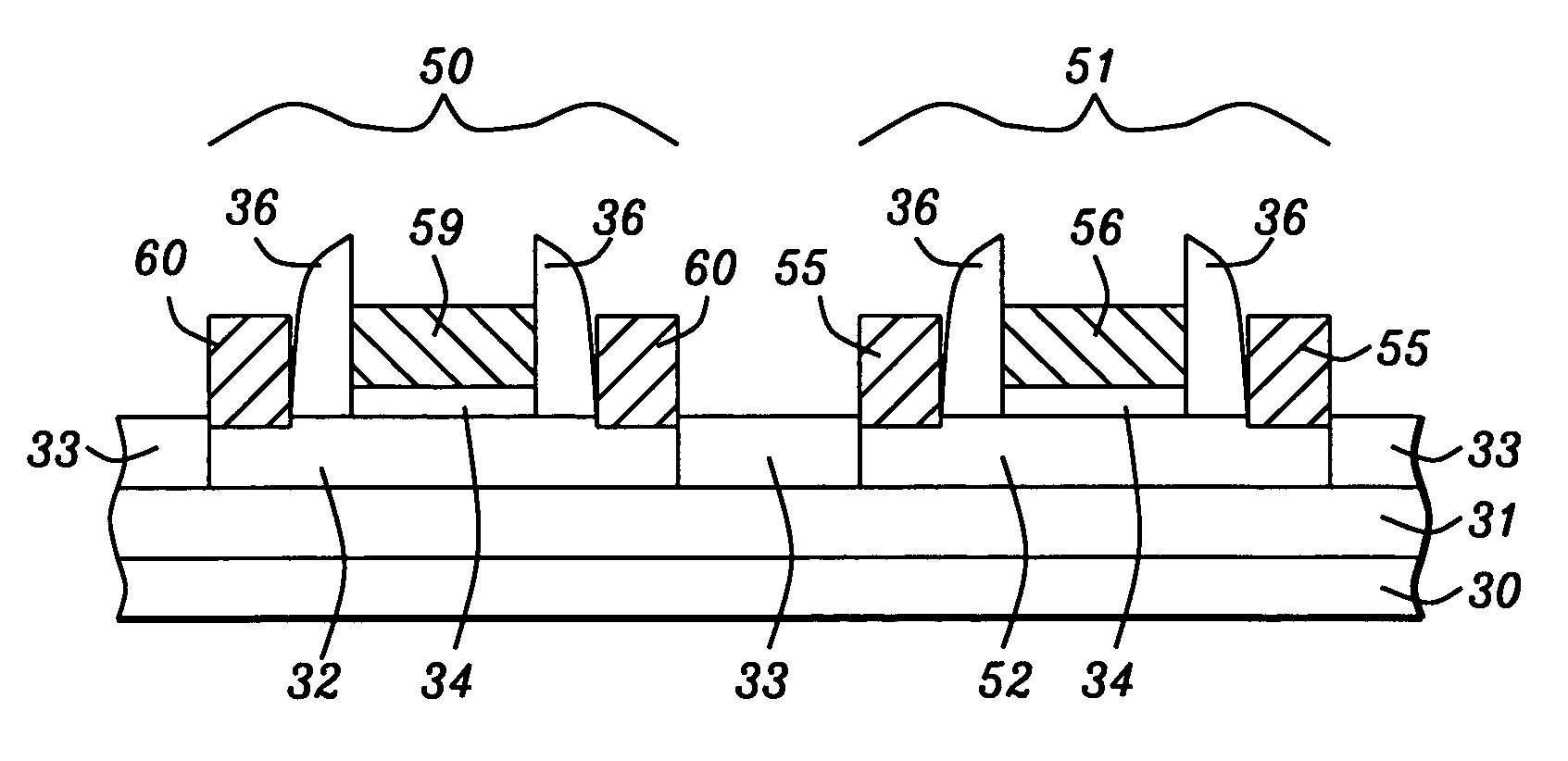

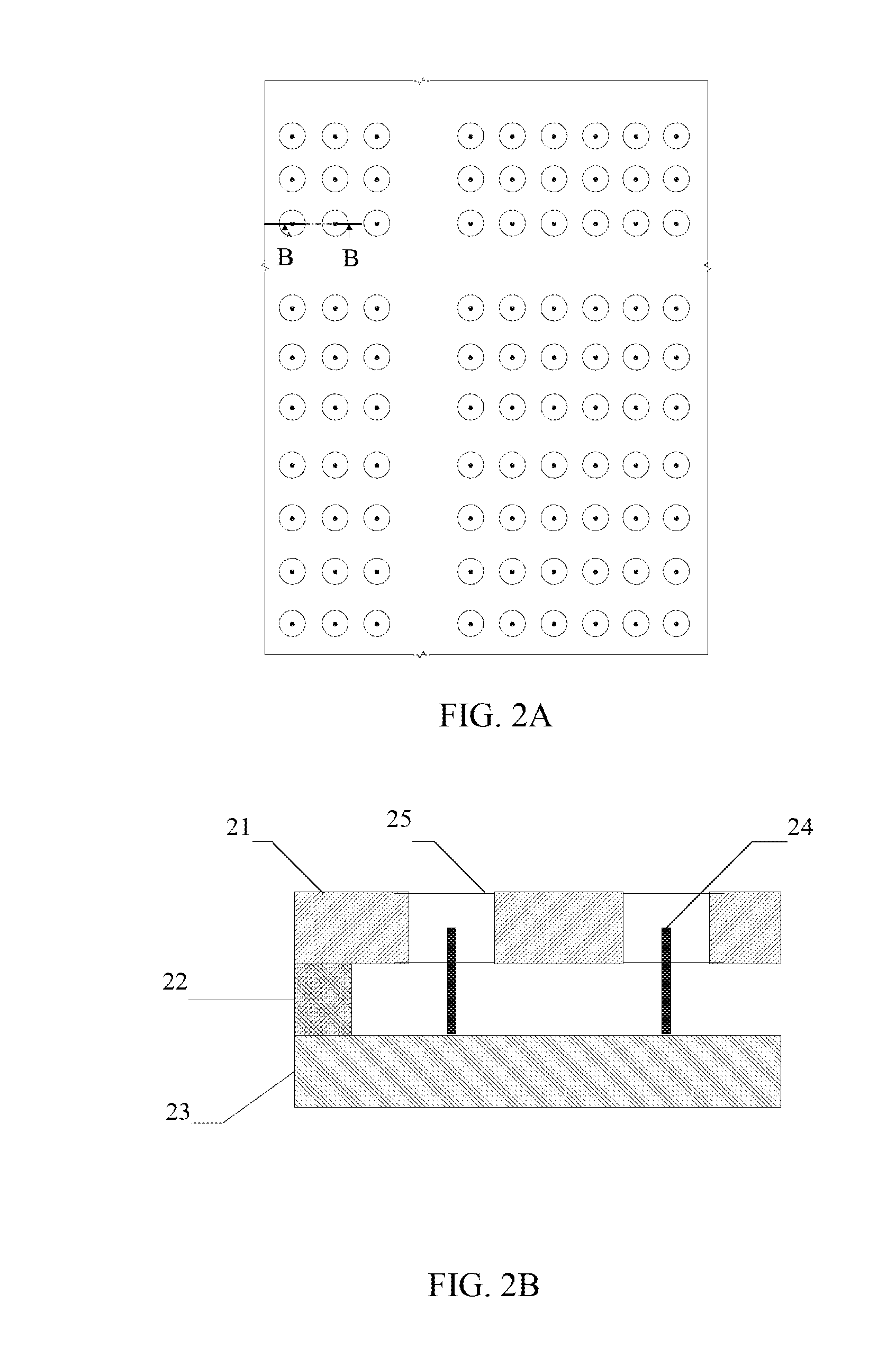

Method for making device with transistors of different types

InactiveCN1551333AImprove performanceIncrease productionTransistorSolid-state devicesGate dielectricEngineering

A method and structure for a method of manufacturing a device having different types of transistors, wherein gates of the different types of transistors in the device comprise different materials. The method comprises depositing a silicon layer on a gate dielectric layer, depositing a first-type gate material on the silicon layer, removing the first-type gate material from areas where a second-type gate is to be formed, depositing a second-type gate material on the silicon layer in areas where the first-type gate material was removed, and simultaneously patterning the first-type gate material and the second-type gate material into first-type and second-type gates, and anneal and transform the two types of gate materials.

Owner:IBM CORP +1

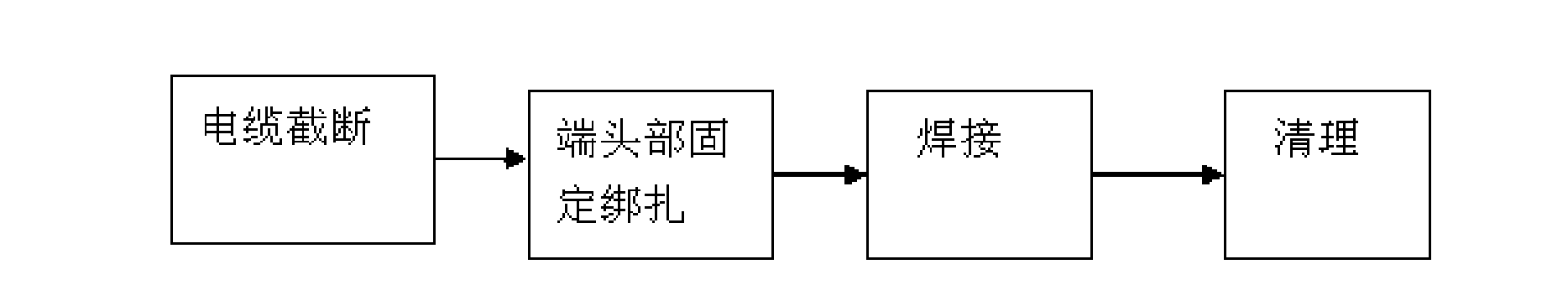

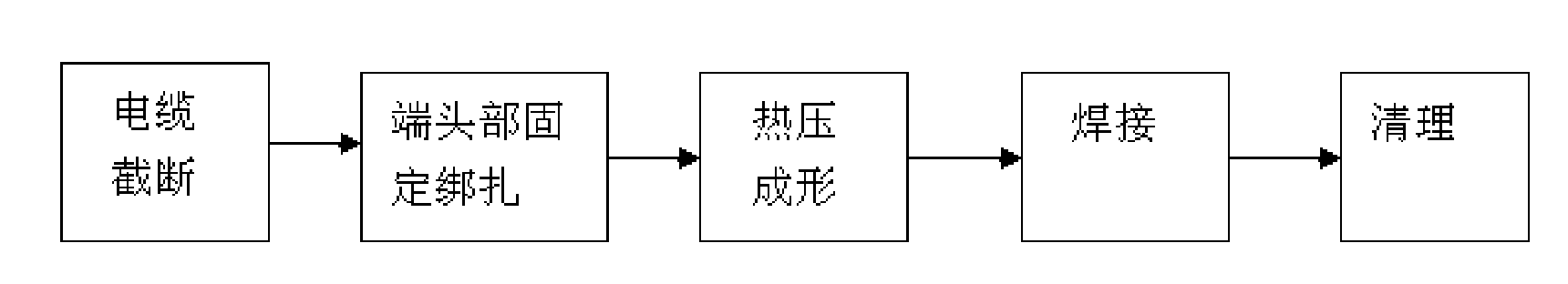

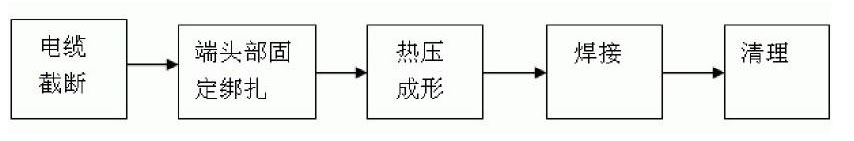

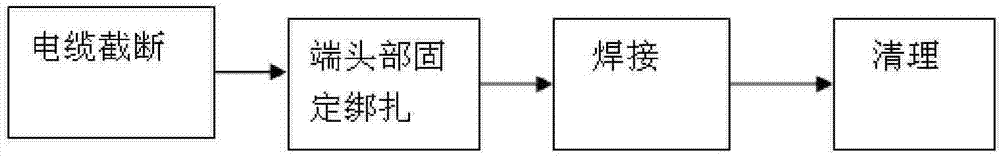

Welding process of copper stranded cable

InactiveCN102074872AIncrease contact surfaceAvoid increased current densityLine/current collector detailsEngineeringHot pressing

The invention provides a welding process of a copper stranded cable. The welding process comprises the following procedures: cutting off the cable; fixing and binding end parts; carrying out hot-pressing molding; welding; and cleaning. In the hot-pressing molding procedure, a pressure shaping process is adopted at a high temperature, namely, the fixedly bound end parts are heated to about 800 DEGC by an oxygen torch, and then the end parts are pressed by hammering with an iron hammer or other tools to form an oblate or semicircular shape or other shapes for facilitating the end parts to be welded with a welding connection piece. By means of the process, an ideal shape of the end parts of the cable can be obtained for the welded section of the cable, thus ideal welding quality can be obtained; and welding addition materials can be saved.

Owner:GUANGXI LIUZHOU SPECIAL TRANSFORMER

Black ink composition

A black ink composition is provided. The black ink composition includes a dispersive black colorant; less than 1 wt % of a glycol ether compound based on total weight of the black ink composition; a solvent; and water. The black ink composition of the present invention is free of surfactants and has excellent compatibility with a nozzle, and thus provides good smoothness in printing and high-quality image.

Owner:EVERLIGHT USA INC

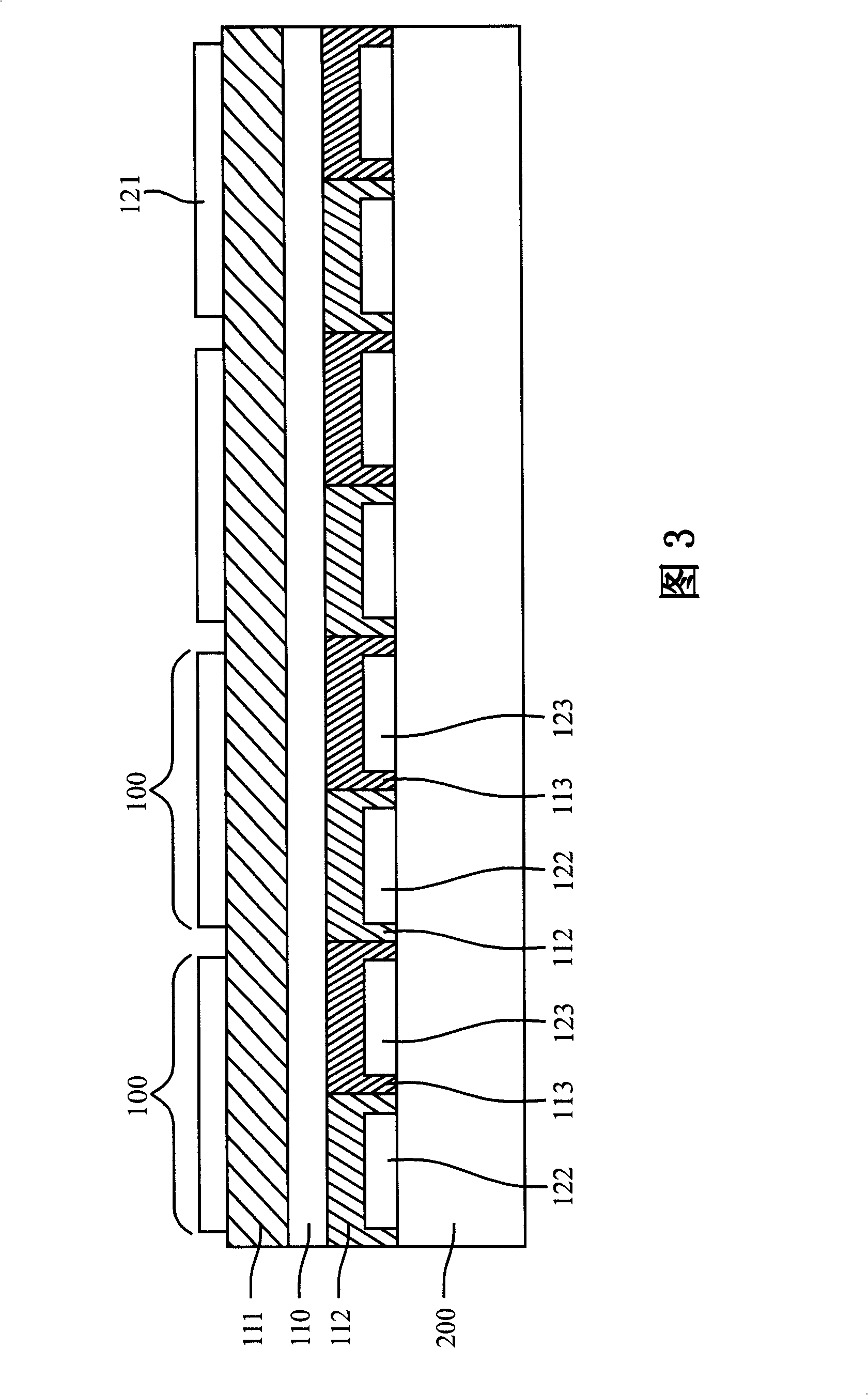

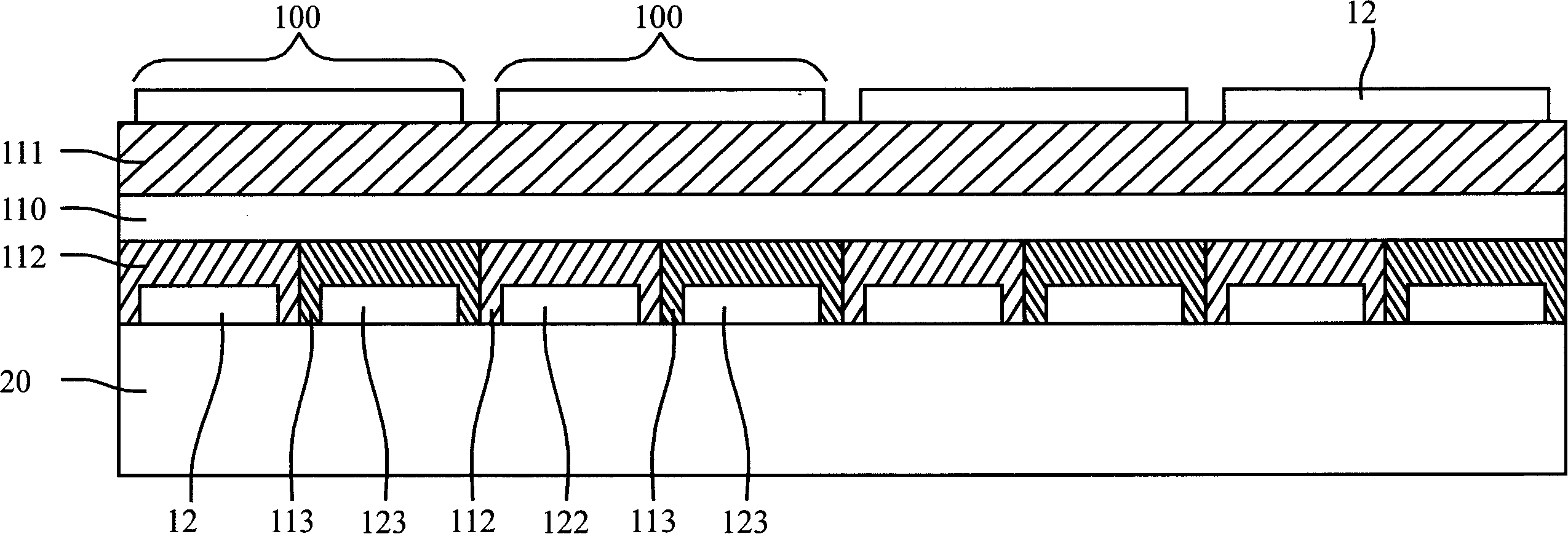

A wholeclour organic electroluminous display element and panel thereof

InactiveCN100414711CImprove finenessEasy to manufactureStatic indicating devicesSolid-state devicesOrganic electroluminescenceSurface plate

An all colored organic electro luminescence display element consists of shared electrode, the first sub pixel organic material layer and the first corresponding electrode, the second sub pixel organic material layer and the second corresponding electrode, the third sub pixel organic material layer and the third corresponding electrode. It is prepared as setting the first sub pixel organic material layer SOML between shared electrode and the first corresponding electrode CE, setting the second and the third SOML in parallel at another side surface of shared electrode and setting the second SOML between shared electrode and the second CE, setting the third SOML between shared electrode and the third CE.

Owner:WORLDLED

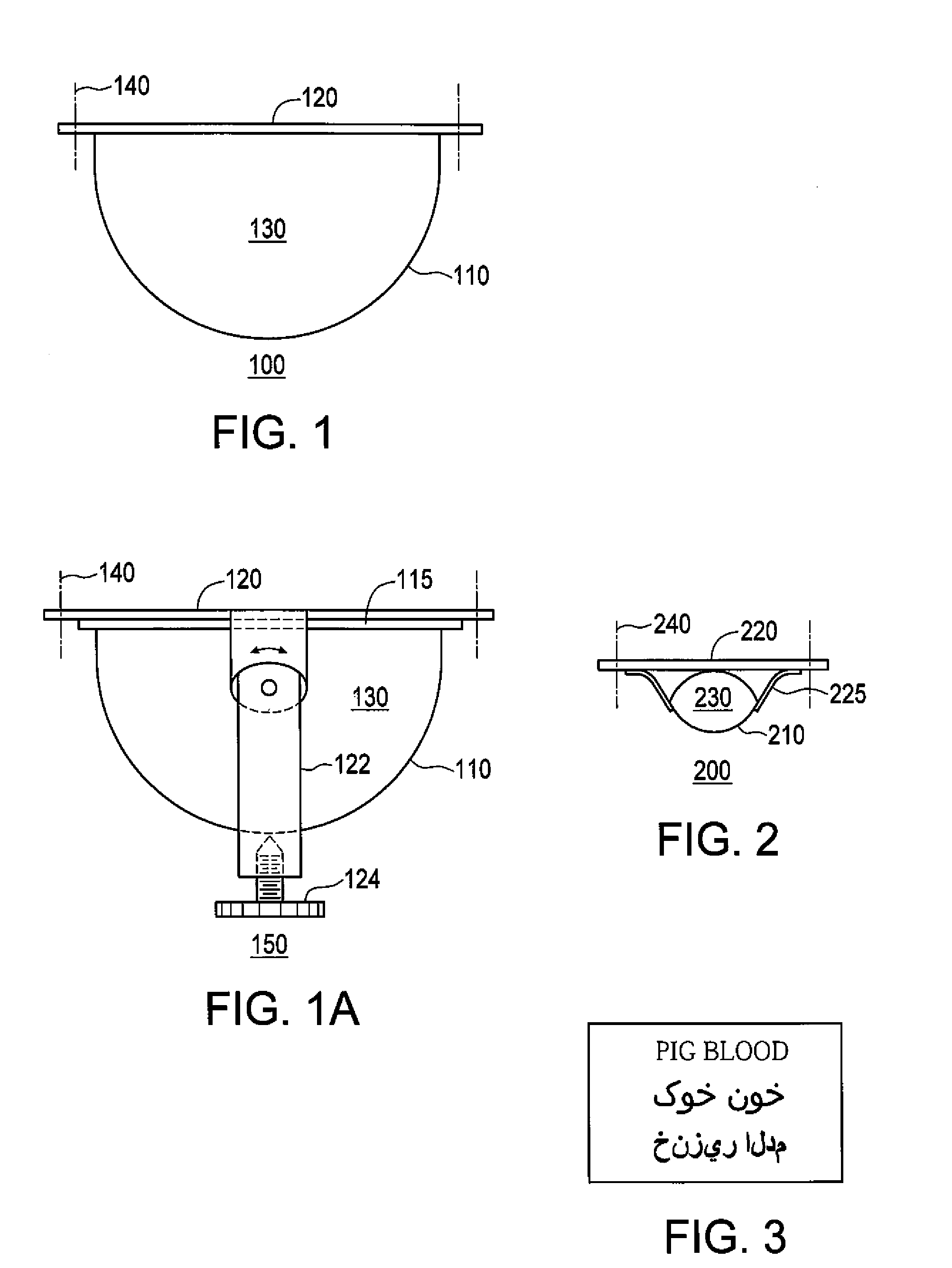

System for protecting against terrorist and illegal invasion

InactiveUS20130047879A1Prevent penetrationKeep pig-blood sensitive terrorists awayDefence devicesAmmunition projectilesAmpouleBlood derivatives

The system includes one or more devices to deter pig-blood sensitive terrorists' and others from passing across borders and across perimeters. It also deters similar terrorist suicide bombers. Sources of deterrence include pig blood derivatives in paint, spray, and detonation distribution form. In addition there are sources of deterrence from ampoules containing pig blood derivatives positioned in public buildings and on public transportation vehicles accompanied by appropriate signage.

Owner:LACY FRANKLIN R

Welding process of copper stranded cable

InactiveCN102074872BEasy to shapeIncrease current densityLine/current collector detailsTorchEngineering

Owner:GUANGXI LIUZHOU SPECIAL TRANSFORMER

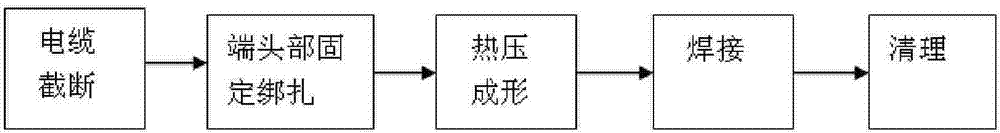

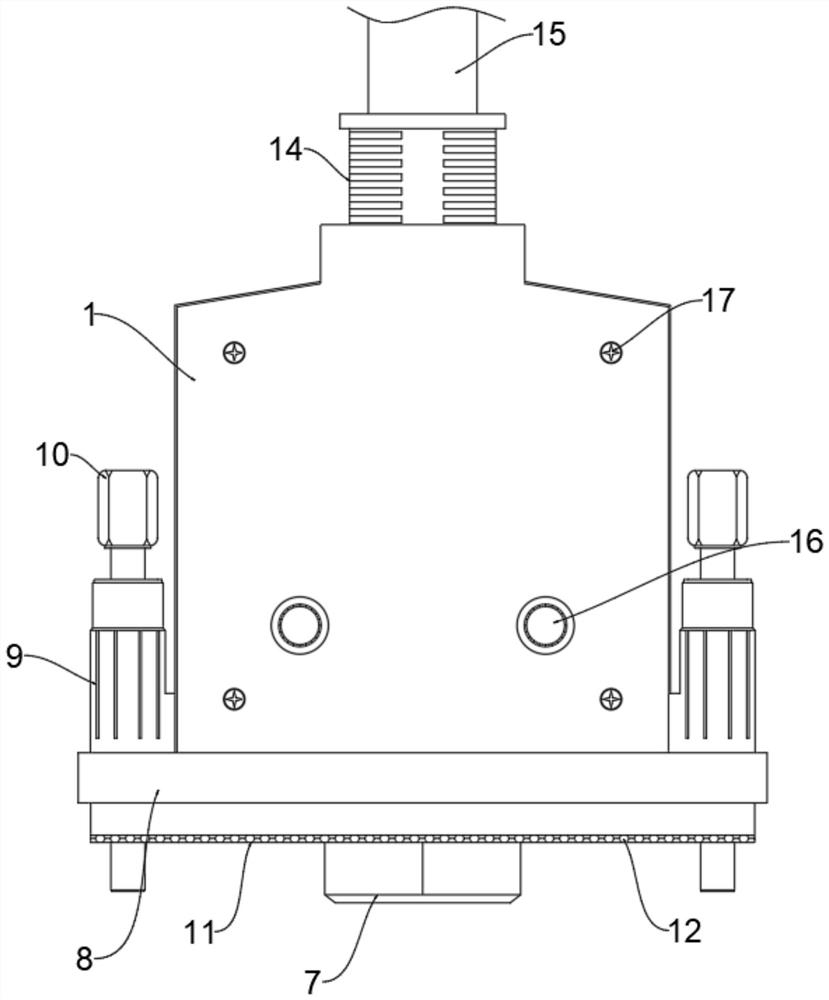

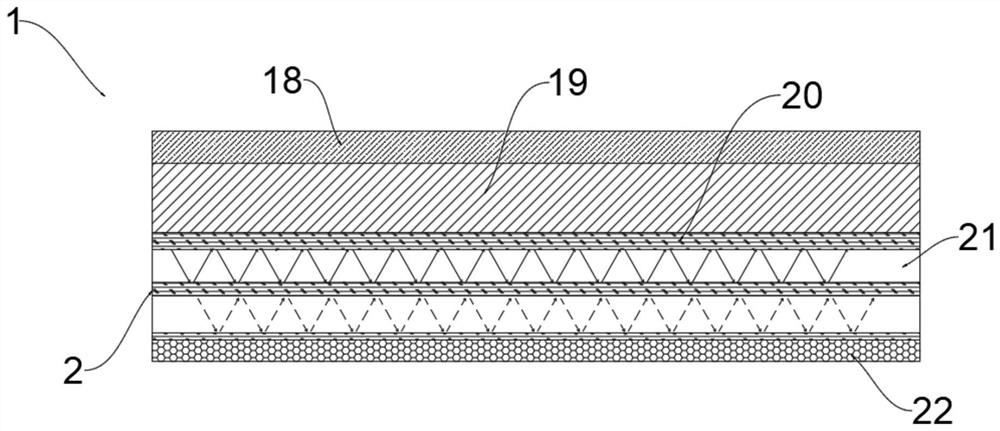

A high-definition video connector with good shielding effect and its use method

ActiveCN112490780BPrevent penetrationEliminate penetrationCouplings bases/casesCoupling protective earth/shielding arrangementsStructural engineeringMechanical engineering

The invention discloses a high-definition video connector with good shielding effect and a use method thereof, relates to the technical field of high-definition video connectors, and aims to solve the problem that the magnetic shielding effect of the existing high-definition video connector is poor. The outer shell is composed of a permalloy inner shell, an eddy current shielding layer and an insulating rubber, and the eddy current shielding layer is fixed between the permalloy inner shell and the insulating rubber, the lower end of the outer shell is fixedly provided with a fixing block, and the outer shell An inner cavity is arranged inside, and a converging mechanism is fixedly installed at the middle position inside the inner cavity. A joint is installed at the lower end of the inner cavity, and a terminal is installed at the rear end of the joint. Both sides of the bottom of the joint Both sides are fixedly provided with slide rails, both sides of the rear end of the housing are provided with slide grooves, a shielding bottom plate is installed inside the fixed block, fixed columns are fixedly installed on both sides of the upper end of the fixed block, and the fixed column There are fixed bolts installed inside.

Owner:安徽兄弟电子有限公司

Use of pyridine quaternary ammonium salt type alkaline or alkalescent polymer membranous

InactiveCN101328275BIncrease the rate of oxidation reactionsEliminate penetrationFuel cell detailsReaction rateAlcohol fuel

The invention discloses a quaternary pyridine salt type alkaline or alkalescent polymer membrane, which is used as a membrane material of a direct alcohol fuel cell. The quaternary pyridine salt type alkaline or alkalescent polymer membrane is produced from polymer materials which are subjected to membrane formation, quaternization reaction and alkalization reaction. The polymer materials are polymer materials produced by pyridine quaternization and a blend prepared from the polymer materials and polyvinylidene fluoride, bisphenol A polyethersulfone, polyether-ether-ketone, polyethersulfone, polyethersulfoneketone, poly(phthalazinone ether ketone), poly(phthalazinone ether sulfone) or poly(phthalazinone ether sulfone ketone) and so on which are blended. A direct methanol fuel cell (AMDMFC) adopting the quaternary pyridine salt type alkaline or alkalescent polymer membrane works under alkaline or alkalescent conditions, has the advantages of improving the oxidation reaction rate of methanol, eliminating the methanol permeation caused by electric dragging, widening the selection range of catalysts (including the catalysts of anodes and cathodes) and cell materials, simplifying watermanagement and so on.

Owner:SHANDONG UNIV OF TECH

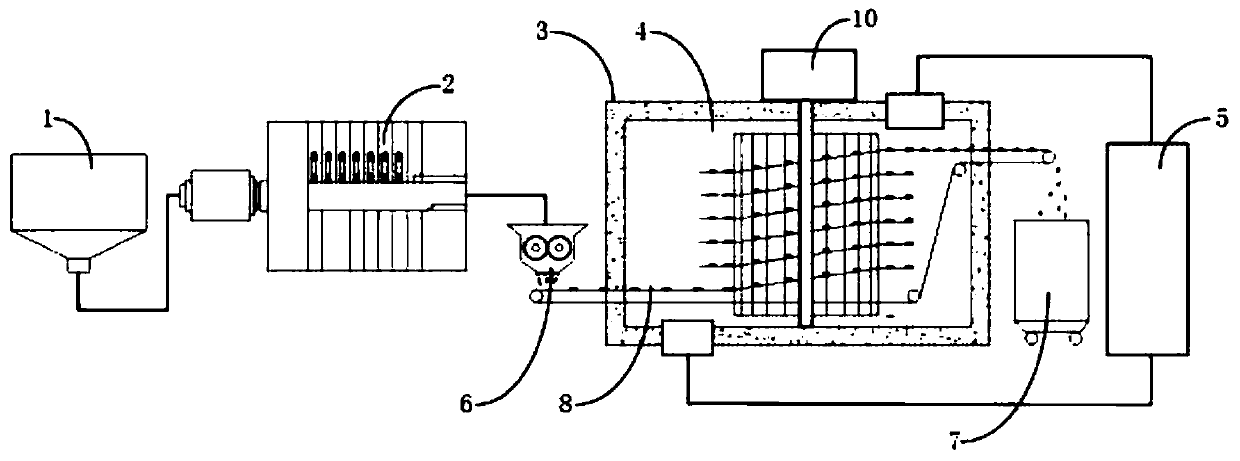

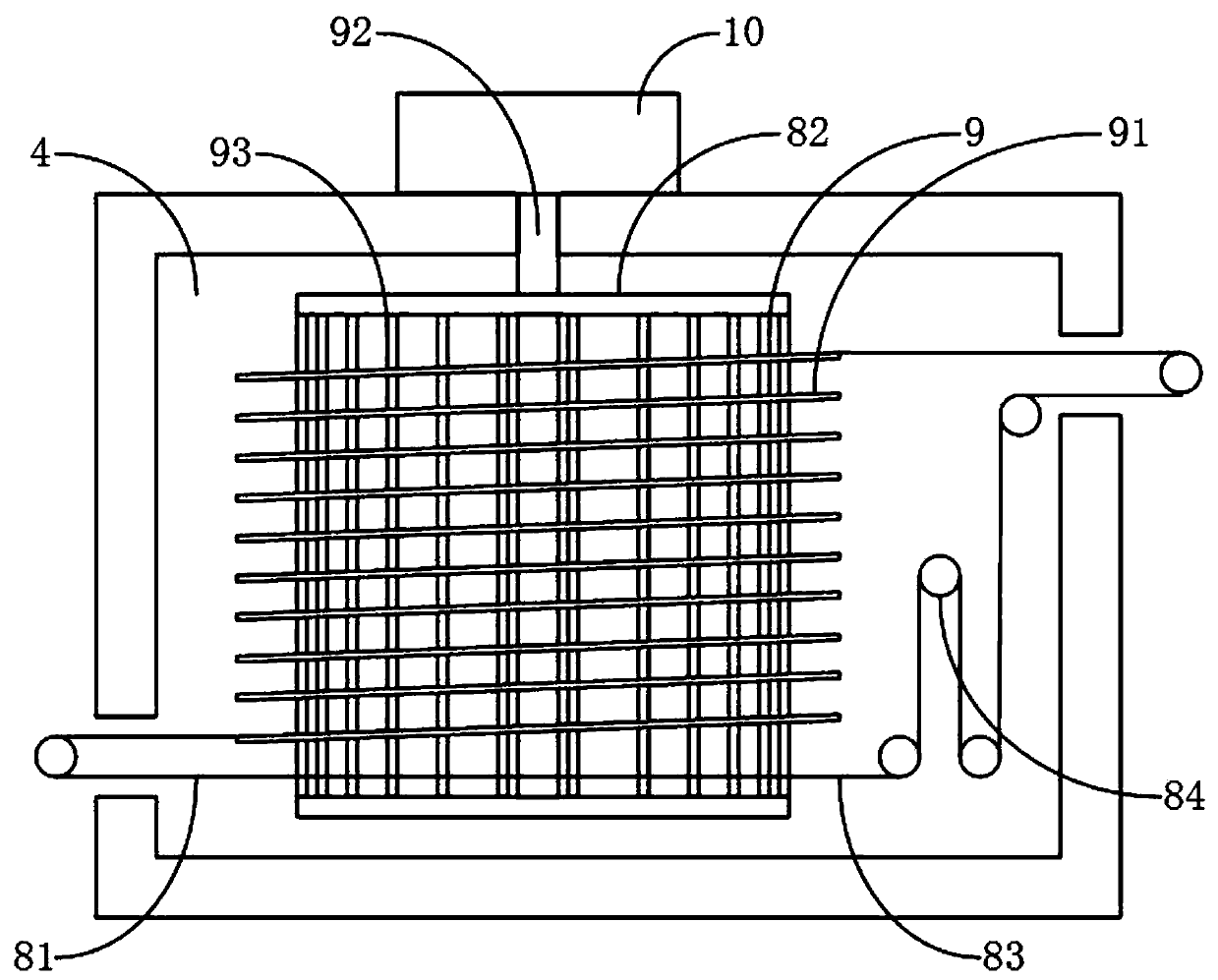

Sludge treatment system and process

PendingCN110563301AAchieve reductionEliminate penetrationSludge treatment by de-watering/drying/thickeningSlurryPulp and paper industry

The invention discloses a sludge treatment system and a process. Sludge paste with the moisture content of 50% to 60% can be obtained by adopting a slurry hopper and a press filter and can be dried into clods with the moisture content of 40% or less through a drying unit. A drying room and a hot air supply circulating mechanism can exert a relatively good drying effect, an extruding mechanism anda circulating conveying mechanism are combined, and thus, materials are uniformly tiled and heated and are uniformly dried. According to the sludge treatment system and the process, sludge can be thickened and dehydrated, the volume weight of the sludge is greatly reduced, the decrement of the sludge is achieved, and the pollution caused by liquid permeation and odor emission is eliminated. By designing the hot air supply circulating mechanism, the operation of an evaporator can be effective, a circulating hot air supply is relatively dry, the materials in the drying room can be deeply dehumidified, the effect is remarkable, the loss of heat energy caused by hot-cold offset is lowered, and the utilization ratio of energy is increased. The circulating conveying mechanism is ingeniously designed, the circulation of the circulating hot air supply is facilitated, the materials are heated and dried uniformly, the space usage is relatively low, and thus, the requirements of materials on a thorough drying course in a limited space are met.

Owner:江苏同益能源科技有限公司

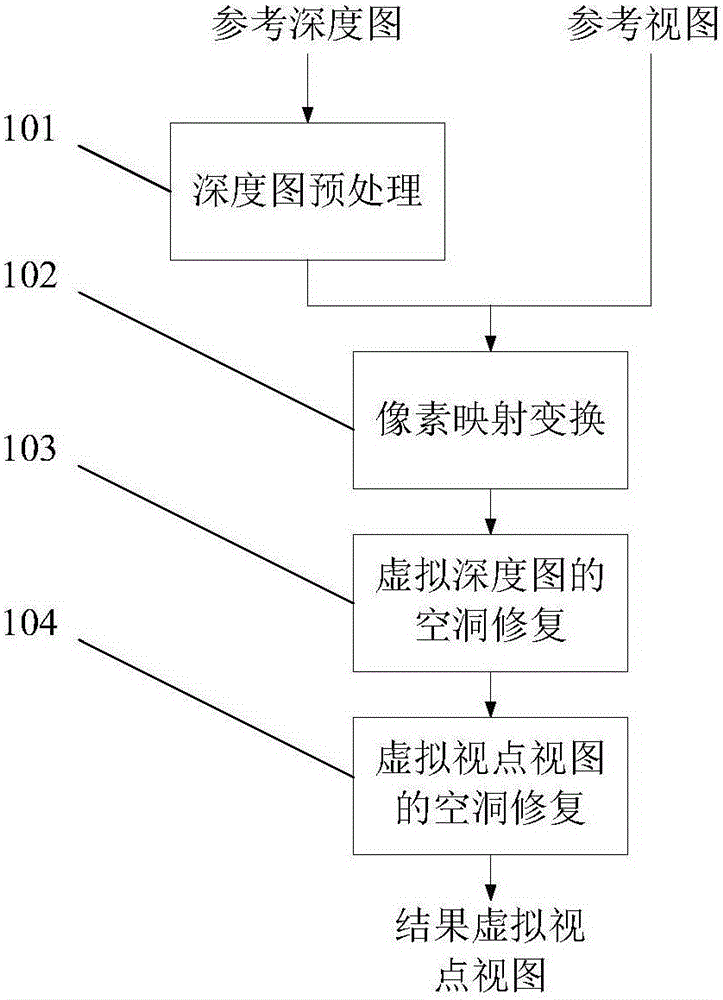

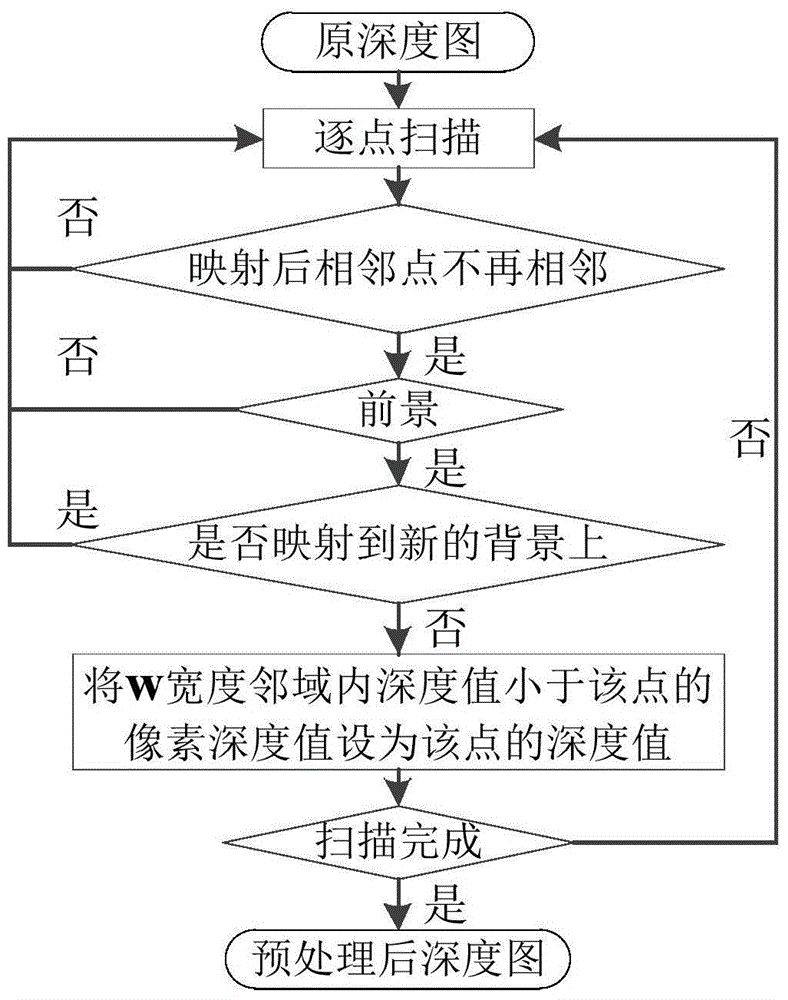

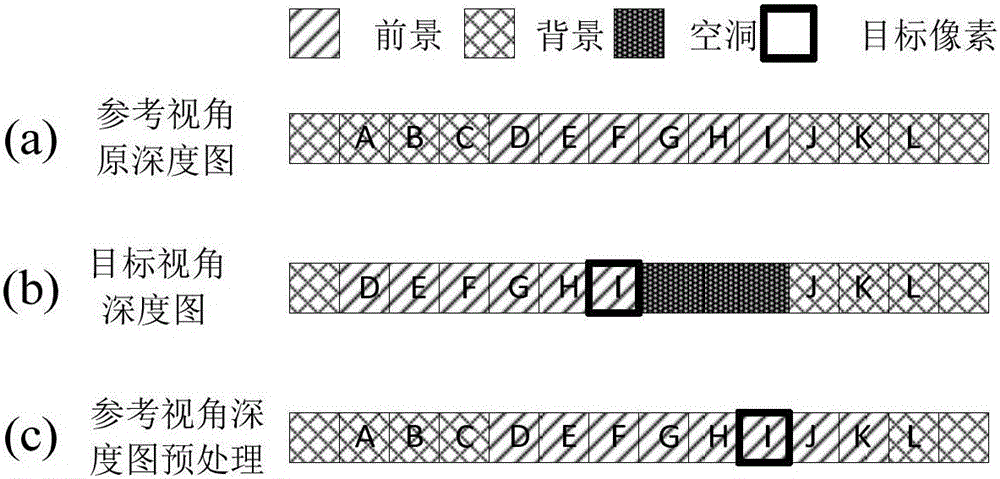

A Depth-Based Hole Repair Method in View Synthesis

InactiveCN104780355BImprove retentionImprove repair effectSteroscopic systemsPattern recognitionView synthesis

The invention discloses a depth-based cavity repairing method in viewpoint synthesis. The method comprises steps as follows: (1) performing depth edge one-way expansion preprocessing on an input reference depth map to eliminate inter-infiltration of a foreground pixel and a background pixel in a synthesized virtual viewpoint view; (2) performing pixel mapping transformation by using the preprocessed reference depth map and an original reference view to obtain a virtual viewpoint view with a cavity and a virtual viewpoint depth map; (3) repairing the cavity in the virtual depth map with a pixel-based image repairing method in combination with the relative position relation between the foreground and the background around the cavity in the virtual viewpoint depth map; (4) repairing the cavity in the virtual viewpoint view with an improved sample-based image repairing method in combination with the repaired virtual viewpoint depth map. With the adoption of the method, the virtual viewpoint view with better quality can be obtained, the continuity of image edges can be better kept, and the inter-infiltration of the foreground and background pixels can be eliminated.

Owner:ZHEJIANG UNIV

Electronically-controlled device for release of drugs, proteins, and other organic or inorganic chemicals

InactiveUS20090216176A1Suppresses molecular flowEliminate systemic side-effectsMaterial nanotechnologyElectrotherapyDrug reservoirInorganic Chemical

A device for drug release including a drug reservoir including a gate, wherein opening of the gate releases a drug stored in the drug reservoir, an electronic command and control (C & C) unit in communication with the gate that produces a gate bias voltage and time profile supplied to the gate for controlling opening of the gate, and a power source for supplying power to the electronic command and control unit.

Owner:GILAD PINCHAS

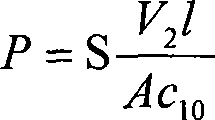

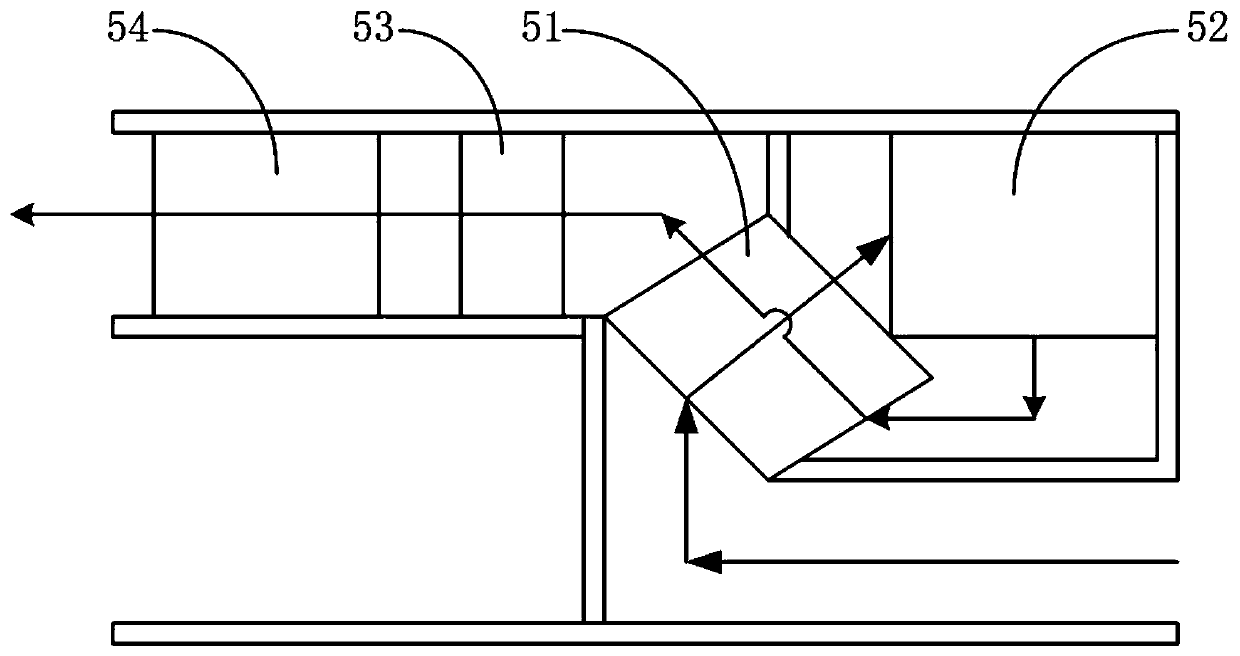

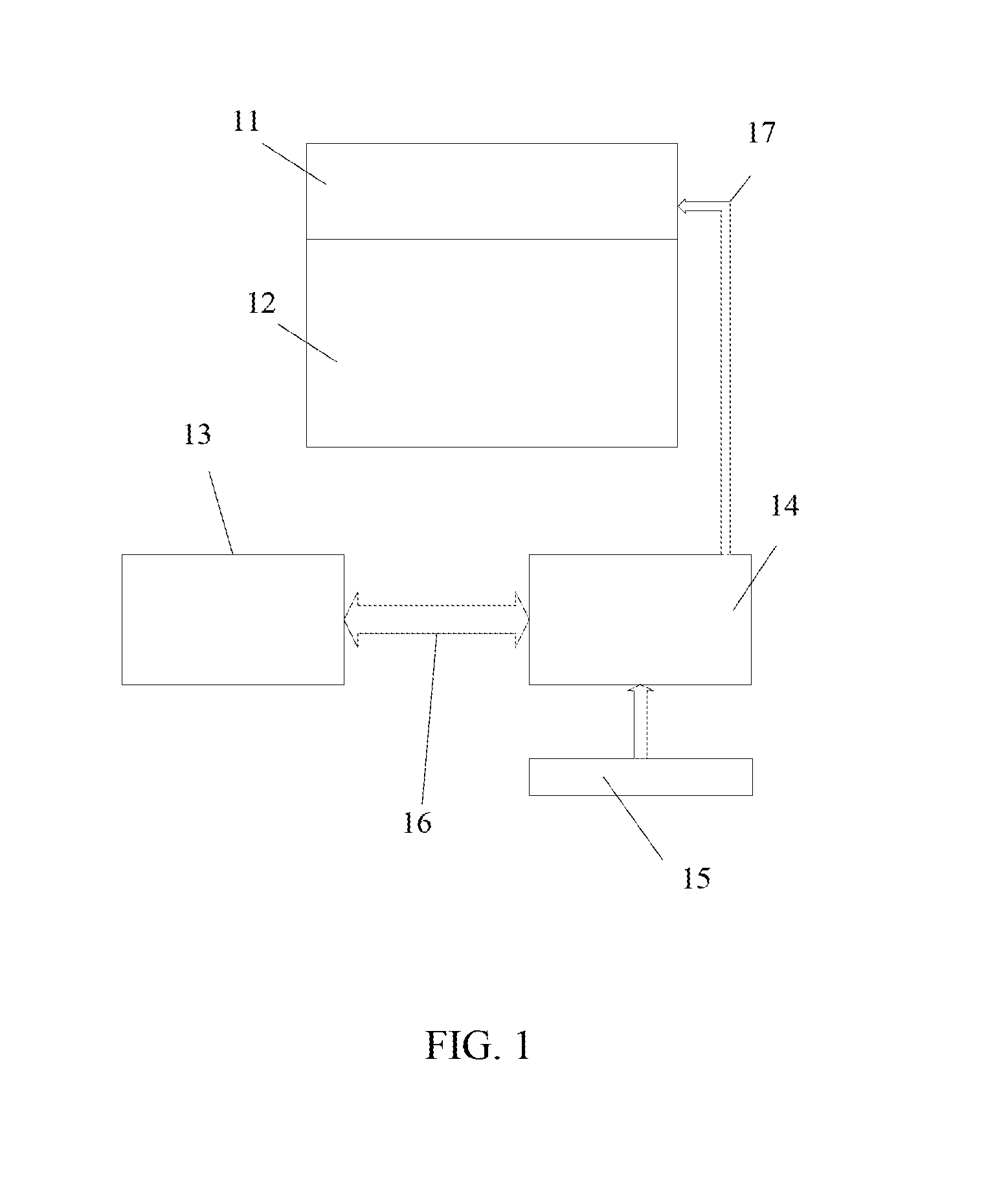

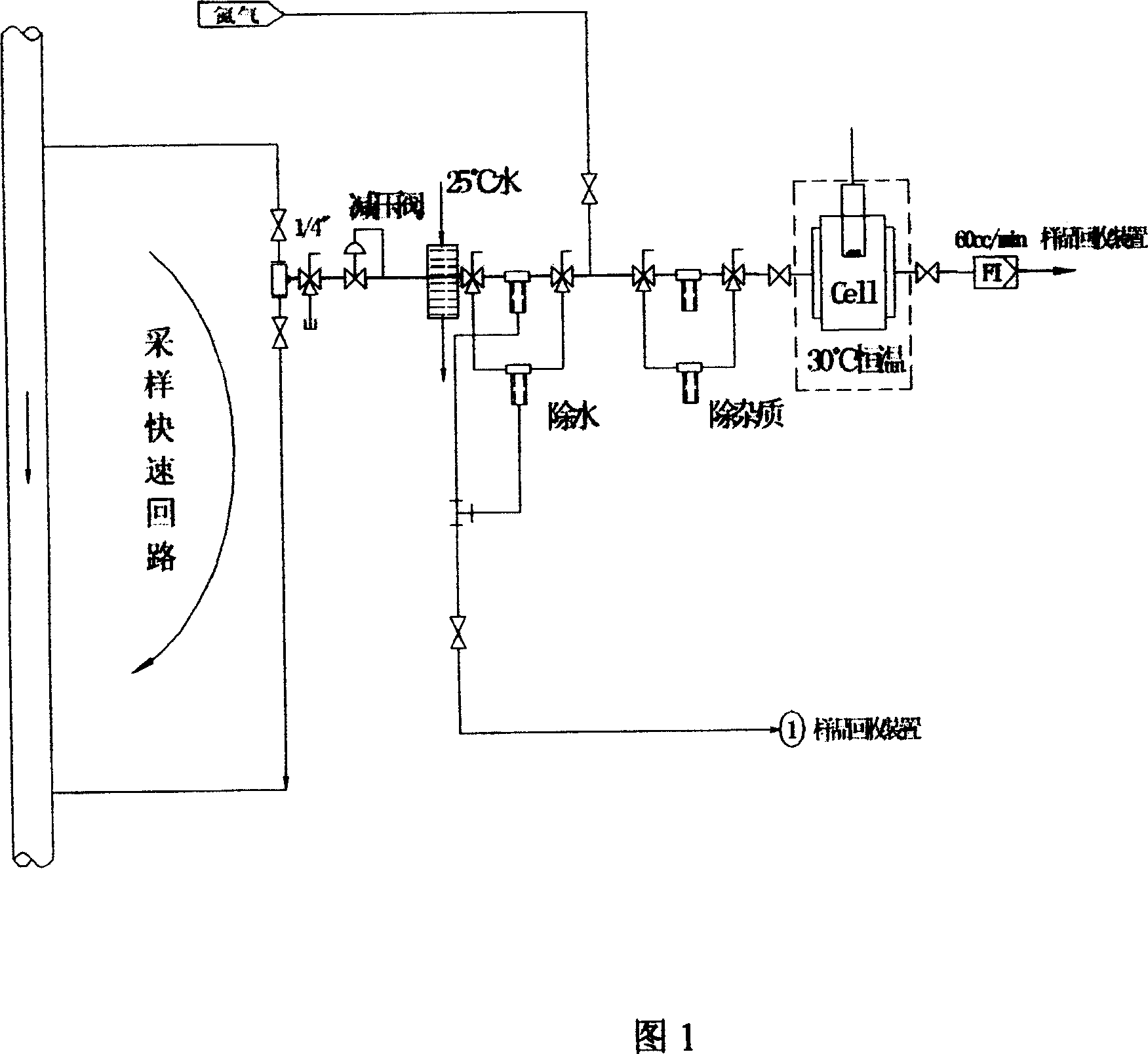

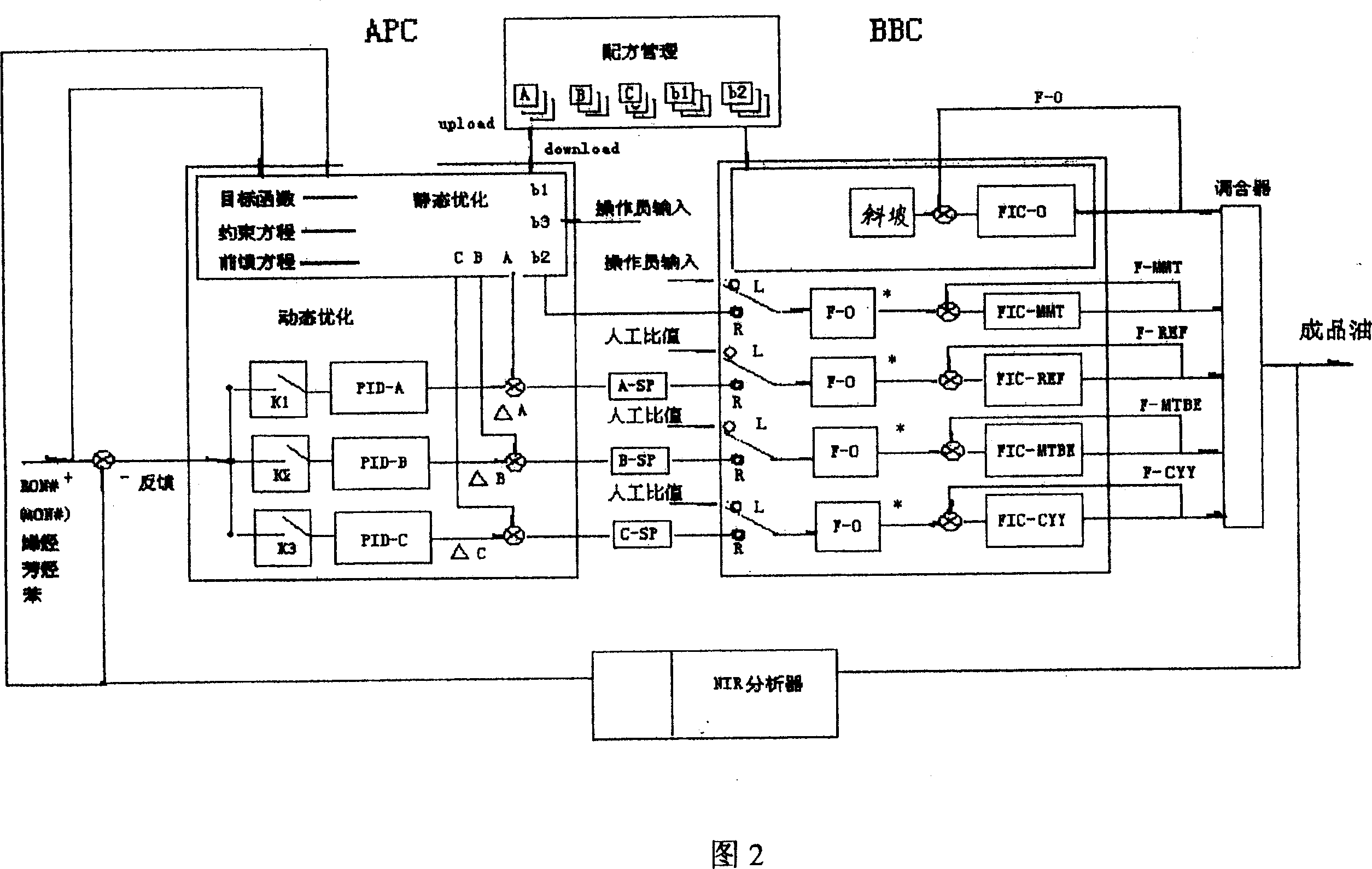

Online optimized method for blending oil products, and system of implementing the method

InactiveCN1327306CGuaranteed qualityImprove qualityControlling ratio of multiple fluid flowsComputer controlControl flowControl system

This invention provides an oil-product on-line optimized mixing method including a basic control system controlling flow of each component and an optimized control system with intelligent operation connecting to it via an interface, a sample device and a near infrared on-line analyzer analyzing the sample characterizing in including the following technological steps: before analyzing the sample by the near infrared on-line analyzer, the sample is pre-processed including a constant temperature process and water remove process. The invention also provides an oil-product on-line optimized mixing system.

Owner:CATECH TECH

Method for making device with transistors of different types

InactiveCN1320635CImprove performanceIncrease productionTransistorSolid-state devicesGate dielectricEngineering

Owner:INT BUSINESS MASCH CORP +1

High-definition video connector with good shielding effect and using method

ActiveCN112490780APrevent penetrationEliminate penetrationCouplings bases/casesCoupling protective earth/shielding arrangementsPermalloyStructural engineering

The invention discloses a high-definition video connector with a good shielding effect and a using method, relates to the technical field of high-definition video connectors, and aims to solve the problem that an existing high-definition video connector is worse in magnetic shielding effect. An outer shell is composed of a permalloy inner shell, an eddy current shielding layer and insulating rubber, the eddy current shielding layer is fixed between the permalloy inner shell and the insulating rubber, and a fixing block is fixedly arranged at the lower end of the outer shell; an inner cavity isformed in the outer shell, and a bundling mechanism is fixedly installed in the middle of the interior of the inner cavity; a connector is installed at the lower end of the interior of the inner cavity, a terminal is installed at the rear end of the connector, and sliding rails are fixedly arranged at the two sides of the bottom of the connector; sliding grooves are formed at the two sides of therear end of the outer shell, a shielding bottom plate is installed in the fixing block, fixing columns are fixedly arranged at the two sides of the upper end of the fixing block, and a fixing bolt ismounted in the fixing column.

Owner:安徽兄弟电子有限公司

Positioning device for blind nut hand tool

The invention relates to a positioning device for a blind nut hand tool, which comprises a rotating sleeve, a pull rod and a positioning ring. An installation groove is formed inside a through hole at the position of a rotating head of the rotating sleeve; the positioning ring is arranged in the installation groove by an outer lateral ring surface; the pull rod is provided with a positioning groove corresponding to the positioning ring, and thus, when the pull rod moves to be inserted into the through hole, an inner lateral ring surface of the positioning ring is elastically sleeved on the positioning groove and a pull rod head can be surely positioned at a fixed position without shaking, so that the blind nut hand tool can stably rivet a blind nut on a workpiece. According to the device, by the technical means, a positioning device in the prior art is simplified, assembly labor hours and cost can be reduced and a better positioning effect is provided.

Owner:KARAT INDAL CORP

Surface sizing process for corrugated cardboard processing

InactiveCN110863388AIncrease load rateSolve penetrationWater-repelling agents additionPaper coatingCardboardFiber

The invention discloses a surface sizing process for corrugated cardboard processing. The process comprises the following steps: 1) preparation of a glue solution; 2) preparation of a bubble agent; 3)bubble glue solution preparation: the glue solution A and the bubble agent B are mixed, and poured on a colloid mill, and a double-mill kneading method is used to obtain the bubble glue solution C, and 4) a sizing process of the bubble glue solution: the surface of corrugated base paper is coated with the bubble glue solution C in a rolling brush manner, and drying with hot air is performed; a sizing machine is used to coat the bubble glue solution C; and surface bubbles are eliminated with a polyurethane scraper, leveling is performed, and then drying is performed to obtain finished corrugated paper. According to the process, the glue solution is foamed and then mounted on the corrugated paper surface for the first time, a new sizing process in which a relatively thin glue solution is smoothly mounted on the corrugated paper surface can be realized, and the smooth penetration of the glue solution into fiber pores is promoted by cooperating with the bubble elimination process. At thesame time, the adverse phenomenon that the corrugated paper is soaked by the relatively thin glue solution is avoided, the yield is high, the obtained corrugated paper has relatively high strength, and the application in the field of high-strength cartons is met.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

A wholeclour organic electroluminous display element and panel thereof

InactiveCN1741695AImprove finenessEasy to manufactureElectrical apparatusStatic indicating devicesOrganic electroluminescenceSurface plate

An all colored organic electro luminescence display element consists of shared electrode, the first sub pixel organic material layer and the first corresponding electrode, the second sub pixel organic material layer and the second corresponding electrode, the third sub pixel organic material layer and the third corresponding electrode. It is prepared as setting the first sub pixel organic material layer SOML between shared electrode and the first corresponding electrode CE, setting the second and the third SOML in parallel at another side surface of shared electrode and setting the second SOML between shared electrode and the second CE, setting the third SOML between shared electrode and the third CE.

Owner:WORLDLED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com