Sludge treatment system and process

A sludge treatment and treatment process technology, applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of waste of circulating hot air humidity and uneven heating of materials, etc. Achieve the effect of improving energy utilization, reducing volume and weight, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention provides a sludge treatment system and process. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

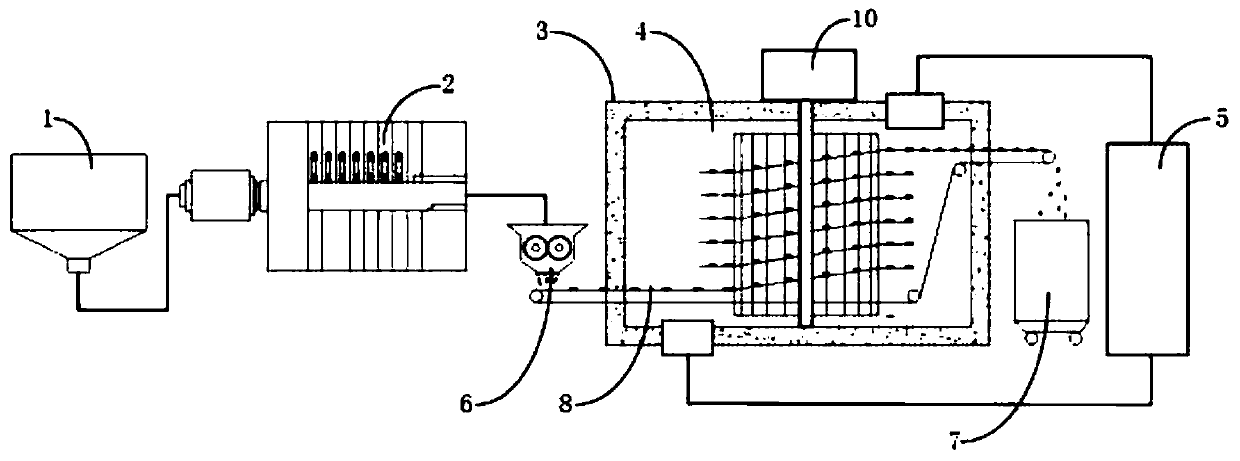

[0041] sludge treatment systems such as Figure 1 to Figure 4 As shown, it includes a mud hopper 1 for transporting mud, a filter press 2 for receiving mud from the mud hopper, and filtering the mud into mud paste with a water content of 50% to 60%, and a drying unit 3 .

[0042] The mud hopper 1 and the filter press 2 are in the prior art, and will not be repeated here.

[0043] The drying unit 3 is used to dry the mud paste into mud blocks.

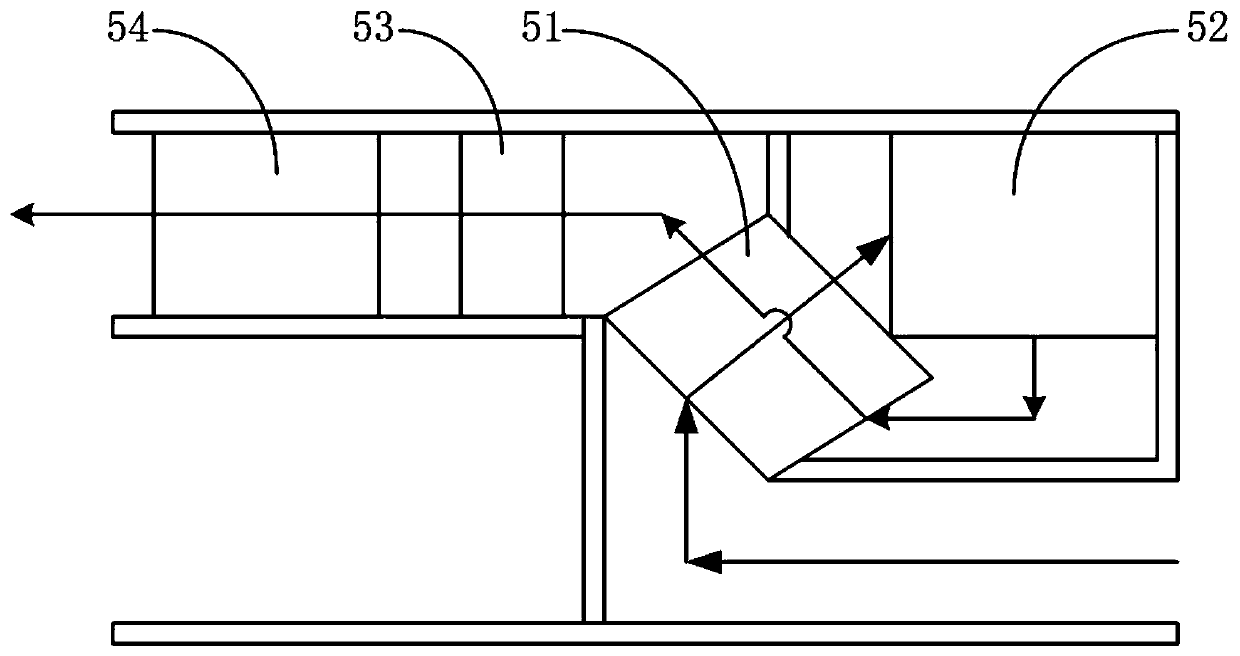

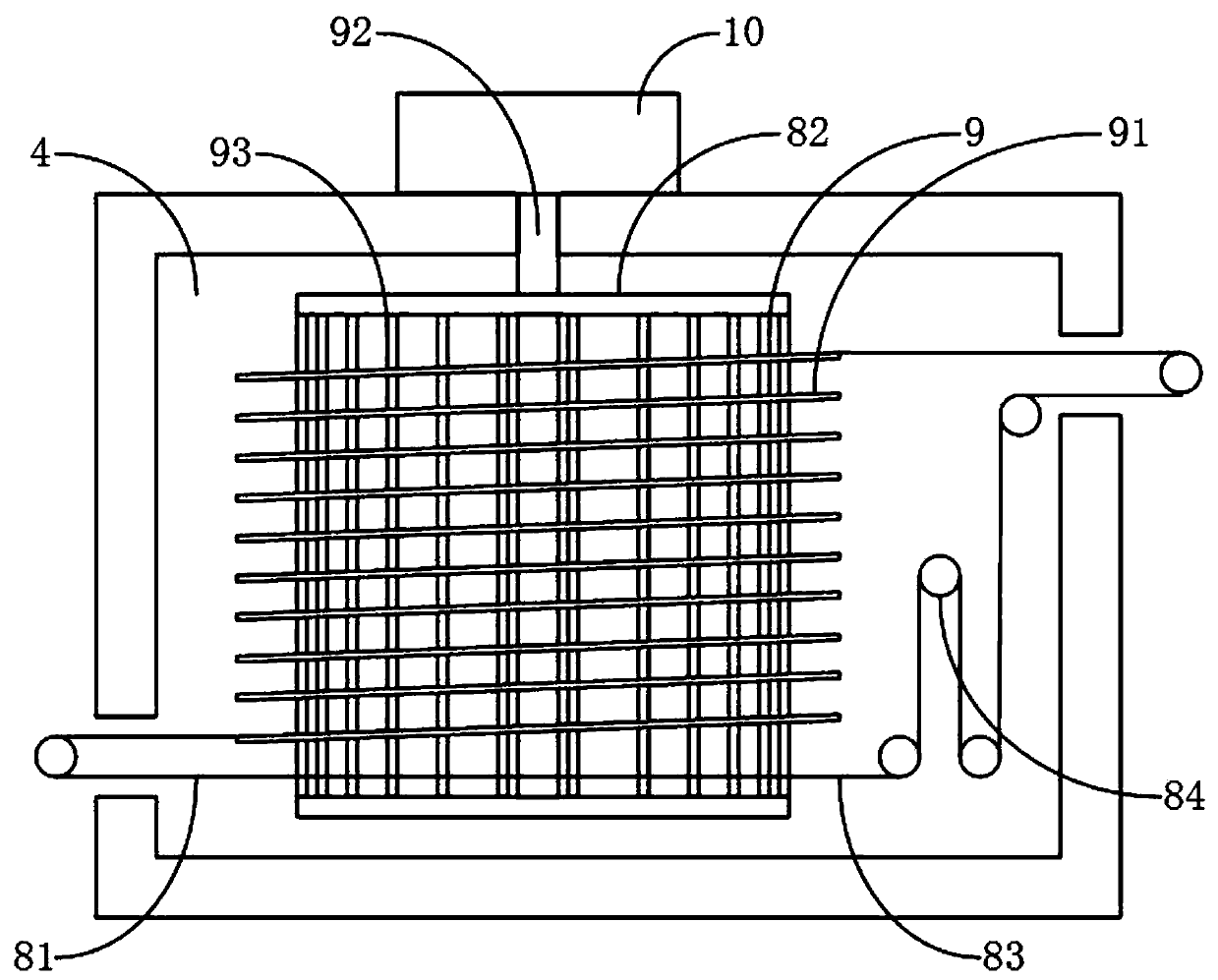

[0044] It includes a drying room 4, a hot air source circulation mechanism 5 for air circulation in the drying room 4, an extrusion mechanism 6 for extruding the mud paste into strips, and a material receiving mechanism 7 for receiving mud blocks.

[0045] The drying room 4 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com