Patents

Literature

51results about How to "Effective work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

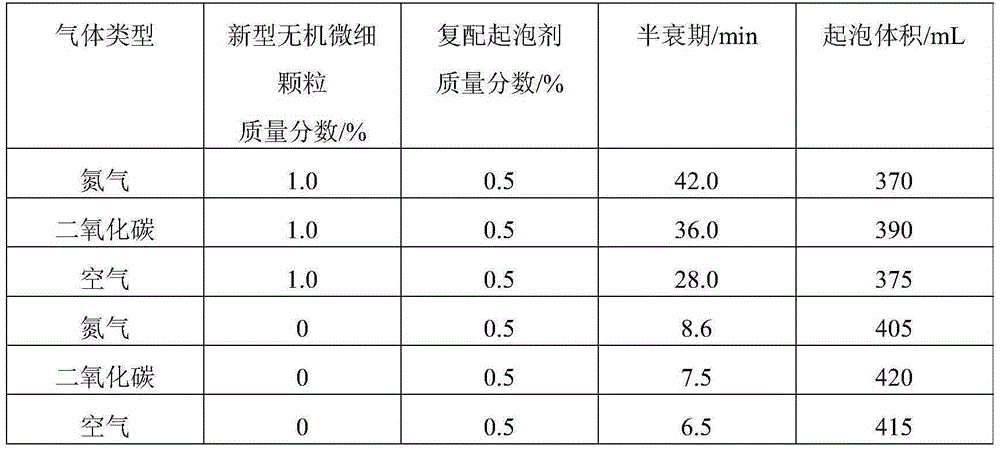

Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

ActiveCN105238380AFormation damage is smallImprove performanceDrilling compositionFoaming agentGas phase

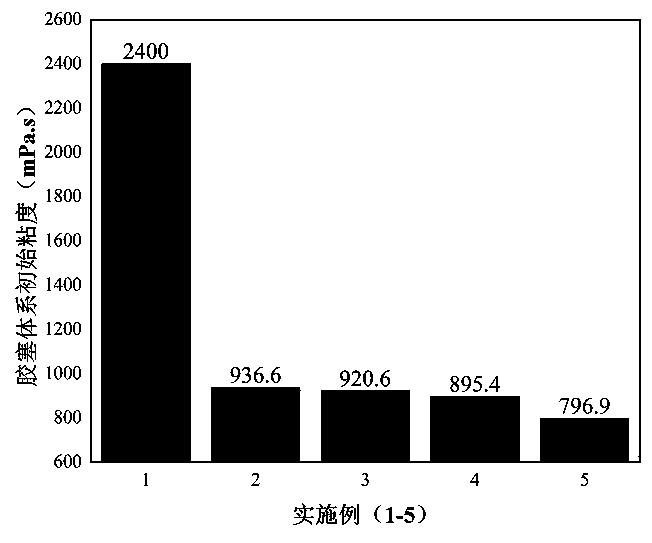

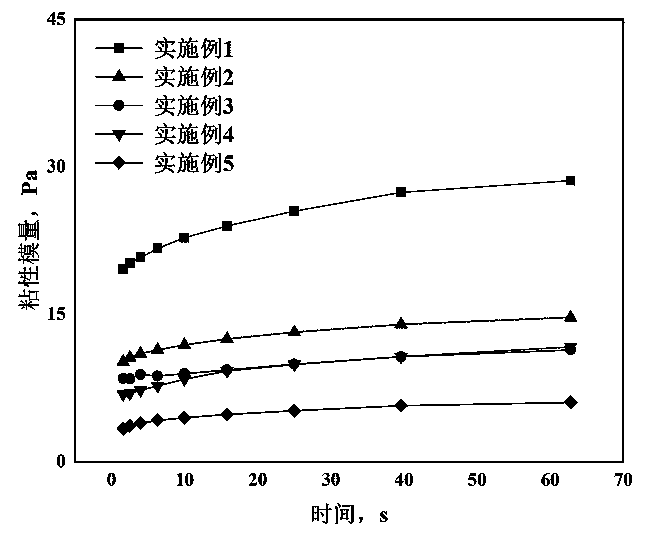

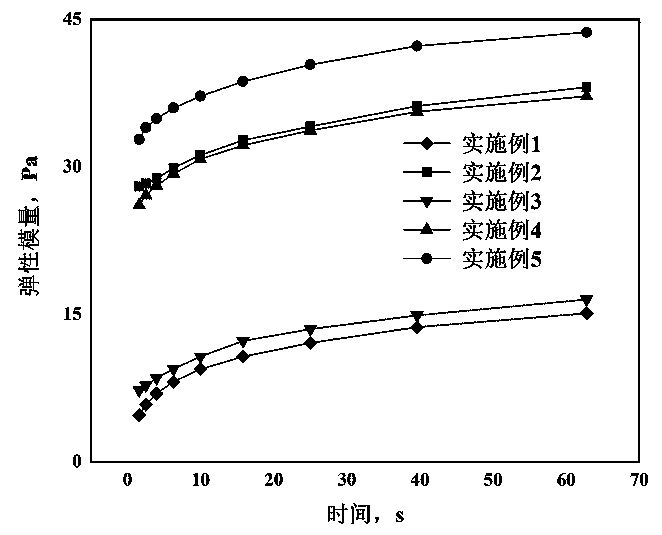

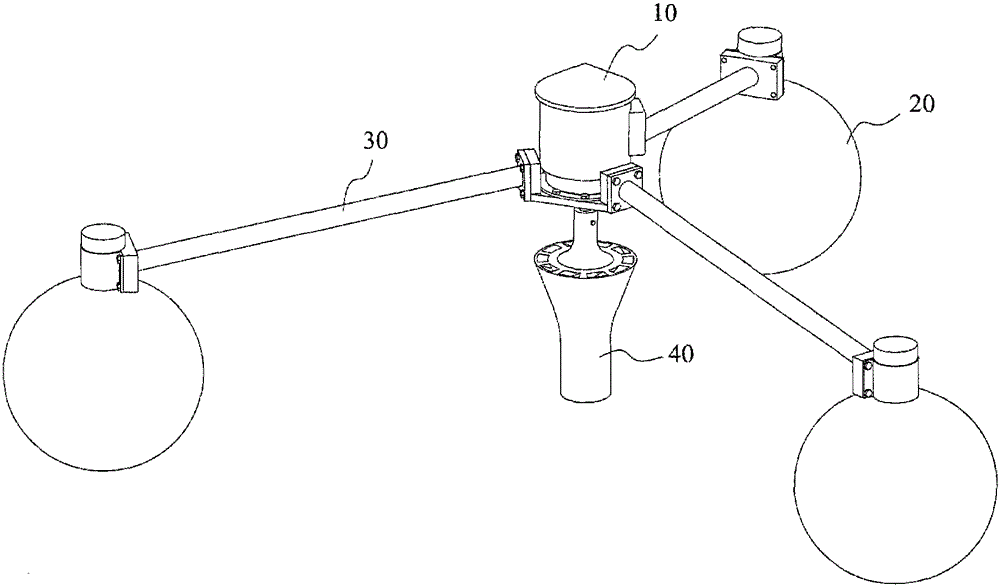

The invention relates to a novel inorganic fine particle enhanced foam system for oil and gas fields, and a preparation method thereof. The enhanced foam system comprises a gas phase and a liquid phase; the gas phase is nitrogen, carbon dioxide or air; the liquid phase comprises 0.2-0.8wt% of a foaming agent, 0.5-2.0wt% of novel inorganic fine particles, and the balance of water; and the novel inorganic fine particles are fine particles with the particle size being not greater than 2.5[mu]m, trapped and screened from air. The invention also provides the preparation method of the foam system. The enhanced foam system can be used to benefit efficient exploitation of oil and gas resources, can change the novel inorganic fine particles into valuables, reduces pollution of the novel inorganic fine particles to air environment, and has the advantages of low cost of the raw materials, simple preparation process, low operation cost, good oil and gas yield increasing effect, and high economic benefit.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

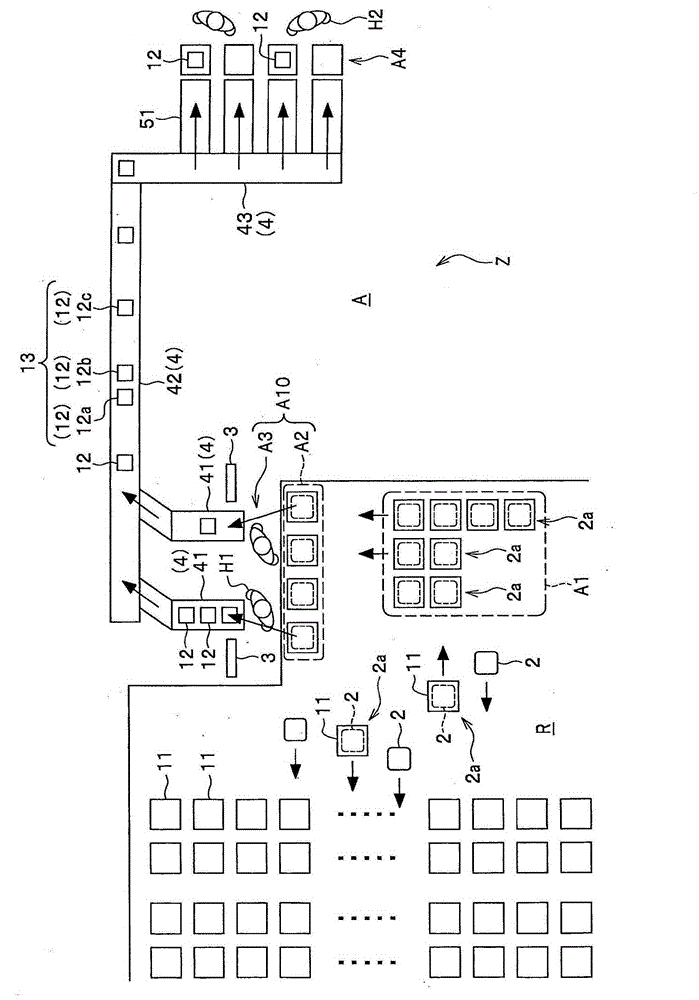

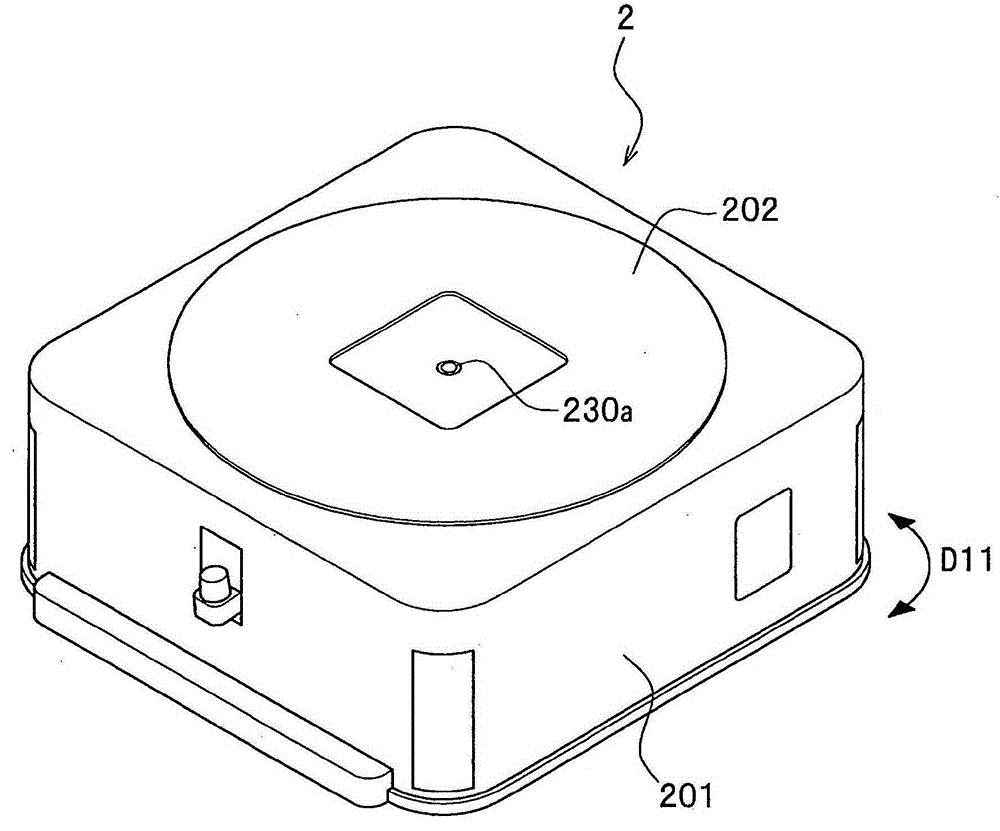

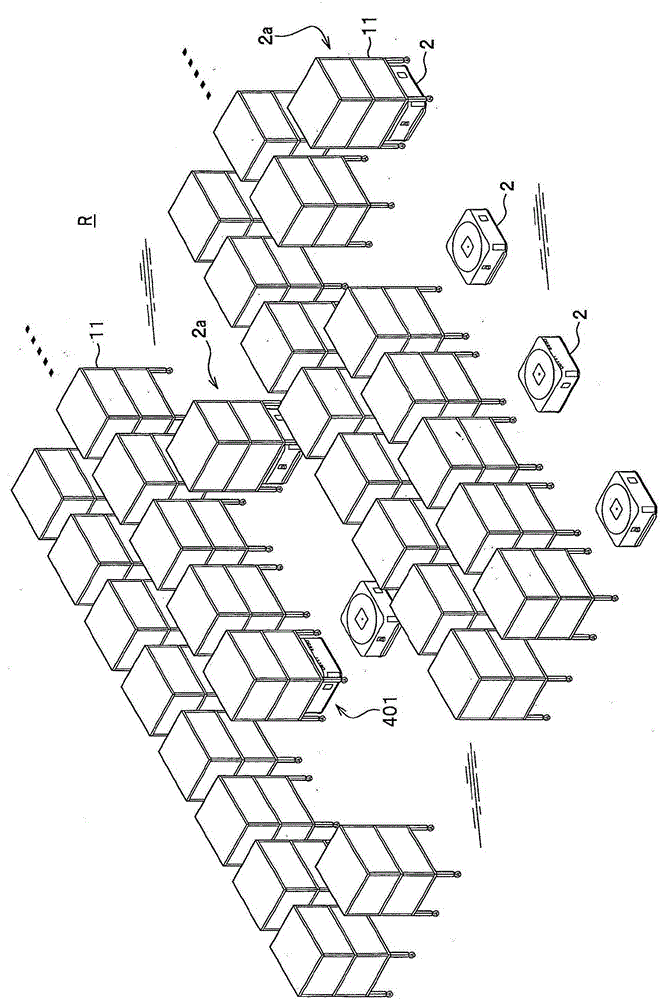

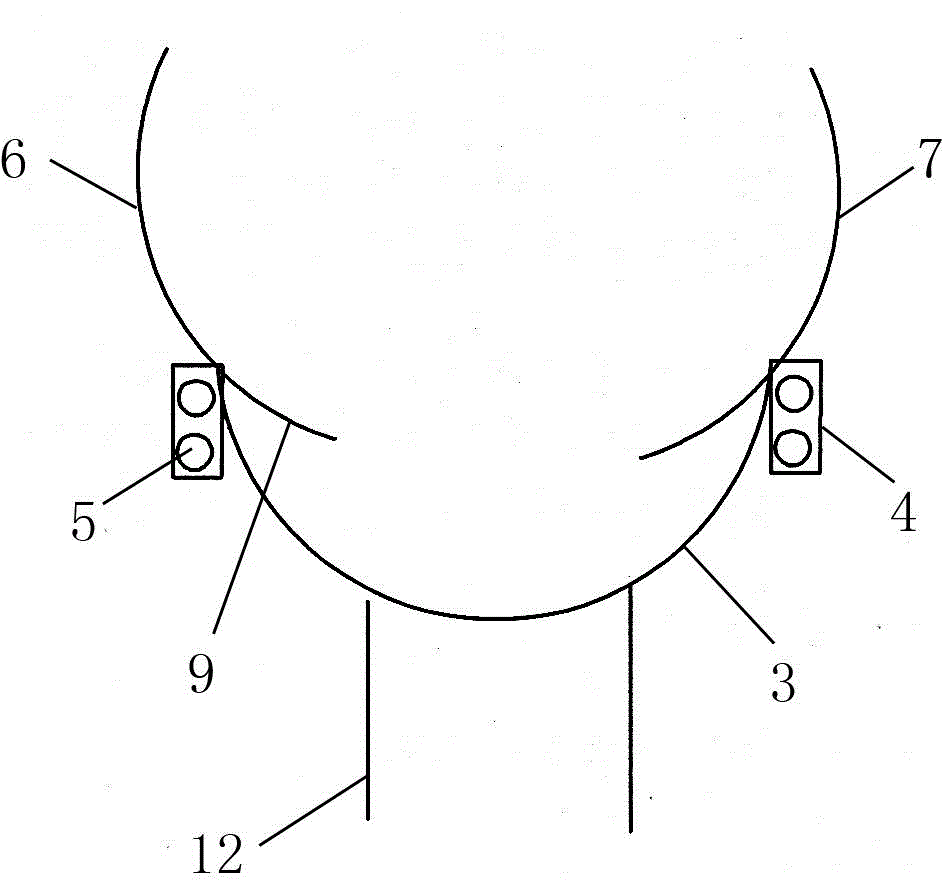

In-coming and shipment auxiliary system, unmanned carrying vehicle and in-coming and shipment auxiliary method

The invention provides an in-coming and shipment auxiliary system, an unmanned carrying vehicle and an in-coming and shipment auxiliary method. An object is to effectively carry out operation even multiple goods are shipped out in groups. The unmanned carrying vehicle (2) moves to a preset standby region (A1) when articles (12) in the article groups (13) formed by a plurality of articles (12) are carried for standby until the articles (12) forming the article groups 913) in the standby region (A1) arrive. When the articles (12) forming the articles groups (13) arrive, the unmanned carrying vehicle (2) moves to a picking region (A10) where picking operators (H1) pick up the articles (12).

Owner:HITACHI LTD

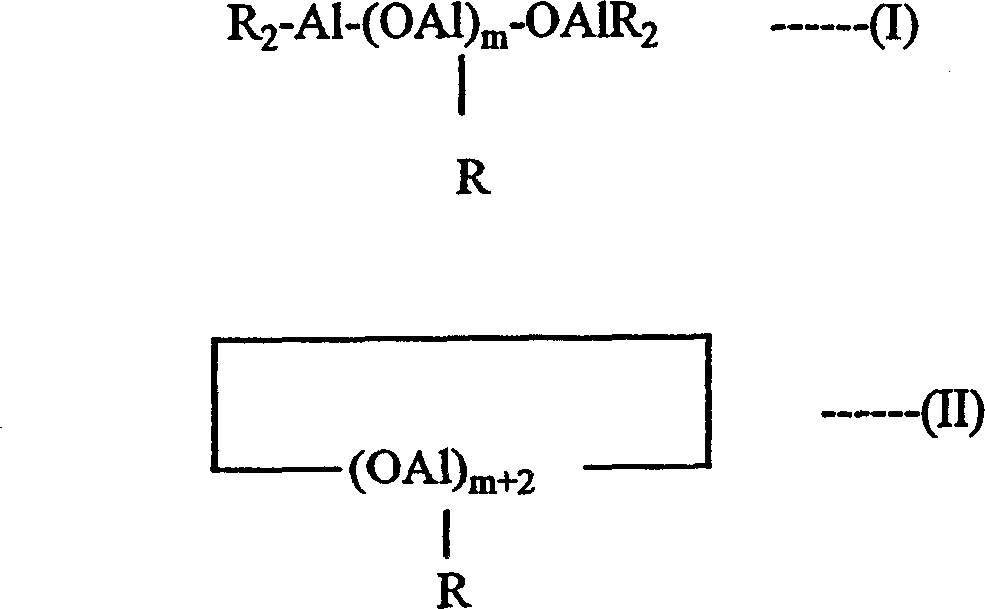

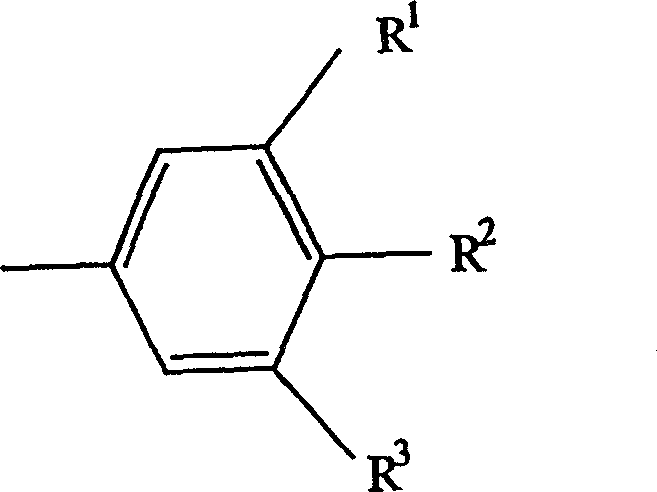

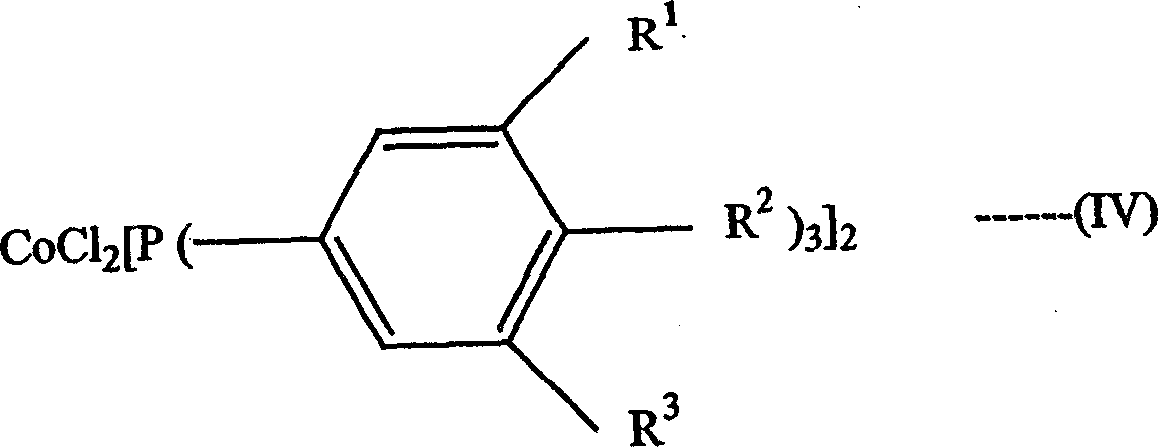

Oil extended 1,2-polybutadiene and method of manufacturing polybutadiene, and composition and formed product thereof

InactiveCN1511176AExcellent formabilityHigh mechanical strengthSynthetic resin layered productsHeelsFoaming agentWear resistance

Disclosed are oil-extended 1,2-polybutadiene containing an extender oil in a specific amount based on 1, 2-polybutadiene and a production method thereof, and a composition further containing another (co)polymer, a foaming agent, a crosslinking agent, a softening agent and other additives. The resulting oil-extended 1,2-polybutadiene and the composition thereof has excellent functions characterizing conventional 1,2-polybutadiene and is further excellent in wear resistance, fluidity (processability), coloring properties (high distinctness of images), flexibility, attachability and the like, so that they can be applied to various formed articles, shoe sole materials and laminate having high performances.

Owner:JSR CORPORATIOON

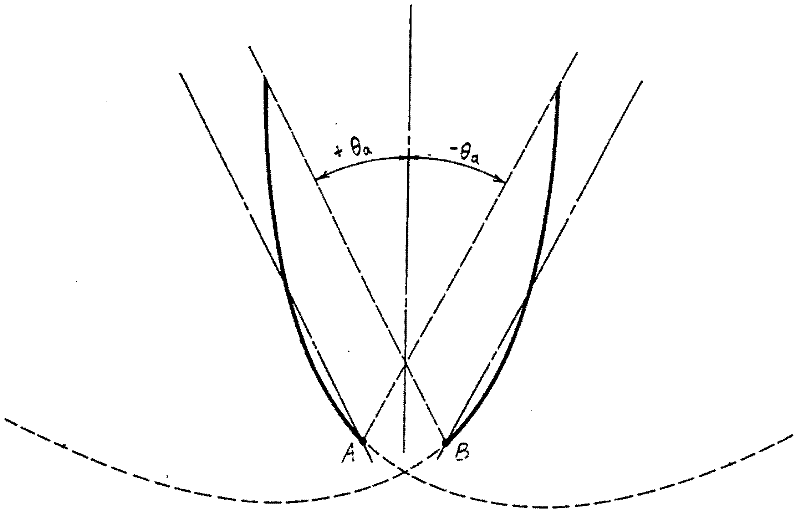

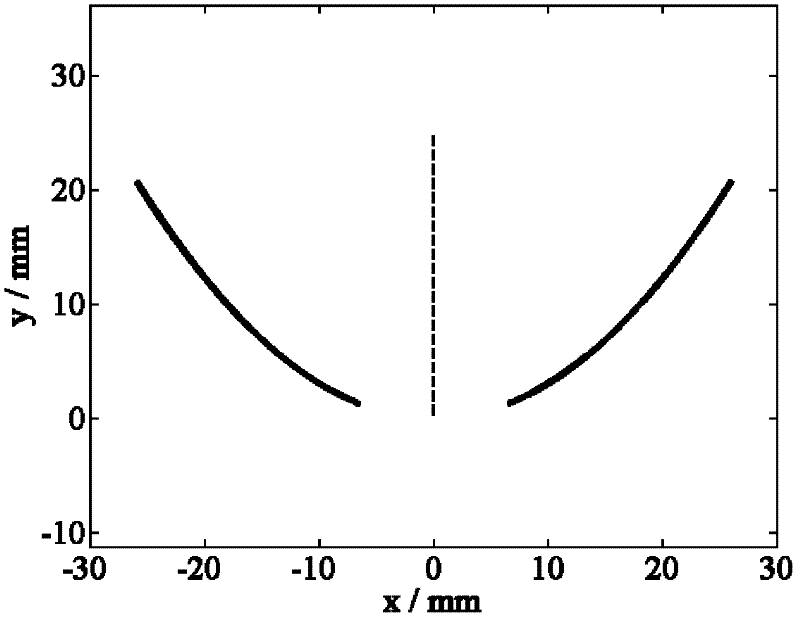

Two-stage asymmetrical composite parabolic reflector condenser in smooth transition connection

InactiveCN102213825AImprove spotlight effectEffective workMirrorsCondensersOptical radiationNon symmetric

Owner:ZHEJIANG UNIV OF TECH

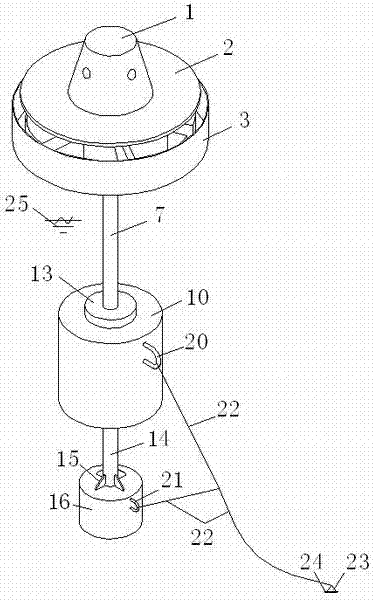

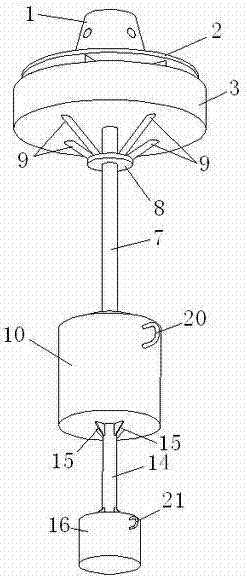

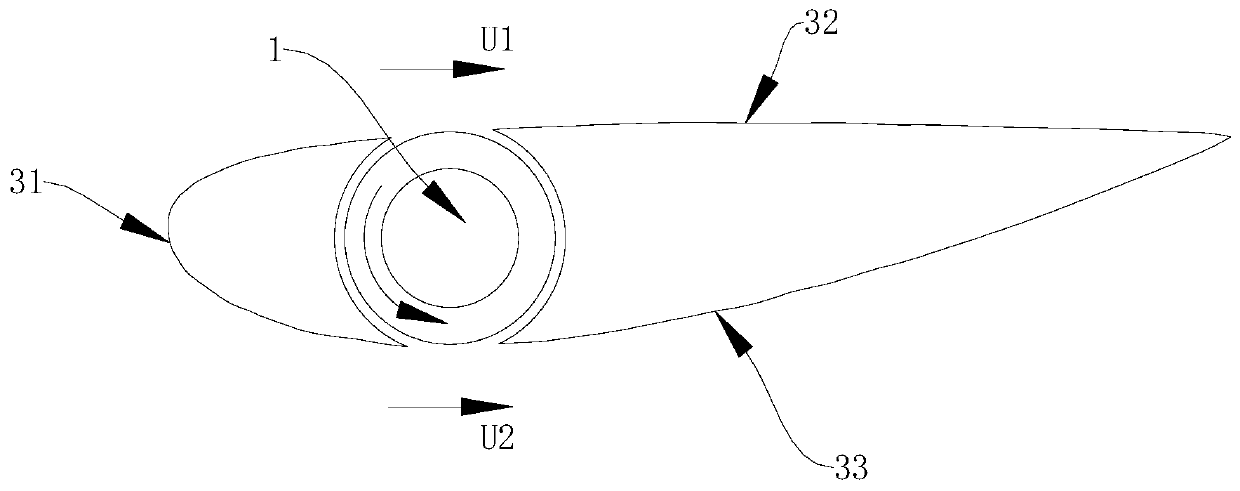

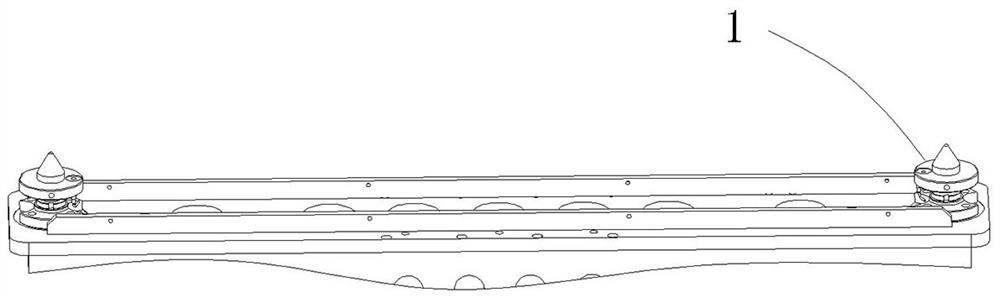

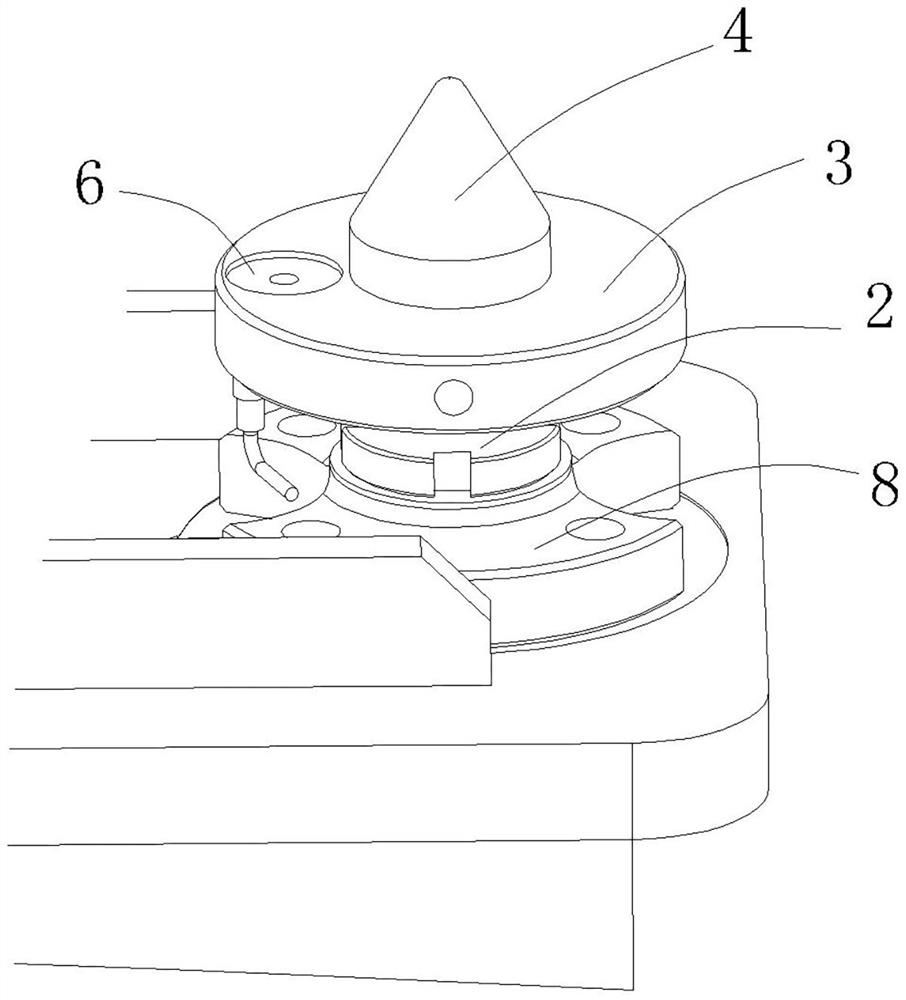

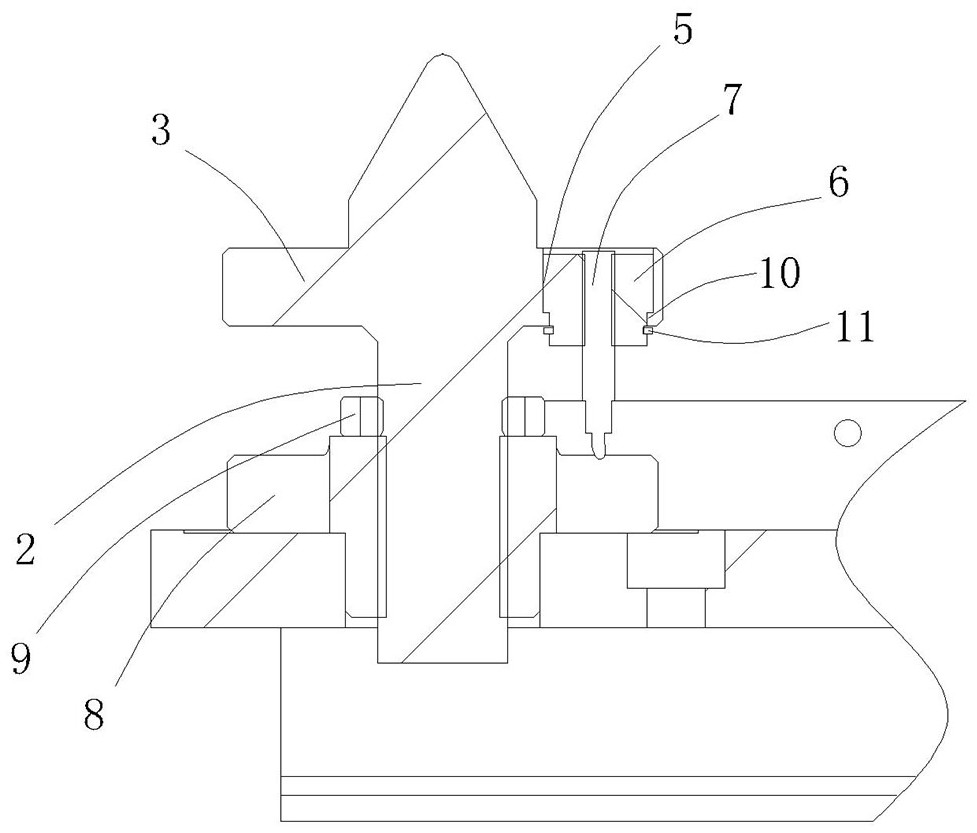

Sea surface adaptive observation platform device

ActiveCN106882336AImprove damping abilityHas self-righting propertiesSpecial purpose vesselsAnchoring arrangementsMarine engineeringOptical measurements

The invention discloses a sea surface adaptive observation platform device, and belongs to the technical field of ocean engineering and ocean environment detection. The observation platform device comprises a platform deck, an observation mechanism, a first-stage swing reducing and self-righting mechanism and a second-stage swing reducing mechanism. A lower supporting rod is connected with a balance weight cabin and a buoyancy cabin, and an upper supporting rod is inserted in a sleeve of the buoyancy cabin to be fixed. The upper end of a wing-type support is connected to the platform deck, the lower end of the wing-type support is connected to a fan-shaped floating cabin, the upper supporting rod is connected with a water tray, water is added in the water tray, and a combination of the fan-shaped floating cabin, the wing-type support, the platform deck and the observation mechanism floats in the water in the water tray. The center of buoyancy of the observation platform device is located above the centre of gravity all the time, and the sea level is located at the upper middle position of the buoyancy cabin and the water tray. The observation platform device is simple in structure, convenient to use, high in stability, high in swing resisting and swing reducing capability, capable of saving energy and small in maintenance workload, and can carry optical measurement instruments or other monitoring and detecting instruments.

Owner:DALIAN UNIV OF TECH

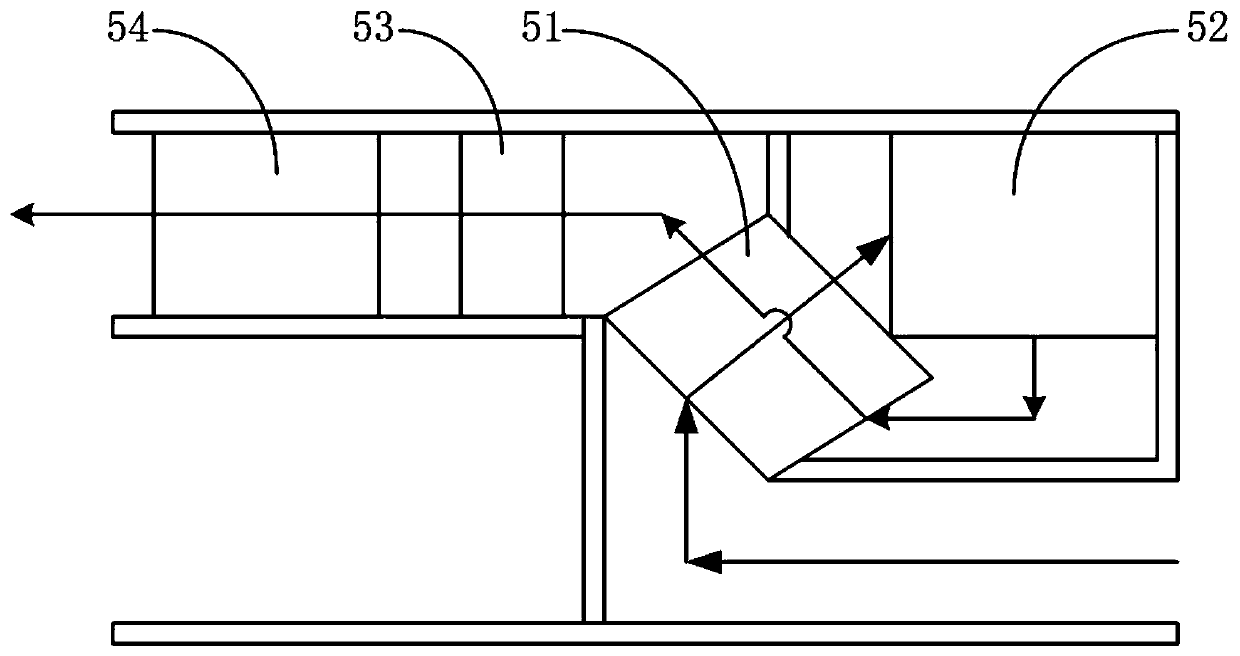

Pneumatic wedging pushing method and apparatus thereof

A pneumatic wedge-type method and mechanism for pushing vehicle features that the vehicle is pushed to move by the friction force between the push wheel and the wheel of the vehicle to be pushed. Its advantages are light weight and small size.

Owner:株洲市长征机电设备有限公司

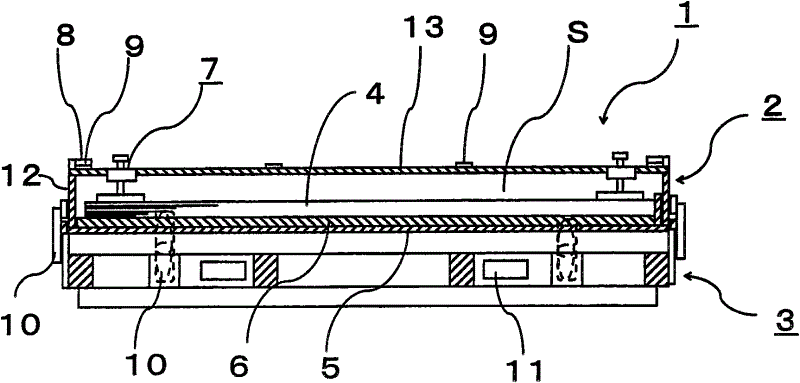

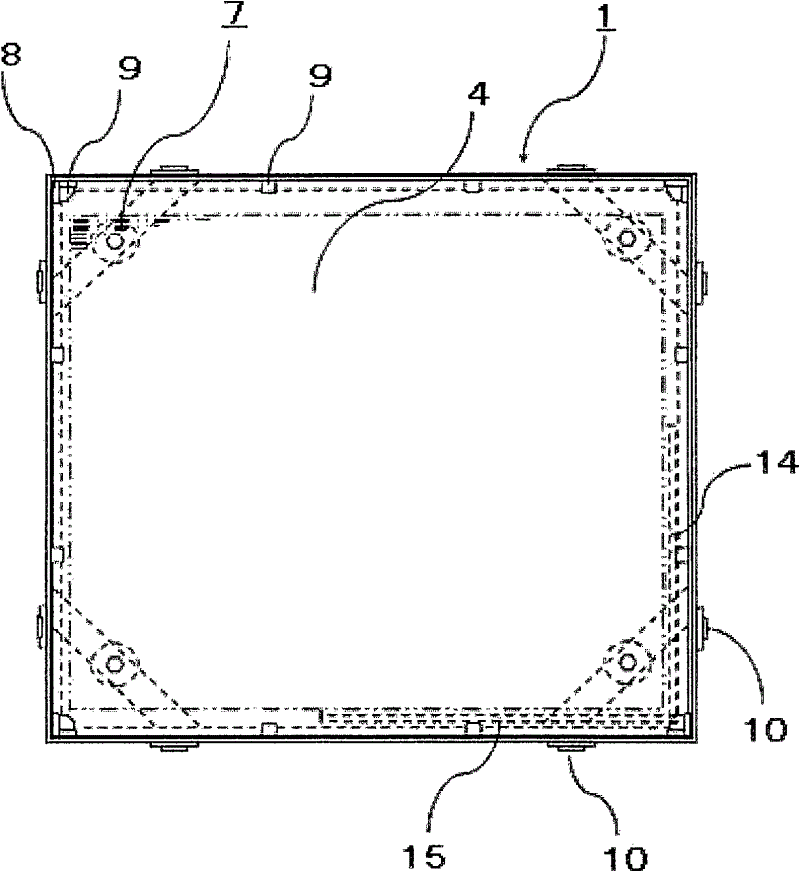

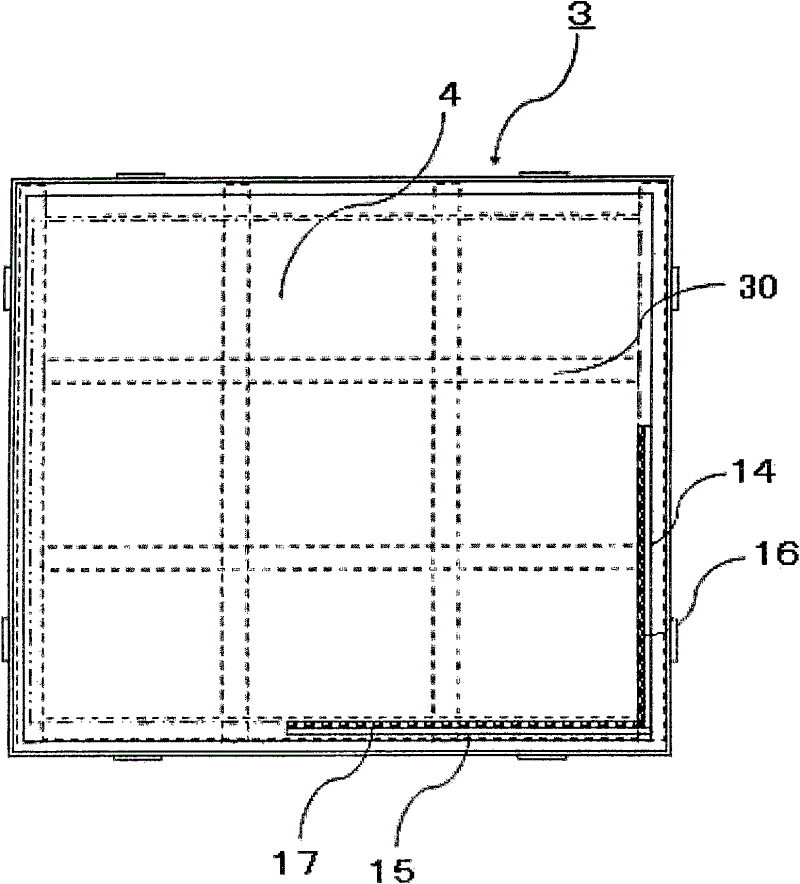

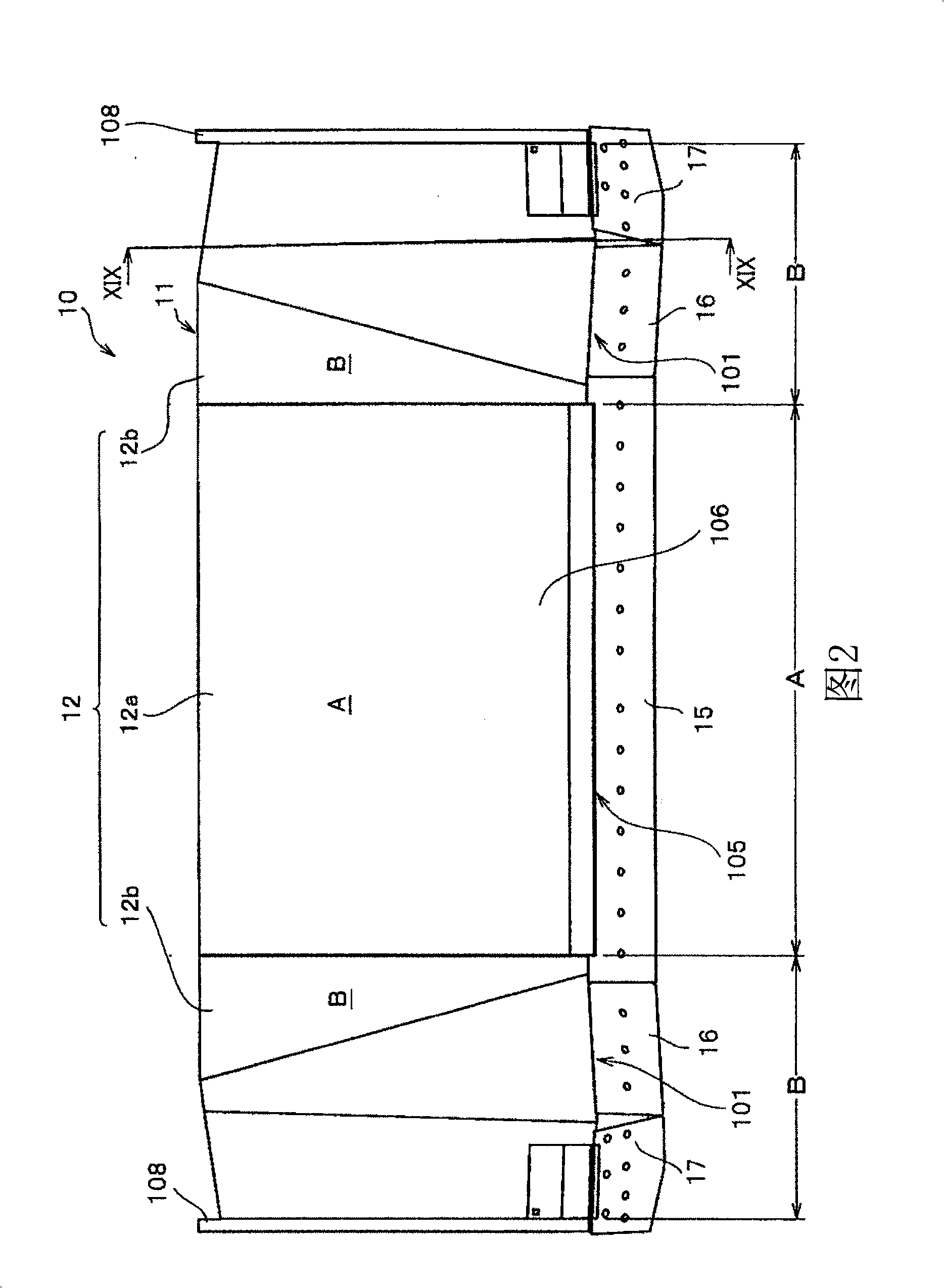

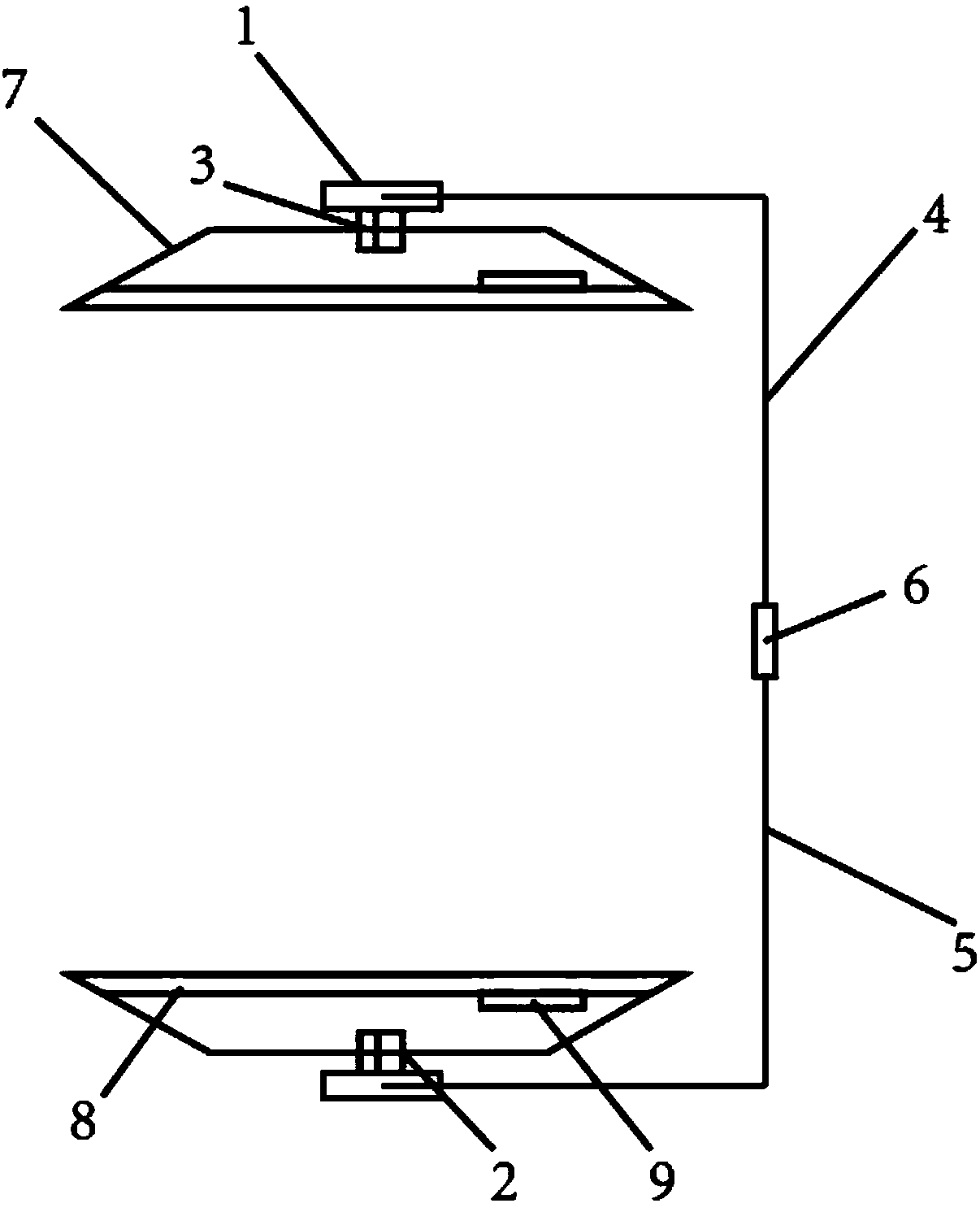

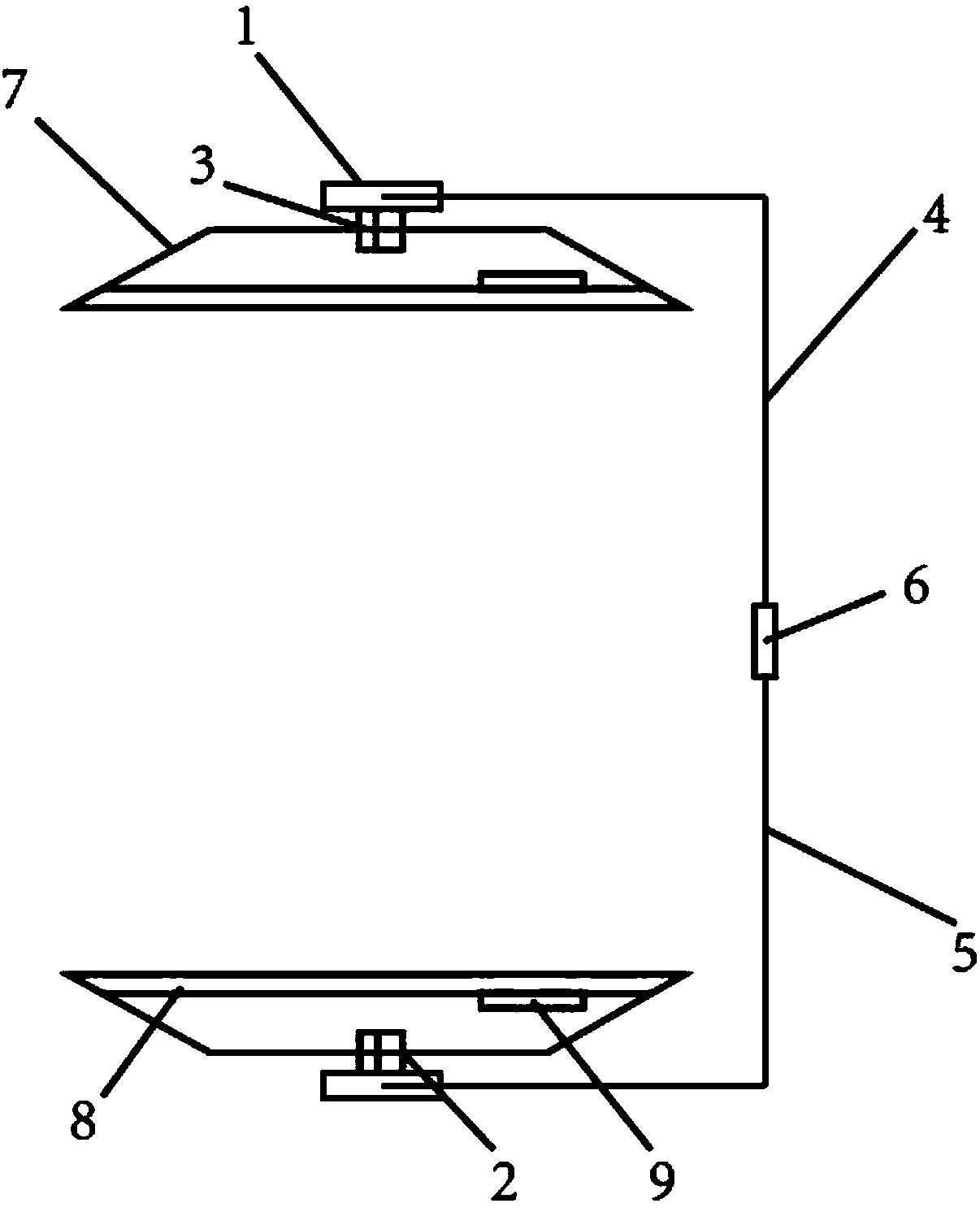

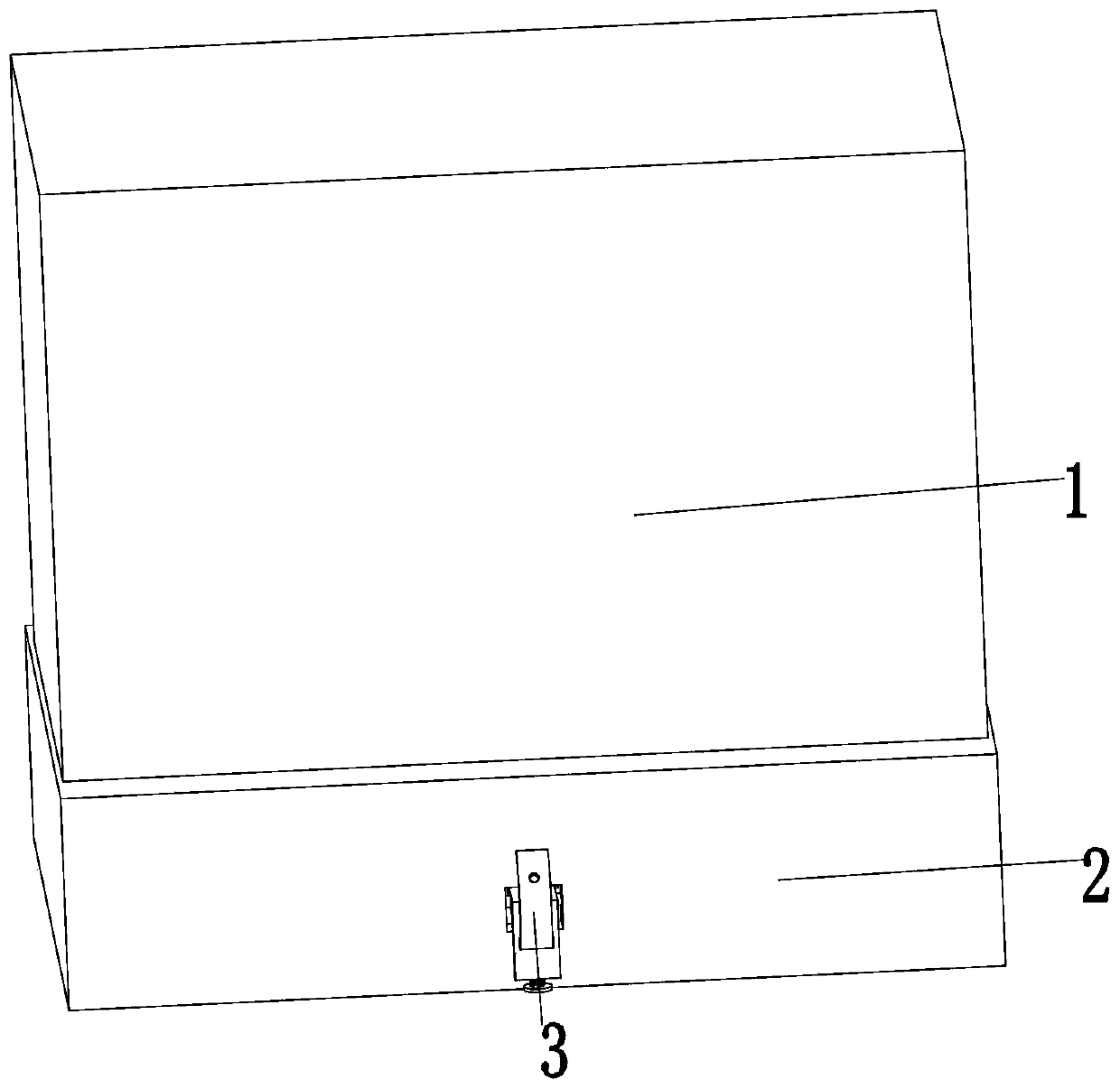

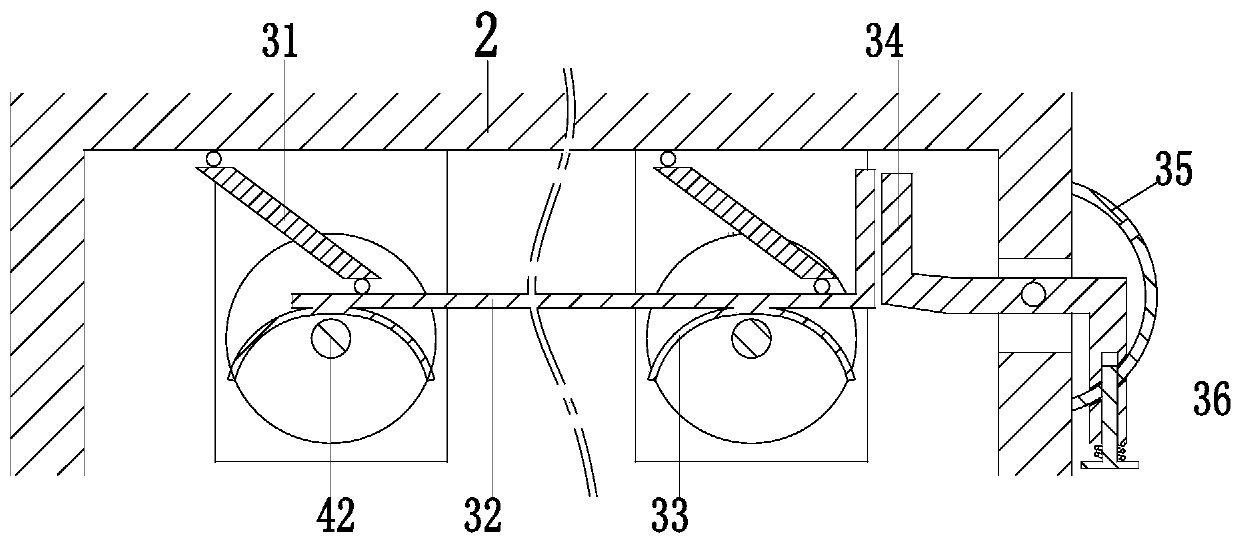

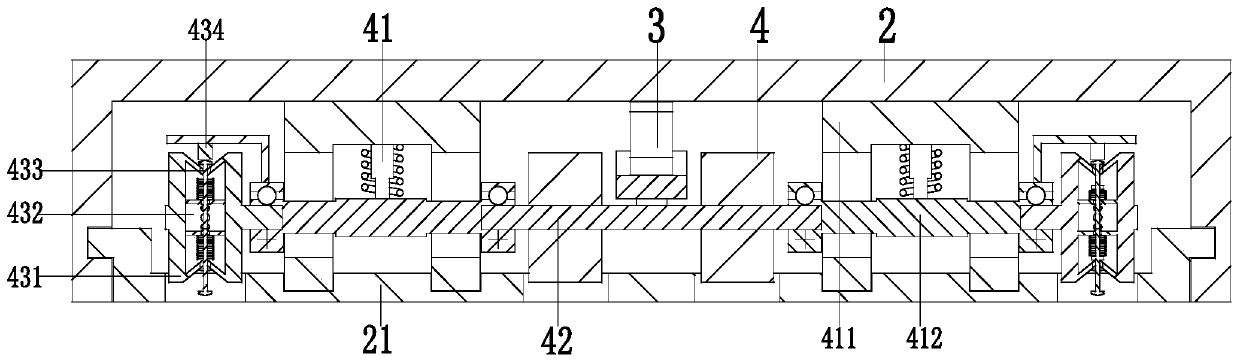

Large plate-shaped body packaging box

InactiveCN102616487ALower the altitudeNo incisionContainers to prevent mechanical damageRigid containersEngineering

The invention provides a large plate-shaped body packaging box, a method for transporting plate-shaped bodies by using the plate-shaped body packaging box, a method for loading the plate-shaped bodies, and a method for taking the plate-shaped bodies out. Dust is prevented from invading the packaging box, height during conveying is reduced, the packaging box can be easily stored in a storage room with a low top, and the plate-shaped bodies are efficiently and stably stored and transported. The plate-shaped body packaging box comprises a pedestal (3) with a veneer material, a plate-shaped body packaging box body (1) loaded on the pedestal (3), and an upper cover (2) which encircles the plate-shaped bodies (4) loaded on the pedestal (3) and can be assembled and disassembled relative to the pedestal (3), wherein the pedestal (3) is a supporting body with an open upper surface and comprises plate-shaped body protection materials (6) and side plates (14 and 15), a plurality of plate-shaped bodies (4) are fixed on the upper surface of the veneer material (5) in an approximately horizontally laminated state, and the side plates (14 and 15) are arranged on two sides in an L shape in the four sides; and the upper cover (2) consists of a top cover (13) which covers the upper surface of the plate-shaped body packaging box body (1) and side covers (12) on the four sides, has a shape of a box body with an open lower surface, and is provided with pressing pieces (7) which press the upper parts of the plate-shaped bodies.

Owner:ASAHI GLASS CO LTD

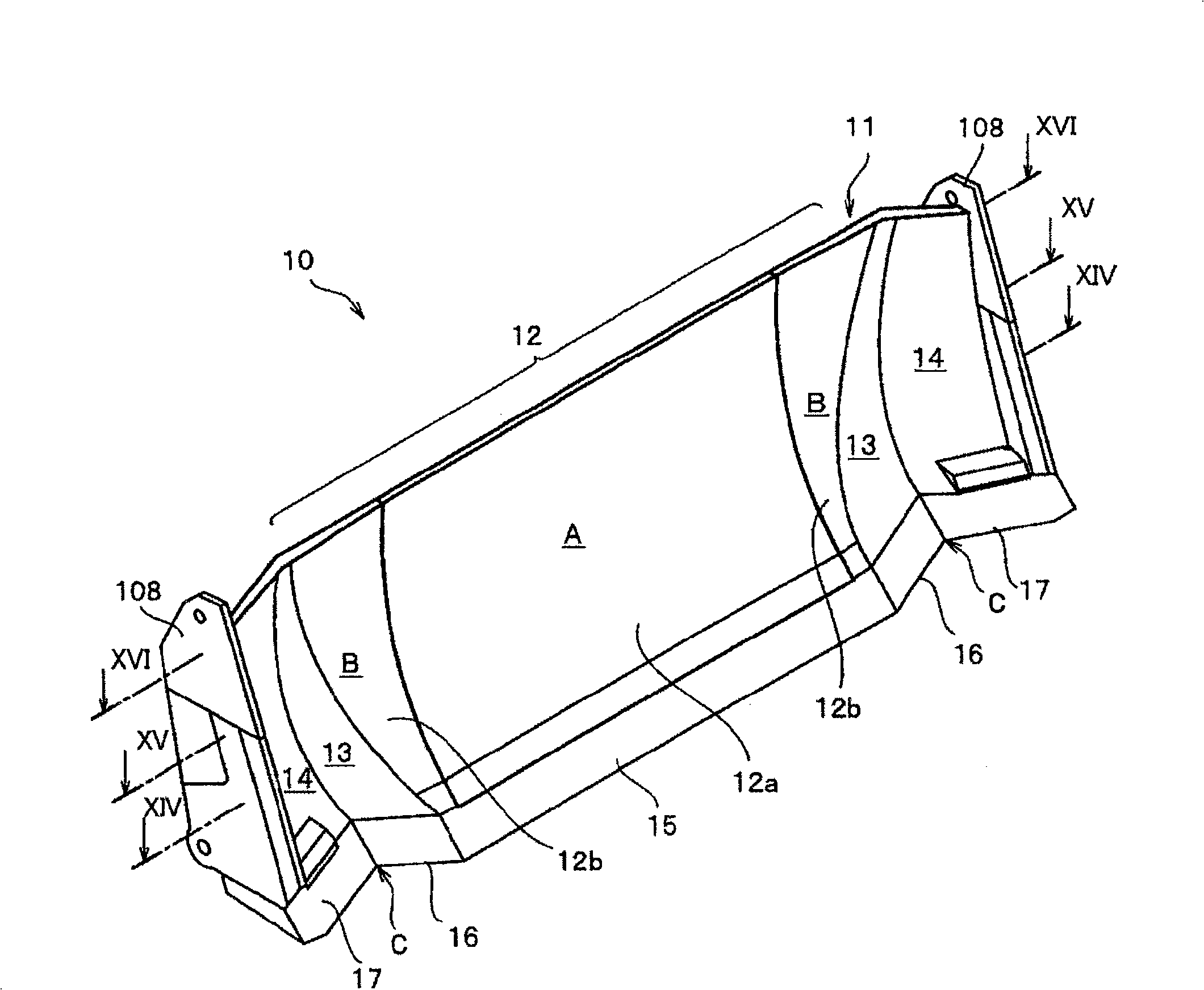

Blade device for working machine and working machine mounted with the same

The present invention provides a blade deice for a working machine, having an overall blade width of W, and having a center front-face section (12) that has at its lower end a rectilinear first cutting blade (15) with a predetermined blade width (W1), connection front-face sections (13) each having a second cutting edge (16) that extends rearward continuous from the first cutting blade (15) and bent at a predetermined angle d relative to the first edge (15), and end front-face sections (14) each having a third cutting edge (17) that extends continuous from the second cutting blade (16) and is bent at an angle theta relative to a line extended from the first cutting blade (15). When each cutting blade (15-17) extends in a tangential direction from the lower end of each front-face sections (12-14), a blade edge angle a of each cutting blade (15-17) is in a cutting position in a rage of 40 DEG - 55 DEG , and the height, in a side view, from the edge of the first cutting blade (15) to the upper end of the blade is H, the blade device satisfies the following expression: R2 = (0.7 to 1.0) H ...(1).

Owner:KOMATSU LTD

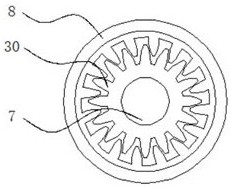

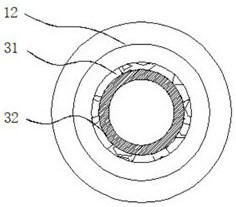

Laser head used for laser welding and facilitating to multi-directionally adjust angle

ActiveCN109175699AKeep it workingReduce cleaning timesLaser beam welding apparatusEngineeringImpurity

The invention discloses a laser head used for laser welding and facilitating to multi-directionally adjust an angle, relates to the technical field of welding, and specifically discloses a laser headused for laser welding and facilitating to multi-directionally adjust an angle. The laser head used for laser welding and facilitating to multi-directionally adjust the angle comprises a slide rail, an inner gear sleeve and a main gas pipe, wherein a slide block is installed at the middle part of the slide rail, and a stainless steel housing is installed above the slide block; a support rod is installed above the inner gear sleeve, and the inner gear sleeve is located above the stainless steel housing; and a servo motor is installed above the support rod. According to the laser head used for laser welding and facilitating to multi-directionally adjust the angle, through the cooperation among a compressor, the main gas pipe and a gas blowing pipe, inert gas in a gas storage tank can be effectively guided into the gas blowing pipe; when the laser head applies work on a workpiece, the gas blowing pipe blows the inert gas to a welding part of the workpiece, and the problem that the weldingpart of the workpiece is infirm and incapable of achieving the needed working effect because the welding part of the workpiece is rapidly oxidized, and impurities are easily generated at the weldingpart, is avoided.

Owner:四会市耀华精密机械有限公司

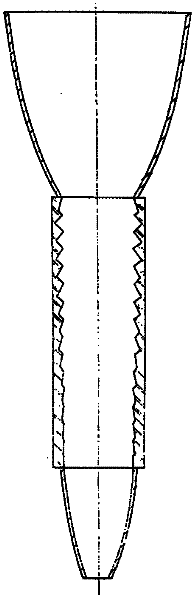

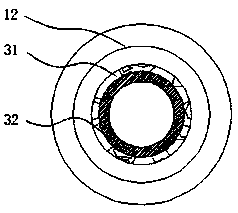

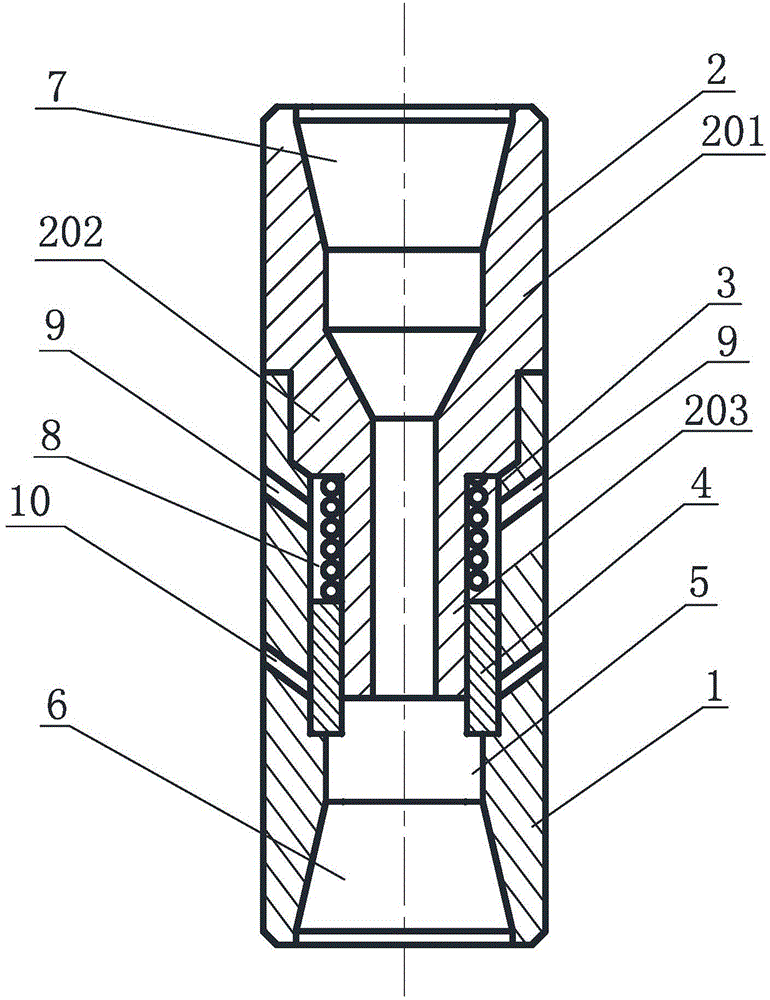

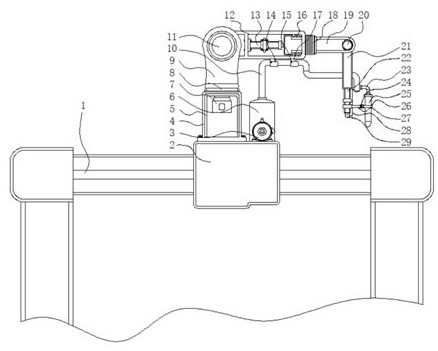

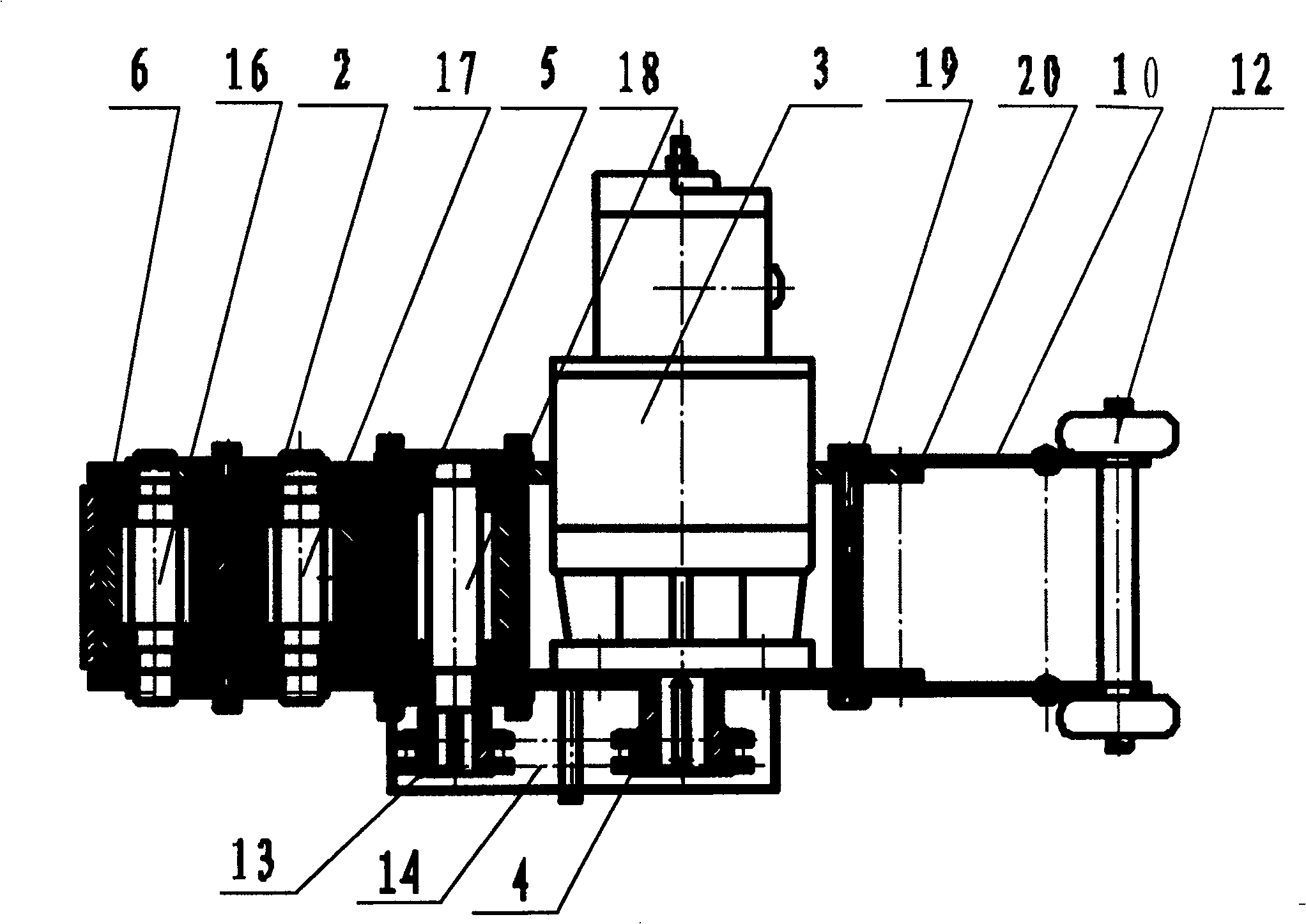

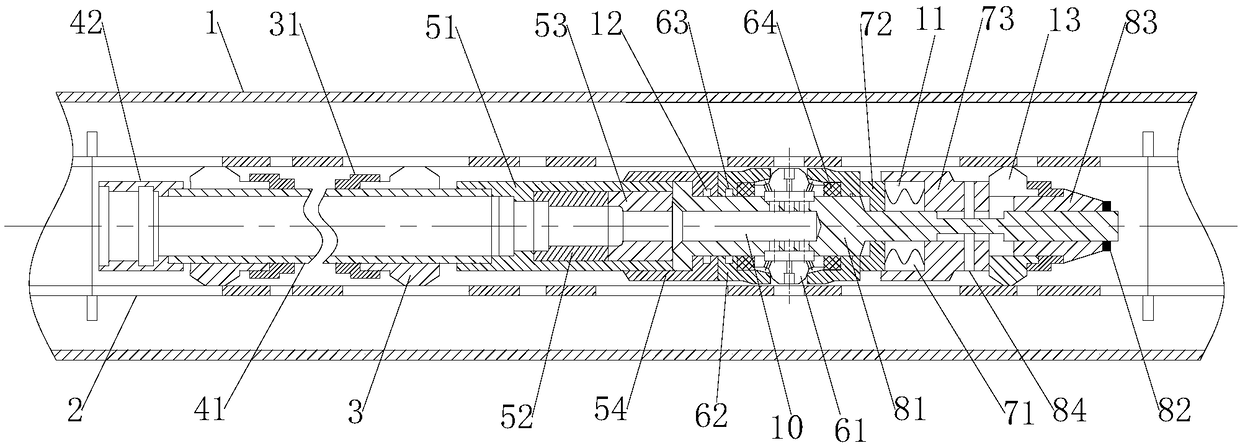

Intermittent shaft bottom pressure difference reduction sub

InactiveCN104895507AImprove jet pressure reduction effectImprove rock breaking abilityDrilling rodsDrilling casingsWater flowEngineering

The invention discloses an intermittent shaft bottom pressure difference reduction sub. The sub comprises an outer cylinder, a drill rod joint, a spring and a circular piston. A through axle hole is formed in the outer cylinder axially, the upper end of the outer cylinder is connected with the drill rod joint, part of the drill rod joint is inserted in the axle hole, and a water flow channel is formed in the center of the drill rod joint axially. The spring and the circular piston are sleeved on the lower portion of the drill rod joint and capable of moving along the axis vertically, the upper end of the spring is connected with the drill rod joint, and the lower end of the spring is connected with the upper end of the circular piston. Pressure release holes and reverse nozzles are formed in the side wall of the outer cylinder, the pressure release holes are communicated with a chamber, the upper end of the circular piston is subjected to external annular pressure, the lower end of the circular piston is subjected to drilling liquid pressure in the axial hole, and the reverse nozzles are communicated with the axle hole when the circular piston moves upwards for certain distance under the action of the pressure difference on the upper and lower ends. By means of the sub, the shaft bottom pressure difference reduction effect can be improved, the drilling speed of drilling machinery is improved, and the shaft bottom cleaning auxiliary rock fracture capacity of bit nozzles is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Rotary type two-end heat-sealing die

InactiveCN109878820AControllable job speedImprove heat sealing efficiencyWrapper twisting/gatheringEngineeringPressure sensor

Owner:TIANJIN HAIJING PLASTIC PROD

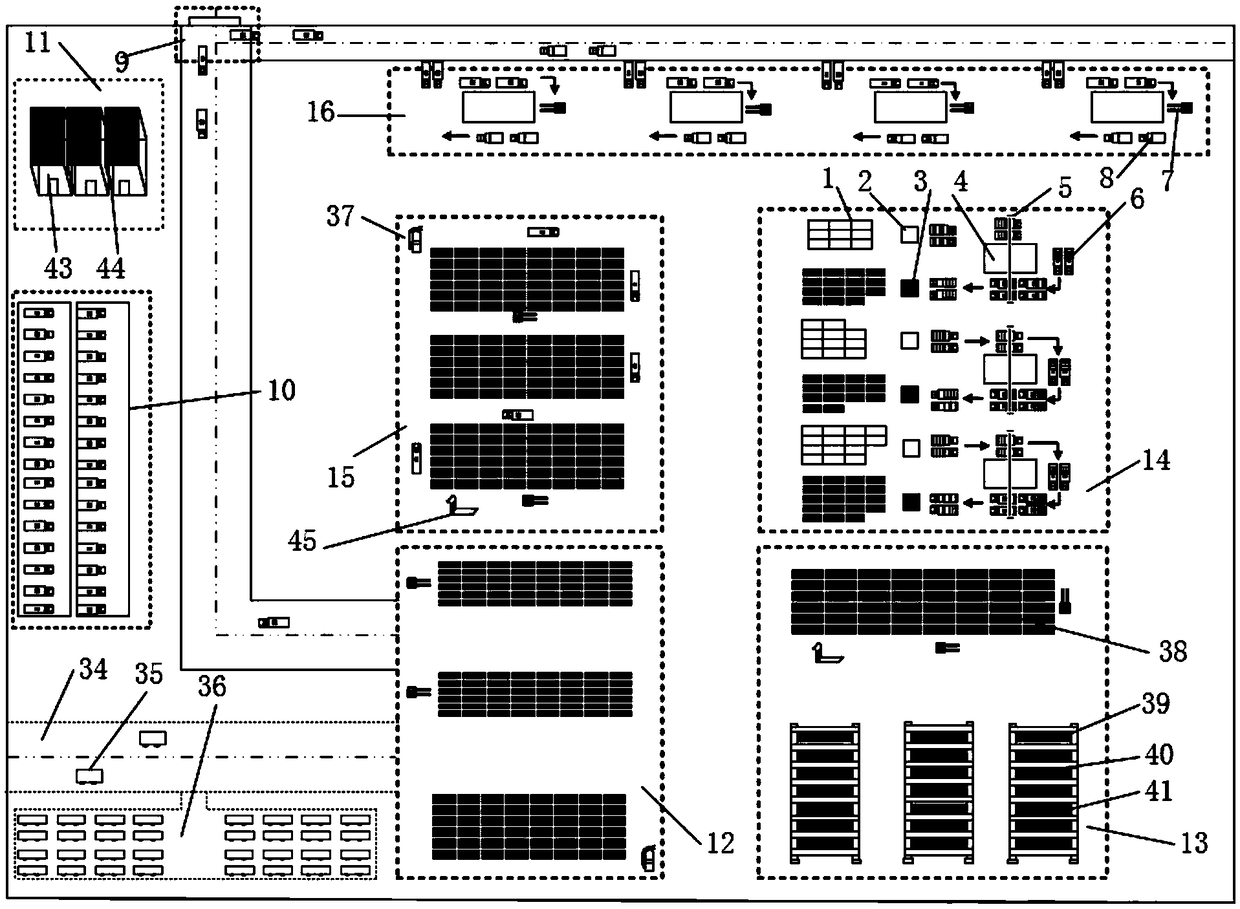

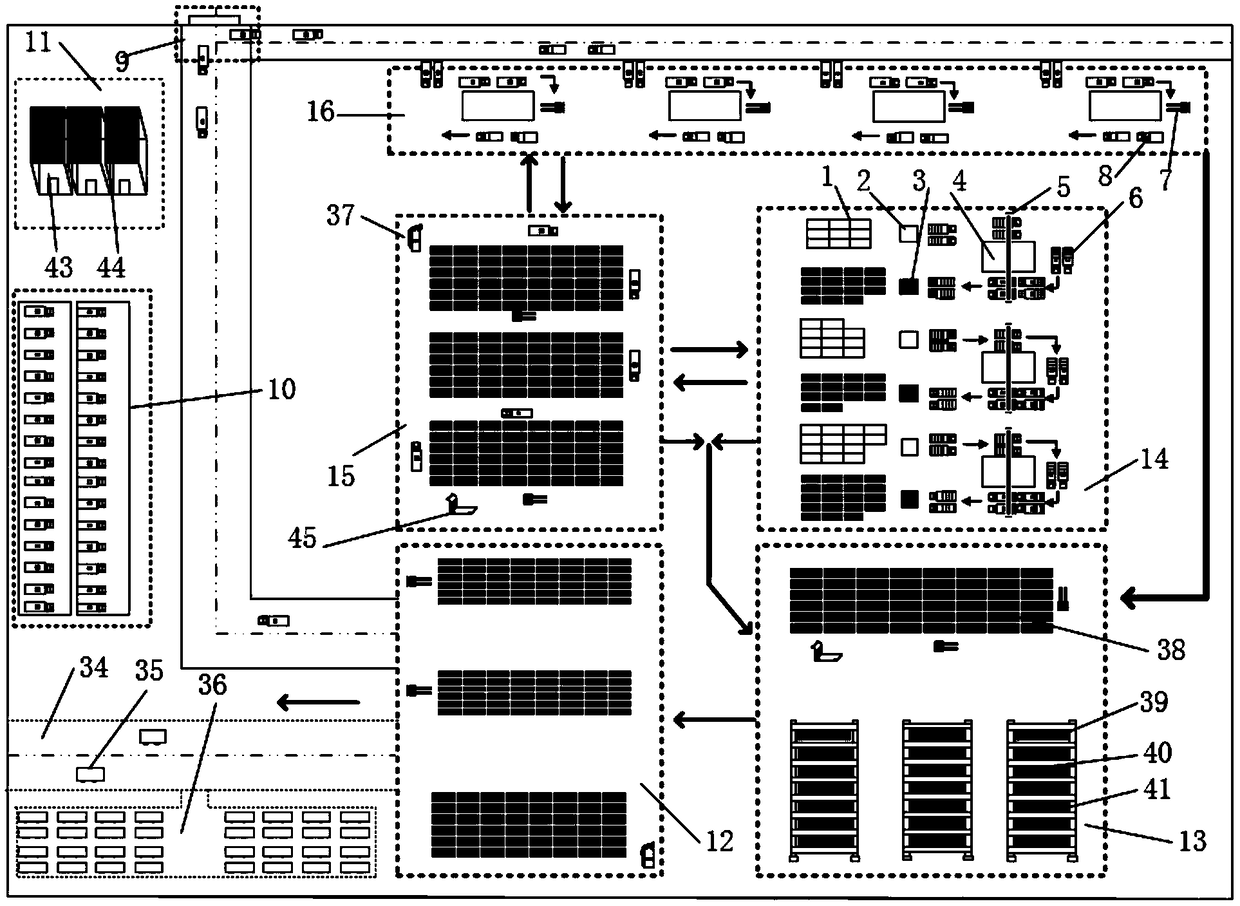

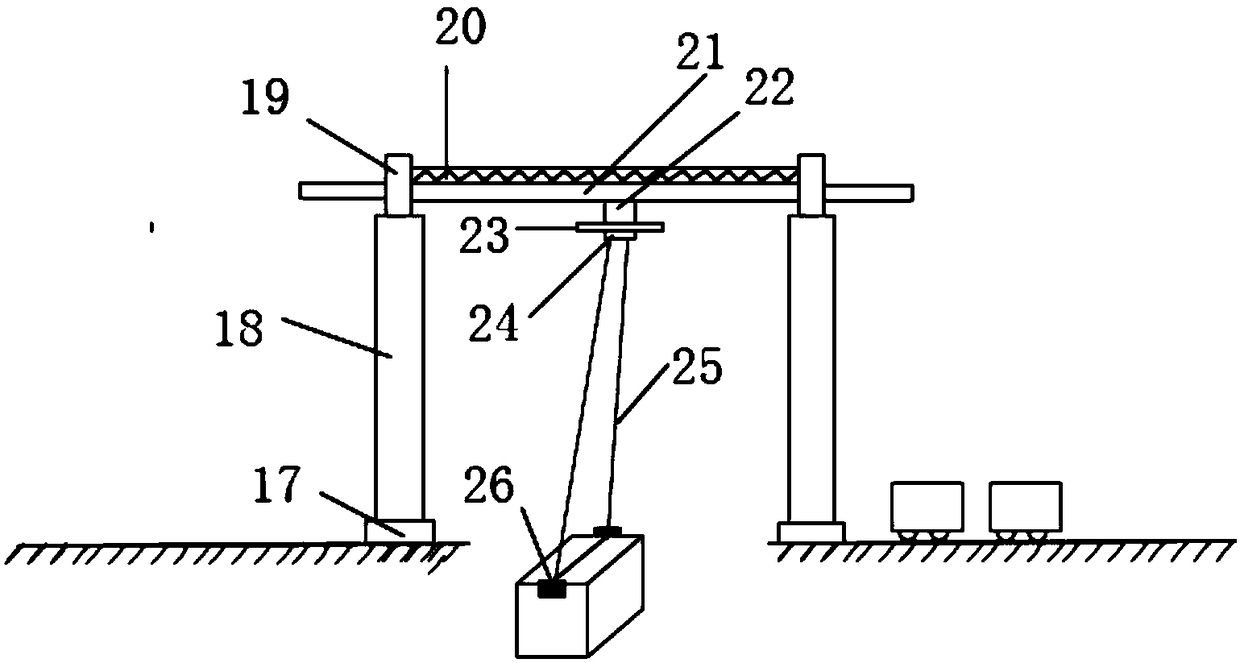

Port logistics park combined with underground logistics system

ActiveCN109319515AAchieve drainageEffective connectionStorage devicesLogistics managementPort logistics

The invention discloses a port logistics park combined with an underground logistics system. The port logistics park comprises an underground cargo loading and unloading area and the like; the underground cargo loading and unloading area includes two parts, namely, the ground part and the over-ground part, so that ground and underground operations are closely combined, and effective connection oflines between a port and the logistics park is realized; and a temporary storage yard and an underground logistics access are arranged above the ground, so that port containers an e conveyed to an over-ground logistics park in sequence. A deep-layer underground logistics passage is arranged below the underground cargo loading and unloading area and is 40-50 m below the ground; a gantry crane is arranged above the underground logistics passage, and the civil engineering cost, the transportation cost and the park ground area for ramp transportation can be saved through vertically upwards hangingof containers; and the deep-layer underground logistics passage, a shallow-layer underground logistics passage and a ground passage are designed, so that effective connection and multi-mode combinedtransportation among the port logistics park, the port and the urban area can be realized through multiple passage combined transportation.

Owner:SHANGHAI MARITIME UNIVERSITY

Preparation of recyclable high-density liquid rubber plug and degradation prediction method of recyclable high-density liquid rubber plug

InactiveCN111205836ADensity does not affectThe density does not affect the performance of the rubber stopper while improvingMaterial heat developmentDrilling compositionPolymer scienceCross linker

The invention provides preparation of a recyclable high-density liquid rubber plug and a degradation prediction method of the recyclable high-density liquid rubber plug, and relates to the field of oil-gas chemical engineering. The recyclable high-density liquid rubber plug is mainly prepared from the following components in percentage by mass through a cross-linking reaction: 30-90% of a weighting agent, 0.01-0.03% of a stabilizer, 0.2-0.6% of a reinforcing material, 1.5-2.0% of a polymer, 0.5-0.6% of a cross-linking agent, and the balance water, wherein the ratio of the polymer to the cross-linking agent is 3: 1. The recyclable high-density liquid rubber plug is prepared from the raw materials, the density is 1.2-1.5 g / cm < 3 >, and the recyclable high-density liquid rubber plug has theadvantages of being good in pumping performance, resistant to temperature, free of rubber breaking, efficient in circulating flowback and the like. Degradation time of different rubber plug systems under different temperature conditions is predicted by establishing a degradation prediction linear regression equation model of the recyclable high-density liquid rubber plug, a flowback process is guided, and safety, effectiveness and smoothness of well completion and workover operation of oil-gas wells are guaranteed.

Owner:SOUTHWEST PETROLEUM UNIV

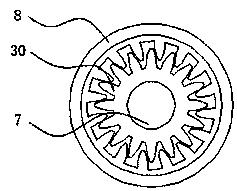

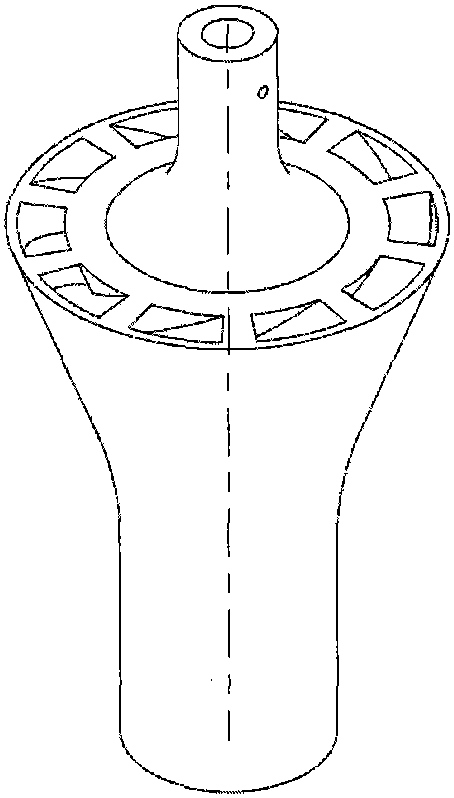

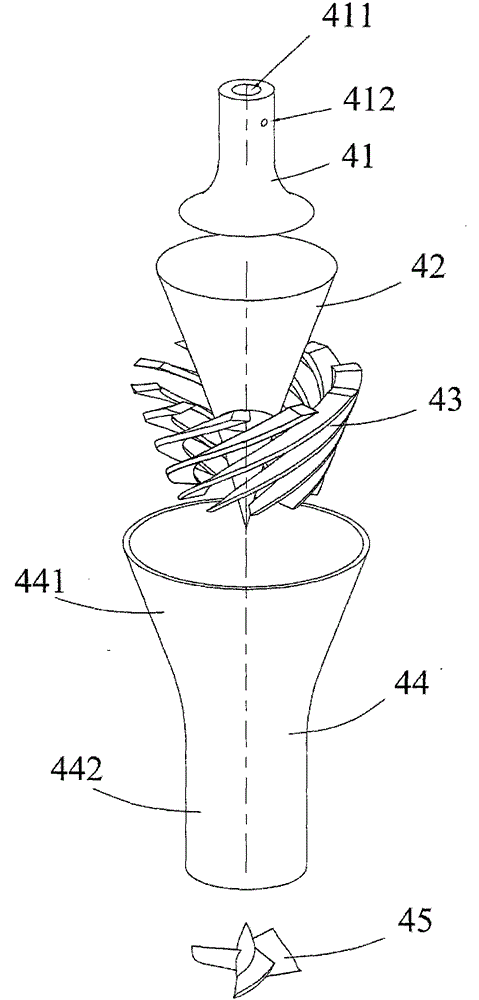

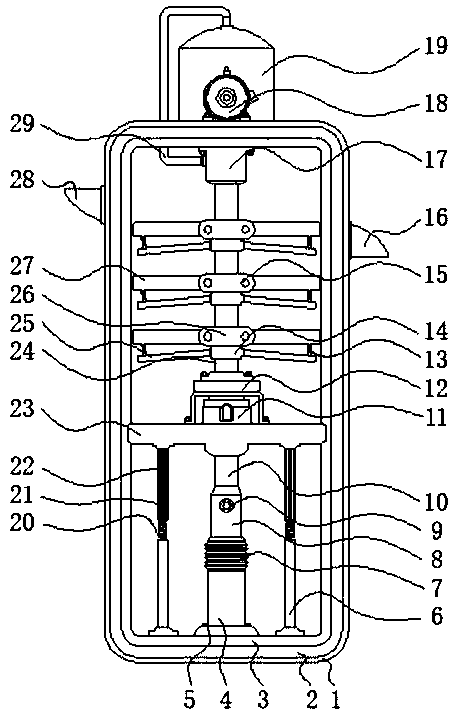

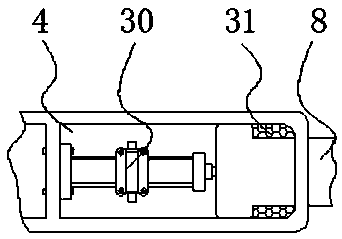

Oxygen increasing machine for aquaculture

The invention discloses an oxygen increasing machine for aquaculture. The oxygen increasing machine for aquaculture comprises a motor and further comprises a non-backflow impeller, wherein the motor can drive the whole non-backflow impeller to rotate; the non-backflow impeller comprises a centrifugal cavity; the centrifugal cavity has a water inlet and a water outlet which are relative to each other; a propeller capable of lifting water to the centrifugal cavity is arranged in the water inlet; the propeller is in no-gap connection with the side wall of the centrifugal cavity. The oxygen increasing machine for aquaculture disclosed by the invention is simple in structure, stable in performance, low in cost, low in process and low in power consumption and is suitable for increasing oxygen for water bodies for aquaculture in non-frozen water levels.

Owner:舒甦

Robot conveying mechanism facilitating disassembly and provided with balancing device

InactiveCN109397335ADelay rust timeReduce mechanical wearManipulatorWear resistantMechanical engineering

The invention discloses a robot conveying mechanism facilitating disassembly and provided with a balancing device, and relates to the technical field of robots. The robot conveying mechanism facilitating disassembly and provided with the balancing device comprises an epoxy resin coating, a dust cover and a main shaft. The inside of the epoxy resin coating is provided with wear-resistant stainlesssteel, the inside of the wear-resistant stainless steel is provided with a water-absorbent resin coating, the interior of the water-absorbent resin coating is provided with a main pillar, and the leftand right sides of the main pillar are provided with ejecting rods; and a push rod is mounted above the dust cover, and the dust cover is mounted above the main pillar. According to the robot conveying mechanism facilitating disassembly and provided with the balancing device, different containing spaces can be provided for different materials through a plurality of storage trays, or different storage trays on one horizontal face can be provided according to different internal compositions of the same materials, and a user can take the materials out of the interior of the storage trays according to the needs of a robot.

Owner:DONGGUAN UNIV OF TECH

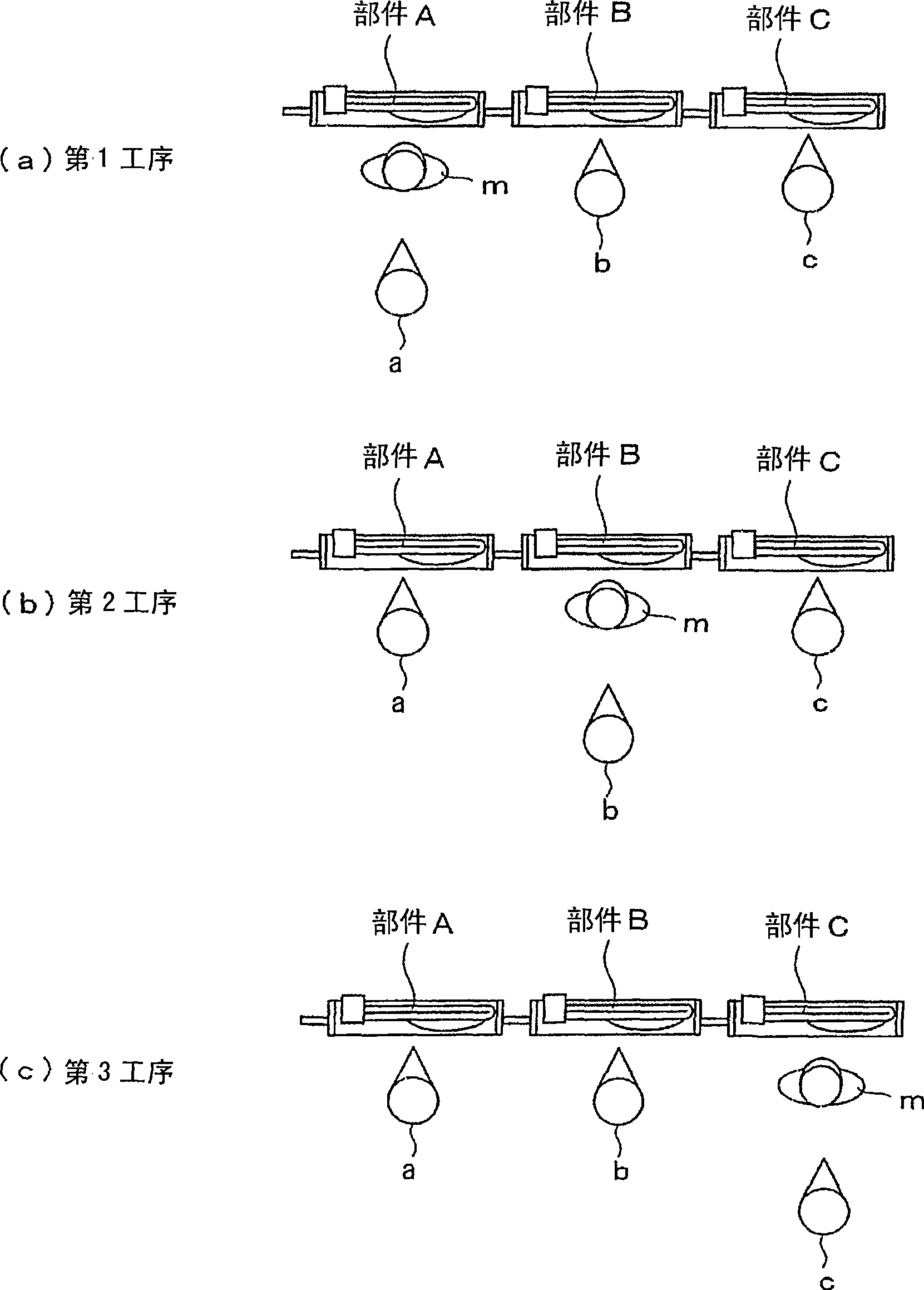

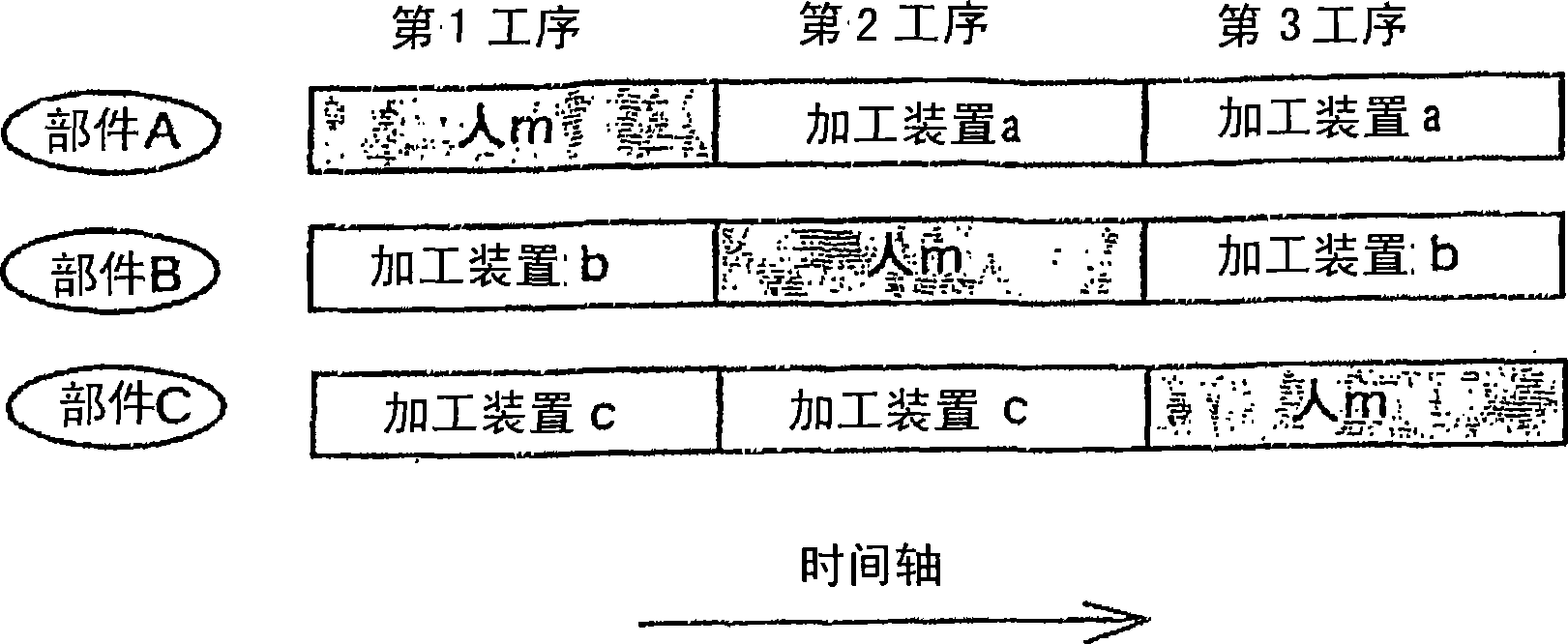

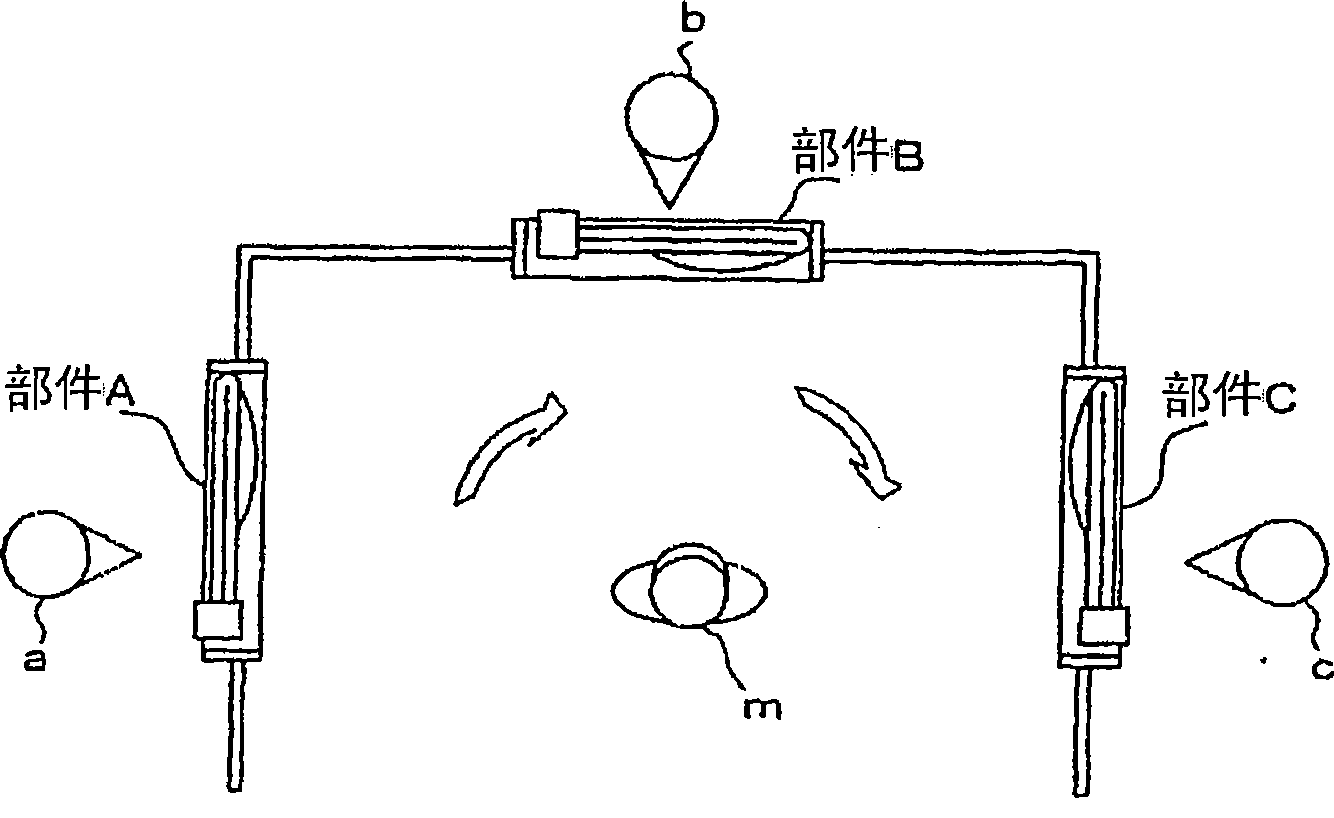

Collaboration work system

InactiveCN101390026AEffective workTotal factory controlProgramme total factory controlEngineeringWork systems

Owner:HONDA MOTOR CO LTD

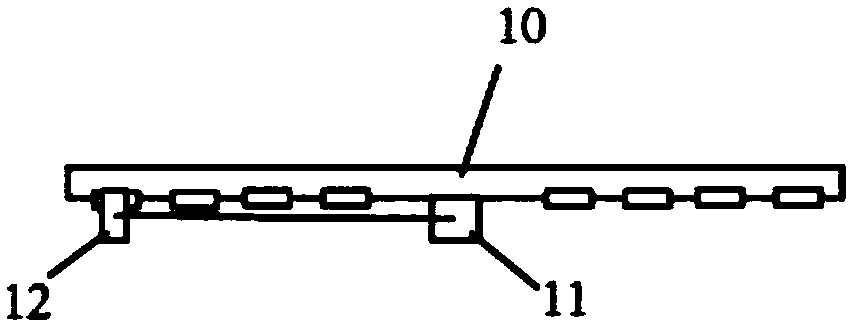

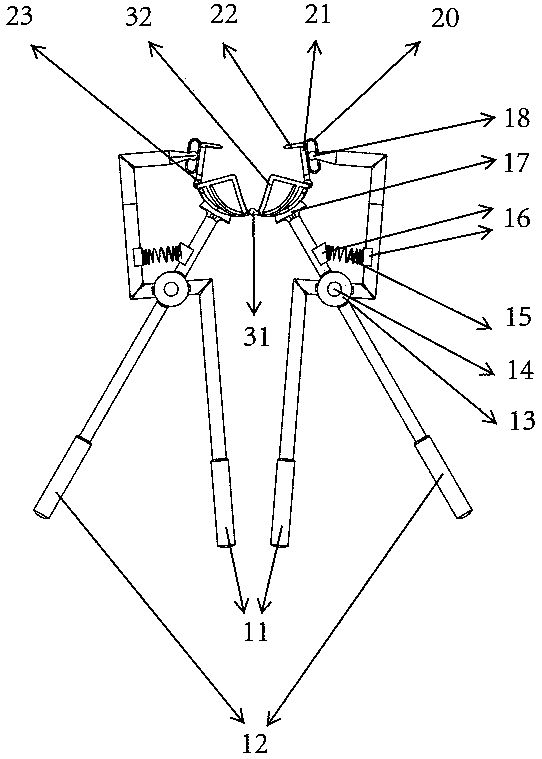

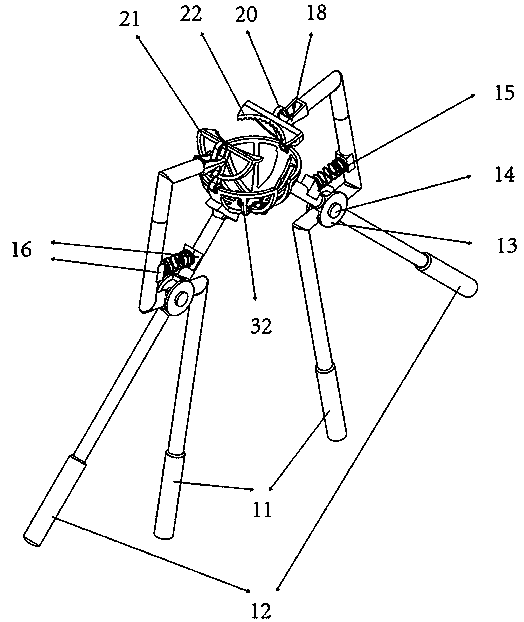

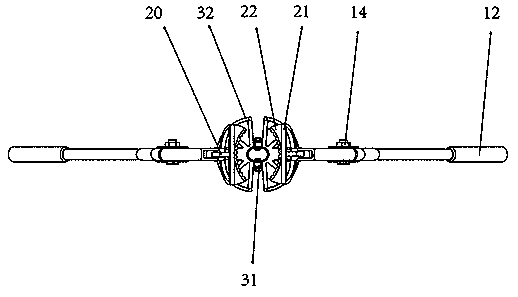

Manual Chinese chestnut thorn ball stripping equipment

The invention discloses manual Chinese chestnut thorn ball stripping equipment and relates to the technical field of dried fruit processing. The manual Chinese chestnut thorn ball stripping equipmentmainly comprises an inner wrench (11), an outer wrench (12), pressing plates (21) and locating components (32); the manual Chinese chestnut thorn ball stripping equipment is characterized in that theinner wrench (11) and the outer wrench (12) are matched in a hinging way; sliding blocks (18) are welded on the top end of the inner wrench (11); the locating components (32) are arranged on the top end of the outer wrench (12); the pressing plates (21) are matched between the sliding blocks (18) and the locating components (32); sliding grooves (20) are formed in the pressing plates (21) in a welding way; the sliding grooves (20) and the sliding blocks (18) are in sliding match; the pressing plates (21) and the locating components (32) are matched in the hinging way; the two locating components (32) are matched in the hinging way. The manual Chinese chestnut thorn ball stripping equipment disclosed by the invention is simple in structure, simple in operation, easy to learn, low in cost and light in weight and can be easily carried to a designated workplace for safe and effective operation by a user.

Owner:GUIZHOU NORMAL UNIVERSITY

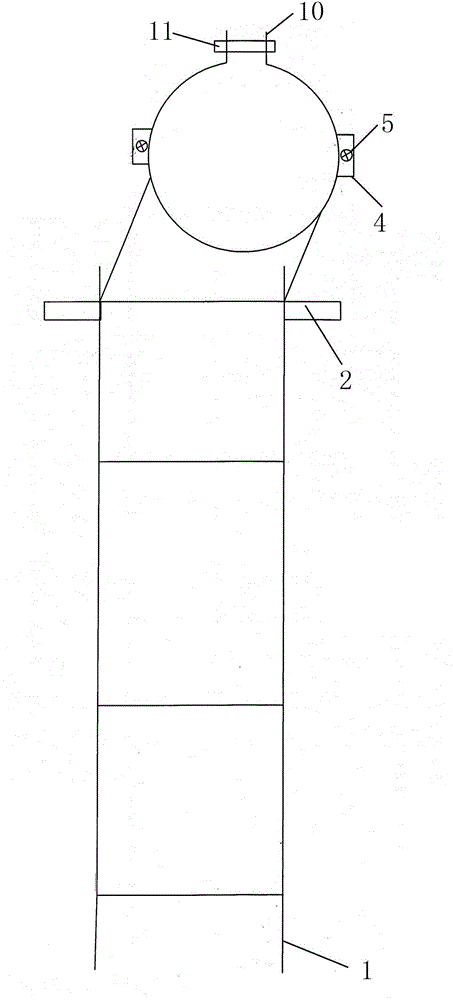

10KV-circuit combined ladder stand

The invention relates to a 10KV-circuit combined ladder stand which comprises a ladder body and a connecting piece. One end of the ladder body is provided with insertion sheets. The other end of the ladder body is provided with slots and lock pins. The slots are matched with the insertion sheets in shape. According to the structure of the connecting piece, an electric pole fixing clamp is arranged to be of a circular arc shape, the two ends of the circular arc of the circular-arc-shaped electric pole fixing clamp are provided with connecting plates, the connecting plates are connected with a connecting plate of a movable clamp I and a connecting plate of a movable clamp II in a rotating mode through connecting shafts respectively, a body connecting plate is arranged outside the circular arc of the circular-arc-shaped electric pole fixing clamp, and the body connecting plate is fixed to the ladder body through the lock pins. The 10KV-circuit combined ladder stand can be used safely on special conditions of freeze, rain, snow and frost, enables circuit operation to be smooth, safe and effective and provides a special safety guarantee for an operator on a pole; besides, the 10KV-circuit combined ladder stand lowers cost, eliminates harm to staff, livestock and the like when a fixed ladder stand is too low, and has popularizing value.

Owner:STATE GRID CORP OF CHINA +1

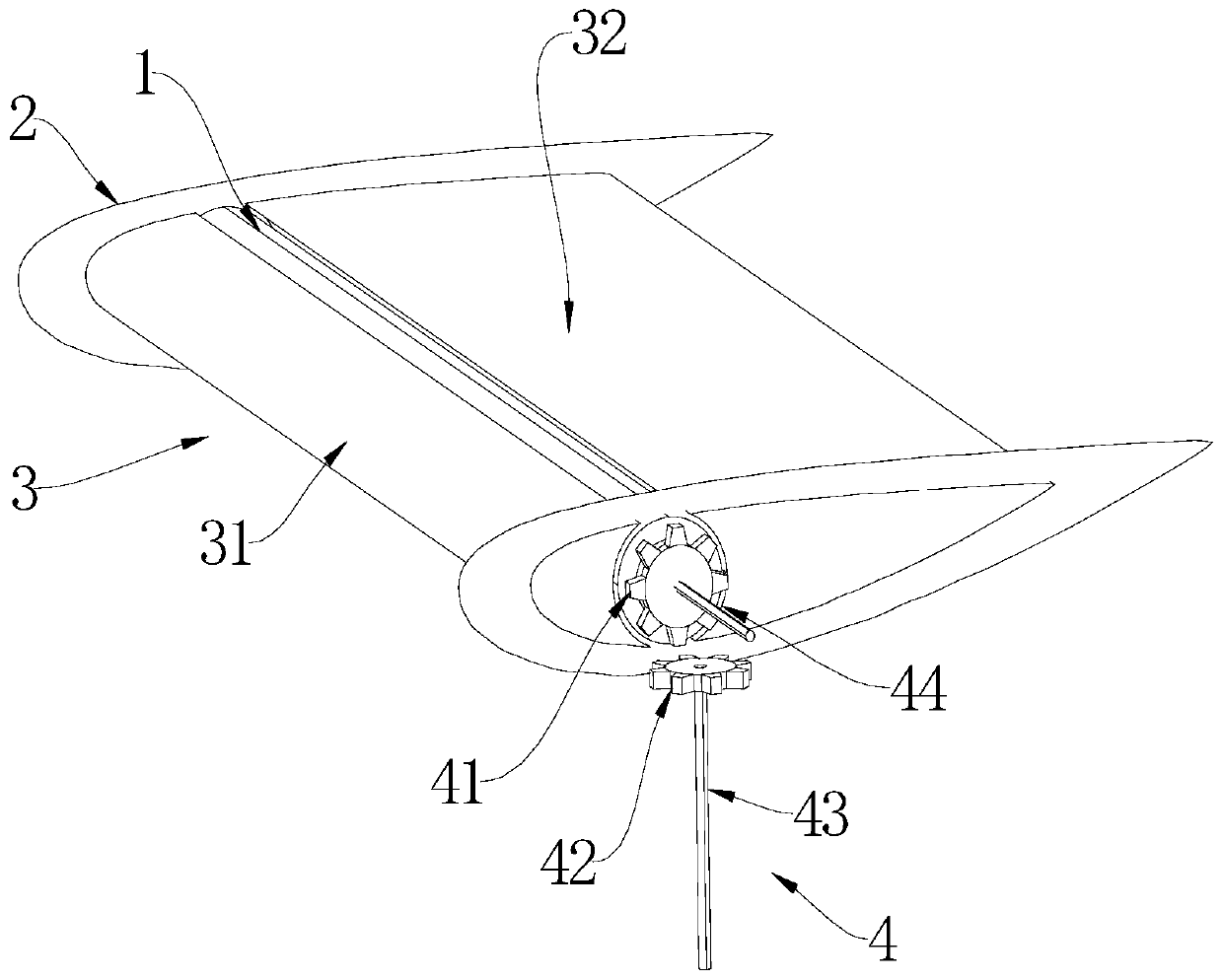

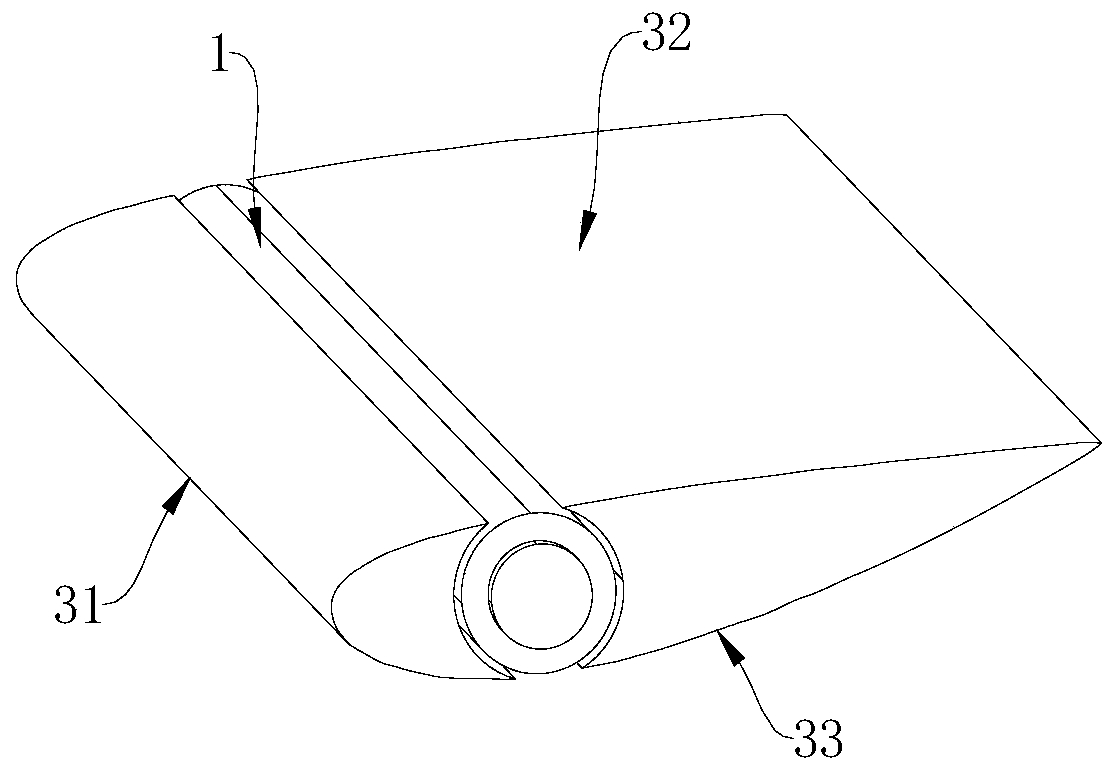

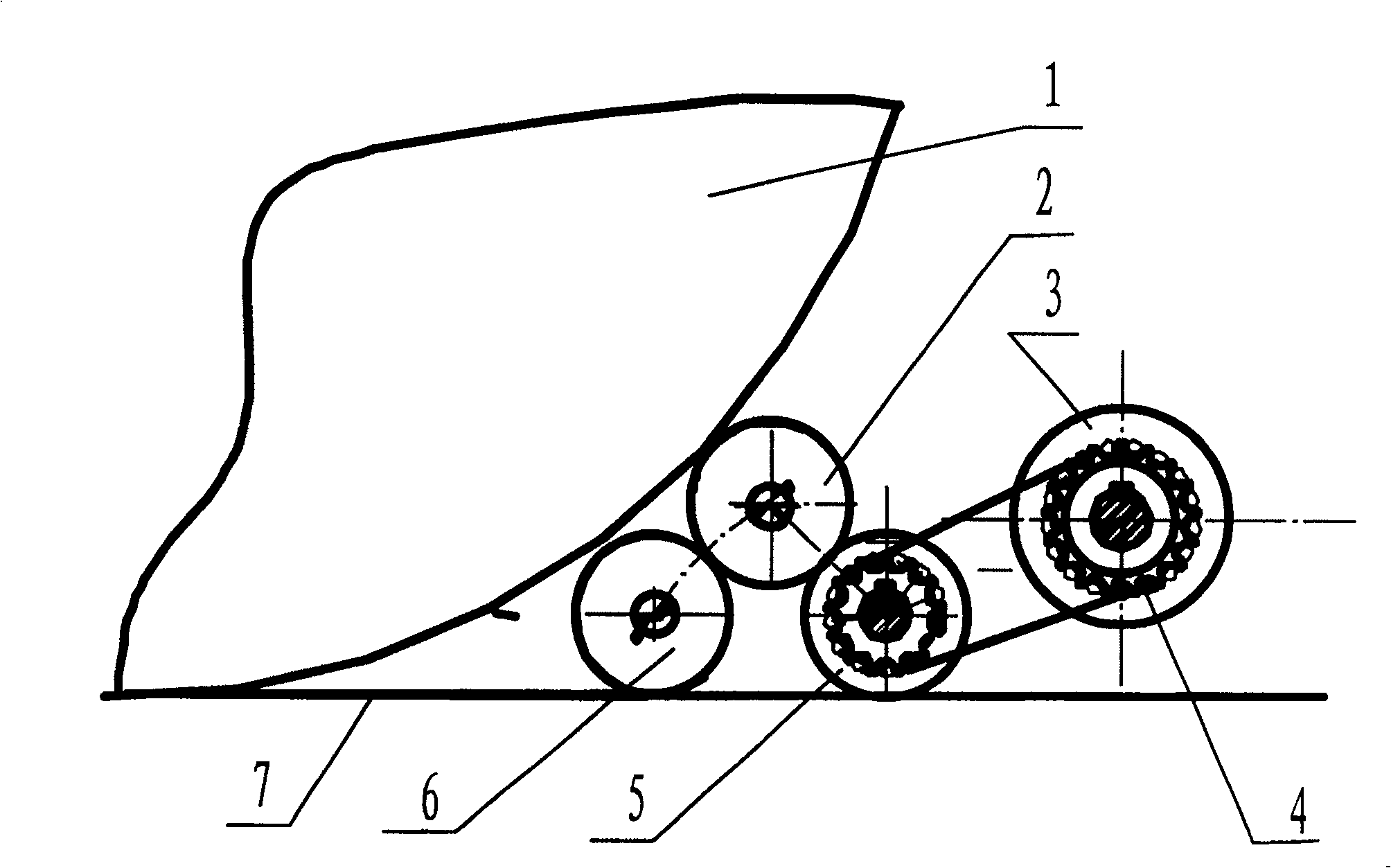

Racing car spoiler and racing car

InactiveCN111216813AImprove gripIncrease flow rateAerodynamics improvementVehicle body streamliningMechanical engineeringMotor racing

The invention provides a racing car tail wing and a racing car, and belongs to the technical field of aerodynamics. The racing car tail wing comprises a main wing plate, side wing plates, a cylinder and a driving mechanism, wherein the main wing plate comprises a first arc-shaped curved surface, a second arc-shaped curved surface and a transition arc surface smoothly connected to the front ends ofthe first arc-shaped curved surface and the second arc-shaped curved surface, the curvature of the first arc-shaped curved surface is smaller than that of the second arc-shaped curved surface, and arotating cavity with slits in the upper portion and the lower portion is formed in the front end of the main wing plate; the side wing plates are symmetrically arranged at the left end and the right end of the main wing plate; the cylinder is arranged in the rotating cavity, the center line of the cylinder coincides with the center line of the rotating cavity, and the upper arc face and the lowerarc face of the cylinder protrude out of the corresponding first arc-shaped curved surface and the second arc-shaped curved surface through the corresponding slots. The driving mechanism is connectedwith the cylinder and used for driving the cylinder to rotate. According to the racing car tail wing, the wheel road holding effect can be improved, and the effective work of a propelling system is improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

Jacking positioning mistake-proofing device

PendingCN111660865ASmooth job changeExtend your lifeCharging stationsVehicular energy storageStructural engineeringMechanical engineering

The invention relates to a jacking positioning mistake-proofing device which comprises a jacking piece arranged on a lifting table; the jacking piece comprises a jacking rod; a jacking flange and a guide pin located on the jacking flange are arranged on the jacking rod; a mounting groove is formed in the jacking flange; and a sensor mounting block is arranged in the mounting groove; a middle holeis formed in the sensor mounting block; a sensor is installed in the middle hole; and the upper end face of the sensor mounting block is lower than the upper end face of the jacking flange. With the jacking positioning mistake-proofing device adopted, the battery replacement success ratio is effectively improved; the interference risk between equipment and a vehicle body is reduced; battery replacement time can be shortened; operation is quickly and effectively completed; equipment and vehicle losses are effectively reduced; the service life of the equipment and a vehicle is prolonged, and operation cost is reduced;

Owner:宁波江宸智能装备股份有限公司

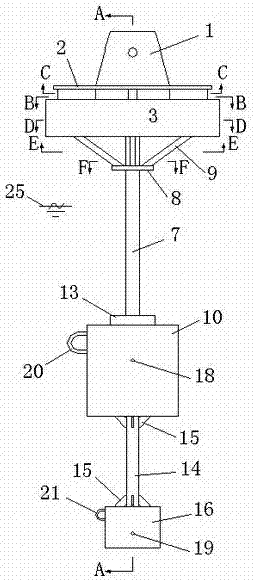

A portable inflatable cabinet for distribution automation in distribution network

ActiveCN110086110BDrive stabilityEffective workSwitchgear arrangementsSubstation/switching arrangement detailsStructural engineeringDistribution grid

The invention relates to a portable inflation cabinet for power distribution automation of a power distribution network. The inflation cabinet comprises a cabinet body, a mounting rack is arranged inthe lower end of the cabinet body, a driving groove is arranged in the front end of the mounting rack, a driving mechanism is arranged in the driving groove, and abuts against two movement mechanisms,and the two movement mechanisms are symmetrically mounted in the front and back sides of the lower end surface of the mounting rack. The portable inflation cabinet of the invention can be used to solve problems, of a present temporary inflation cabinet in the movement process, that a) the inflation cabinet needs to be moved by means of tools as a present go-cart, operation is complex, the applicability is low, and due to frequency movement of the temporary inflation cabinet, the movement efficiency is low, and there is hidden safety troubles; and b) the contact frictional force between the tools as the go-cart and the ground is low, effective conveying cannot be ensured on the complex road, and the stability is low.

Owner:ELECTRIC CO LTD SHENZHEN DOUBLE PROFIT

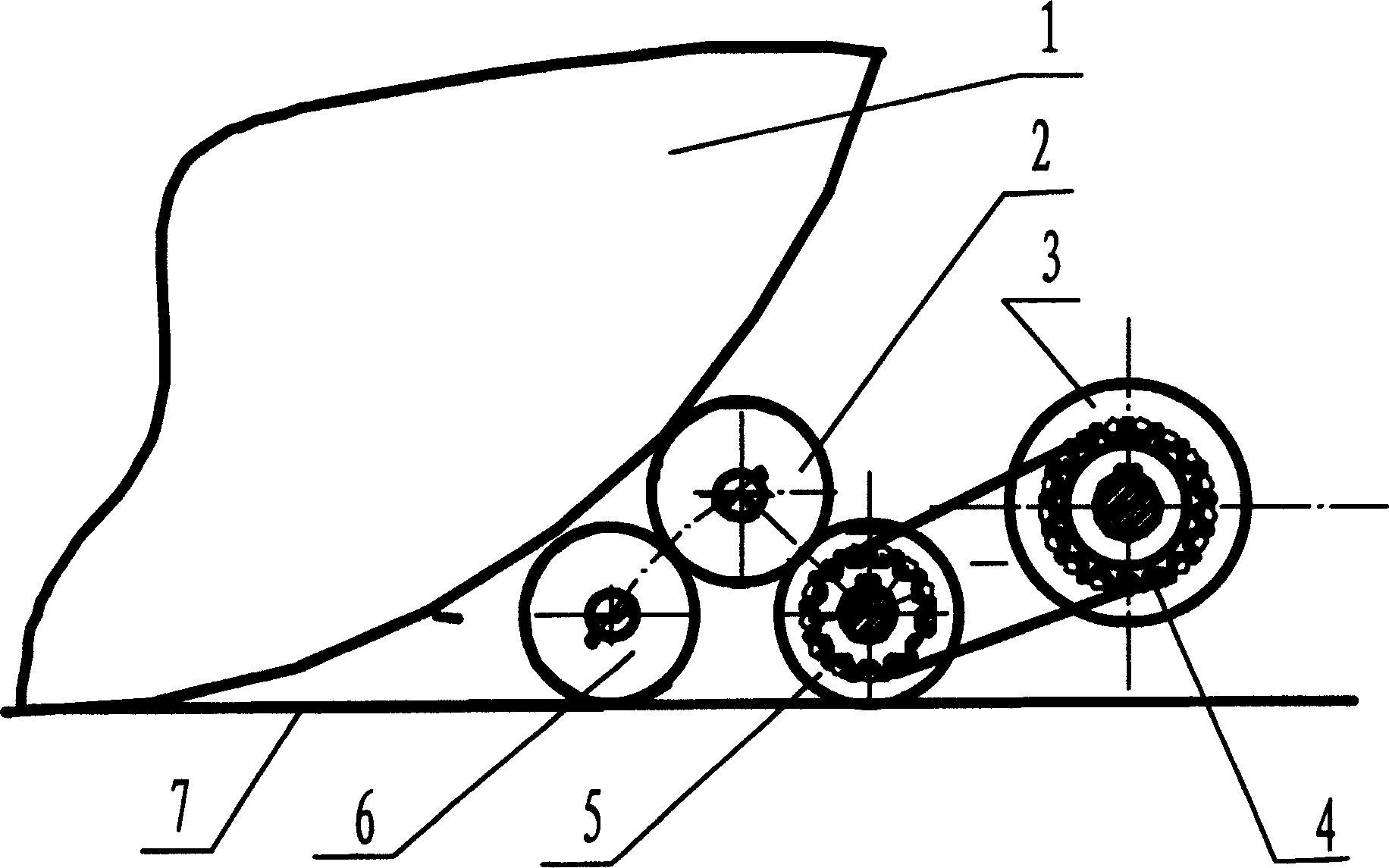

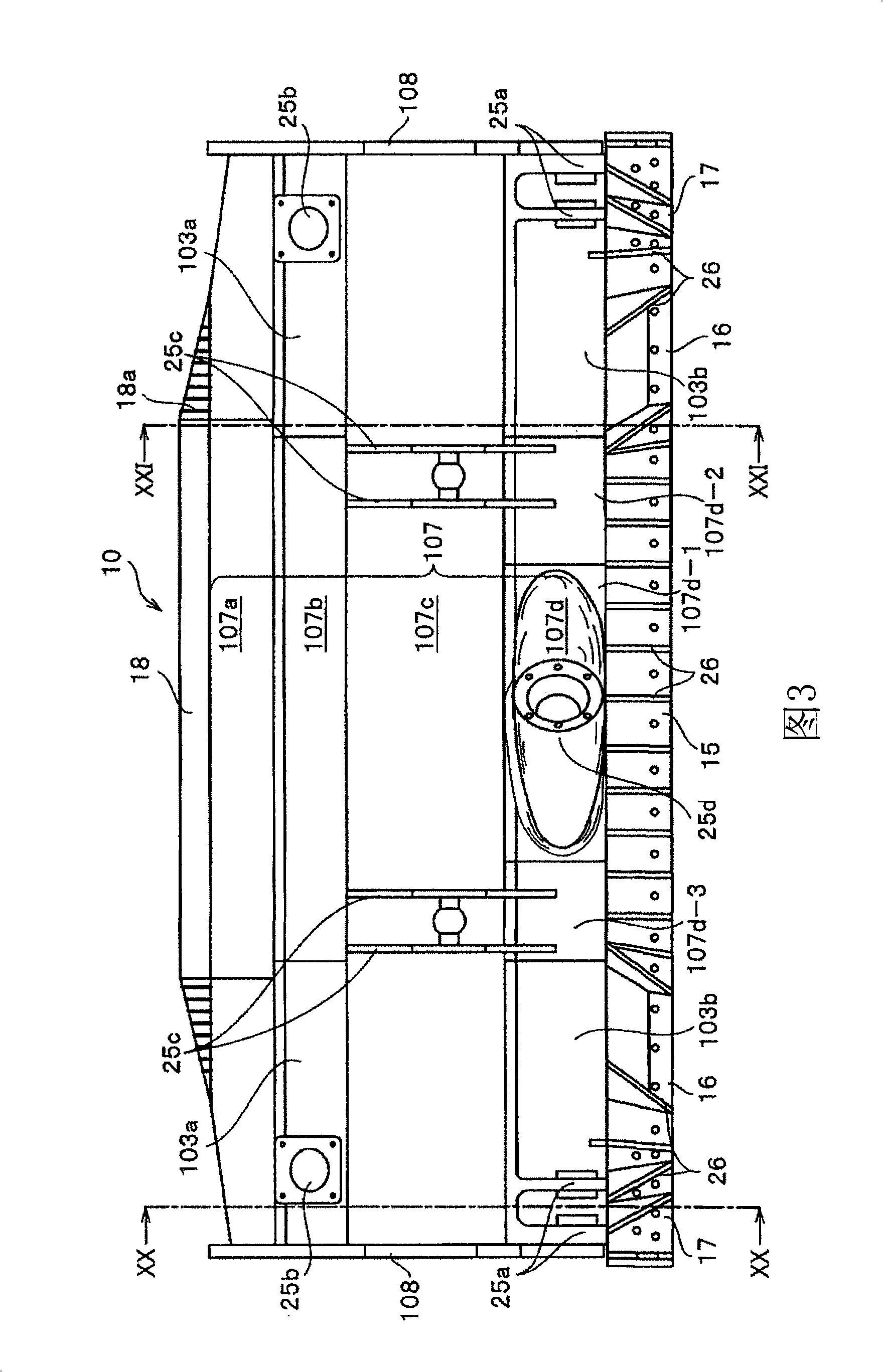

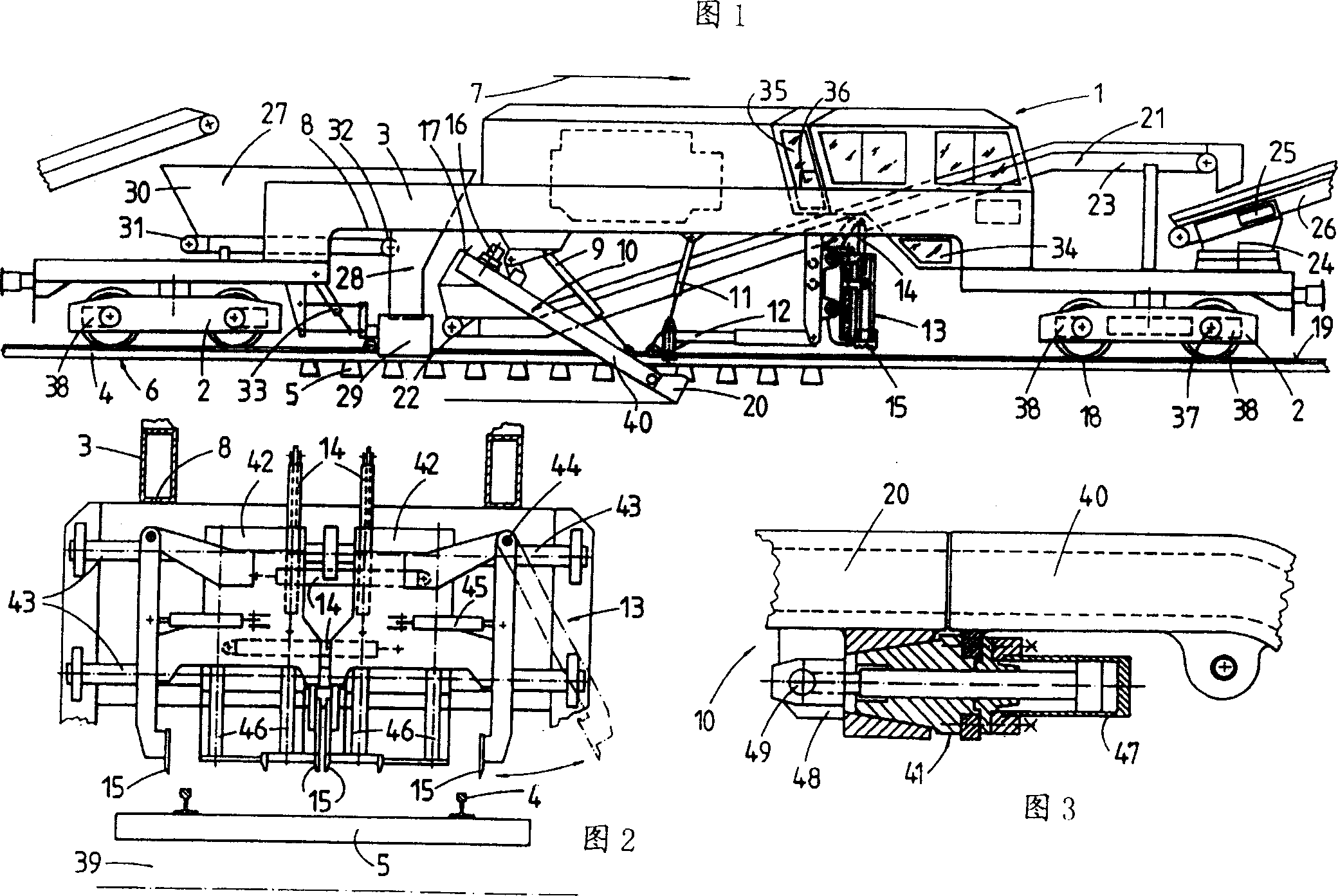

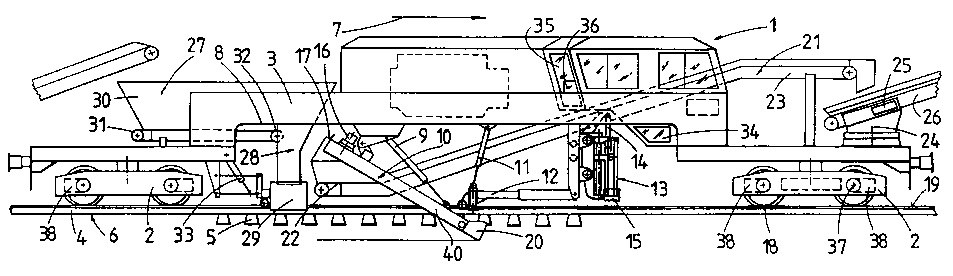

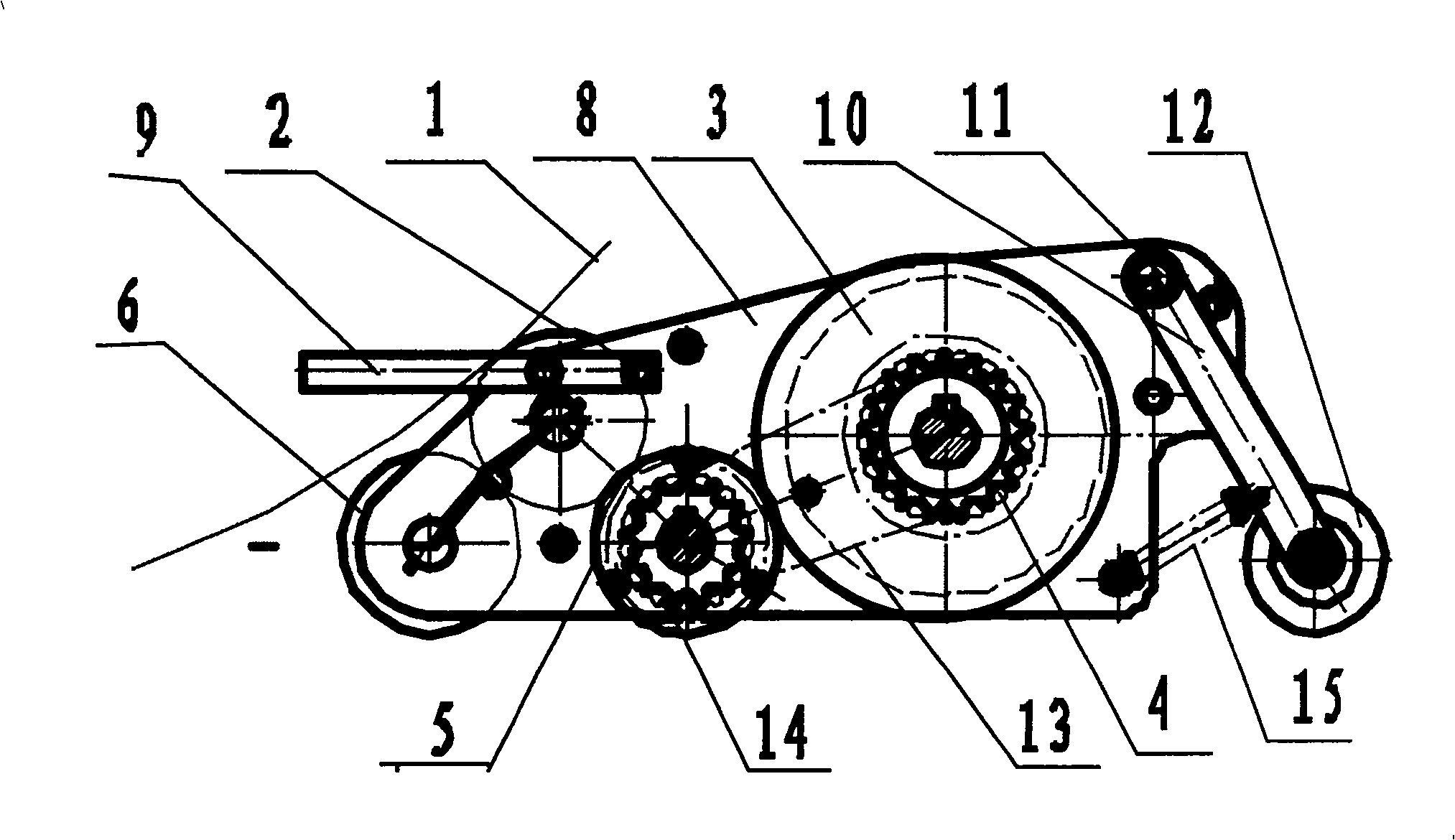

Pipeline construction machinery for digging track sub-grade material

The present invention provides a line construction machine (1) for excavating track bed material, including a frame (3) with an upward bending section (8) supported on a rail-mounted mechanism (2). An excavation chain (10), a digging set (13) provided with a digging mechanism (15) by utilizing a drive device (14) to regulate the height and the horizontal position which is vertical with the longitudinal direction of the machine are arranged below the upward bending section (8) on the frame. And a track jack (12) is arranged between the excavation chain (10) and the digging set (13). In addition, a discharging chute (29) with a ballast releasing entrance (28) is directly arranged behind a receiving end (22) of a conveying device (21) below the excavation chain (10).

Owner:FRANZ PLASSER BAHNBAUMASCHINEN IND GMBH

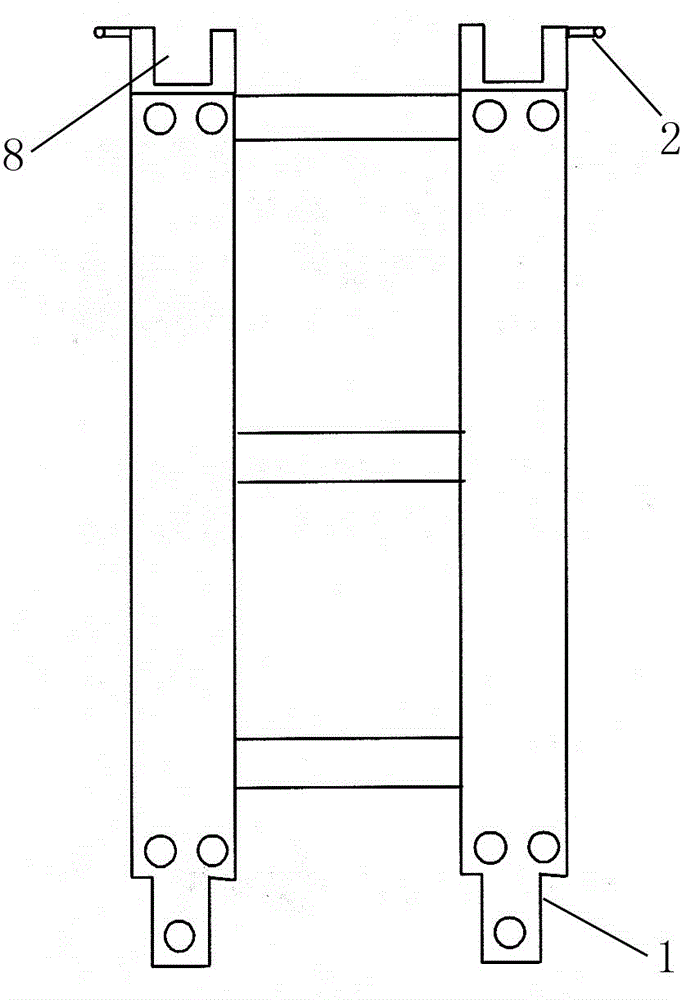

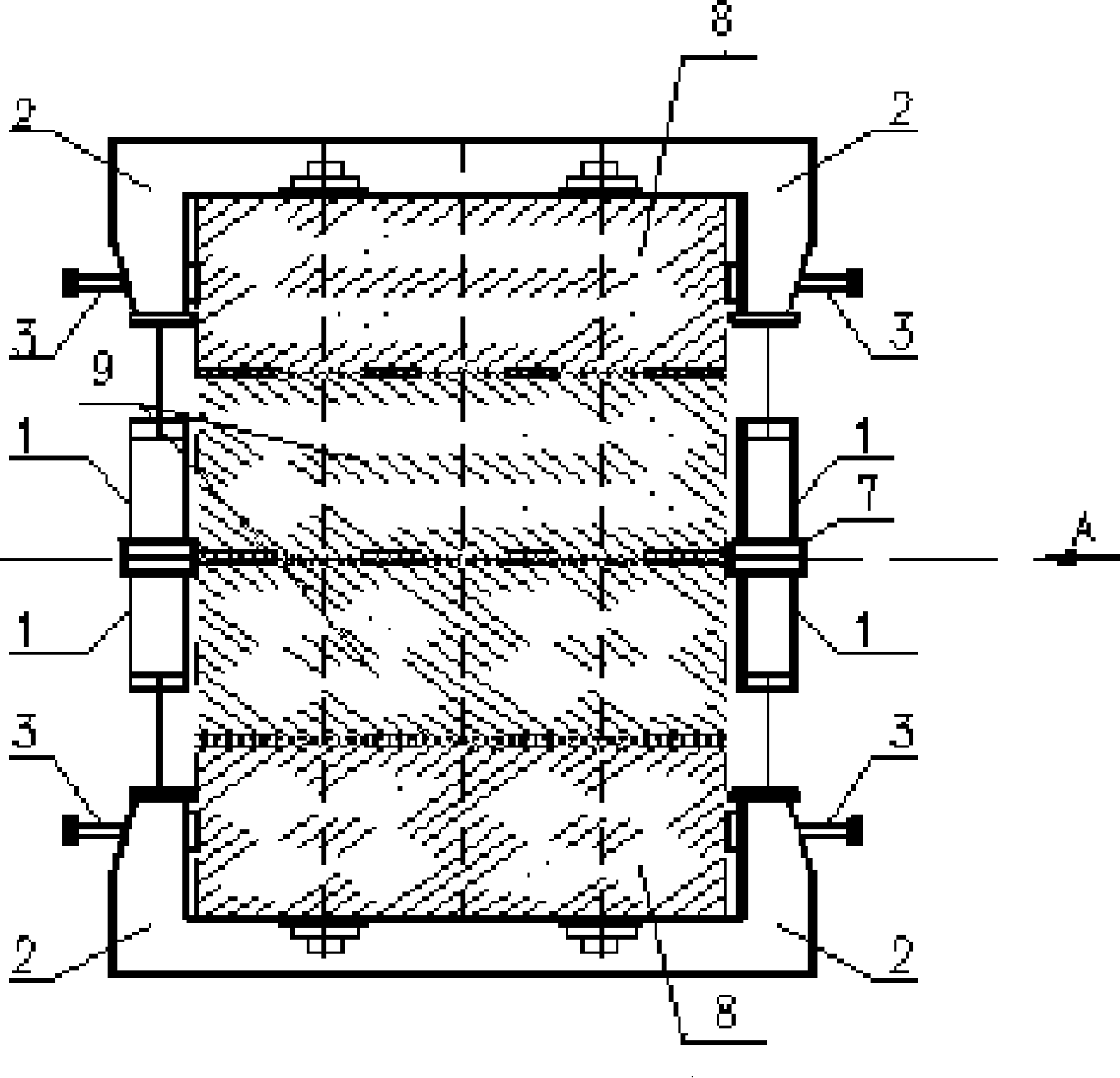

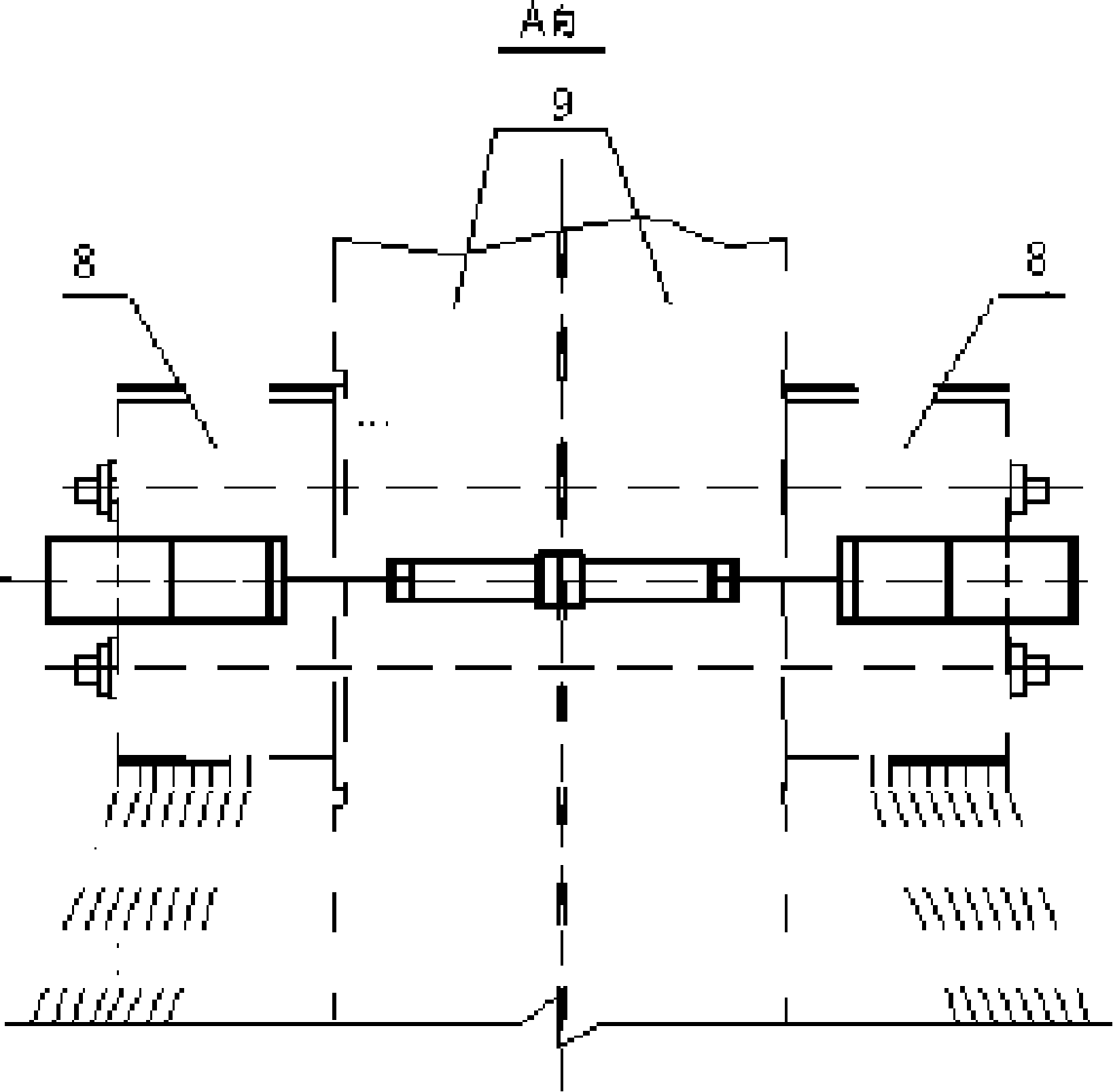

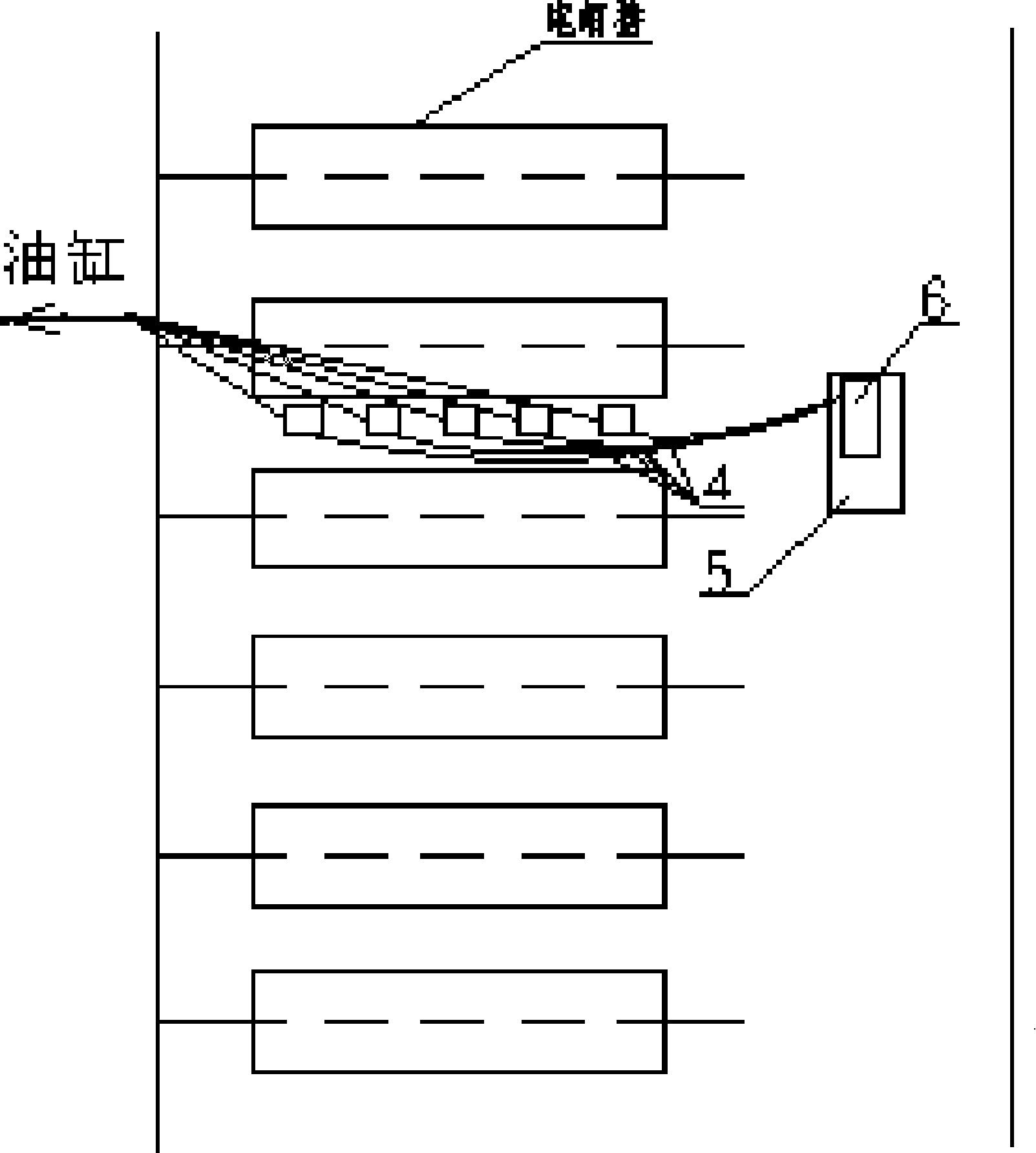

Electrolytic tank hydraulic pressure short circuit ora switch device

The invention discloses an electrolytic cell hydraulic pressure short circuit ora opening / closing device, which comprises a riser bus (9). A clamping device (2) is clamped on a short circuit ora bus (8) through a tightening bolt (3), an oil cylinder (1) is connected with the clamping device (2), one end of a hose (4) is connected with a hydraulic station (6), and the other end is connected with an oil cylinder (1). The hydraulic station (6) is installed on a movable type holding car (5). The two oil cylinders are mutually connected through a flange (7). By utilizing the invention, the automatic opening / closing can be realized without power off or reduction of the electric current of the electrolytic cell production series, thus not only the electrolytic cell production series is ensured that the main process engineering criteria is not disturbed or affected by the power off or reduction of the electric current, but also the labor intensity of the worker is reduced simultaneously, and the labor capacity and the safety coefficient are enhanced. The invention can be used on the electrolytic cells with different volumes as the device for rapid opening / closing the short circuit ora of the riser bus.

Owner:GUIYANG AL-MG DESIGN & RES INST

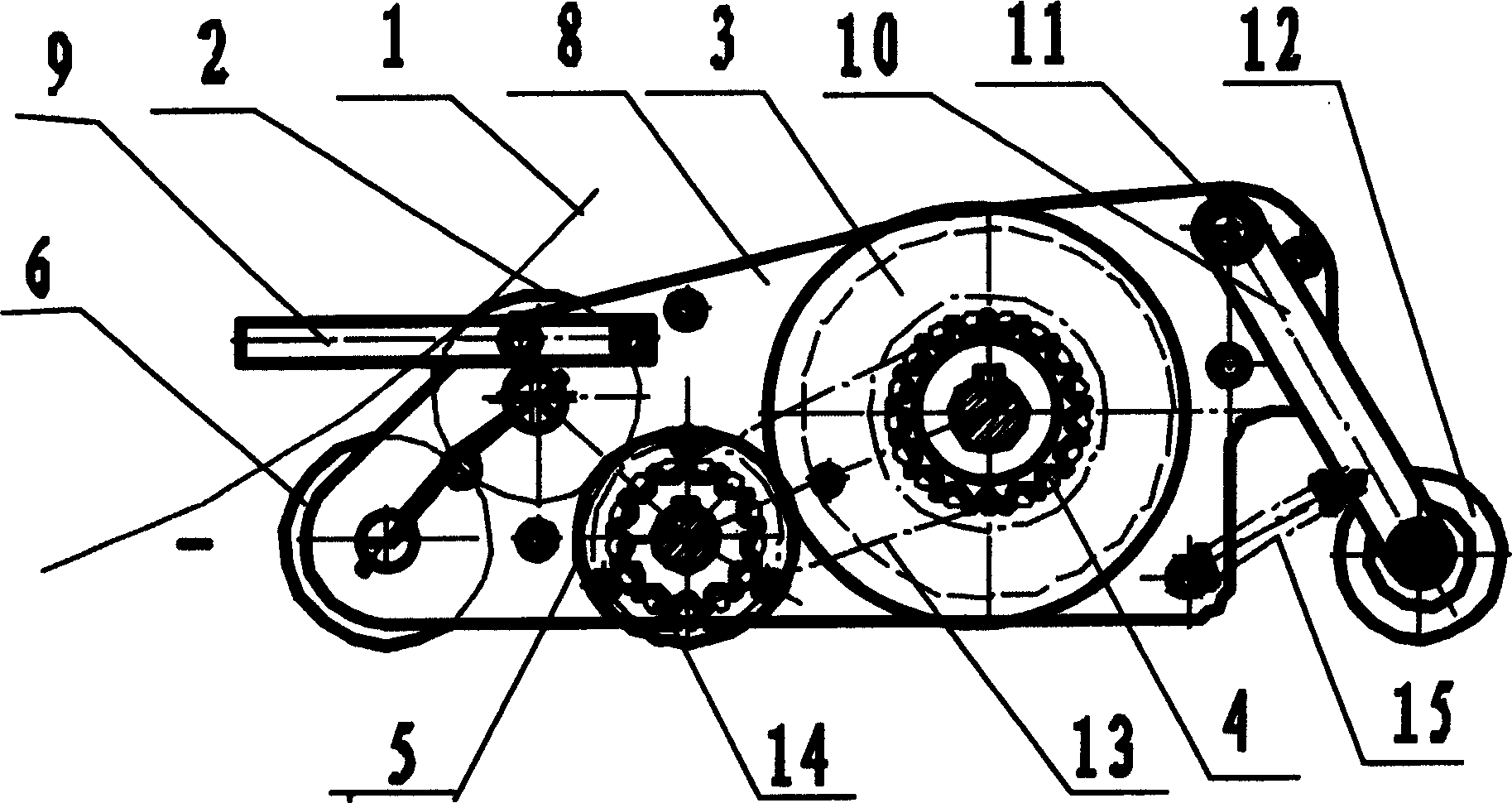

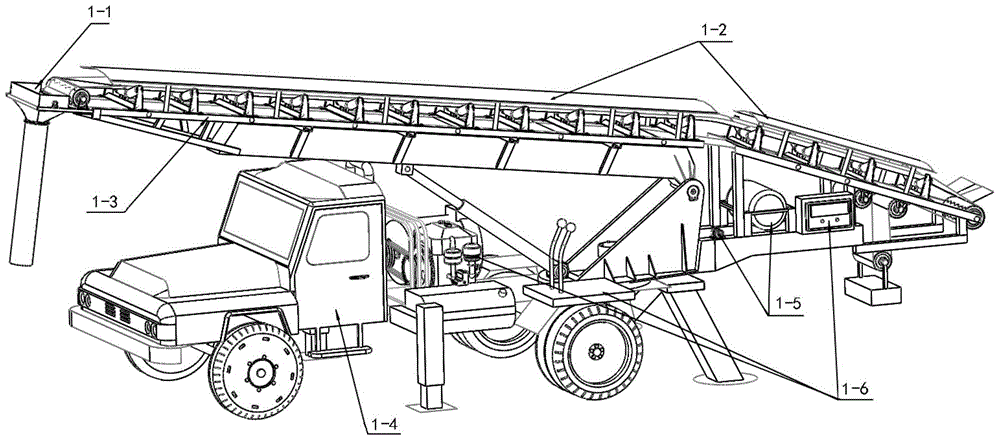

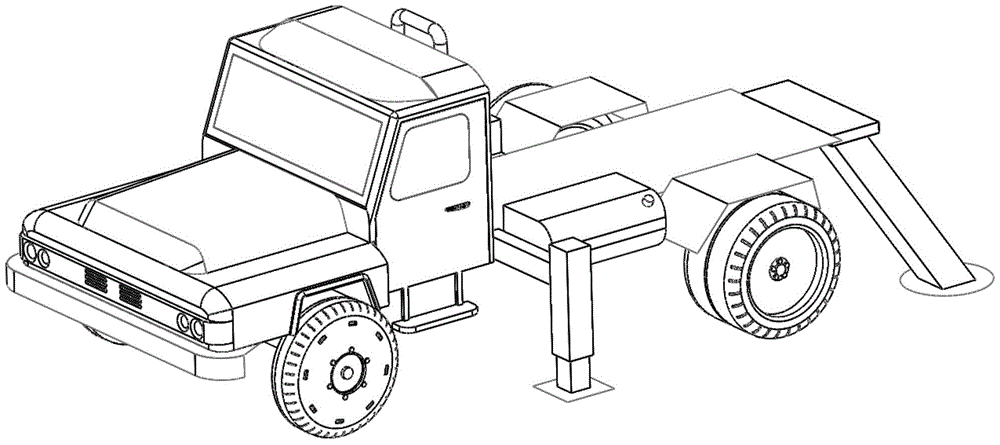

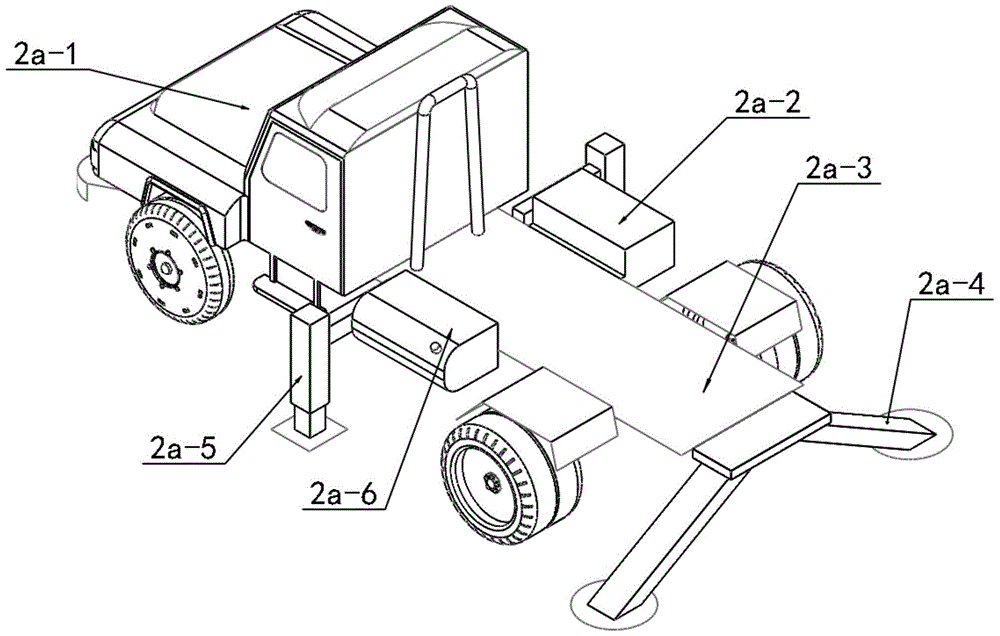

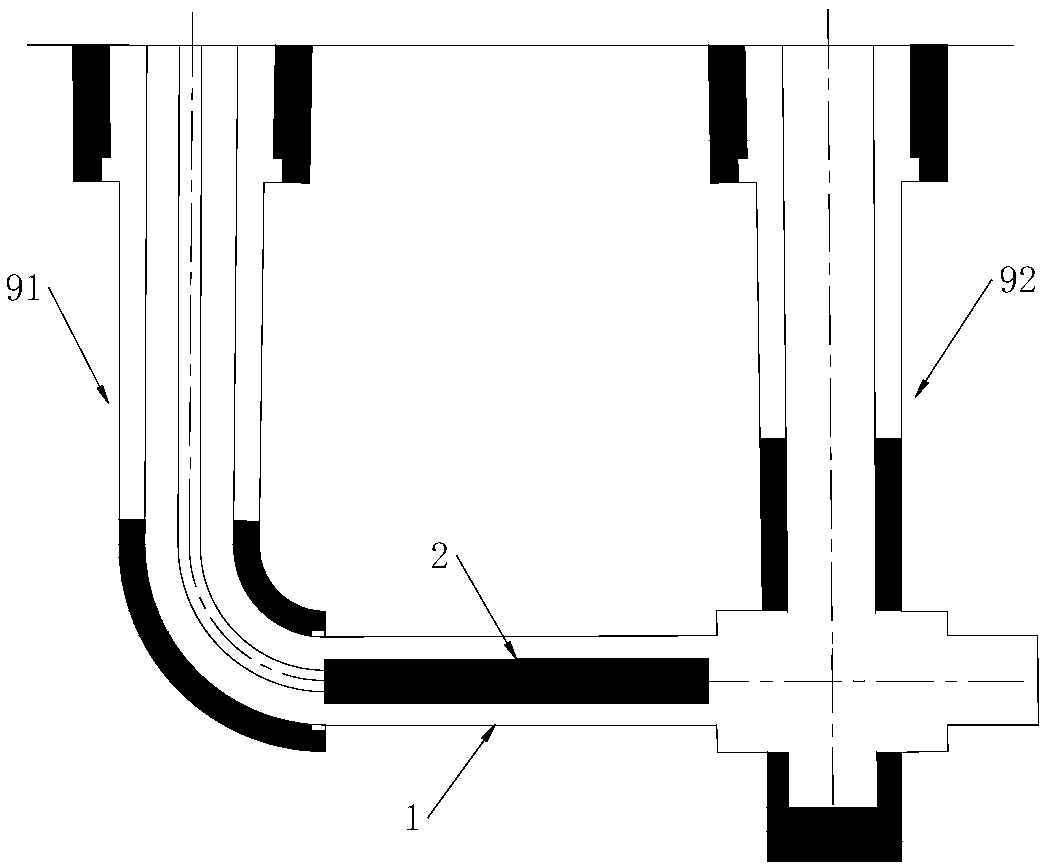

Concrete delivery system and concrete delivery vehicle with the delivery system

ActiveCN104947675BPouring realizationIncrease the effective construction rangeGround-workFoundation engineeringConveyor beltHinge joint

The invention relates to a concrete conveying system and a concrete transport vehicle with the same. The concrete conveying system mainly comprises a rotating support. The rotating support is fixedly connected with a tail portion supporting frame. The front end of the tail portion supporting frame is hinged to a hydraulic crane boom. The upper end of the tail portion supporting frame is hinged to a load-bearing beam. The hydraulic crane boom drives the load-bearing beam to rotate with the hinge joint of the load-bearing beam and the tail portion supporting frame as the circle center. The load-bearing beam carries a conveyor belt through an upper portion supporting beam. The conveyor belt is driven by a driving wheel and a driven wheel on the upper supporting frame to move. The end of the upper portion supporting frame is fixedly connected with a concrete guiding and pouring device which comprises a pouring guide pipe. The discharge port of the pouring guide pipe is lower than the conveyor belt so that concrete on the construction face lower than the horizontal face can be conveyed. By means of the transport vehicle, the construction progress of on-site concrete pouring can be accelerated, and the workability of concrete in the pouring period can be ensured.

Owner:SHANDONG UNIV +1

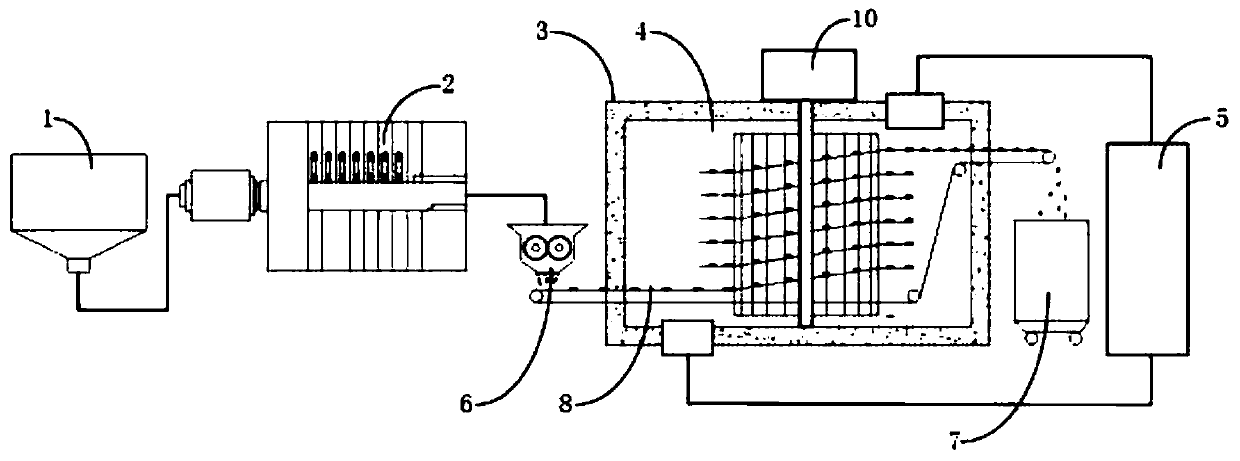

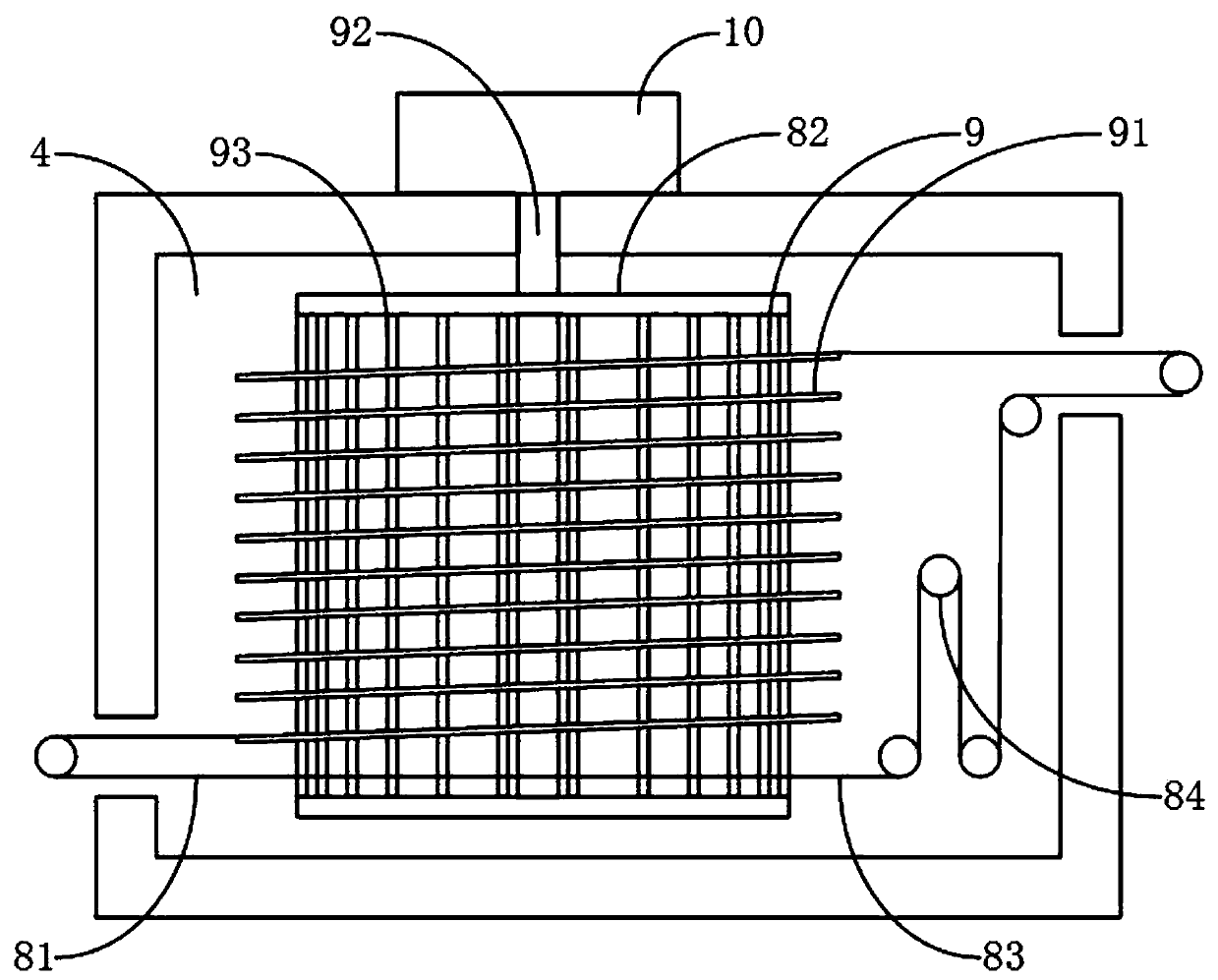

Sludge treatment system and process

PendingCN110563301AAchieve reductionEliminate penetrationSludge treatment by de-watering/drying/thickeningSlurryPulp and paper industry

The invention discloses a sludge treatment system and a process. Sludge paste with the moisture content of 50% to 60% can be obtained by adopting a slurry hopper and a press filter and can be dried into clods with the moisture content of 40% or less through a drying unit. A drying room and a hot air supply circulating mechanism can exert a relatively good drying effect, an extruding mechanism anda circulating conveying mechanism are combined, and thus, materials are uniformly tiled and heated and are uniformly dried. According to the sludge treatment system and the process, sludge can be thickened and dehydrated, the volume weight of the sludge is greatly reduced, the decrement of the sludge is achieved, and the pollution caused by liquid permeation and odor emission is eliminated. By designing the hot air supply circulating mechanism, the operation of an evaporator can be effective, a circulating hot air supply is relatively dry, the materials in the drying room can be deeply dehumidified, the effect is remarkable, the loss of heat energy caused by hot-cold offset is lowered, and the utilization ratio of energy is increased. The circulating conveying mechanism is ingeniously designed, the circulation of the circulating hot air supply is facilitated, the materials are heated and dried uniformly, the space usage is relatively low, and thus, the requirements of materials on a thorough drying course in a limited space are met.

Owner:江苏同益能源科技有限公司

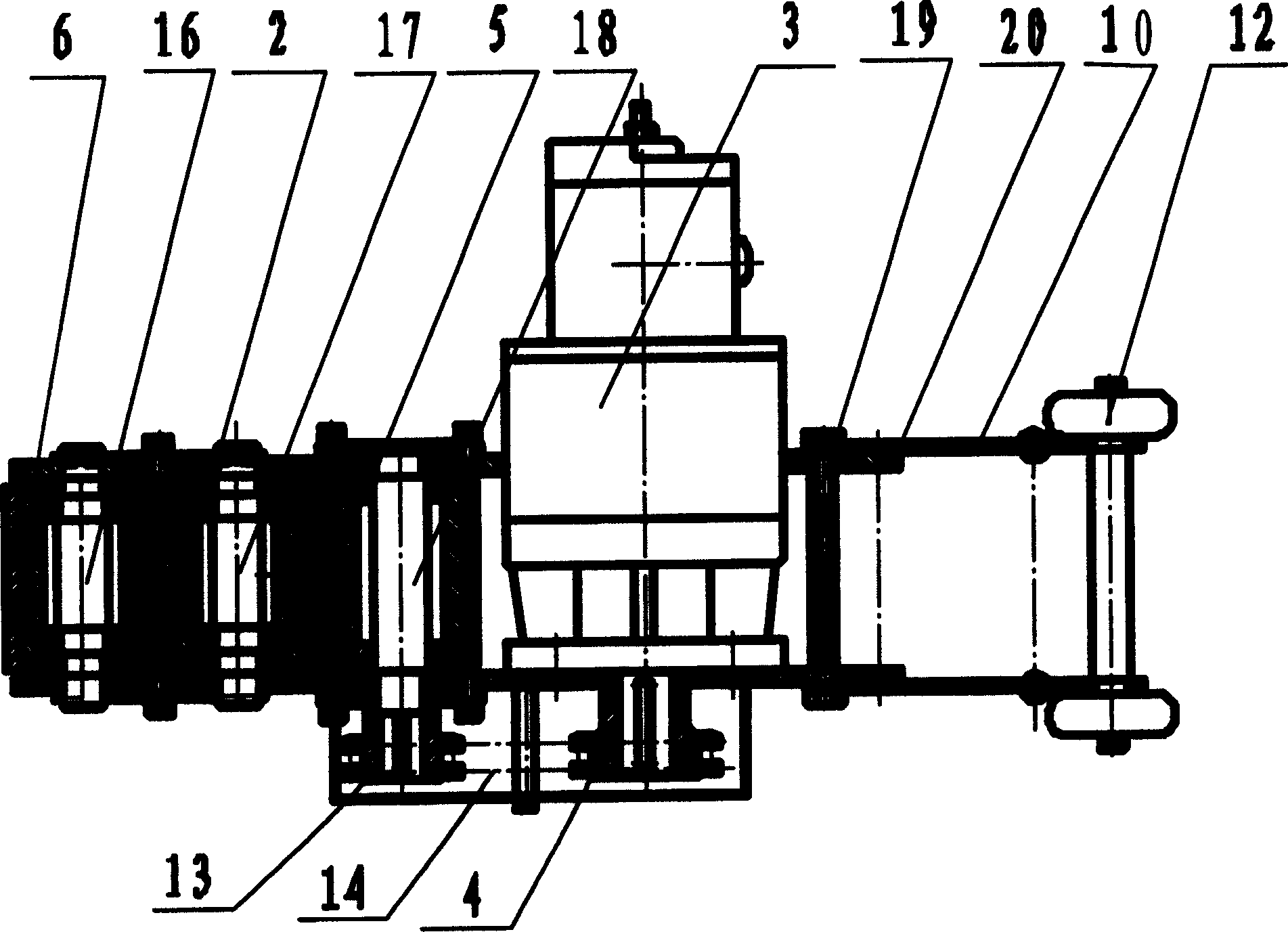

Finishing and packaging heat seal equipment

InactiveCN109878830AControllable job speedImprove heat sealing efficiencyWrapper twisting/gatheringEngineeringSpeed regulator

The invention provides finishing and packaging heat seal equipment. The equipment comprises a fixing device, a heat seal device, a rotary device and an adjusting device, wherein the adjusting device is arranged on the fixing device, the heat seal device is connected with the adjusting device, the rotary device comprises a rotary motor, a rotary shaft and a speed regulator, the rotary motor is arranged on the adjusting device, an output shaft of the rotary motor is connected with the rotary shaft, the other end of the rotary shaft is connected with the heat seal device, and the speed regulatoris arranged on the rotary shaft. The equipment has the advantages that a to-be-heat sealed object is fixed to the packaging device, cooperative telescopic clamping of a clamping air cylinder and a connecting member is adopted by the fixing device, so that the device can adapt to the to-be-heat sealed object with different transverse size, and therefore the application range of the device is improved.

Owner:TIANJIN HAIJING PLASTIC PROD

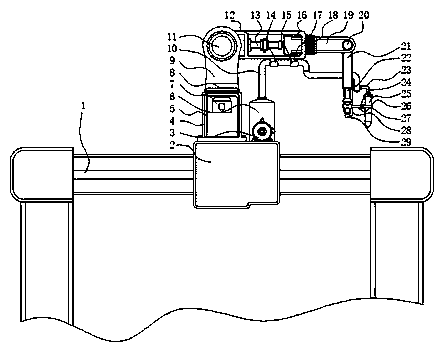

A laser head for multi-directional angle adjustment for laser welding

ActiveCN109175699BKeep it workingReduce cleaning timesLaser beam welding apparatusEngineeringGas holder

The invention discloses a laser head for multi-directional angle adjustment for laser welding, which relates to the field of welding technology, in particular to a laser head for multi-directional angle adjustment for laser welding, including a slide rail, an inner tooth sleeve and a main air pipe. A slide block is installed in the middle of the slide rail, and a stainless steel shell is installed above the slide block, a strut is installed above the inner gear sleeve, and the internal gear sleeve is located above the stainless steel shell, and a stainless steel shell is installed above the strut There are servo motors. This laser welding uses a laser head that is convenient for multi-directional adjustment of the angle. Through the cooperation between the compressor, the main air pipe, and the blowing pipe, the inert gas inside the gas storage tank can be effectively introduced into the inside of the blowing pipe. When the laser head is on the workpiece When doing work, the blowing pipe blows the inert gas to the welding part of the workpiece to prevent the rapid oxidation of the welding part of the workpiece, and it is easy to generate impurities in the welding part, resulting in the weak welding part of the workpiece and failing to achieve the required working effect.

Owner:四会市耀华精密机械有限公司

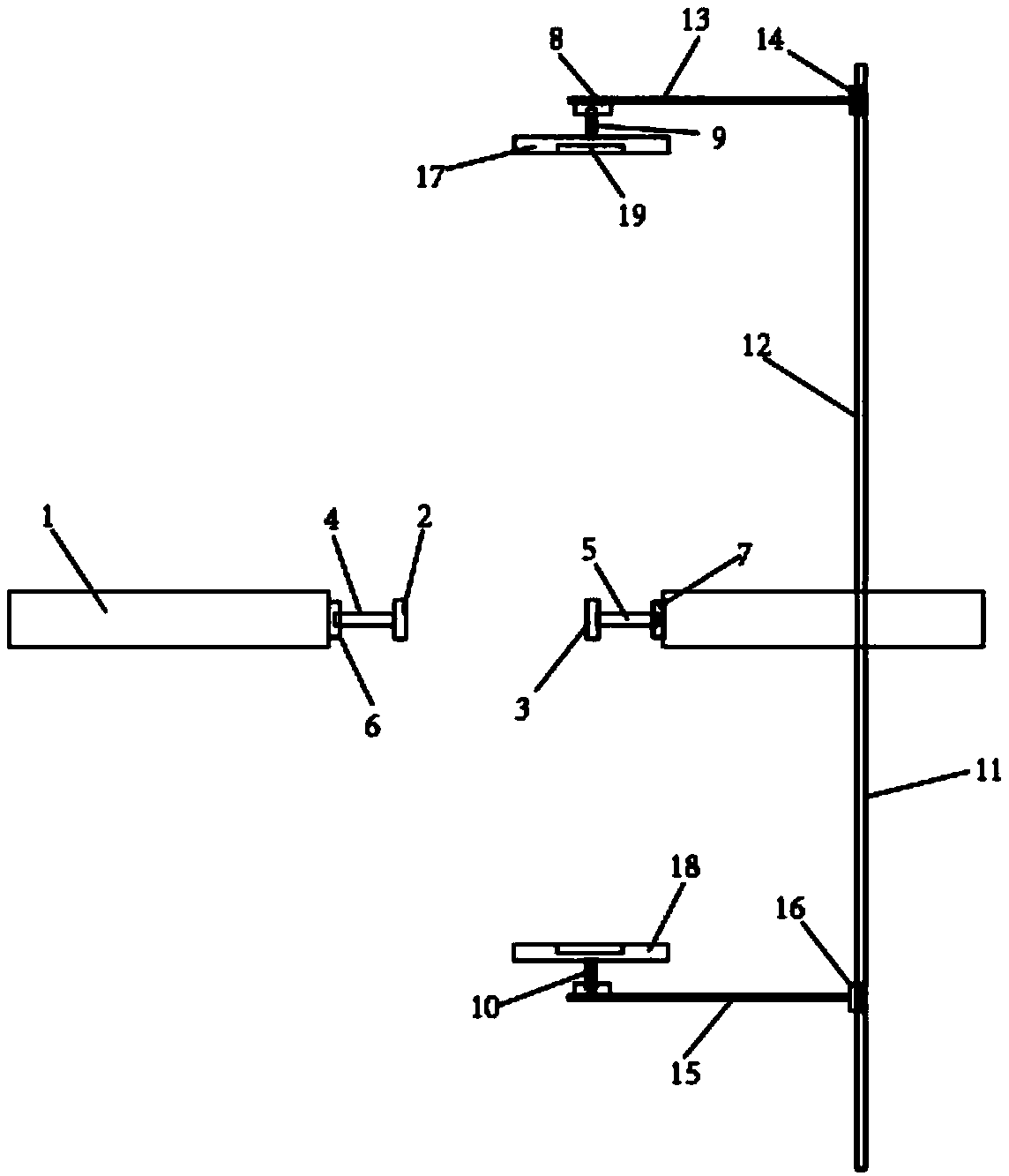

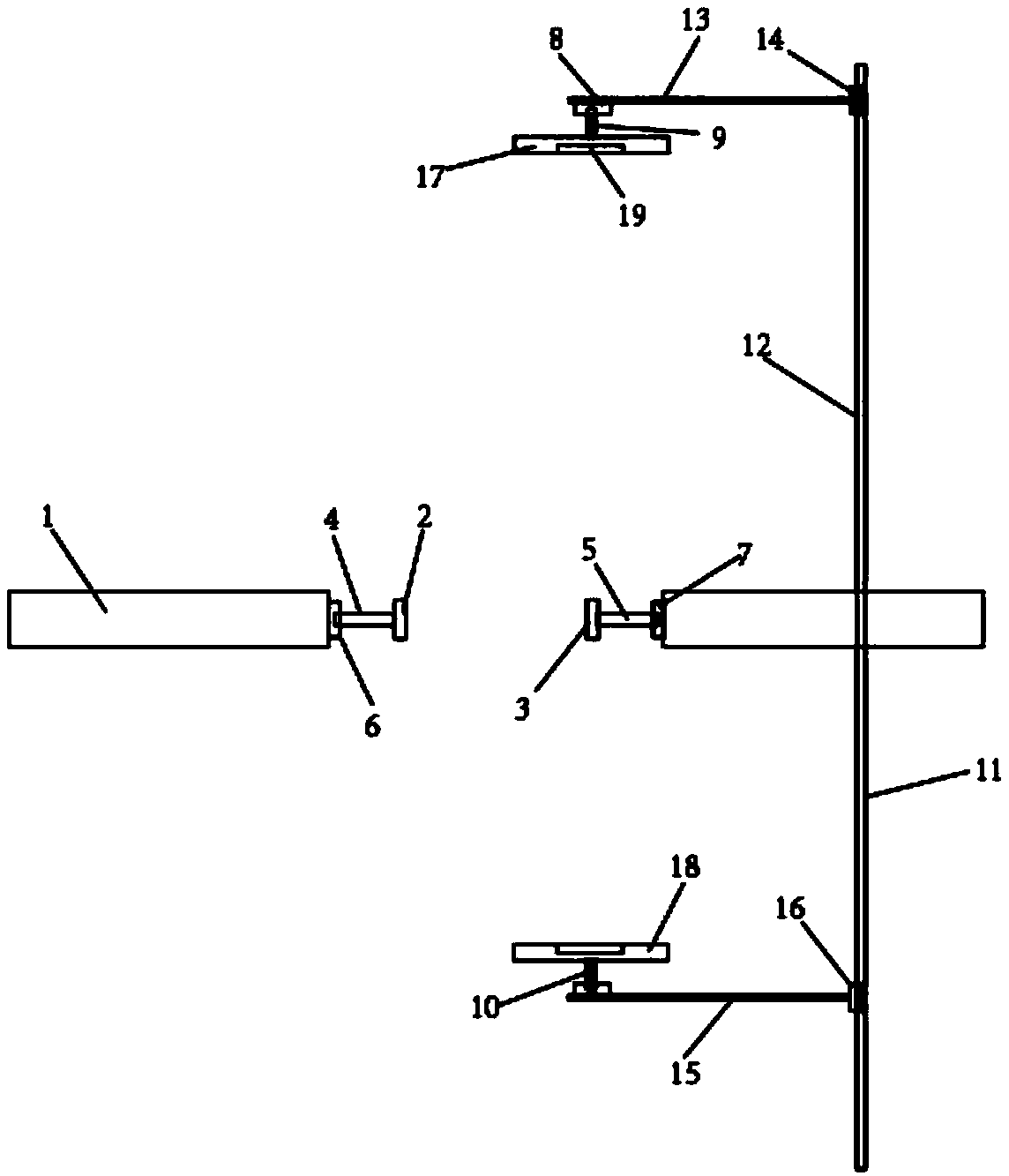

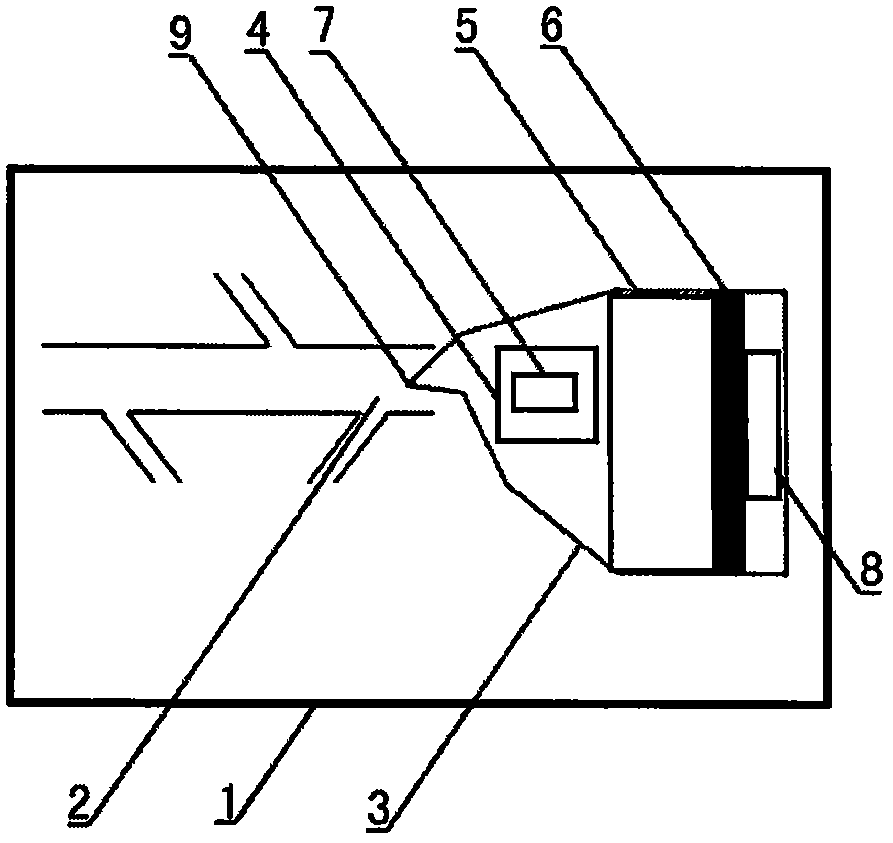

Lubricating oil adding and injecting device for injection molding machine

A lubricating oil filling device for an injection molding machine, comprising a body (1), on which a pipeline (2), a lubricating gun (3), and a management module (4) are arranged, and on the lubricating gun (3) The storage module (5), extrusion module (6), during operation, the lubricating gun (3) squeezes the lubricating oil in the storage module (5) through the extrusion module (6) to refuel the body (1) through the pipeline (2) ;A timing module (7) is set on the management module (4), and the lubricating gun (3) is set to automatically add lubricating oil to the body (1) within a certain period of time; a power module (8) is set on the extrusion module (6), It is used to provide extrusion power and adjust the extrusion force; set the inlet (9) on the lubricating gun (3) to adjust the amount of lubricating oil injected; add lubricating oil automatically to the vertical injection molding machine by setting the timing lubricating oil to make it work more efficiently.

Owner:YINCHUAN BOJU IND PROD DESIGN

Pneumatic wedging pushing method and apparatus thereof

A pneumatic wedge-type method and mechanism for pushing vehicle features that the vehicle is pushed to move by the friction force between the push wheel and the wheel of the vehicle to be pushed. Its advantages are light weight and small size.

Owner:株洲市长征机电设备有限公司

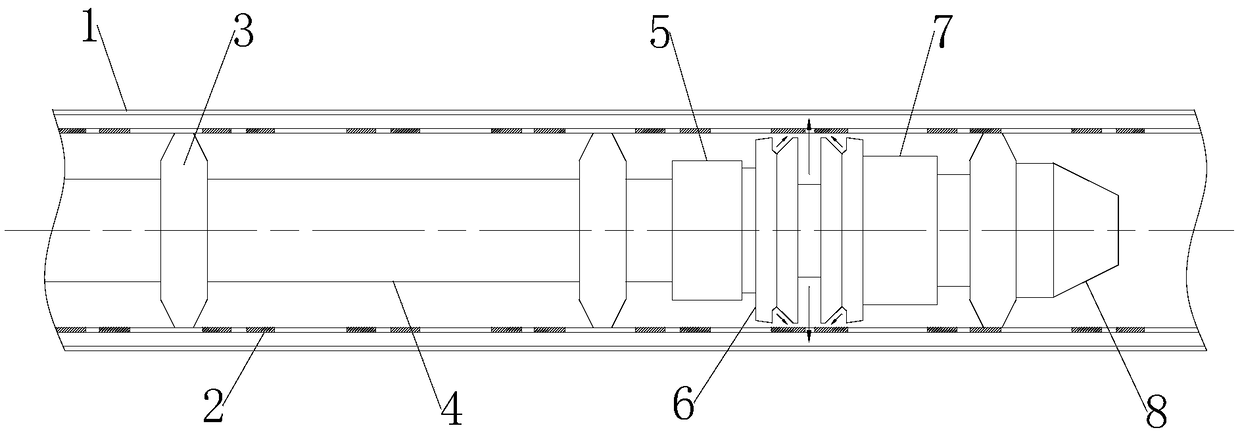

Coal seam gas well washing tool passing through glass fiber reinforced plastics screen pipe and method

The invention discloses a coal seam gas well washing tool passing through a glass fiber reinforced plastics screen pipe. The coal seam gas well washing tool passing through the glass fiber reinforcedplastics screen pipe comprises a washpipe, a jet-flow vibration nozzle, a waterpower blocking type spraying nozzle, a pressure adjuster and a guide head. The washpipe is arranged at the center of theglass fiber reinforced plastics screen pipe. A first elastic centering sleeve is arranged between the washpipe and the glass fiber reinforced plastics screen pipe. The washpipe is sequentially connected with the jet-flow vibration nozzle, the waterpower blocking type spraying nozzle, the pressure adjuster and the guide head. According to the coal seam gas well washing of the screen pipe, due to alarge gap of the screen pipe, the flow speed of high pressure fluid released by the washing tool lowers after the high pressure fluid passes through the screen pipe, and therefore corresponding washing effect can not be achieved. During the cleaning process, fluid space can be shrunk and extruded by movement of a waterpower blocking ring and a movable pressing sleeve, and therefore the speed of the fluid flowing through the gas of the screen pipe increases, and cleaning effect is improved. In addition, the jet cleaning effect is improved by pressure pulse mechanism. A vibration cavity is formed in a nozzle mounting body, and the cleaning effect can be improved by pressure pulse generated by the vibration cavity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com