Pipeline construction machinery for digging track sub-grade material

A technology of construction machinery and ballast bed, applied in the direction of roads, tracks, ballast layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

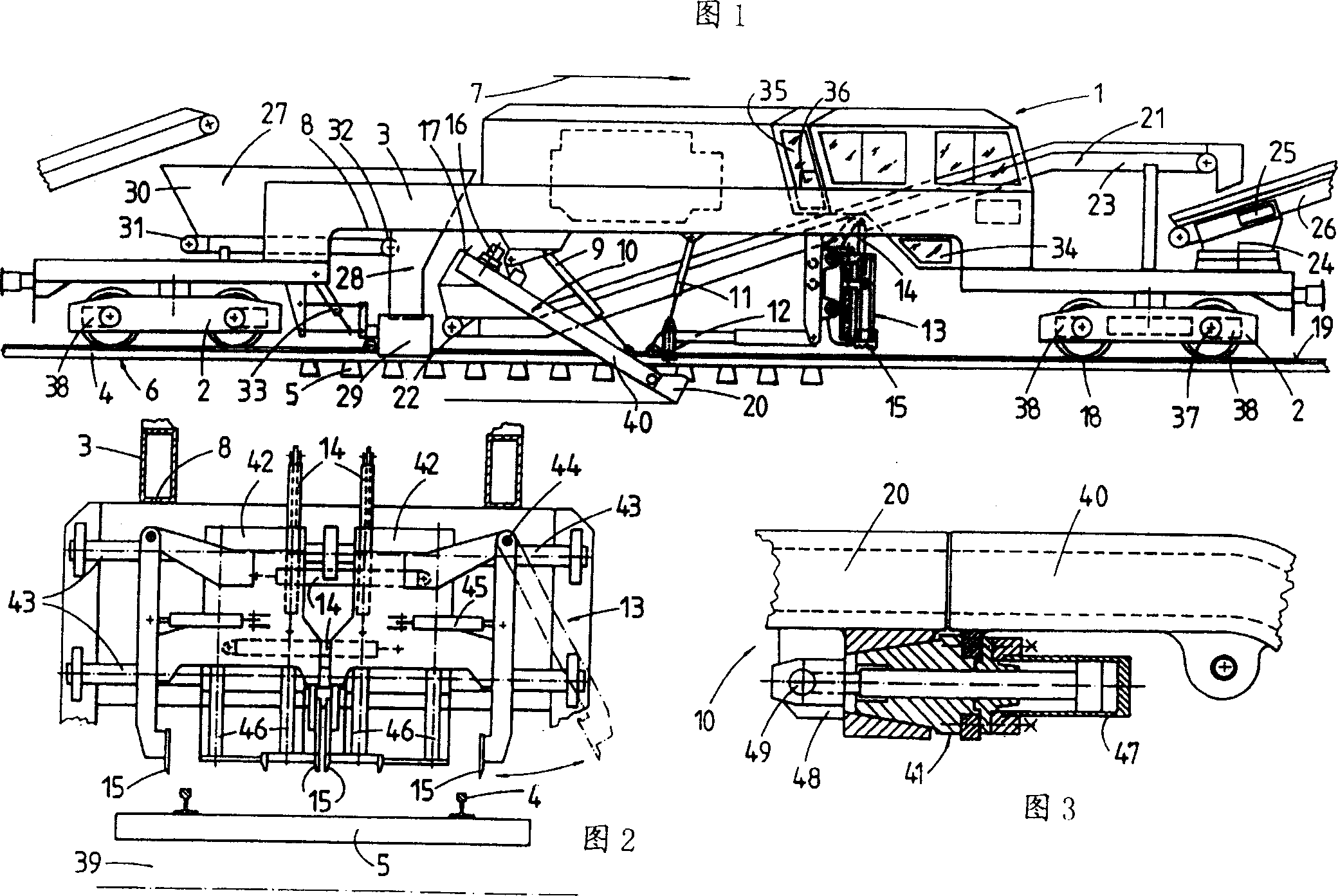

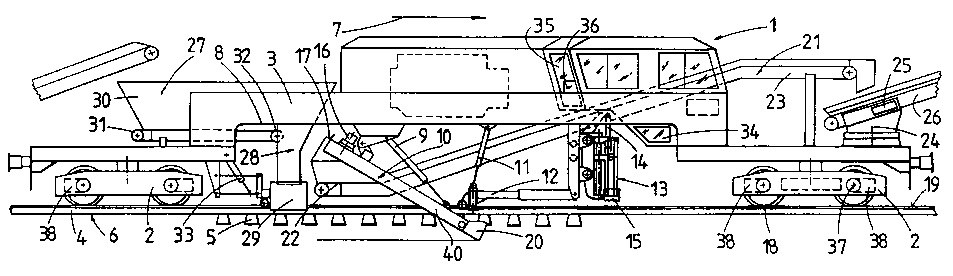

[0012] The line construction machine 1 shown schematically has a frame 3 mounted on a track 2 . Frame can walk along the working direction shown by arrow 7 on a track 6 that is made up of rail 4 and sleeper 5.

[0013] In an upwardly curved section 8 where the frame 3 is located between the track mechanisms 2, there are: the digging chain 10 that utilizes the adjustable height of the driving device 9, the lifting device 12 that utilizes the adjustable height of the driving device 11 and a set of digging Ballast unit 13. The unit is equipped with a dredging mechanism 15 that utilizes a driving device 14 to adjust the height and the vertical position of the machine. The excavating chain 10 with the chain drive 16 at its upper end and the excavating unit 13 is located below the upwardly bent section 8 of the frame 3 . When the highest point 17 of the excavating chain 10 to the vertical line is in the operating position, the reference plane 19 formed by the wheels of the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com