Rotary type two-end heat-sealing die

A rotary, mold technology, applied in packaging sealing/tightening, external support, transportation packaging, etc., can solve the problems of unsuitable batch operation, high labor cost, labor consumption, etc. The effect of sealing quality and improving heat sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below through specific examples.

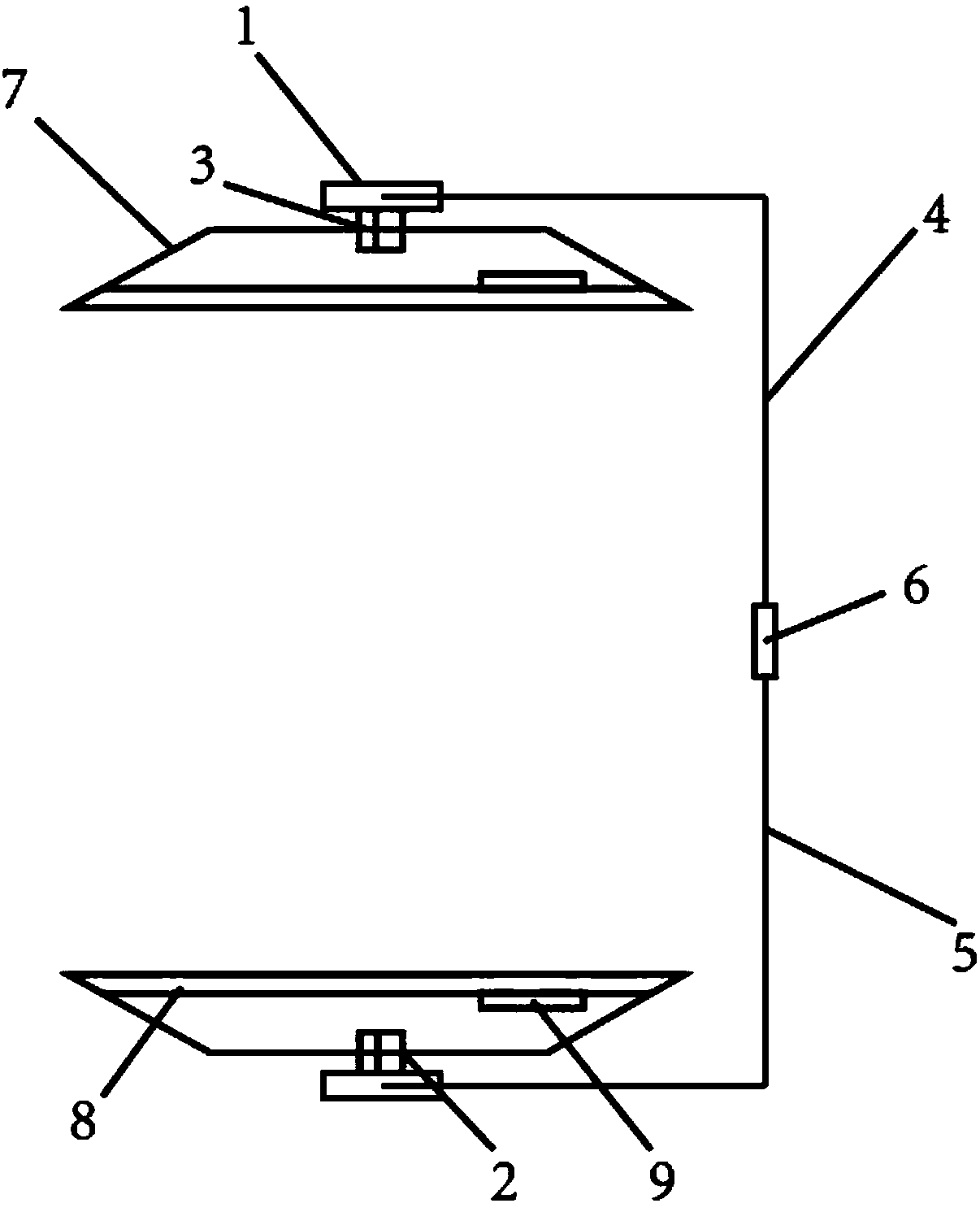

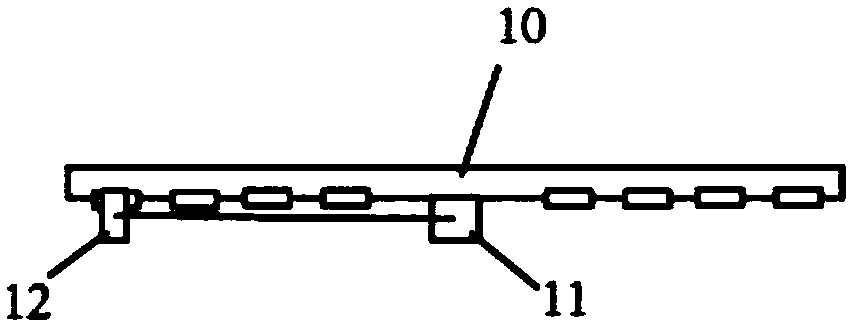

[0016] Such as figure 1 and figure 2 As shown, among them, 1 is the rotating motor, 2 is the rotating shaft, 3 is the speed regulator, 4 is the upper connecting frame, 5 is the lower connecting frame, 6 is the telescopic cylinder, 7 is the heat sealing plate, and 8 is the sealing film heater , 9 is a pressure sensor, 10 is a heat conduction body, 11 is a rotary drive, and 12 is a heat seal heater.

[0017] Rotary two-end heat-sealing mold, including a top heat-sealing device, a bottom-end heat-sealing device, a rotating device and an adjusting device, and the adjusting device is provided with a top heat-sealing device and a bottom-end heat-sealing device through the rotating device;

[0018] The top heat-sealing device and the bottom-end heat-sealing device include a heat-sealing plate, a sealing film heater and a pressure sensor. A pressure sensor, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com