Novel inorganic fine particle enhanced foam system for oil and gas fields, and preparation method thereof

一种微细颗粒、泡沫体系的技术,应用在化学仪器和方法、钻孔的组合物等方向,能够解决经济可行性不强、二氧化硅纳米颗粒造价高昂、二氧化硅纳米颗粒用量高等问题,达到增产效果好、低地层伤害、骨架结构稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

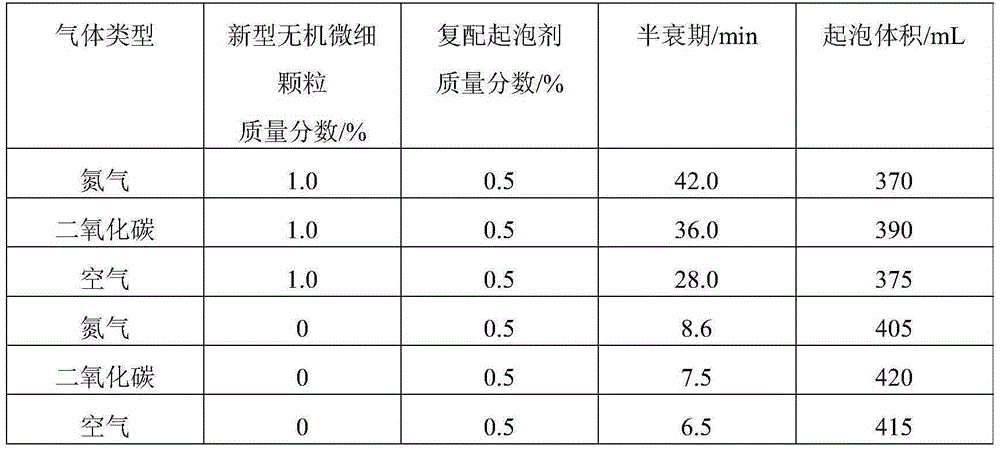

Embodiment 1

[0041] A novel inorganic fine particle reinforced foam system for oil and gas fields, including a gas phase and a liquid phase; the gas phase is nitrogen, and the mass percentage of the raw material components in the liquid phase is as follows:

[0042] 0.5wt% foaming agent, 1.0wt% new inorganic fine particles, and the balance is water;

[0043] The foaming agent is a compound system composed of camellia saponin and sodium lauroyl glutamate in a mass ratio of 6:1; the new inorganic fine particles are fine particles with a particle size of ≤2.5 μm captured and screened in the atmosphere .

[0044] The preparation method is as follows:

[0045] Add the foaming agent into 100mL water according to the proportion, stir to form a foaming agent solution, then add new inorganic fine particles, and stir on a magnetic stirrer for 15 minutes to obtain the foam base liquid. Using the Waring Blender method, 100 mL of the foam base liquid was stirred and foamed at a stirring speed of 7000...

Embodiment 2

[0047] A novel inorganic fine particle reinforced foam system for oil and gas fields, including a gas phase and a liquid phase, the gas phase is air, and the mass percentages of raw material components in the liquid phase are as follows:

[0048] 0.5wt% foaming agent, 1.0wt% new inorganic fine particles, and the balance is water;

[0049] The foaming agent is a compound system composed of camellia saponin and sodium lauroyl glutamate in a mass ratio of 6:1; the new inorganic fine particles are fine particles with a particle size of ≤2.5 μm captured and screened in the atmosphere .

[0050] The preparation method is as follows:

[0051] Add the foaming agent into 100mL water according to the proportion, stir to form a foaming agent solution, then add new inorganic fine particles, and stir on a magnetic stirrer for 15 minutes to obtain the foam base liquid. Using the Waring Blender method, 100 mL of the foam base liquid was stirred and foamed at a stirring speed of 7000 rpm fo...

Embodiment 3

[0053] A new type of inorganic fine particle reinforced foam system for oil and gas fields, including gas phase and liquid phase, the gas phase is carbon dioxide. The mass percent of raw material component in liquid phase is as follows:

[0054] 0.5wt% foaming agent, 1.0wt% new inorganic fine particles, and the balance is water;

[0055] The foaming agent is a compound system composed of camellia saponin and sodium lauroyl glutamate in a mass ratio of 6:1; the new inorganic fine particles are fine particles with a particle size of ≤2.5 μm captured and screened in the atmosphere .

[0056] The preparation method is as follows:

[0057] Add the surfactants in the foaming agent to 100mL water in sequence according to the proportion, stir to form a foaming agent solution, then add new inorganic fine particles, and stir on a magnetic stirrer for 15 minutes to obtain the foam base liquid. Using the Waring Blender method, 100 mL of the foam base liquid was stirred and foamed at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com