Concrete delivery system and concrete delivery vehicle with the delivery system

A concrete conveying vehicle and conveying system technology, applied in the direction of road bottom layer, building, infrastructure engineering, etc., can solve the problems of hindering construction progress, waste of resources, waste of manpower and material resources, etc., and achieve the goal of increasing the effective construction scope and ensuring the quality of the project Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

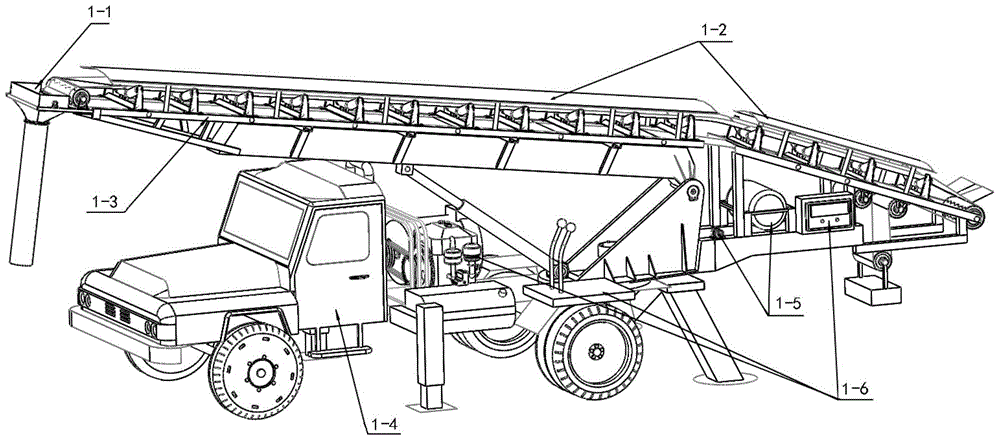

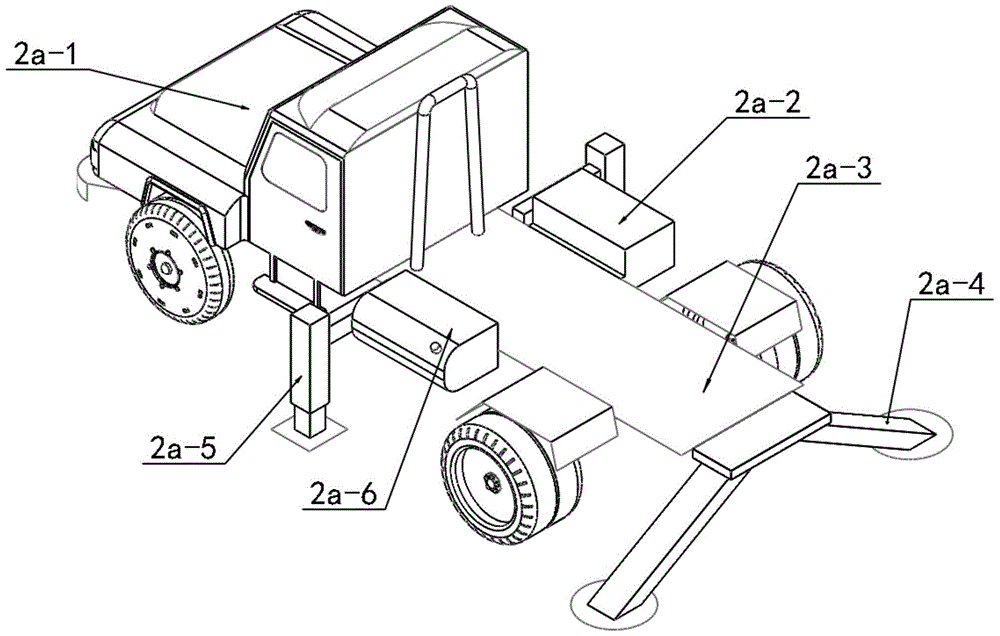

[0049] Embodiment 1: A kind of concrete transmission system 1-3, its structure reference image 3 , Figure 3a , Figure 4 and Figure 4a As shown, it includes: a rotating support 3-8, the rotating support 3-8 is fixedly connected with the tail support frame 3-9, the front end of the tail support frame 3-9 is hinged with the hydraulic lifting arm 3-7, and the tail support frame The upper end of 3-9 is hinged with the load-bearing beam 3-6, and the hydraulic lifting arm 3-7 can drive the load-bearing beam 3-6 to rotate with the hinge node of the load-bearing beam 3-6 and the tail support frame 3-9 as the center of circle;

[0050]The load-bearing beam 3-6 carries the conveyor belt 3-2 through the upper support frame 3-5, and the conveyor belt 3-2 is driven by the driving wheel and the driven wheel on the upper support frame 3-5 to realize its own movement; the driving wheel is mainly for the conveyor belt 3. The -2 transmission provides the power take-off. Driving wheel com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com