Continuous wall formwork and construction method of continuous wall

A wall formwork and formwork technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of uneven concrete, easy generation of voids, easy to shake, etc., and achieves simple construction technology, guaranteed stability, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

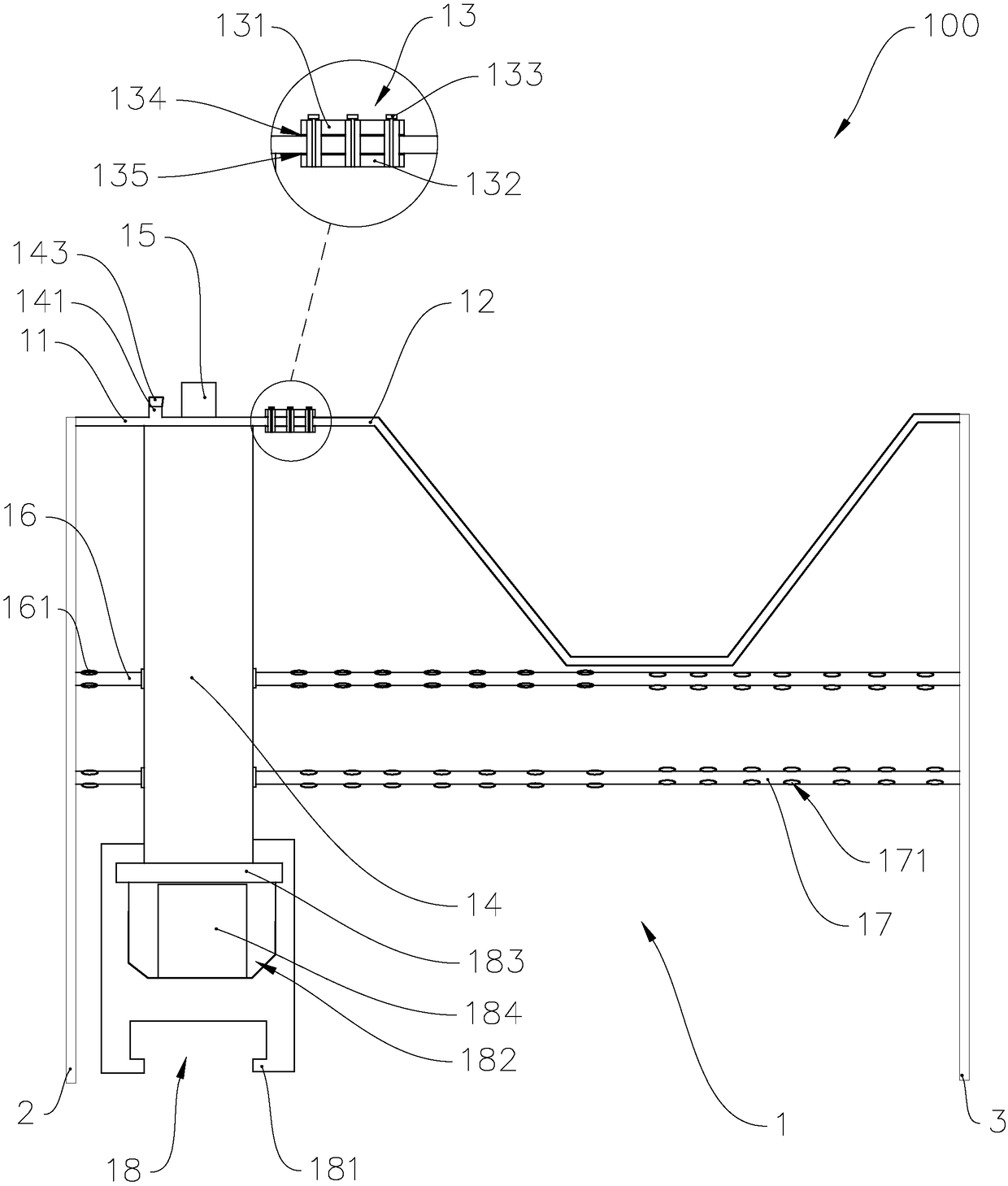

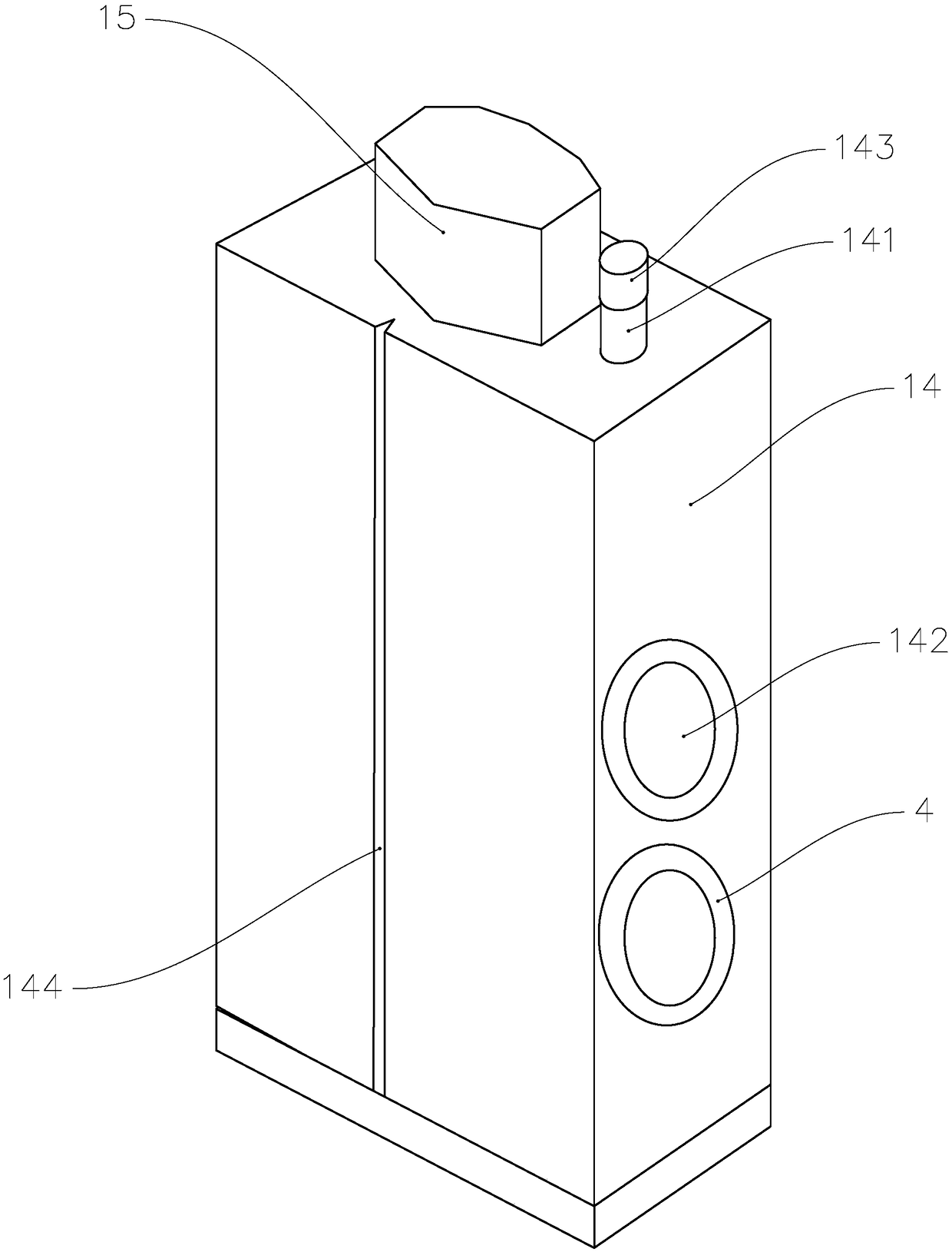

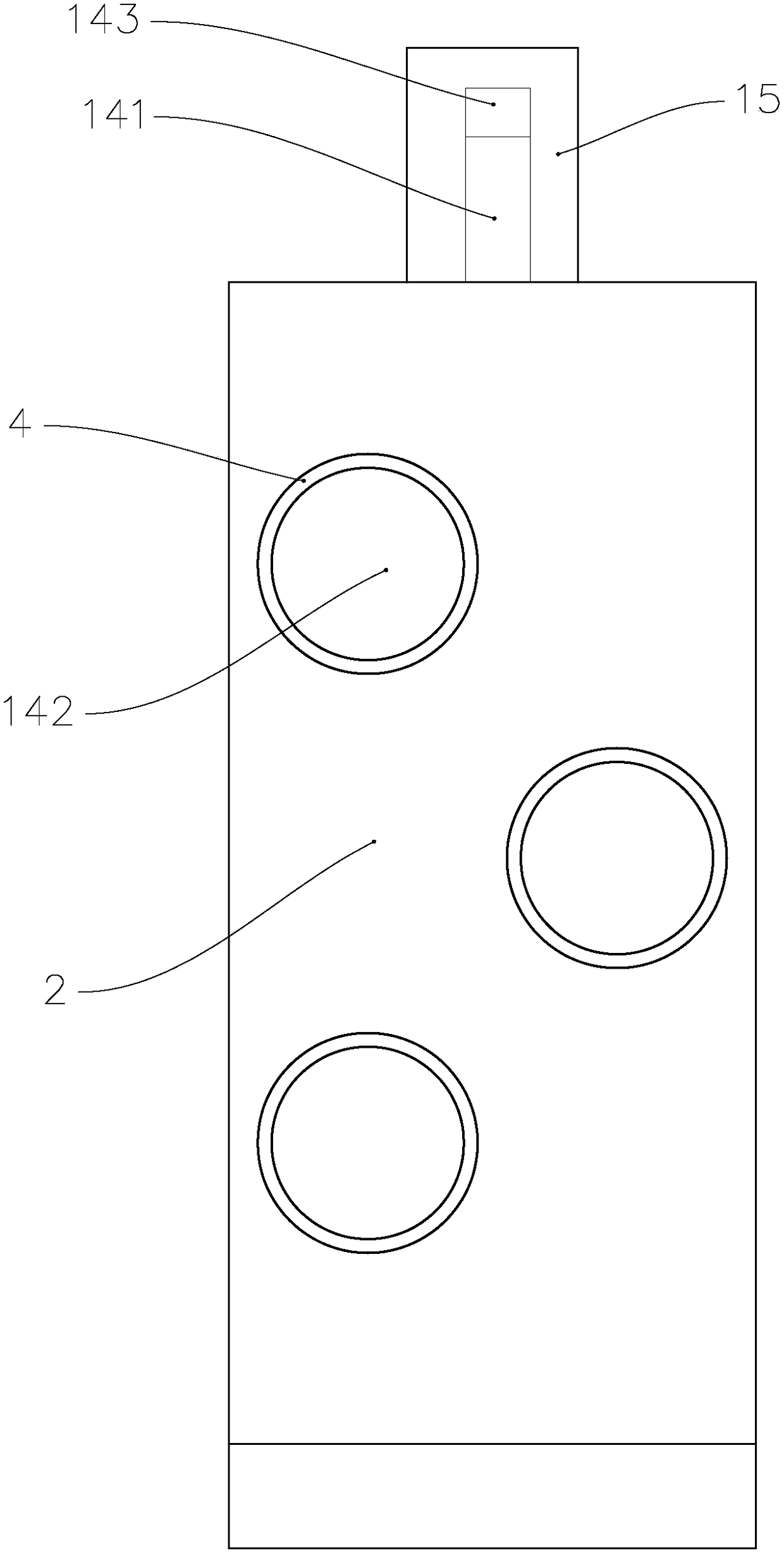

[0043] Such as Figure 4 As shown, applying the inventive concept of the first embodiment of the continuous wall formwork, the difference between the second embodiment of the continuous wall formwork and the first embodiment is that the formwork assembly of the second embodiment includes a plurality of formwork units 60, and one formwork unit The second end of the second steel frame plate 62 of 60 is connected with the second end of the first steel frame plate 61 of another formwork unit 60 by connector 63; The second end of the first connecting pipe 64 of another template unit 60 is connected.

[0044] The first end face formwork 7 is fixedly connected to the second end of the first steel frame plate 61 of the formwork unit 60 at the head end of the formwork assembly, and the second end of the first connecting pipe 64 of the formwork unit 60 at the head end of the formwork assembly is sealed. . The second end formwork 8 is fixedly connected to the second end of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com