Manual Chinese chestnut thorn ball stripping equipment

A chestnut and equipment technology, applied in the field of manual chestnut thorn ball peeling equipment, can solve the problems of heavy weight, difficulty in moving, and easy injury of manual peeling thorn balls, etc., and achieve the effect of light weight, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

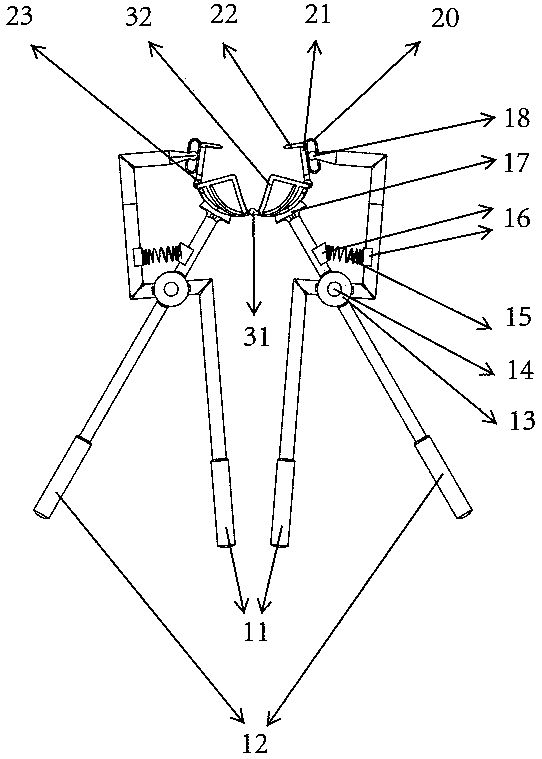

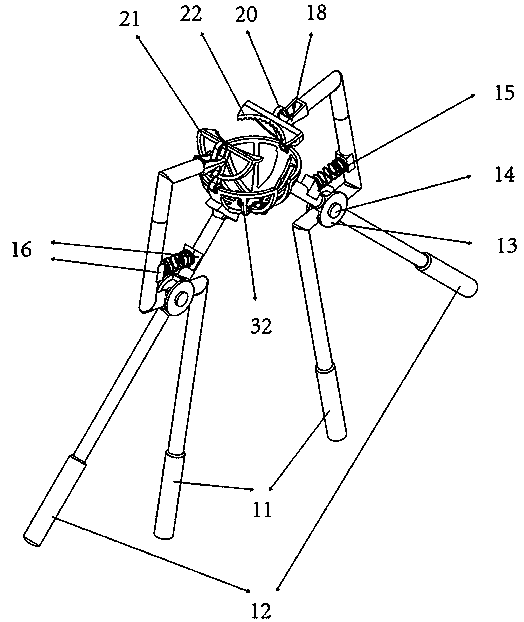

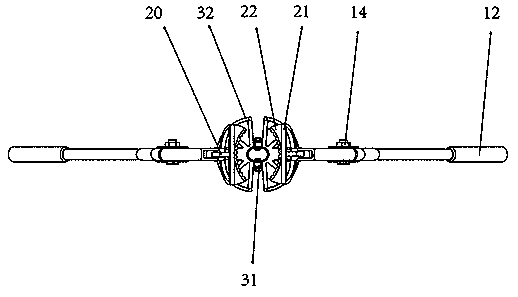

[0028] Below in conjunction with the drawings and preferred embodiments, the specific implementation, structure, features and effects of the manual chestnut thorn ball stripping device proposed according to the present invention will be described in detail as follows.

[0029] See attached Figure 1-7 , the manual chestnut thorn ball peeling equipment provided by the present invention mainly includes an inner wrench 11, an outer wrench 12, a pressing plate 21 and a positioning part 32; it is characterized in that: the inner wrench 11 and the outer wrench 12 cooperate through a hinged manner; the inner wrench 11 A sliding block 18 is welded on the top; a positioning part 32 is provided at the top of the outer wrench 12; a pressing plate 21 is fitted between the sliding block 18 and the positioning part 32; a chute 20 is welded on the pressing plate 21; the chute 20 and the sliding block 18 Sliding fit; the pressure plate 21 and the positioning part 32 cooperate through a hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com