Preparation of recyclable high-density liquid rubber plug and degradation prediction method of recyclable high-density liquid rubber plug

A technology of high-density liquid and prediction method, which is applied in the field of preparation of recyclable high-density liquid rubber stoppers and its degradation prediction. Avoid incomplete chemical gel breaking, ensure the stability of hot salt, and avoid the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

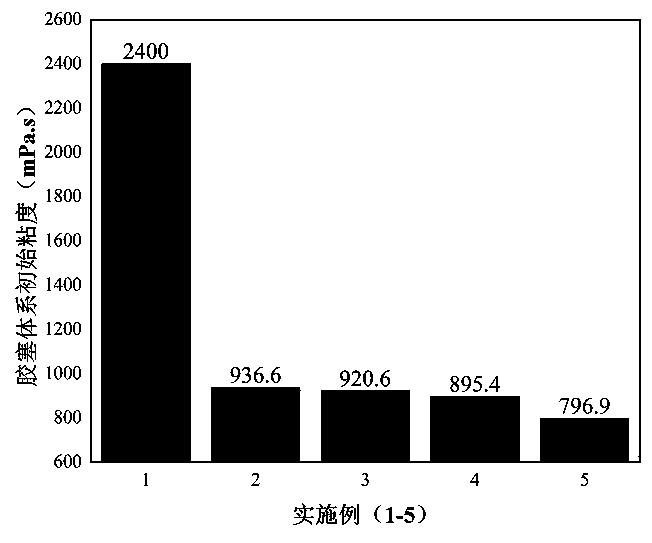

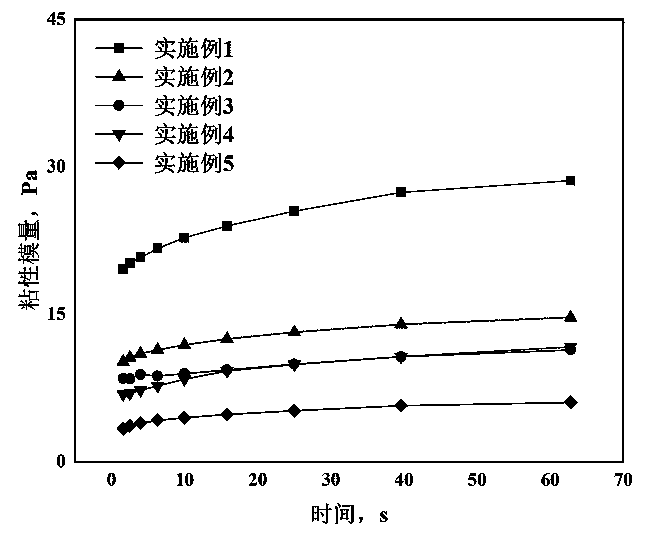

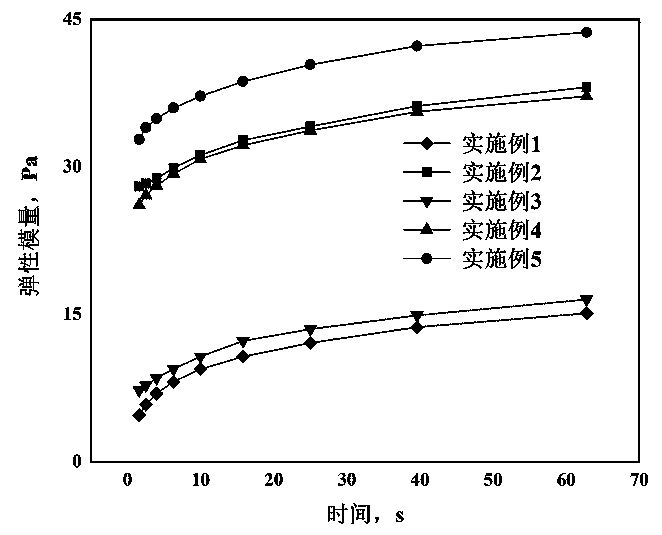

[0044] In the preparation process of a recyclable high-density liquid rubber stopper, the ratio of the weighting agent is implemented according to Table 2.

[0045] Table 2 Weighting agent dosage ratio table (100ml clear water).

[0046] Density (g / cm 3 )

Embodiment 1

[0049] This experimental example provides a preparation of a recyclable conventional density liquid rubber stopper with a density of 1.0g / cm 3 , the purpose is to compare with other embodiments.

[0050] Add stabilizer, reinforcing material and polymer in clear water in sequence and stir for 2-4 hours to form a uniform solution, then add diluted cross-linking agent, fully stir and dissolve to obtain the initial solution of recyclable conventional density liquid rubber stopper. Among them, the system formula is: 0.02% thiourea + 0.2% laponite and montmorillonite mixture (mass ratio is 4:1) + 1.5% polyacrylamide and xanthan gum mixture (mass ratio is 14:1) + 0.5% A mixture of polyethyleneimine, formaldehyde and resorcinol (mass ratio is 8:1:1), the balance is water, and the density is 1.0g / cm 3 , total volume 100ml.

Embodiment 2

[0052] This experimental example provides a method for the preparation and degradation prediction of a recyclable high-density liquid rubber stopper with a density of 1.2g / cm 3 .

[0053] Add weighting agent in clean water and stir evenly, then add stabilizer, reinforcing material, polymer and stir for 2-4 hours to form a uniform solution, then add diluted cross-linking agent, fully stir and dissolve to obtain a recyclable high-density liquid Rubber stopper initial solution. Among them, the system formula is: 36% mixture of sodium bromide and potassium formate (mass ratio is 5:1) + 0.02% thiourea + 0.2% hectorite and montmorillonite mixture (mass ratio is 7:1) + 1.5% Polyacrylamide and xanthan gum mixture (mass ratio 13:2) + 0.5% polyethyleneimine, formaldehyde and resorcinol mixture (mass ratio 3:1:1), the rest is water, density is 1.2g / cm 3 , total volume 100ml.

[0054] Pour the prepared initial solution of the recyclable high-density liquid rubber stopper system into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com