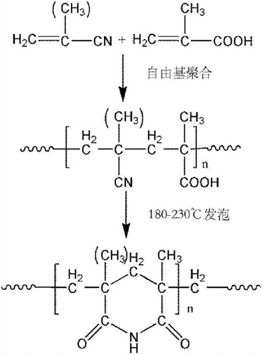

A kind of radiation cross-linked polymethacrylimide foam and preparation method thereof

A technology of polymethacrylimide and radiation crosslinking, which is applied in the direction of coating, etc., can solve the problems of lower photoinitiation efficiency, small molecular weight, and inability to meet the curing process of carbon fiber/bismaleimide prepreg , to achieve the effect of promoting mechanical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038](1) 30 parts by weight of (meth)acrylonitrile, 70 parts by weight of (meth)acrylic acid, 1 part by weight of styrene, 0.1 part by weight of azobisisobutyronitrile, 5 parts by weight of isopropanol, and 0.5 parts by weight of a photosensitizer 1-3 parts by weight of calcium oxide, mixed evenly, fully dissolved and injected into the airtight plane mold;

[0039] (2) Place the mold at 30°C to react for 100 hours to obtain a transparent plastic plate, then heat-treat the plastic plate at 60°C for 60 hours to obtain polymethacrylimide plastic;

[0040] (3) Foaming the board at 180°C for 2 hours to obtain polymethacrylimide foam;

[0041] (4) The polymethacrylimide foam was irradiated, the irradiation energy was 4 Mev, and the irradiation dose was 200KGy to obtain radiation crosslinked polymethacrylimide foam.

[0042] Described photosensitizer is that described photosensitizer is a kind of polyionic liquid type photosensitizer, is prepared according to the following method: ...

Embodiment 2

[0045] (1) 38 parts by weight of (meth)acrylonitrile, 62 parts by weight of (meth)acrylic acid, 2.8 parts by weight of maleimide, 0.48 parts by weight of dibenzoyl peroxide, 7 parts by weight of tert-butanol, photosensitive 2.5 parts by weight of the agent and 2.6 parts by weight of methacrylamide are mixed evenly, and injected into the airtight flat mold after fully dissolving;

[0046] (2) Place the mold at 36°C for 92 hours to obtain a transparent plastic plate, then heat-treat the plastic plate at 74°C for 52 hours to obtain polymethacrylimide plastic;

[0047] (3) Foaming the board at 190°C for 2.8 hours to obtain polymethacrylimide foam;

[0048] (4) The polymethacrylimide foam was irradiated with an irradiation energy of 3.4 Mev and an irradiation dose of 360KGy to obtain radiation crosslinked polymethacrylimide foam.

[0049] Described photosensitizer is that described photosensitizer is a kind of polyionic liquid type photosensitizer, is prepared according to the fol...

Embodiment 3

[0052] (1) 46 parts by weight of (meth)acrylonitrile, 54 parts by weight of (meth)acrylic acid, 4.6 parts by weight of maleic anhydride, 0.86 parts by weight of tert-butyl perpivalate, 9 parts by weight of methylurea, photosensitive 3.5 parts by weight of agent and 2.2 parts by weight of triallyl cyanurate are mixed evenly, and injected into the airtight plane mold after fully dissolving;

[0053] (2) Place the mold at 42°C for 82 hours to obtain a transparent plastic plate, and then heat-treat the plastic plate at 88°C for 44 hours to obtain polymethacrylimide plastic;

[0054] (3) Foaming the board at 200°C for 3.6 hours to obtain polymethacrylimide foam;

[0055] (4) The polymethacrylimide foam was irradiated with an irradiation energy of 2.8 Mev and a radiation dose of 520KGy to obtain a radiation-crosslinked polymethacrylimide foam.

[0056] Described photosensitizer is that described photosensitizer is a kind of polyionic liquid type photosensitizer, is prepared accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com