A kind of hard alloy material for valve ball and preparation method thereof

A technology of hard alloy and valve ball, which is applied in the field of hard alloy materials and hard alloy materials for valve balls. It can solve the problems of aggravated valve ball directional wear, single density, and unsatisfactory, and achieve high hardness and bending strength. , good oxidation resistance, the effect of reducing the magnetic susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

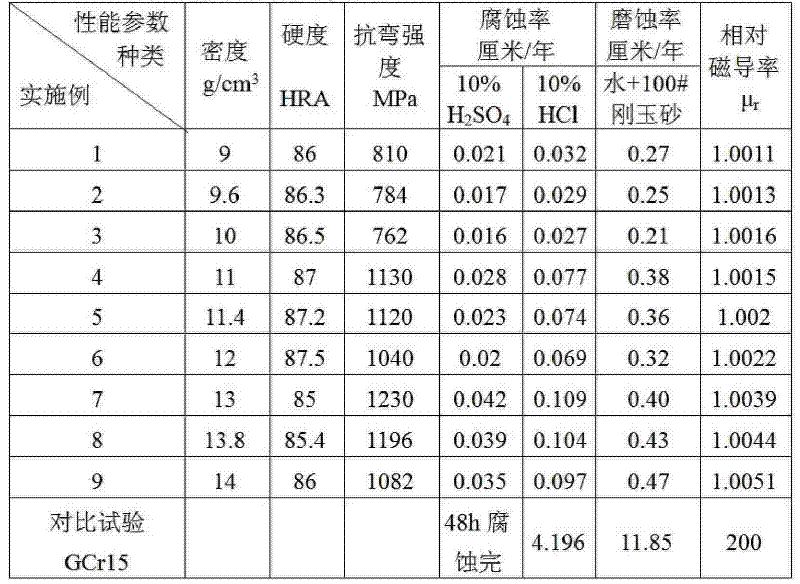

Examples

Embodiment 1

[0023] The cemented carbide material of this embodiment is prepared from the following components by weight percentage: 40% tungsten carbide, 38% chromium carbide, 19% nickel and 3% copper. The preparation method of this cemented carbide material comprises the following steps:

[0024] (1) Take tungsten carbide powder, chromium carbide powder, nickel powder, copper powder and an appropriate amount of absolute ethanol according to the above ratio, and add them to a drum-type ball mill for mixing. The ball-to-material ratio is 2:1, and the mixing time is 24 hours. , and then spray-dried to obtain the mixture;

[0025] (2) Adopt hydraulic press to press the mixture into shape, the pressure of pressing is 80MPa, obtains the molding blank;

[0026] (3) The formed blank was sintered in a vacuum carbon tube furnace at 1350° C. for 1 hour to obtain a cemented carbide material.

Embodiment 2

[0028] The cemented carbide material of this embodiment is prepared from the following components by weight percentage: 45% tungsten carbide, 36% chromium carbide, 17% nickel and 2% copper. The preparation method of the cemented carbide material is the same as in Example 1, except that the sintering temperature is 1360° C. and the sintering time is 1.5 hours.

Embodiment 3

[0030] The cemented carbide material of this embodiment is prepared from the following components by weight percentage: 50% tungsten carbide, 34% chromium carbide, 15% nickel and 1% copper. The preparation method of the cemented carbide material is the same as in Example 1, the sintering temperature is 1370° C., and the sintering time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com