Welding process of copper stranded cable

A multi-strand cable, welding technology, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of easy loosening of ends, increased welding costs, and increased current density of the contact surface, so as to avoid the increase of current density and save money. Welding filler material, the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

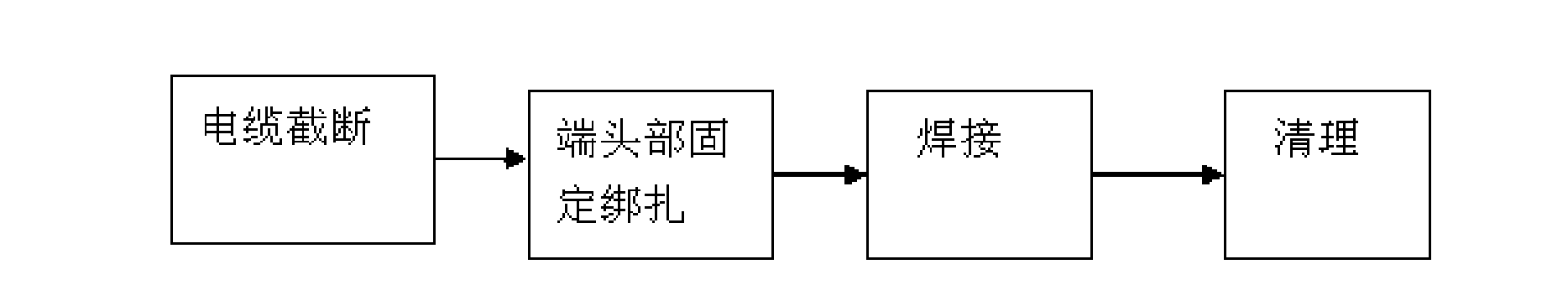

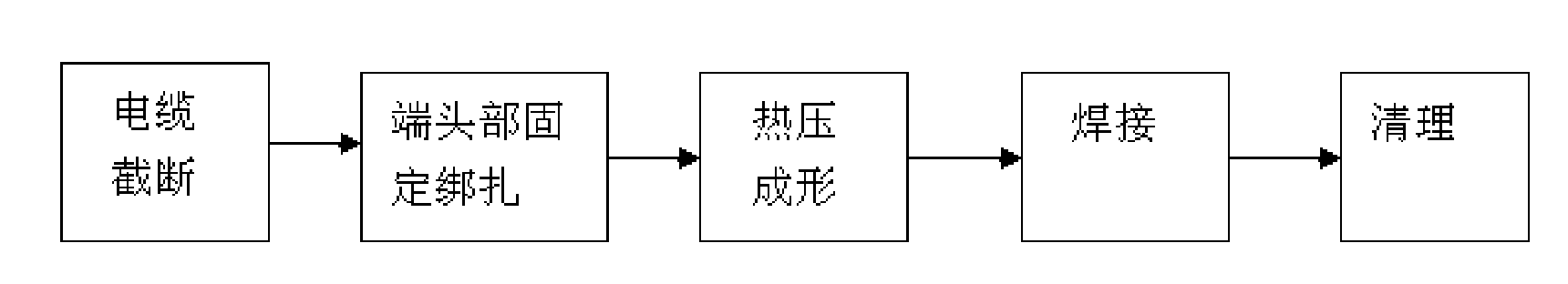

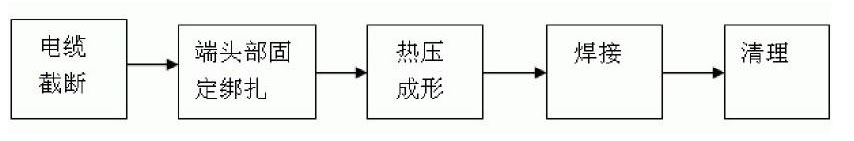

[0019] Embodiment: a copper multi-strand cable welding process, including cable cutting, end head fixing and binding, hot pressing forming, welding and cleaning processes, the hot pressing forming process is after the end head fixing and binding process, Before the welding process, the hot press forming process adopts a high-temperature pressure setting process, that is, the bound and fixed end is heated to about 800°C with an oxygen flame torch, that is, when it is dark red by naked eyes, and then iron hammer or other The method of tool hammering applies pressure to make the end of the cable into an oblate or semicircular shape, and then the thermoformed cable end is welded to the welding connector.

[0020] In the above embodiment, the fixing and binding process of the end portion is to fasten the end portion of the cable with a copper metal core. As a transformation of the above embodiment, other metal cores can also be used to fasten the end portion of the cable; In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com