Use of pyridine quaternary ammonium salt type alkaline or alkalescent polymer membranous

A technology of pyridinium quaternary ammonium salt and polymer membrane, which can be applied to fuel cell components, fuel cells, electrochemical generators, etc., and can solve problems such as difficulty in removing carbon dioxide, degradation of battery performance, and loss of electrolyte solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

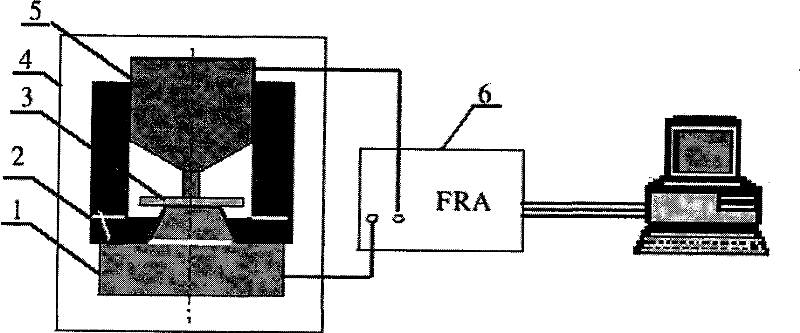

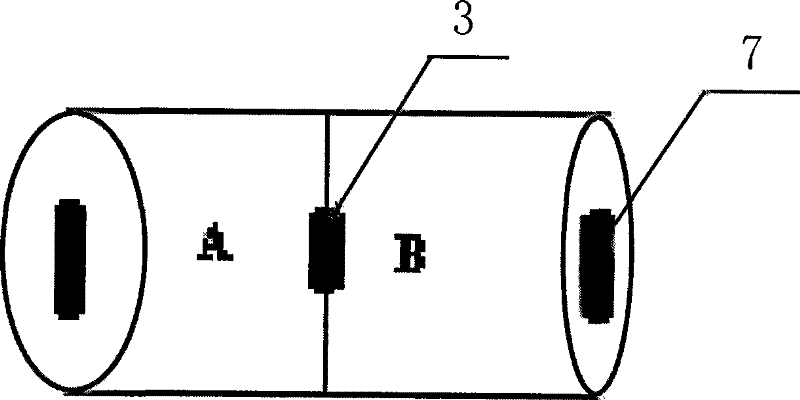

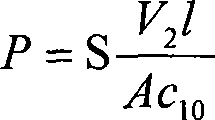

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the synthesis of poly(2-vinylpyridine)

[0019] Pour 80ml of hydroxypropylmethylcellulose (0.15g) aqueous solution into the polymerization bottle, add 25.7ml (25g) of 2-vinylpyridine, 0.2g of benzoyl peroxide, turn on the condensed water, start stirring to mix the reaction reagents evenly , and then pass high-purity nitrogen to eliminate the influence of soluble gases in the polymerization process. After 15 minutes, start heating with a constant temperature device, rapidly increase the reaction temperature to above 65°C, and maintain a certain stirring speed for suspension polymerization for a period of time (1-2h). The reaction temperature was increased to 85°C for another period of time (3h). After the product was washed with a large amount of hot water, it was dried naturally and then vacuum-dried at 60°C.

Embodiment 2

[0020] Embodiment 2: Synthesis of 2-vinylpyridine and styrene copolymer

[0021] Pour 80ml of hydroxypropylmethylcellulose (0.15g) aqueous solution into the polymerization bottle, add a mixture of 2-vinylpyridine and styrene at a mixing ratio of 0.2:1 to 0.8:1, 0.2g of benzoyl peroxide, Turn on the condensed water, start stirring to mix the reaction reagents evenly, and then pass high-purity nitrogen gas to eliminate the influence of soluble gases in the polymerization process, start heating with a constant temperature device after 15 minutes, quickly increase the reaction temperature to above 65 °C, and maintain a certain stirring speed Carry out suspension polymerization for a period of time (1-2h), raise the reaction temperature to 85°C and react for a period of time (3h). After the product was washed with a large amount of hot water, it was dried naturally and then vacuum-dried at 60°C.

[0022] The synthetic reaction of 2-vinylpyridine and trifluorostyrene copolymer is t...

Embodiment 3

[0023] Embodiment 3: the synthesis of poly(4-vinylpyridine)

[0024] The synthetic method of poly(4-vinylpyridine) resin is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com