Riveting machine for riveting of circuit boards

A riveting machine and circuit board technology, applied in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc., can solve the problems of unstable riveting, affecting the riveting accuracy of rivets, and prone to breakage of circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

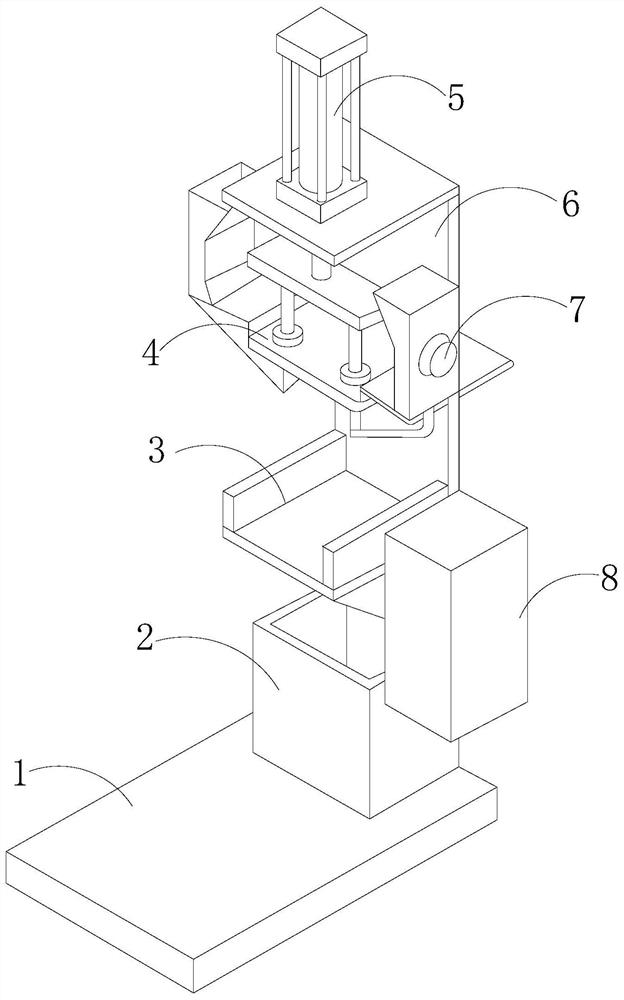

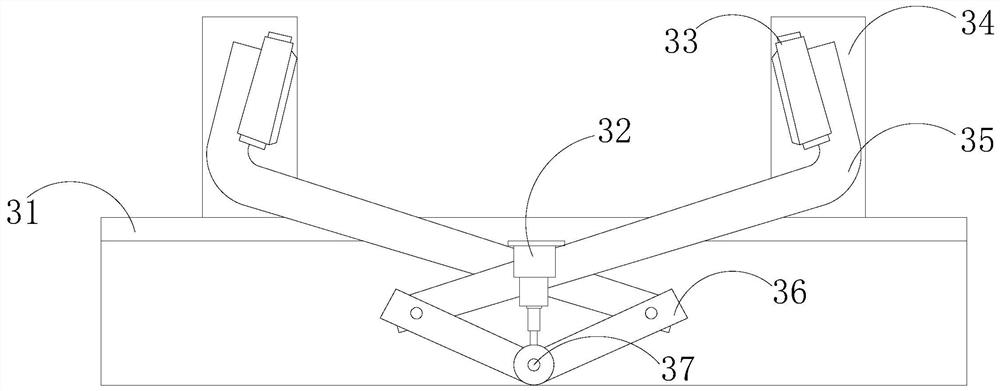

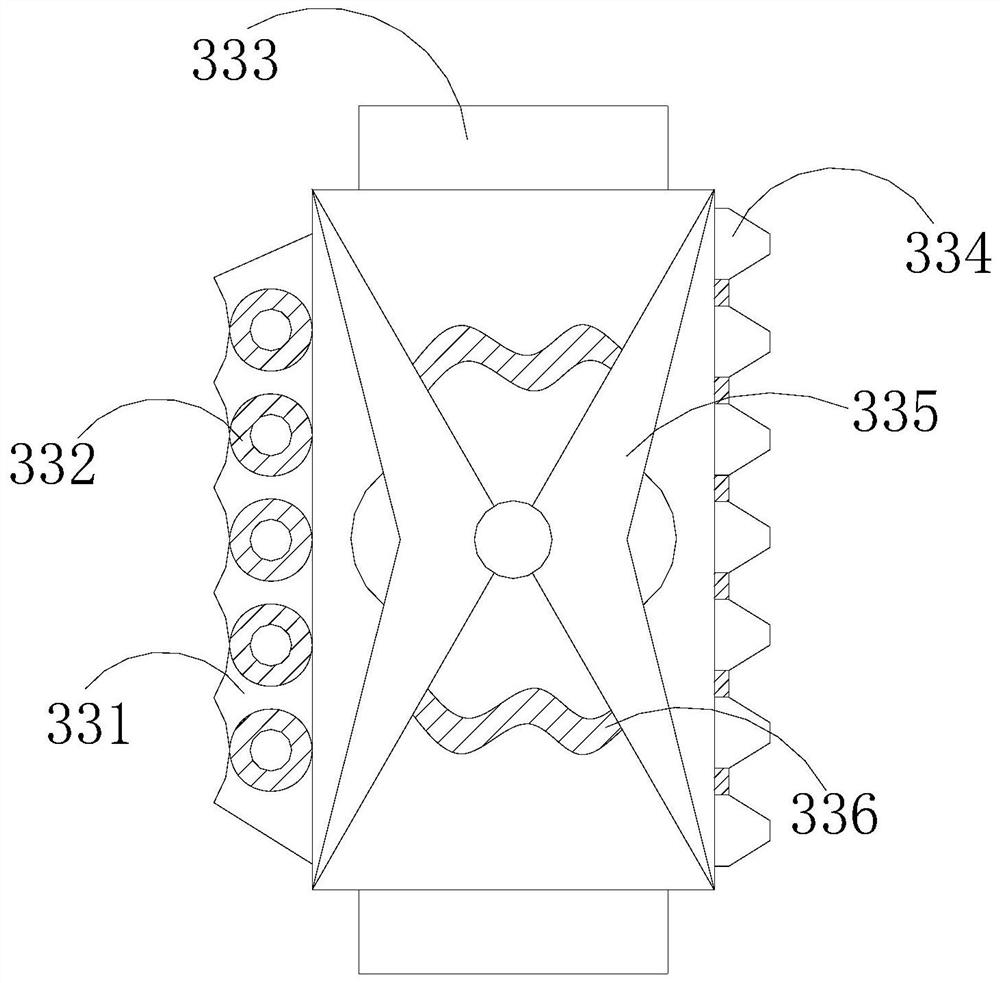

[0033] see figure 1, the present invention provides a technical solution: a riveting machine for circuit board riveting, its structure includes a base 1, a support column 2, a clamping device 3, a riveting head 4, a cylinder 5, a body 6, a protective cover 7, an electric Control box 8, the base 1 is installed at the bottom of the support column 2, the support column 2 is vertically embedded on the base 1, the support column 2 is installed at the bottom of the body 6, and the top of the support column 2 is facing the clamping device 3, the clamping device 3 is inserted and embedded in the body 6 in parallel, and an electric control box 8 is provided on one side of the body 6, and the electric control box 8 is electrically connected to the riveting head 4 through a cable, and the riveting head 4 Cooperating with the body 6 in a movable snap-fitting manner, protective covers 7 are provided on both sides of the riveting head 4, and the protective covers 7 are buckled on both side...

Embodiment 2

[0044] see figure 1 , the present invention provides a technical solution: a riveting machine for circuit board riveting, its structure includes a base 1, a support column 2, a clamping device 3, a riveting head 4, a cylinder 5, a body 6, a protective cover 7, an electric Control box 8, the base 1 is installed at the bottom of the support column 2, the support column 2 is vertically embedded on the base 1, the support column 2 is installed at the bottom of the body 6, and the top of the support column 2 is facing the clamping device 3, the clamping device 3 is inserted and embedded in the body 6 in parallel, and an electric control box 8 is provided on one side of the body 6, and the electric control box 8 is electrically connected to the riveting head 4 through a cable, and the riveting head 4 Cooperating with the body 6 in a movable snap-fitting manner, protective covers 7 are provided on both sides of the riveting head 4, and the protective covers 7 are buckled on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com