Coil holding member for holding motor coil and method for manufacturing motor stator

A coil holding and coil technology, which is used in the manufacture of motor generators, electrical components, electric components, etc., can solve problems such as reducing the stability of partial discharge of the stator, and achieve the effect of improving efficiency, good heat dissipation, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

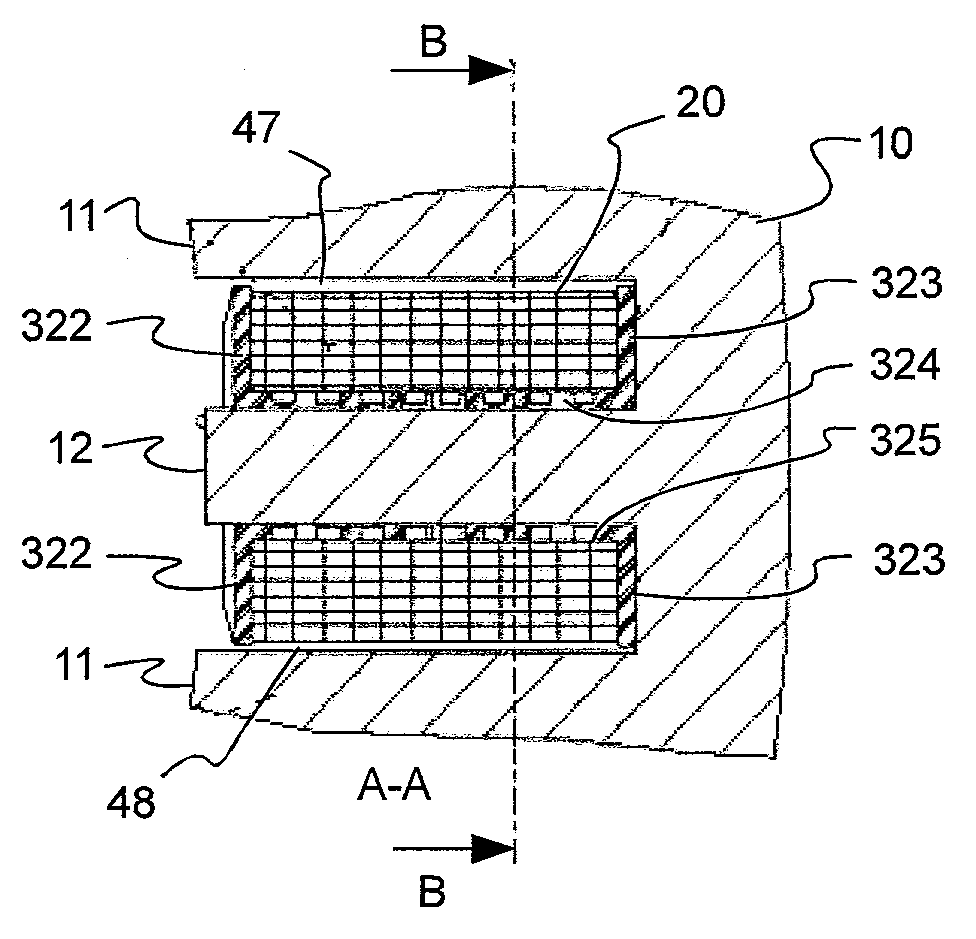

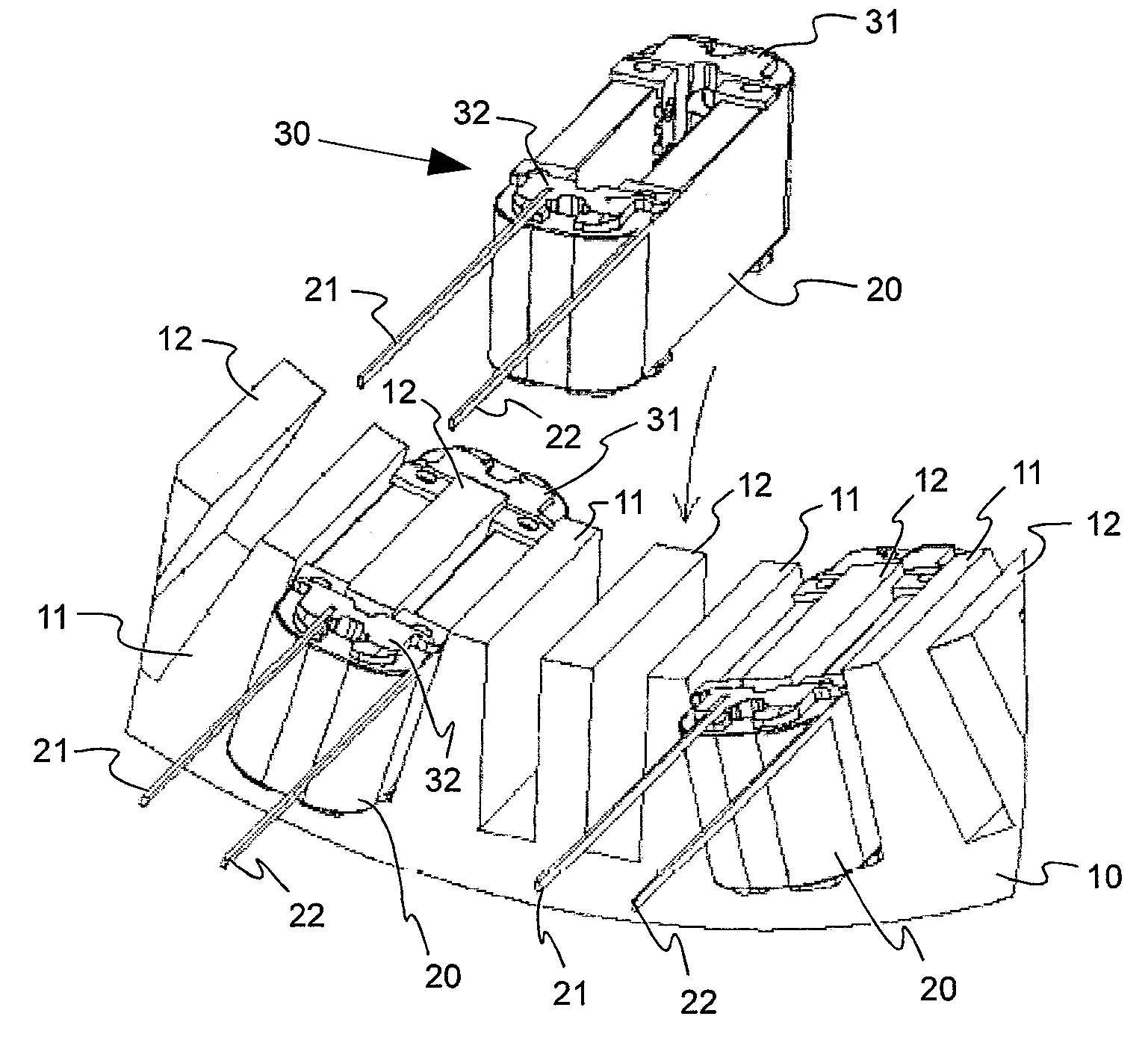

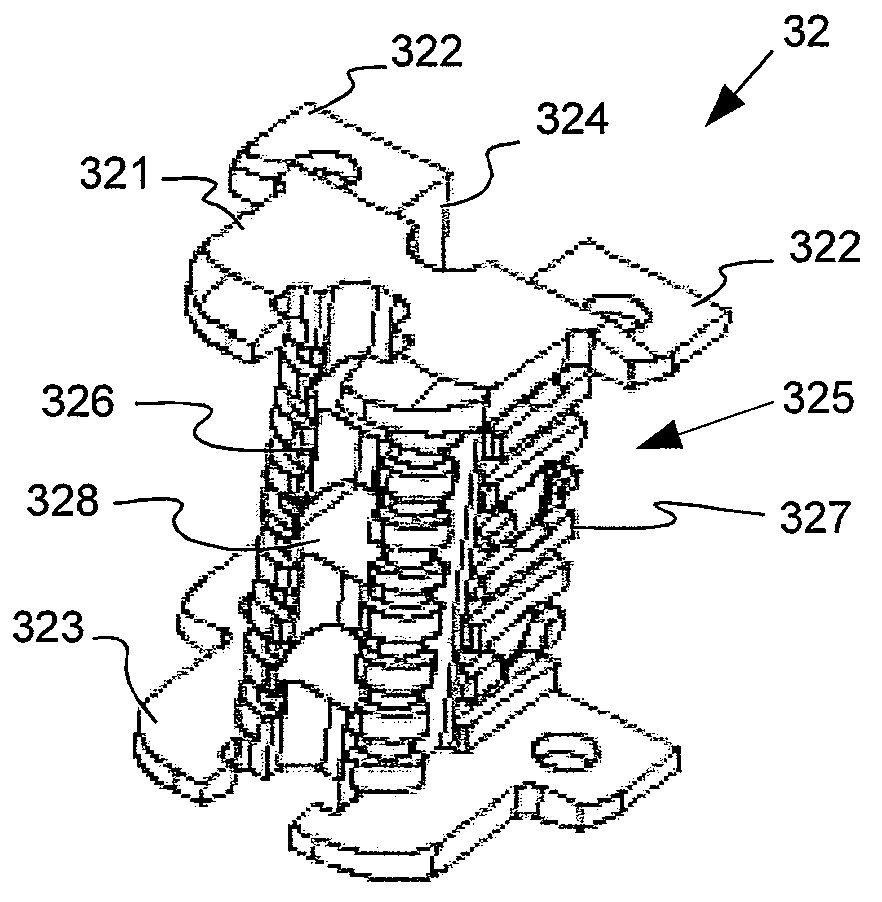

[0025] figure 1 A part of an annular stator core 10 for an electrical machine not shown is shown. The stator core 10 has a large number of first teeth 11 and second teeth 12 which are arranged alternately on the inner side of the annular stator core 10 . In other words, the first and second teeth 11 , 12 protrude on the inner side of the stator core 10 . In this case, the first teeth 11 are narrower on the inner side of the annular stator core 10 than at the bottom of the stator teeth 11 , where the first teeth 11 are connected to the stator core 10 . connected. In contrast, the second teeth 12 are equally wide not only on the inner side of the stator core 10 but also on its base.

[0026] exist figure 1 A coil 20 with a coil holder 30 having a first and a second coil holder 31 , 32 has been mounted on two of the second teeth 12 . as in figure 1 A further coil 20 wound on a further coil holder 30 can be arranged on the first tooth 11 of the stator core 10 , as indicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com