Longitudinal drawing device

A technology of longitudinal stretching and circumferential speed, which can be used in transportation and packaging, object supply, winding strips, etc., and can solve problems such as transfer scratches and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

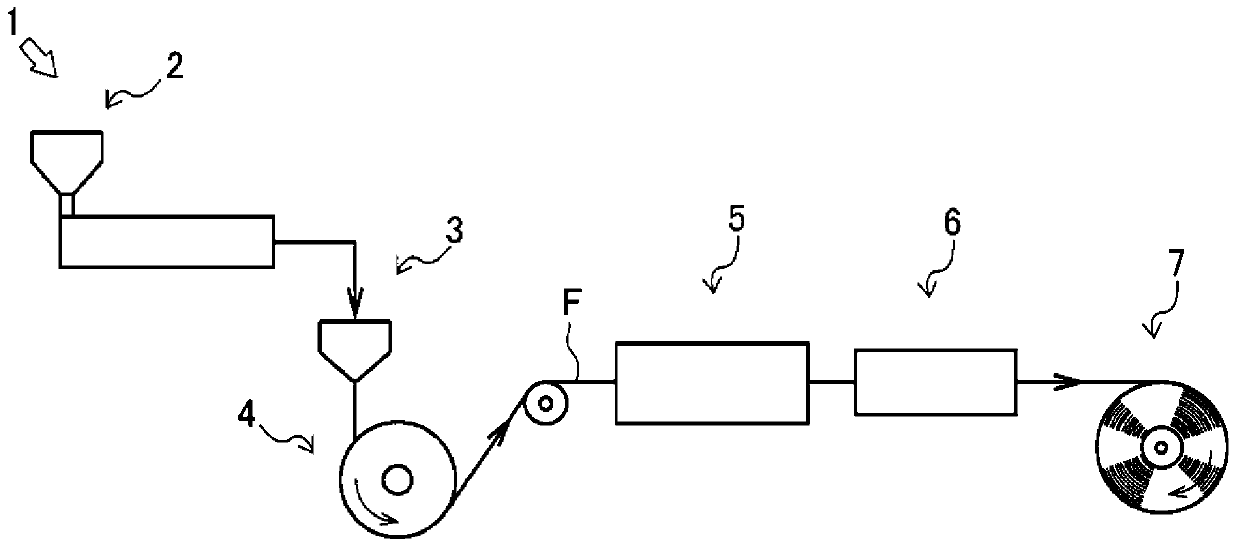

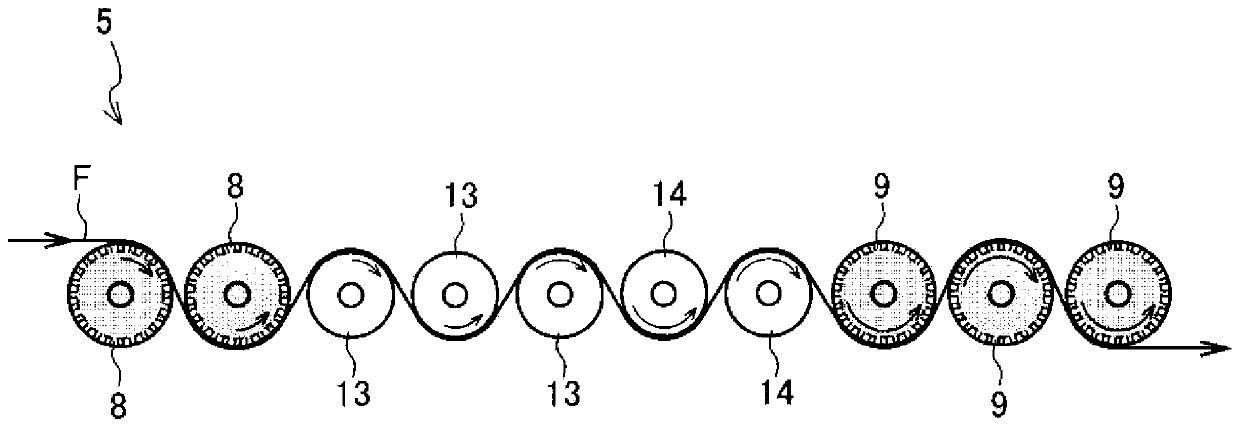

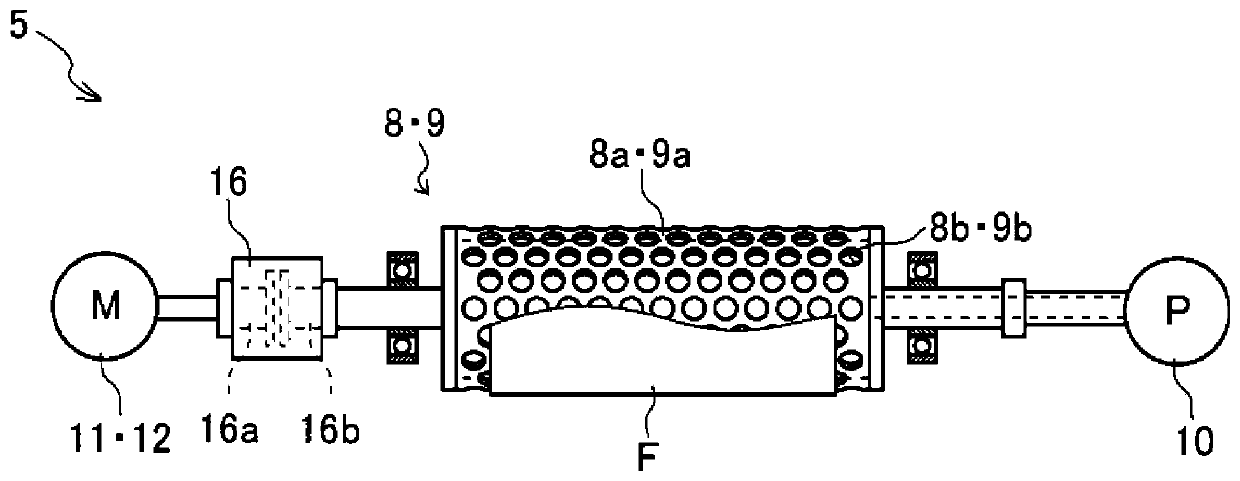

[0028] First, use figure 1 The manufacturing apparatus 1 provided with the longitudinal stretching apparatus 5 which is one embodiment of the longitudinal stretching apparatus of this invention is demonstrated. In addition, the manufacturing apparatus 1 manufactures a thermoplastic film F made of a thermoplastic polymer such as polyester, triacetyl cellulose (TAC), polyolefin, polyamide, etc. The case of the thermoplastic film F will be described.

[0029] Such as figure 1 As shown, the manufacturing apparatus 1 processes the thermoplastic polymer which consists of triacetyl cellulose (TAC), and manufactures the thermoplastic film F which consists of desired film thickness. The manufacturing device 1 has a melt extrusion device 2 , a slot die 3 , a casting roll 4 , a longitudinal stretching device 5 , a transverse stretching device 6 , and a coiling device 7 .

[0030] The manufacturing device 1 heats and melts a sheet-shaped thermoplastic polymer through a melt extrusion d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com