Method and apparatus for mechanical fixation of dynamic extensometer in high temperature fatigue test

A fatigue test and extensometer technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to observe the high temperature corrosion morphology of the sample surface, affecting the accuracy of high temperature fatigue test results, and having certain requirements for operating temperature. , to achieve the effect of good plasticity, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

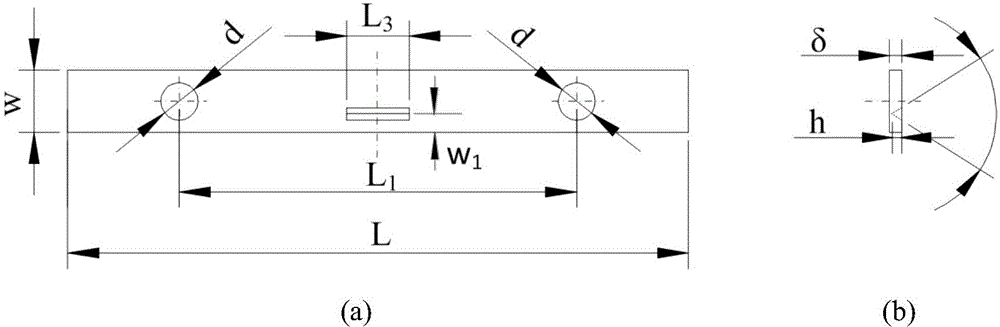

[0040] High temperature fatigue test with strain control mode, the radius R of the parallel section of the fatigue sample is 5mm, and the gauge length L of the dynamic extensometer for measuring the deformation of the fatigue sample 4 is 25mm.

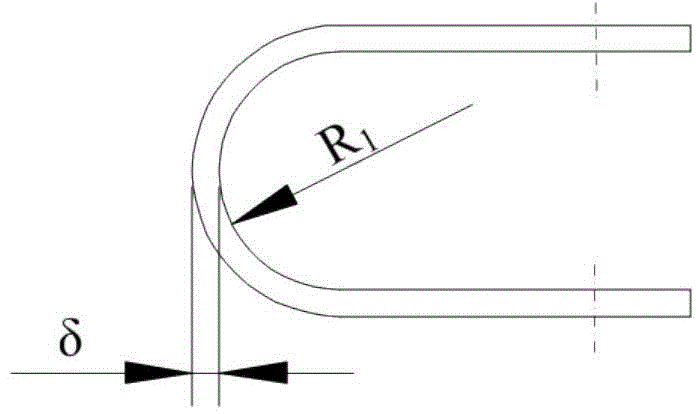

[0041] 1) Select a thin stainless steel plate with a thickness of δ=0.5mm, and symmetrically process the diameter d=3mm on the thin plate, and the hole distance L 1 = Two screw holes of 31.4mm;

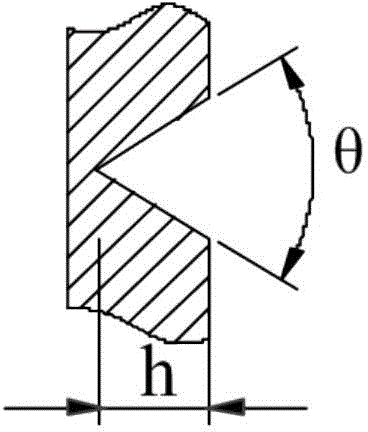

[0042] 2) Using wire cutting technology, process the thin plate in step 1 into a rectangle with a width of W=5mm and a length of L=50mm, and the center of symmetry of the rectangle coincides with the center of symmetry of the two screw holes, as figure 1 shown, and grind the roughness of one of the two surfaces of the thin plate to Ra0.2 with a length of 50mm and a width of 5mm;

[0043] 3) Fit the surface of the polished thin plate to the surface of the sample, take the cylinder in the parallel section of the fatigue sample as the standard,...

Embodiment 2

[0049] High-temperature fatigue test under complex load with strain-stress compound control method, the radius R of the parallel section of the fatigue sample is 3 mm, and the gauge length L of the dynamic extensometer for measuring the deformation of the fatigue sample 4 is 12.5mm.

[0050] 1) Select a thin stainless steel plate with a thickness of δ=0.5mm, and symmetrically process the diameter d=2.5mm on the thin plate, and the hole distance L 1 = Two screw holes of 18.8mm;

[0051] 2) Using wire cutting technology, process the thin plate in step 1 into a rectangle with a width of W=4mm and a length of L=37mm. The center of symmetry of the rectangle coincides with the center of symmetry of the two screw holes, as figure 1 shown, and grind the roughness of one of the two surfaces of the thin plate with a length of 37mm and a width of 4mm to Ra0.2;

[0052] 3) Fit the surface of the polished thin plate to the surface of the sample, take the cylinder in the parallel section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com