Brush ring hobbing and riveting machine for brush-type steam seals

A brush type steam seal and brush ring technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor connection stability between the brush ring and the original steam seal body, difficult to improve production efficiency, and difficult to guarantee quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

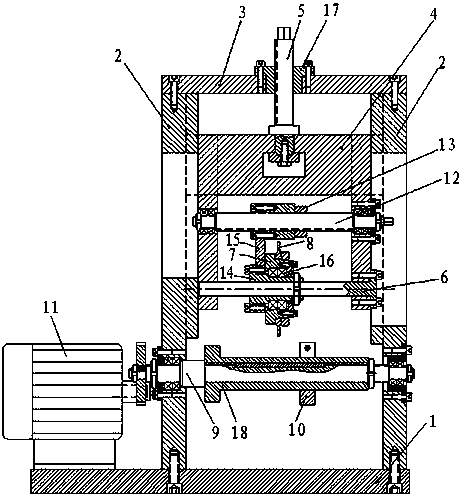

[0015] Such as figure 1 As shown, the present invention includes a frame composed of a base 1, left and right columns 2 and an upper beam plate 3, an "n" type slider 4 is slidably connected between the left and right columns 2, and an up and down adjustment rod is connected to the top of the slider 4 5 (trapezoidal screw), the bottom end of which is rotatably connected to the slider 4, and the upper end is fitted in the C guide sleeve 17 made of the trapezoidal nut, and the C guide sleeve 17 is fixed on the upper beam plate 3; between the lower parts of the slider 4 A horizontal fixed shaft 6 is provided, and a B guide sleeve 14 is installed on the fixed shaft 6. The hob seat 7 is movably fitted on the B guide sleeve 14 through back-to-back angular contact ball bearings 16, and a hob 8 is installed on the hob seat 7. ; The top of the fixed shaft 6 is provided with a horizontal guide rod 12 (trapezoidal screw rod), and the two ends of the guide rod 12 are rotated and installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com