Rectangular lithium ion battery ear-pole and its making method, battery

A lithium-ion battery and tab technology, which is applied in the field of square lithium-ion battery tabs and lithium-ion batteries, can solve the problem of increasing the difficulty of welding or riveting between tabs and cover plates, welding or riveting is not firm, positive and negative electrodes Short circuit and other problems, to achieve the effect of reducing internal resistance drift, reducing the possibility of short circuit phenomenon, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

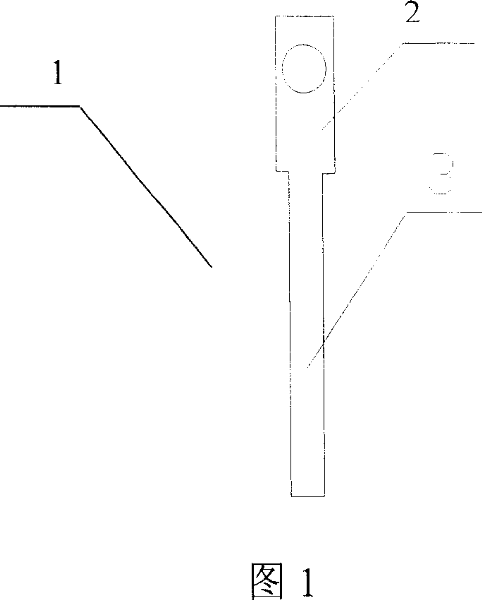

[0015] Embodiment 1. A method for making a tab of a square lithium-ion battery and a tab of a square lithium-ion battery. One end of the tab used to connect to the cover is made wide enough to make it conveniently electrically connected to the cover , Make the other end of the tab used to connect to the positive or negative plate narrow enough to avoid piercing the separator paper and facilitate the entry of the battery into the shell when making the battery. As shown in Figure 1, the tab of a square lithium-ion battery is a bar-shaped tab 1. The strip-shaped tab 1 is composed of a segment 2 and a segment 3. The segment 2 near the upper end of the bar-shaped tab is wider, and the segment 3 near the lower end is wider. Narrower, each segment 2 and segment 3 of equal width are connected as a whole.

Embodiment 2

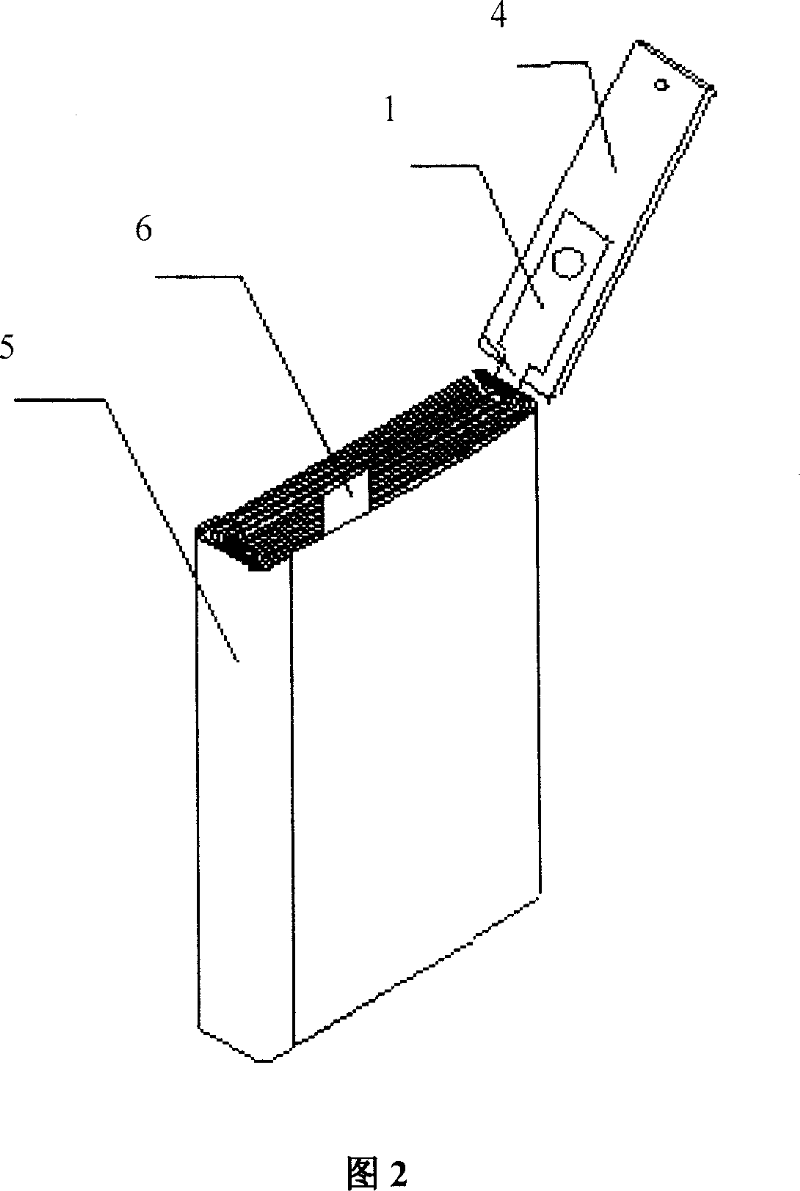

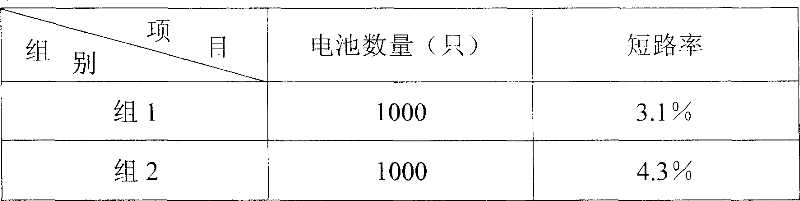

[0016] Embodiment 2. Manufacture 1,000 square steel-shell lithium-ion battery cell bodies with a model number of 033448S, as shown in Figures 1 and 2, including the cell body 5, the positive pole lug 1, the negative pole lug 6 and the cover plate 4 , the structure of the positive tab 1 is a bar-shaped tab as shown in Figure 1, the upper wider section 2 of the positive tab 1 is welded or riveted with the cover plate 4, and the lower narrow section 3 of the positive tab 1 is connected to the positive sheet Welded and located on the narrower side of the cell body 5 , the negative tab 6 is welded on the negative tab (not labeled) of the cell body 5 . Then obtain the lithium-ion battery according to the conventional production method, set it as group 1, and measure its short-circuit rate.

[0017] 1000 lithium-ion batteries of the same type were manufactured in the same way using tabs of equal width, set as group 2, and the short-circuit rate was measured.

[0018] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com