Target material component and preparation method thereof

A production method and target technology, which are applied in the direction of manufacturing tools, tool holder accessories, turning equipment, etc., can solve the problems affecting the quality of sputtering deposition, insufficient vacuum degree of the deposition chamber, etc., and achieve the effect of improving the vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

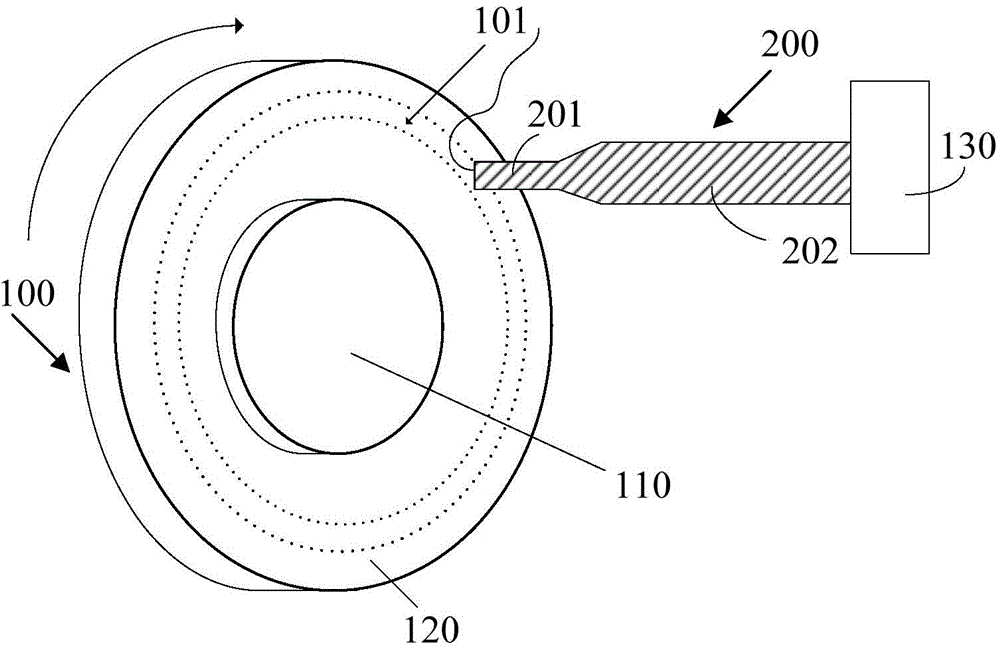

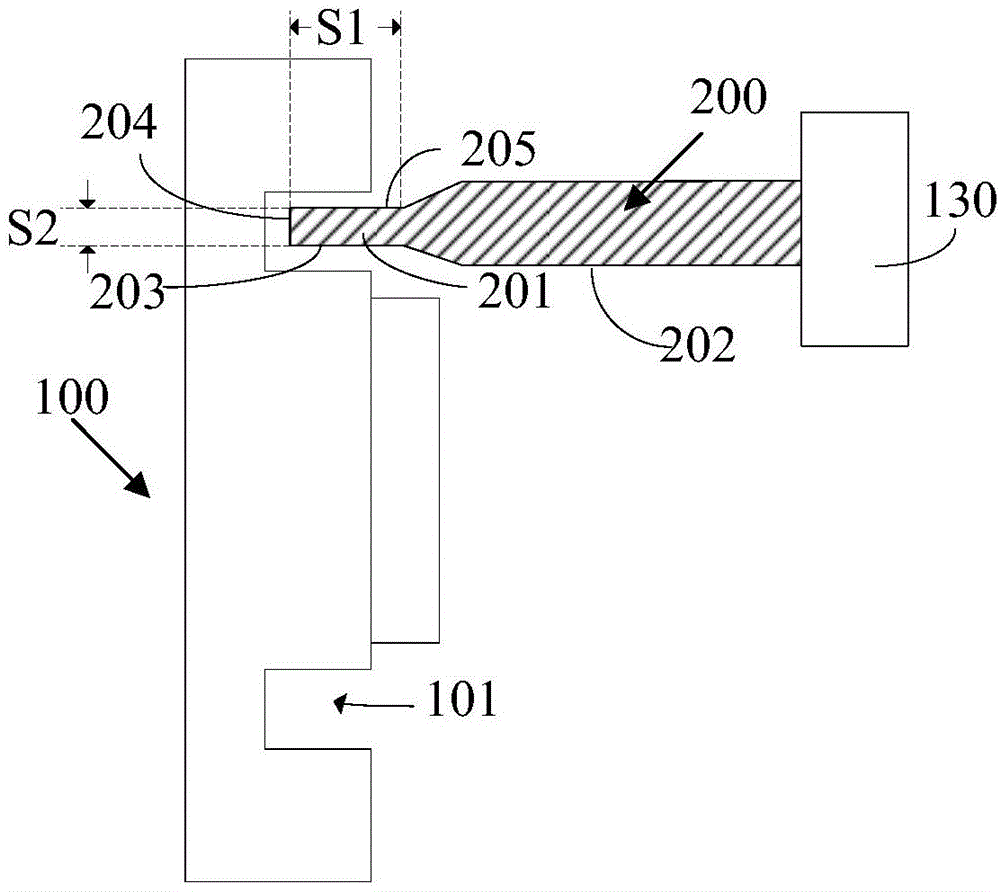

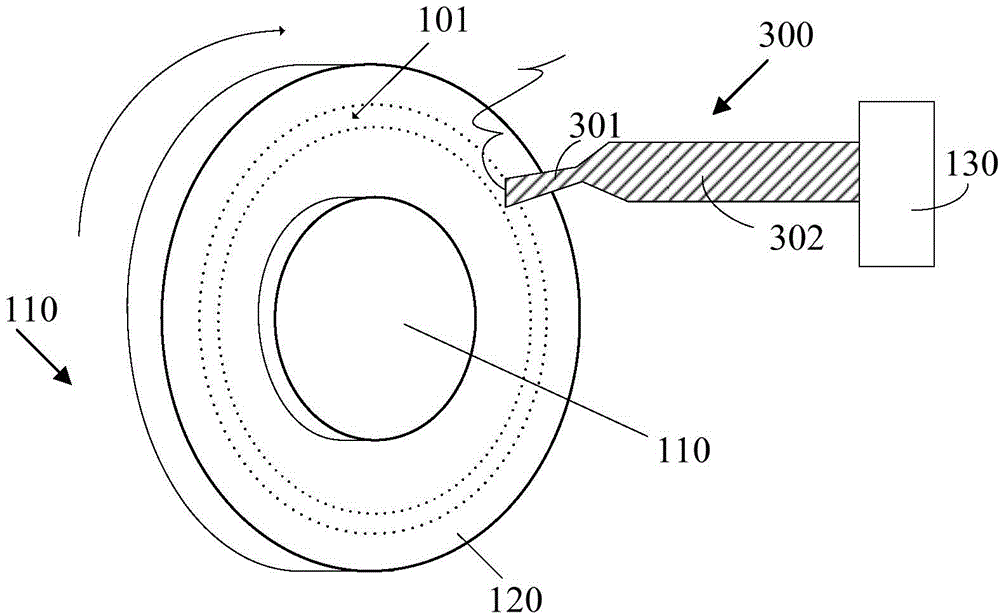

[0046] As mentioned in the background art, in the prior art, during the sputtering deposition process, the problem of insufficient vacuum in the deposition chamber often occurs, which affects the quality of the sputtering deposition.

[0047] Analyzing the cause of insufficient vacuum in the deposition chamber, it is found that the sealing component in the prior art is very easy to fall off from the sealing groove, thus resulting in insufficient vacuum in the deposition chamber.

[0048] In order to solve the above problems, the present invention provides a target assembly and a manufacturing method thereof, so that the sealing component is not easy to fall out of the sealing groove, thereby increasing the vacuum degree of the target assembly in the deposition chamber.

[0049]The manufacturing method of the target assembly of the present invention includes: providing a target assembly, and processing a sputtering surface and a sealing surface surrounding the sputtering surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com