Diaphragm and silicon capacitor microphone comprising same

A silicon condenser microphone and vibration part technology, applied in the field of silicon condenser microphones, can solve the problems of inability to release the stress gradient, low buckling strength of the diaphragm, and high degree of challenge, and achieve the effect of reducing the challenge, optimizing the damping of the diaphragm, and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] The diaphragm provided by the invention is used in microelectronic devices, such as silicon capacitor microphones, loudspeakers, receivers and the like. Silicon condenser microphones are mainly used in electronic devices such as mobile phones to receive sound.

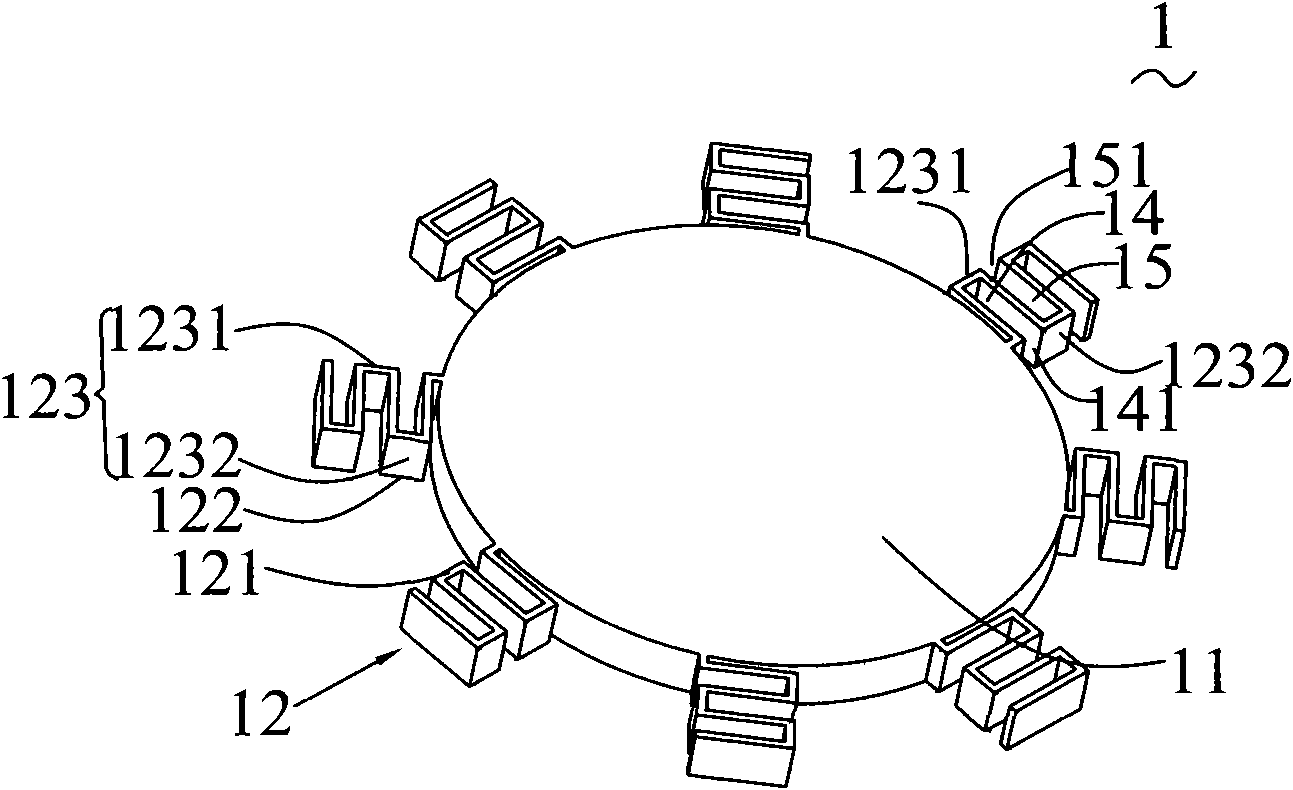

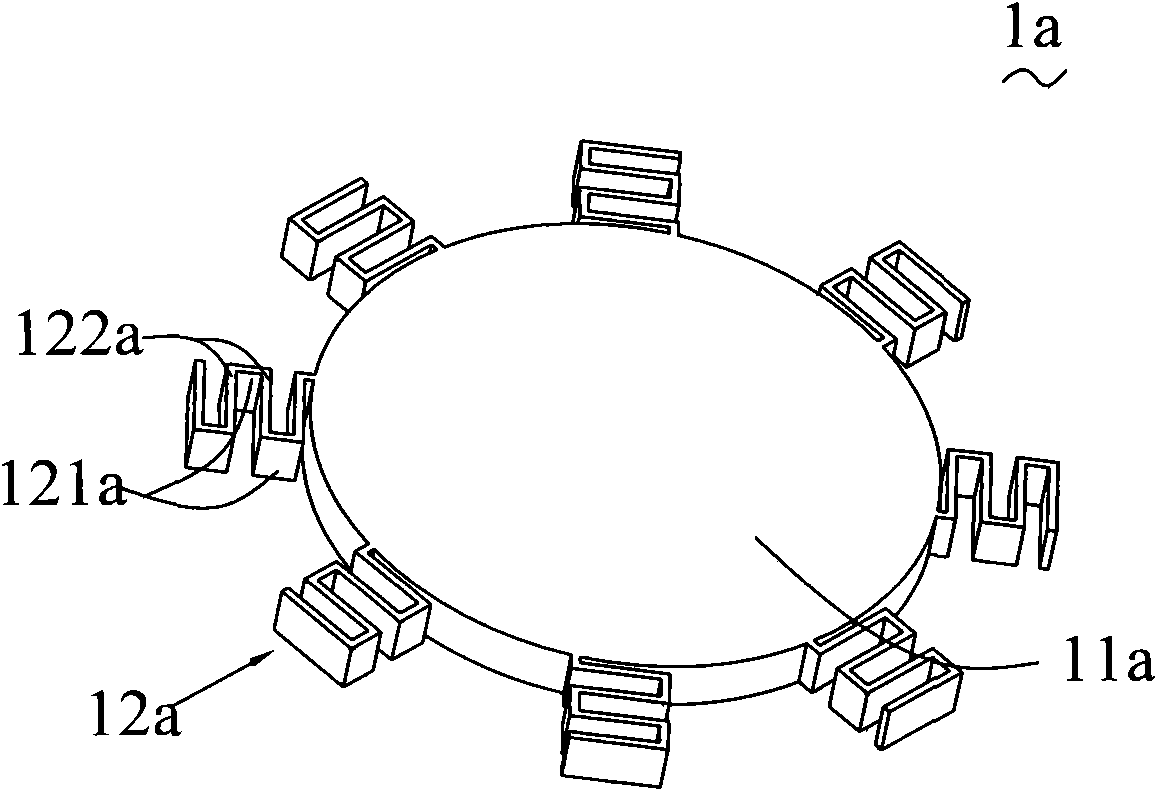

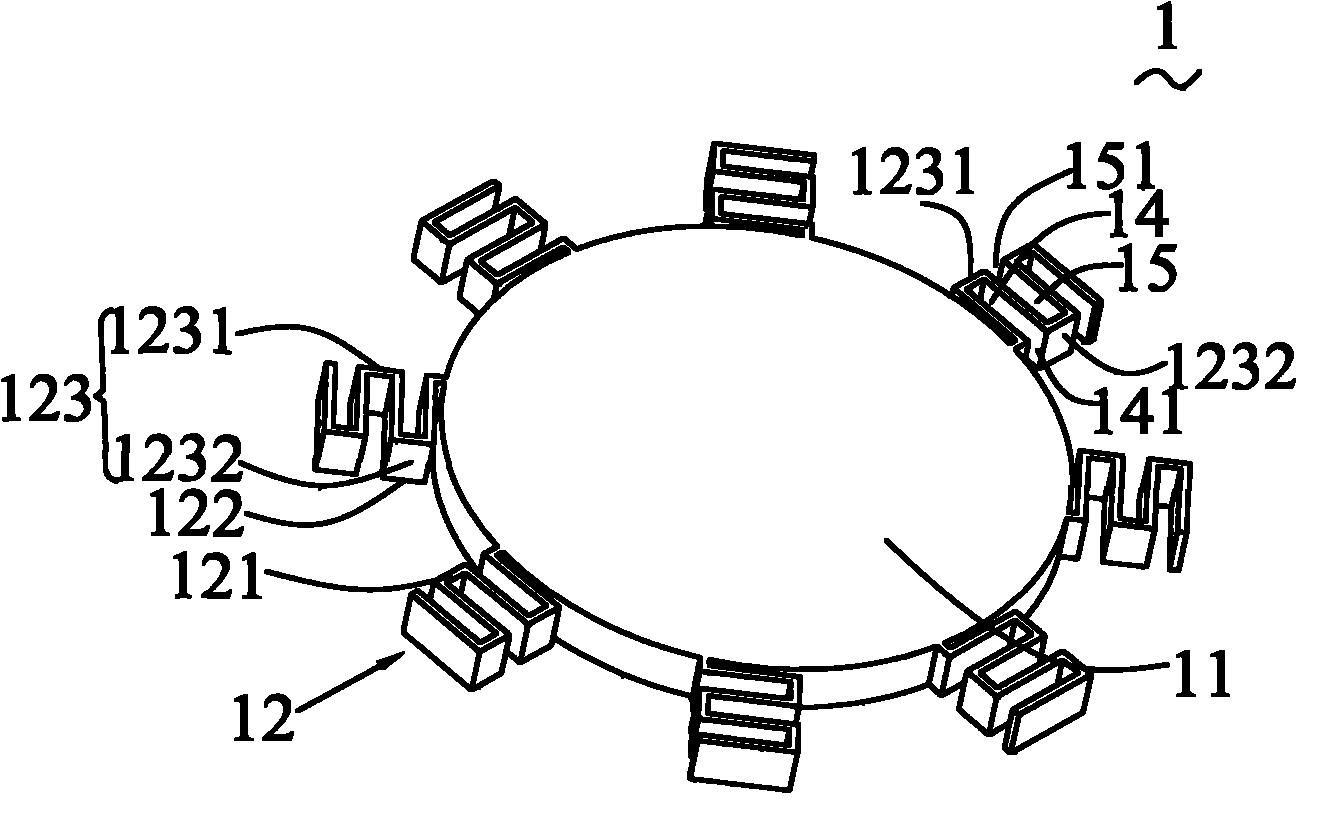

[0018] see figure 1 , the first embodiment provided by the present invention. The diaphragm 1 provided by the present invention includes a vibrating part 11 and a supporting part 12 connected to the vibrating part 11 , and the supporting part 12 extends away from the center of the vibrating part 11 from the outer circumference of the vibrating part 11 .

[0019] The support portion 12 has a first surface 121 , a second surface 122 opposite to the first surface 121 , and a sidewall 123 connecting the first surface 121 and the second surface 122 . The sidewall 123 includes a first sidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com