A preparation method of lead-based anode material with low stress gradient and long service life

An anode material and low-stress technology, applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of complex application environment conditions, low stress gradient, and short service life of lead-based anodes, and achieve Simple preparation method, slow stress decay and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

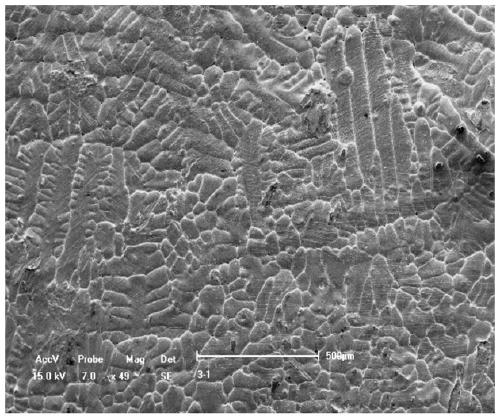

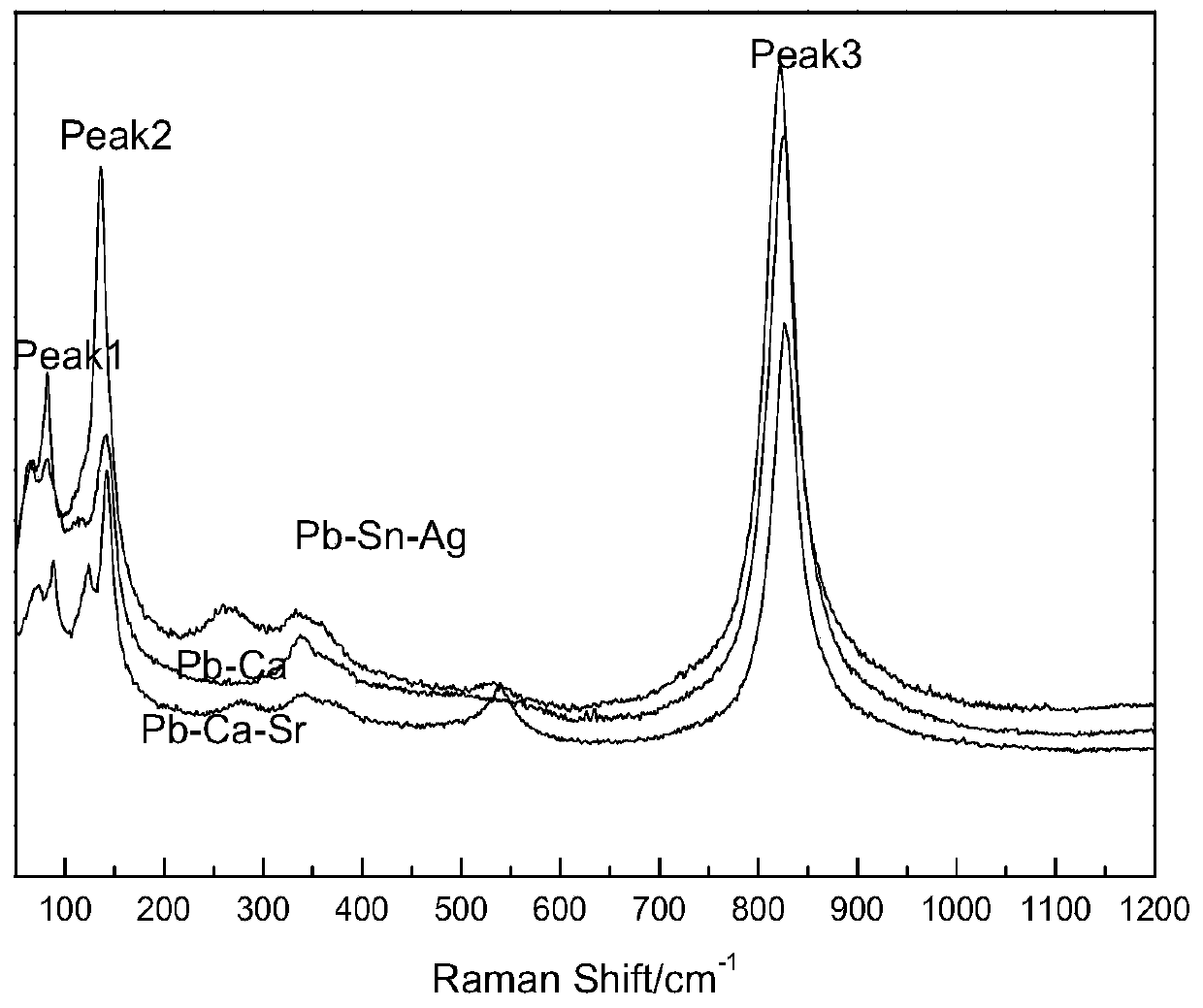

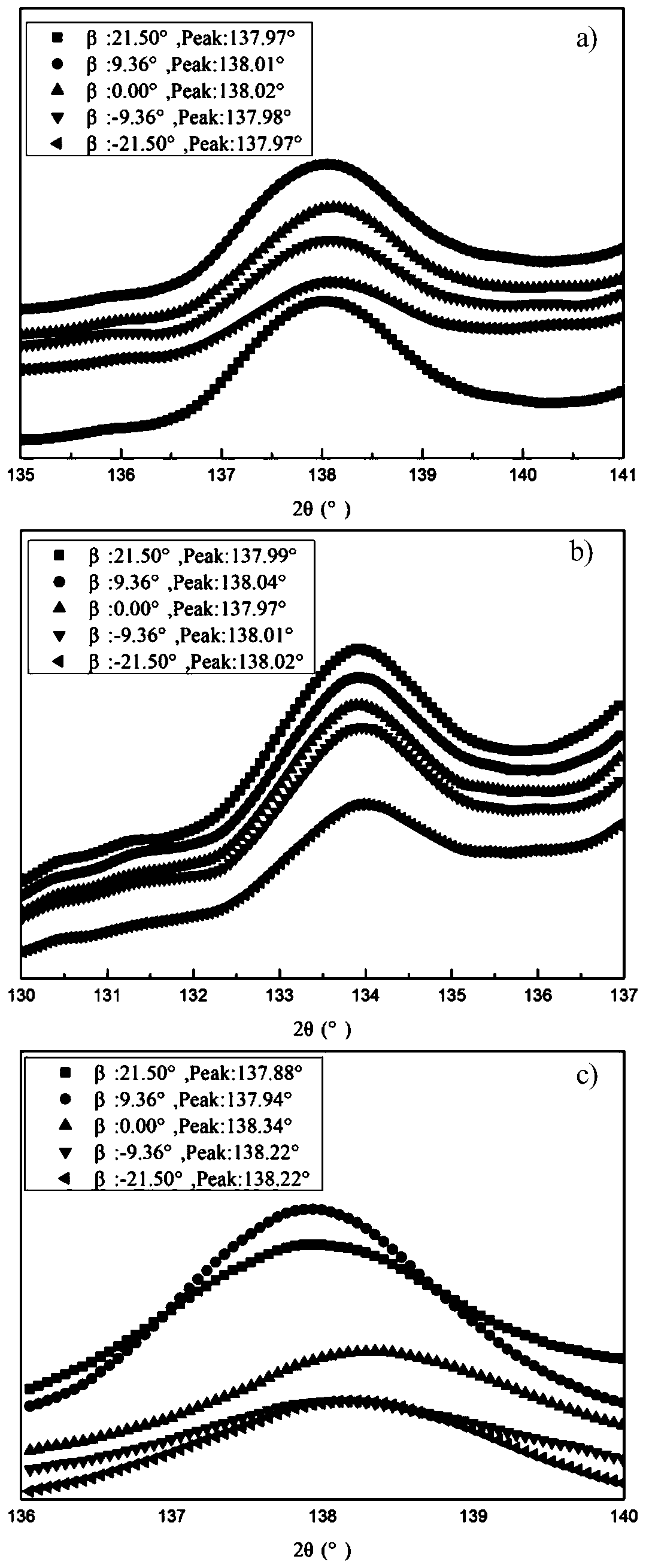

[0032] 1) Use 800# sandpaper to grind the ferritic stainless steel, then use 20wt% nitric acid to activate its surface, then clean it with acetone, and dry it.

[0033] 2) Using a lead-tin-silver alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-tin-silver alloy on the surface of ferritic stainless steel. The electrical parameters are medium voltage 90V and medium frequency 900Hz. The deposition process was protected by side blowing 12L / min argon.

[0034] 3) 20wt% Pb-PbO prepared by hot pressing sintering method is used as the deposition electrode, and the PbO-based coating is directly deposited on the ferritic stainless steel substrate after the surface of the lead-infiltrated tin-si...

Embodiment 2

[0041] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

[0042] 1) Use 900# sandpaper to grind the ferritic stainless steel, then use 15wt% nitric acid to activate its surface, then clean it with acetone, and dry it.

[0043] 2) Using a lead-calcium-strontium alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-calcium-strontium alloy on the ferritic stainless steel. The electrical parameters are medium voltage 80V and medium frequency 1100Hz. The deposition process was protected by side blowing 15L / min argon.

[0044] 3) 25wt% Pb-PbO prepared by the hot pressing sintering method is used as the deposition electrode, and the PbO-based coating is directly deposited on the ferritic stainless steel substrate after the surface lead-calcium-strontium...

Embodiment 3

[0051] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

[0052] 1) Use 1000# sandpaper to grind the ferritic stainless steel, then use nitric acid with a concentration of 10wt% to perform surface activation treatment on it, then clean it with acetone, and dry it.

[0053] 2) Using a lead-calcium alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-calcium alloy on the ferritic stainless steel. The electrical parameters are medium voltage 70V and medium frequency 1500Hz. The deposition process was protected by side blowing 13L / min argon.

[0054] 3) 30wt% Pb-PbO prepared by hot pressing sintering method was used as the deposition electrode, and the PbO-based coating was directly deposited on the ferritic stainless steel substrate after the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com