Manufacturing method of low-stress-gradient and long-service-life lead-based anode material

An anode material and low-stress technology, applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems of complex application environment conditions, short service life of lead-based anodes, low stress gradient, etc., to achieve The preparation method is simple, the cost is low, and the effect of stress decay is slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

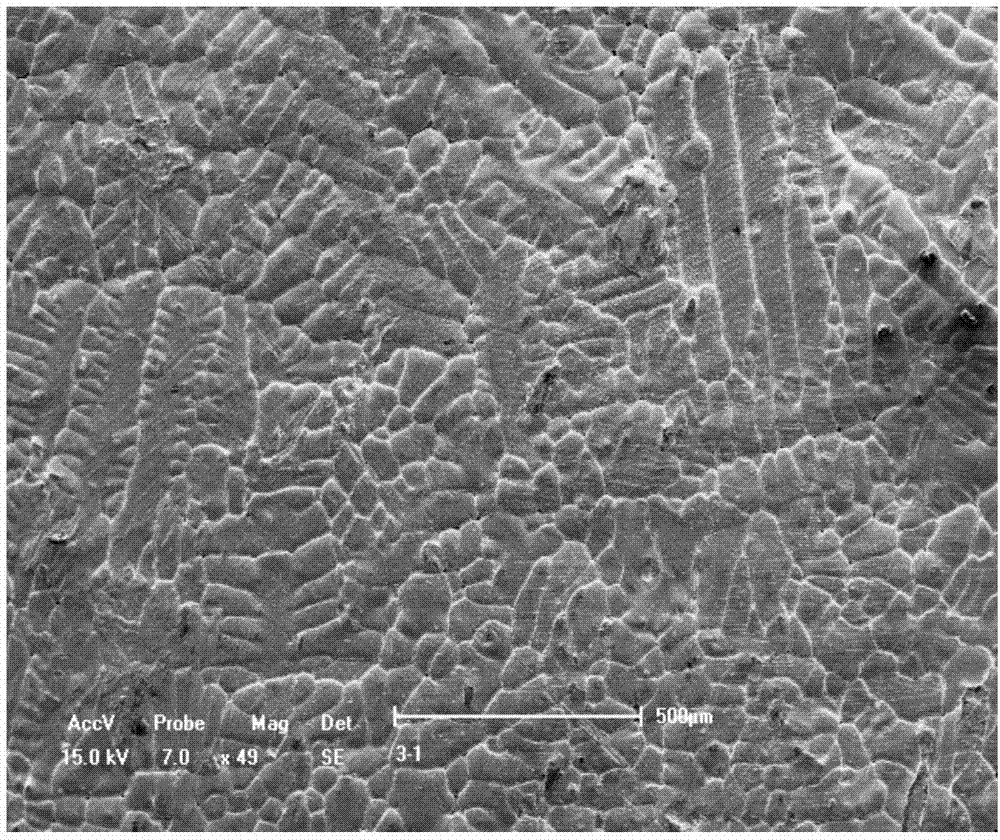

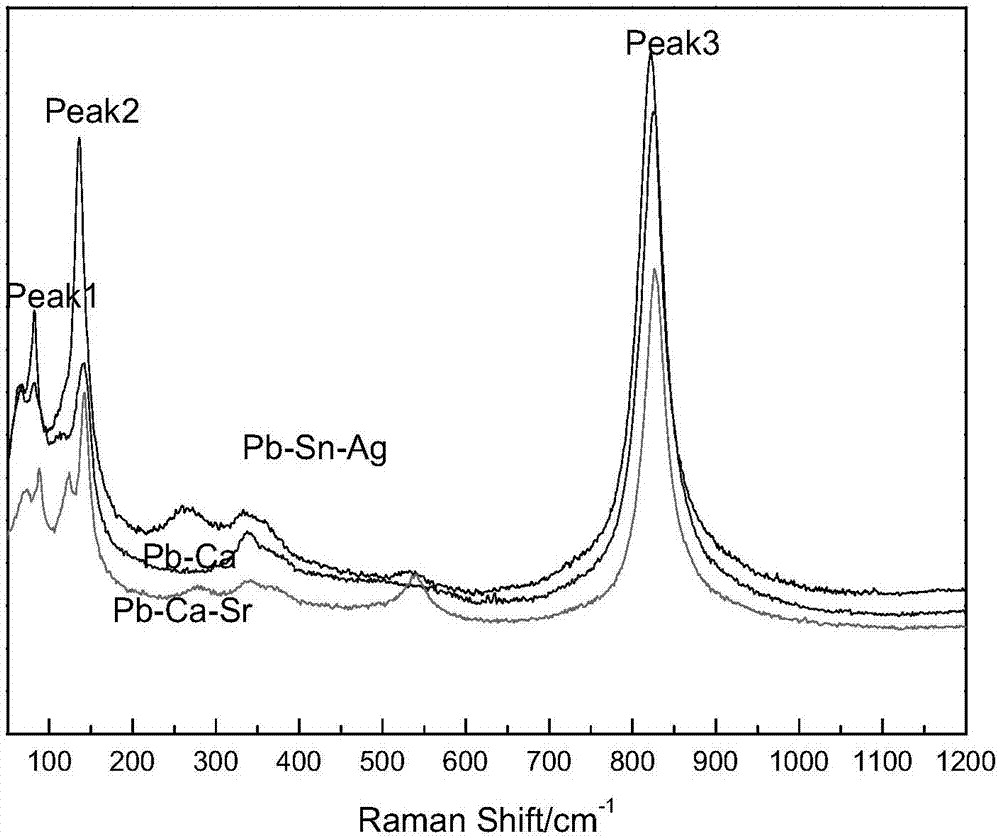

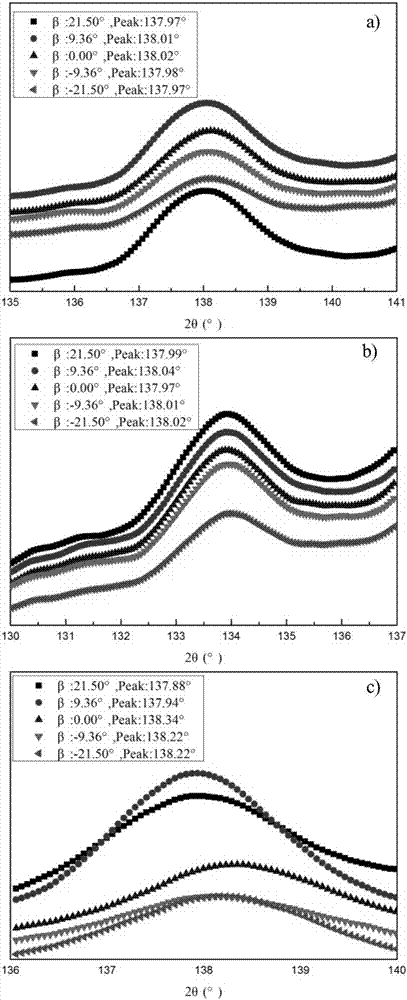

[0031] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

[0032] 1) Use 800# sandpaper to grind the ferritic stainless steel, then use 20wt% nitric acid to activate its surface, then clean it with acetone, and dry it.

[0033] 2) Using a lead-tin-silver alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-tin-silver alloy on the surface of ferritic stainless steel. The electrical parameters are medium voltage 90V and medium frequency 900Hz. The deposition process was protected by side blowing 12L / min argon.

[0034] 3) 20wt% Pb-PbO prepared by hot pressing sintering method is used as the deposition electrode, and the PbO-based coating is directly deposited on the ferritic stainless steel substrate after the surface of the lead-infiltrated tin-si...

Embodiment 2

[0041] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

[0042] 1) Use 900# sandpaper to grind the ferritic stainless steel, then use 15wt% nitric acid to activate its surface, then clean it with acetone, and dry it.

[0043] 2) Using a lead-calcium-strontium alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-calcium-strontium alloy on the ferritic stainless steel. The electrical parameters are medium voltage 80V and medium frequency 1100Hz. The deposition process was protected by side blowing 15L / min argon.

[0044] 3) 25wt% Pb-PbO prepared by the hot pressing sintering method is used as the deposition electrode, and the PbO-based coating is directly deposited on the ferritic stainless steel substrate after the surface lead-calcium-strontium...

Embodiment 3

[0051] In this embodiment, the preparation method of the lead-based anode material with low stress gradient and high service life, the specific steps are as follows:

[0052] 1) Use 1000# sandpaper to grind the ferritic stainless steel, then use nitric acid with a concentration of 10wt% to perform surface activation treatment on it, then clean it with acetone, and dry it.

[0053] 2) Using a lead-calcium alloy with a diameter of 4mm as the deposition electrode, a high-energy micro-arc cold welding machine is used to perform high-energy micro-arc spark surface infiltration of lead-calcium alloy on the ferritic stainless steel. The electrical parameters are medium voltage 70V and medium frequency 1500Hz. The deposition process was protected by side blowing 13L / min argon.

[0054] 3) 30wt% Pb-PbO prepared by hot pressing sintering method was used as the deposition electrode, and the PbO-based coating was directly deposited on the ferritic stainless steel substrate after the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com