Cooling Device for Plasma Spraying of Light Alloy Rotary Parts

A technology of cooling device and rotator, which is applied in metal material coating process, coating, molten spraying, etc., can solve the problem of low bonding strength of light alloy arc-shaped rotator coating, prevent oxidation and improve bonding strength , the effect of reducing the surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

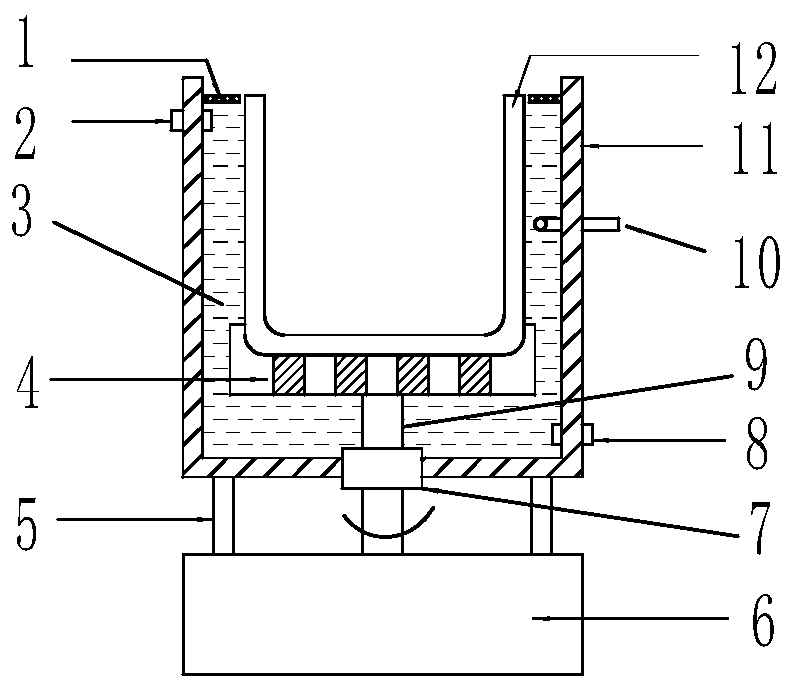

[0042] like figure 1 As shown, it is a schematic diagram of the corresponding structure of the cooling device for plasma spraying of light alloy rotary parts provided in this embodiment; specifically, the specific scheme of this embodiment is as follows:

[0043] This embodiment provides a cooling device for plasma spraying of light alloy revolving parts, see figure 1 , when plasma spraying coating on the inner surface of the light alloy rotating body, the cooling device can form a circulating liquid cooling environment on the outer surface of the workpiece, effectively reduce the surface temperature of the light alloy during the spraying process, and ensure good adhesion between the coating and the light alloy substrate Bonding effect, controlling the temperature of the substrate, improving the bonding strength of the coating.

[0044] The cooling device includes a cooling water tank 11, a workpiece clamping tool 4, a motor shaft 9, a sealing ring 7, and a rotating motor 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com