Lifting engagement chain unit

一种啮合链条、升降驱动的技术,应用在链元件、升降架、皮带/链条/齿轮等方向,能够解决降低啮合精度、增加作业负担、链板213负荷不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

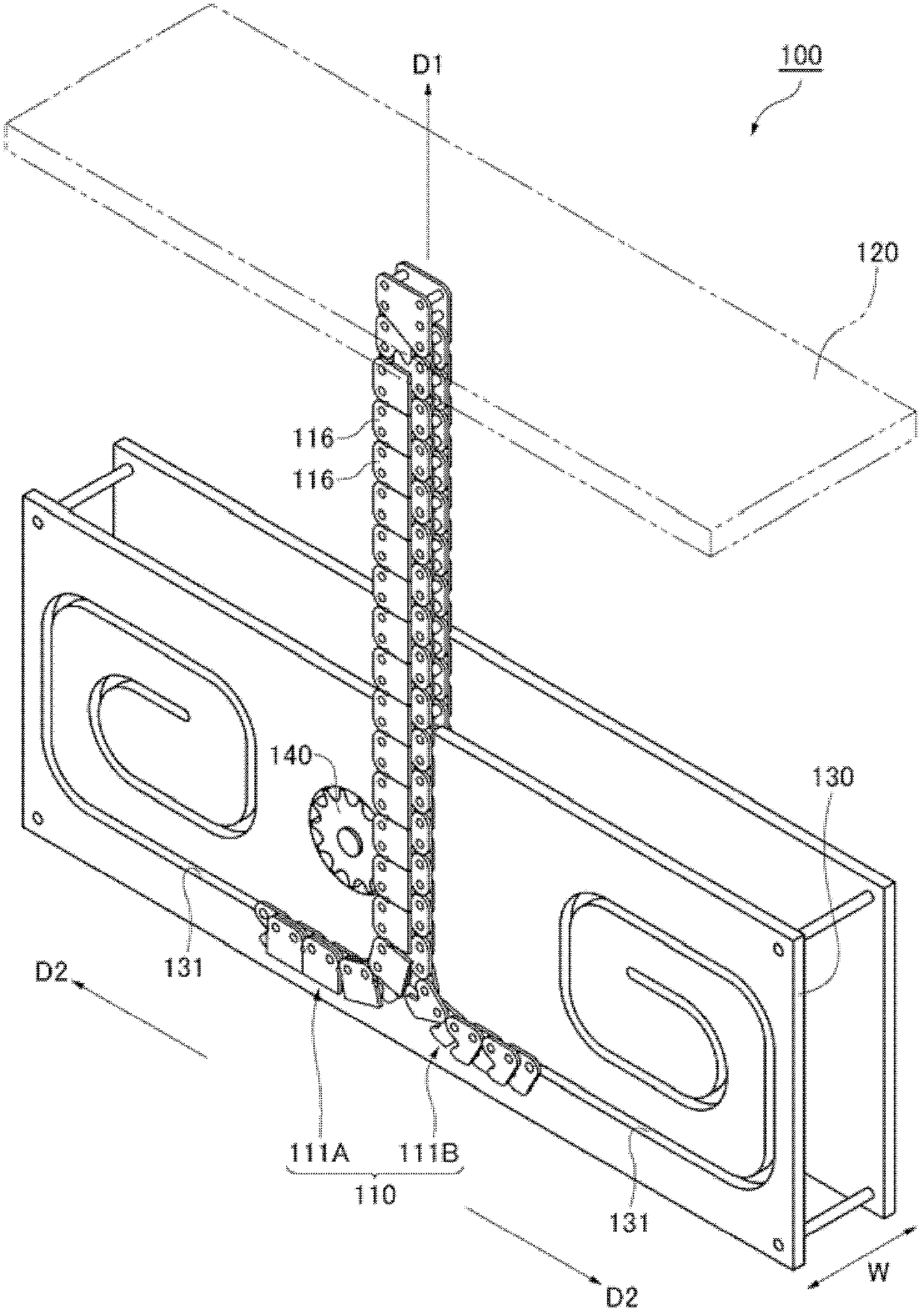

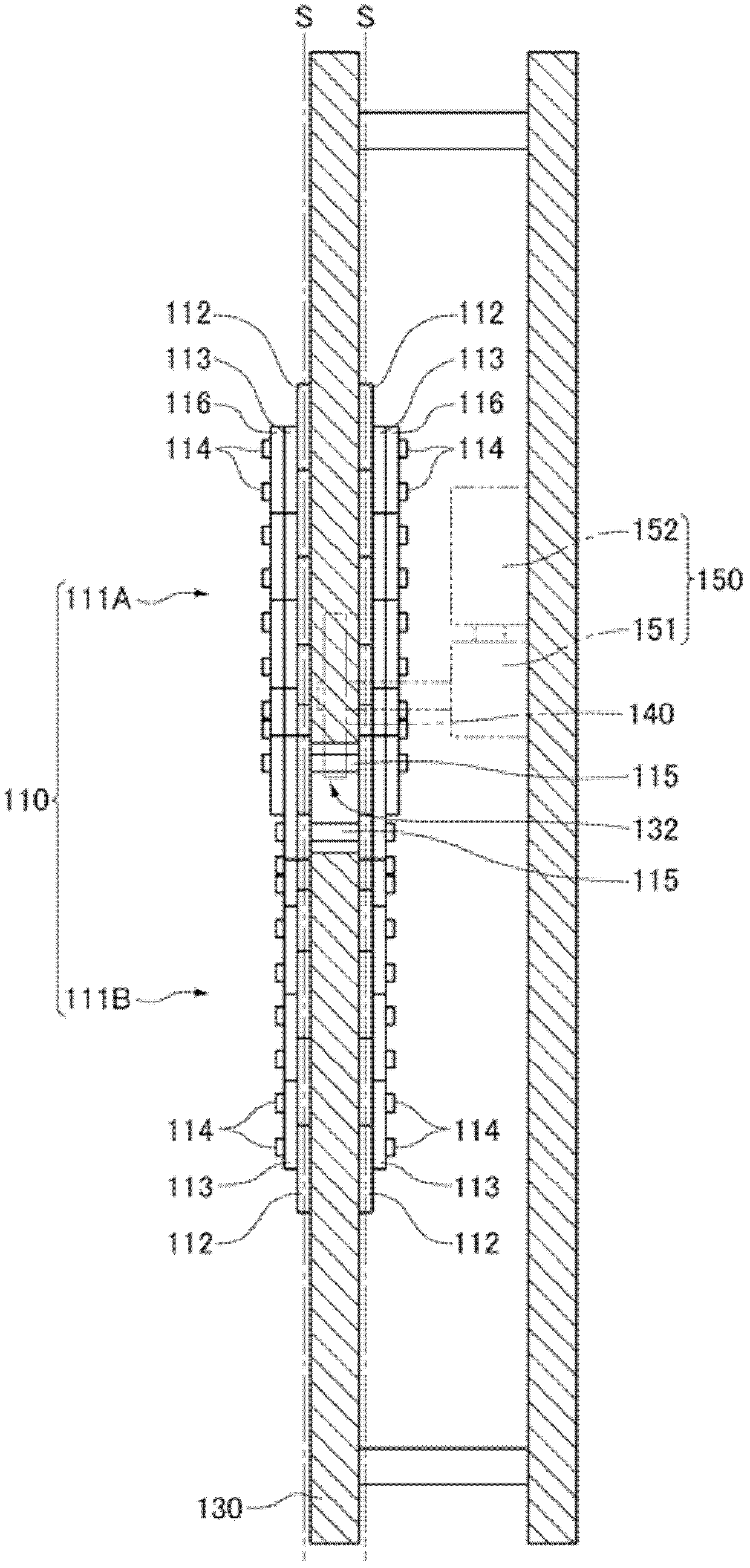

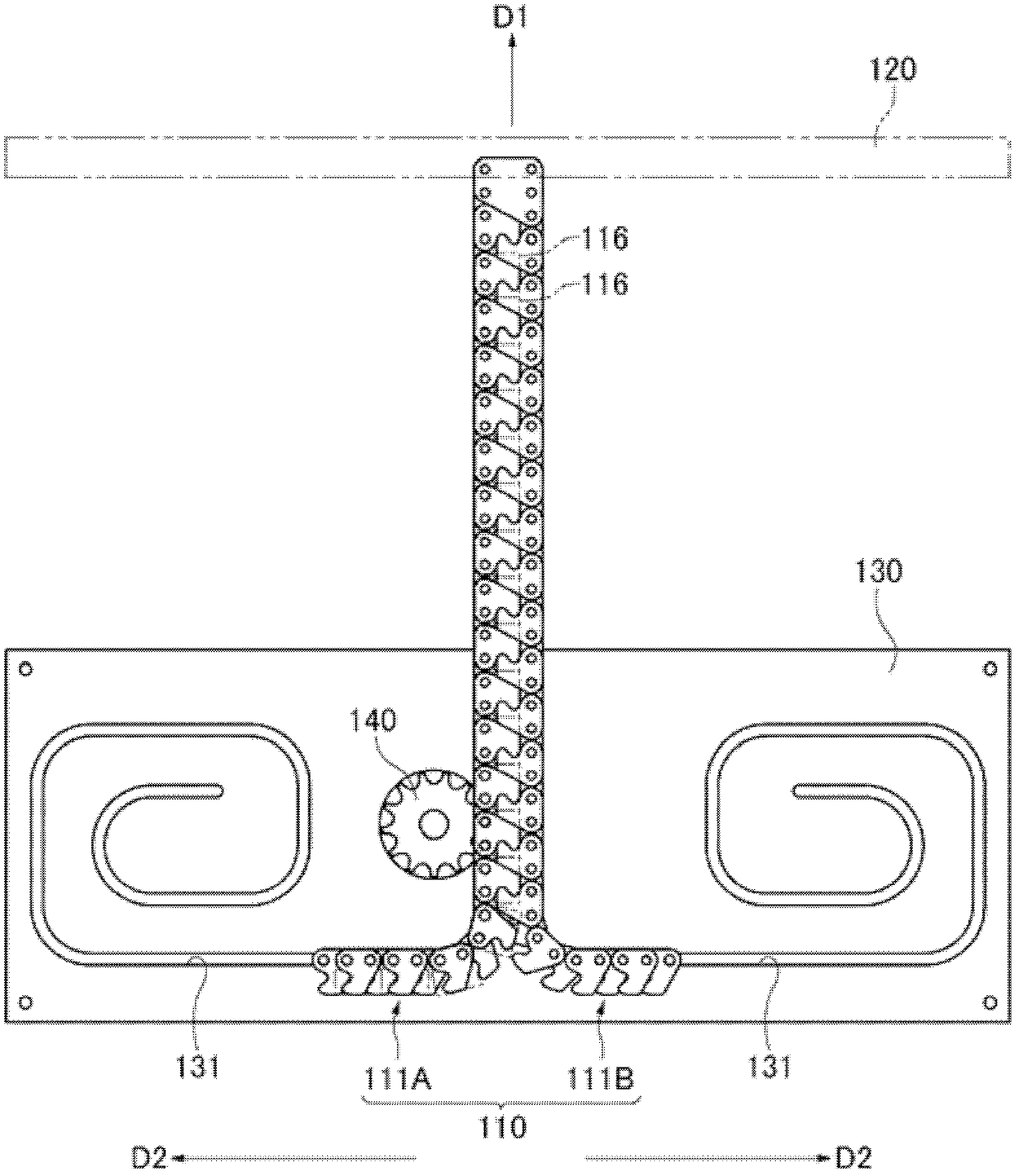

[0060] Hereinafter, the interlocking chain type lifting device 100 using the interlocking chain unit 110 for elevating drive according to one embodiment of the present invention will be described based on the drawings.

[0061] figure 1 It is an overall perspective view of the engaging chain type lifting device adopting the engaging chain unit for lifting drive according to an embodiment of the present invention; figure 2 Yes figure 1 a plan view of the engaging chain hoist shown; image 3 Yes figure 1 A front view of the engaging chain hoist shown; Figure 4 Yes image 3 An enlarged view of a part of the vicinity of the drive sprocket and the meshing chain shown; Figure 5 It is a perspective view showing the disassembled and assembled state and the disengaged state of the elevating drive meshing chain unit according to an embodiment of the present invention; Image 6 It is a front view of the engaging chain unit for lifting drive according to an embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com