Glass ribbon producing apparatus and process for producing the same

The technology of a manufacturing device and manufacturing method, which is applied in the manufacturing device of glass ribbon and its manufacturing field, can solve the problems of uneven thickness of glass ribbon, accelerated glass ribbon flow down speed, difficulty of glass ribbon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

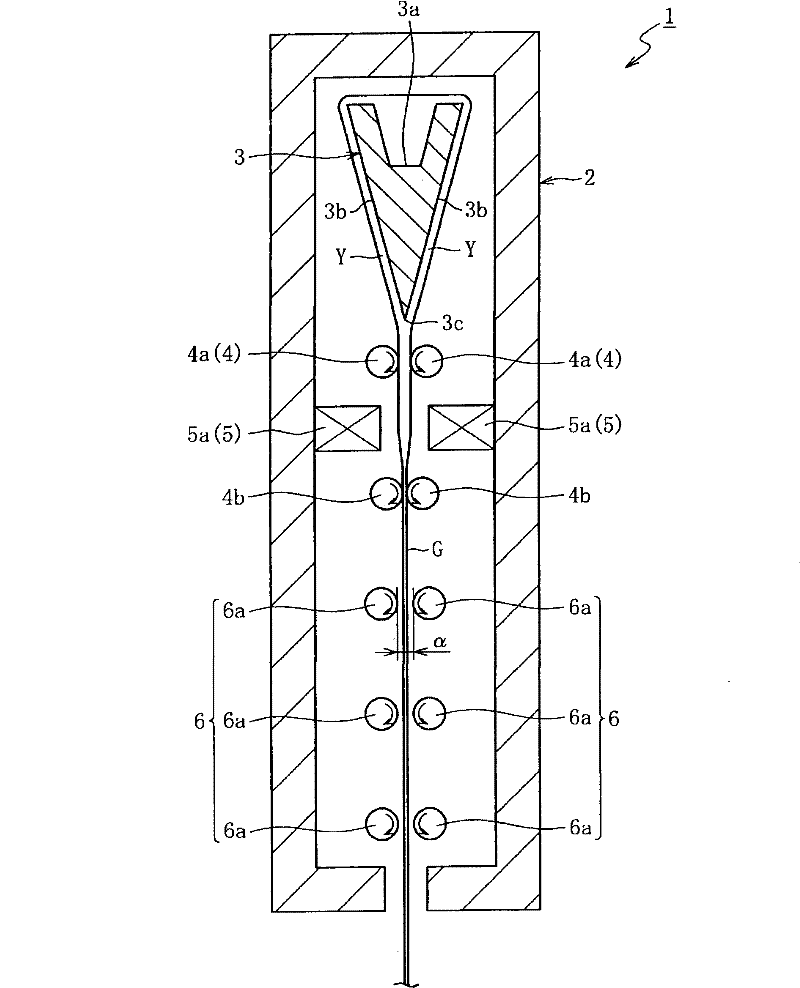

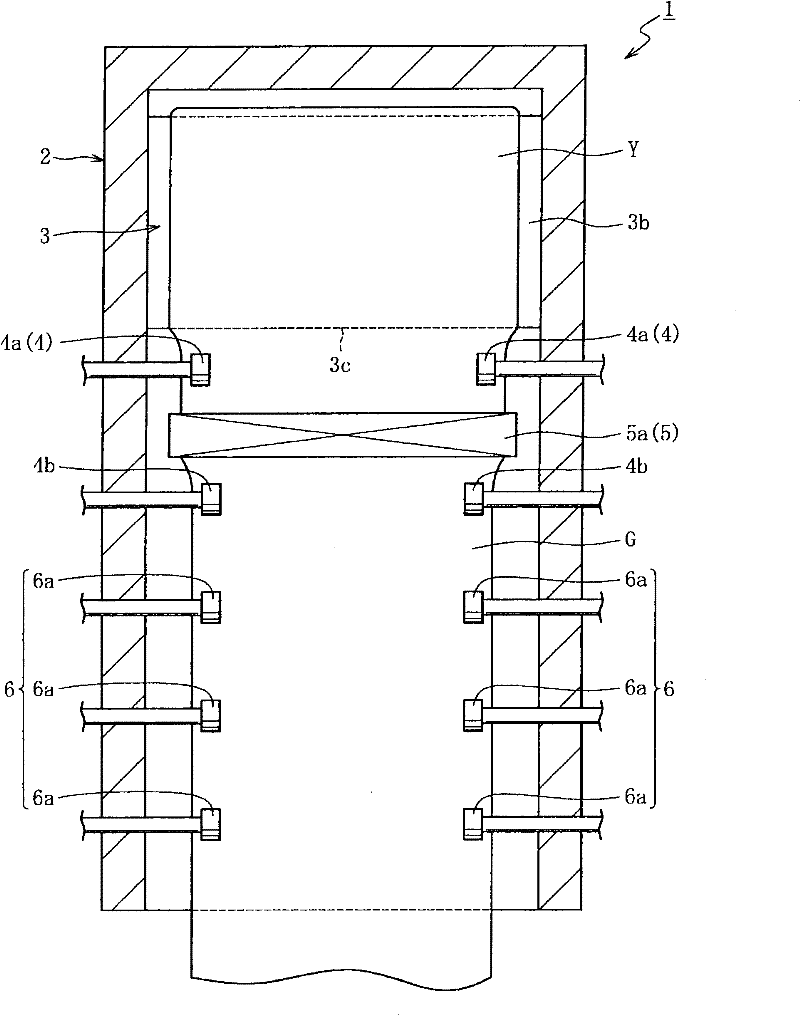

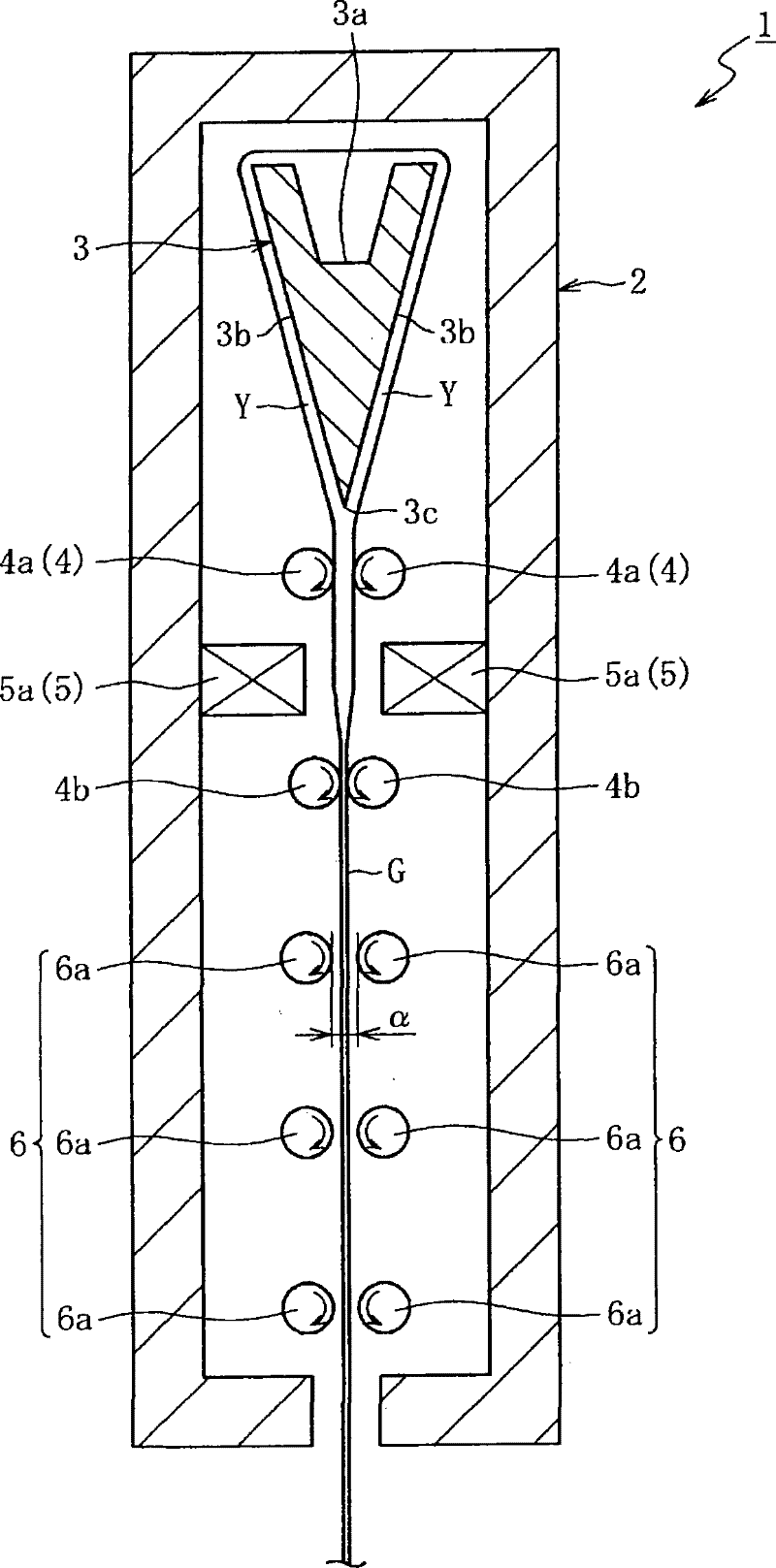

[0062] figure 1 It is a schematic longitudinal sectional side view schematically showing the internal state of a glass ribbon manufacturing apparatus according to an embodiment of the present invention, figure 2 It is a schematic longitudinal sectional front view schematically showing the internal state of the manufacturing apparatus. As shown in the above-mentioned figures, the manufacturing apparatus 1 includes a molded body 3 , a restricting mechanism 4 , a reheating mechanism 5 , and a guiding mechanism 6 sequentially from above inside a furnace 2 made of clay bricks.

[0063] The cross-sectional shape of the molded body 3 is wedge-shaped and has an overflow groove 3a at the top. The lower end part 3c of the molded object 3 fuses and becomes a plate form, and the molten glass Y which became this form is made to flow down as a plate-shaped glass ribbon G in an up-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com