Glass tube for fluorescent lamp, fluorescent lamp, and lighting system

A technology for fluorescent lamps and glass tubes, applied in discharge lamps, low-pressure discharge lamps, gas discharge lamps, etc., which can solve the problems that the strength of the bulb glass is not improved, and it is difficult to realize the thinning of the bulb, and achieve the effect of easy processing and difficult damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

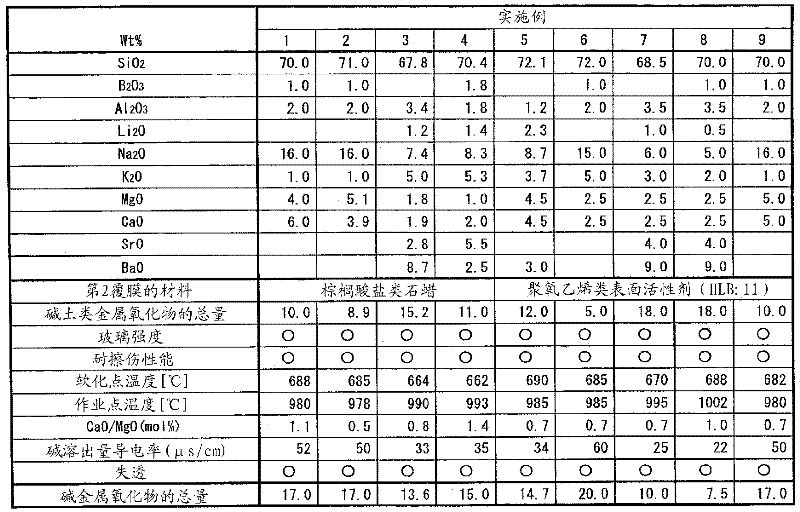

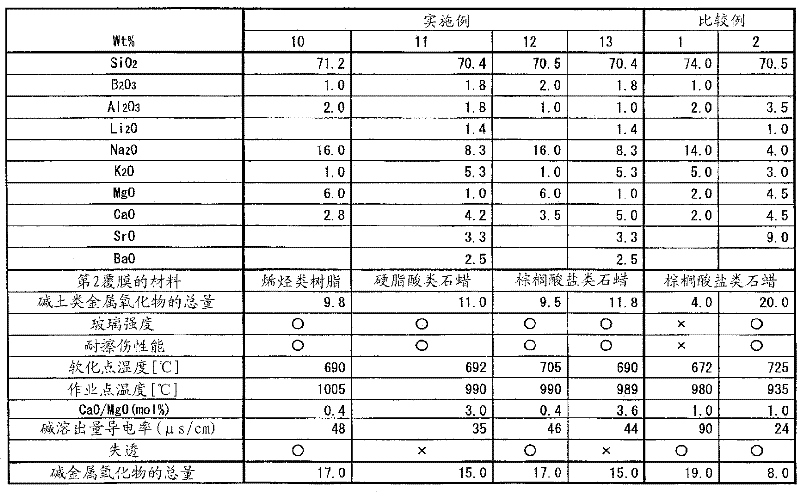

Method used

Image

Examples

Embodiment Construction

[0047] A glass tube for a fluorescent lamp (hereinafter simply referred to as a “glass tube”), a fluorescent lamp, and a lighting device according to an embodiment of the present invention will be described below based on the drawings.

[0048] [Structure of glass tubes, fluorescent lamps and lighting fixtures]

[0049]

[0050] The glass tube of the present invention is composed of a tube body, a first coating formed at least on the outer peripheral surface of the tube body, and a second coating laminated on the first coating.

[0051] The pipe body preferably has a wall thickness t [mm] and an outer diameter φ [mm] satisfying the relationship of t≤0.7 or t / φ≤0.42. In particular, 0.4≦t≦0.6 and 1≦φ≦10 are preferable.

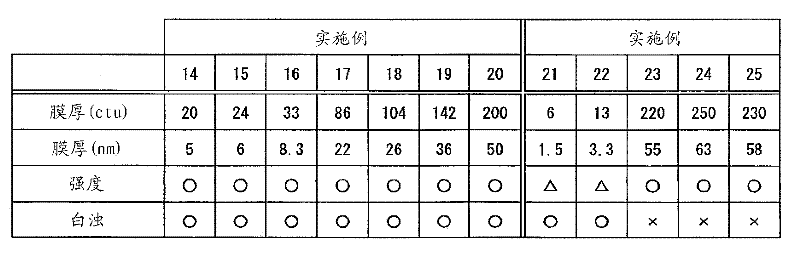

[0052] The thickness of the first coating is preferably 5 to 100 nm, more preferably 5 to 50 nm. image 3 It is a graph showing the test results related to the influence of the film thickness of the first film on the glass strength and clouding of the glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com