Sealing Member

A technology for sealing components and components, which is applied to the sealing of engines, electrical components, telephone structures and other directions, can solve the problems of the sealing gasket 300 not being able to obtain sealing performance and the amount of compression is uneven, and achieve miniaturization and thin-walled, Good usability and stable sealing surface pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the best mode for carrying out the present invention will be described.

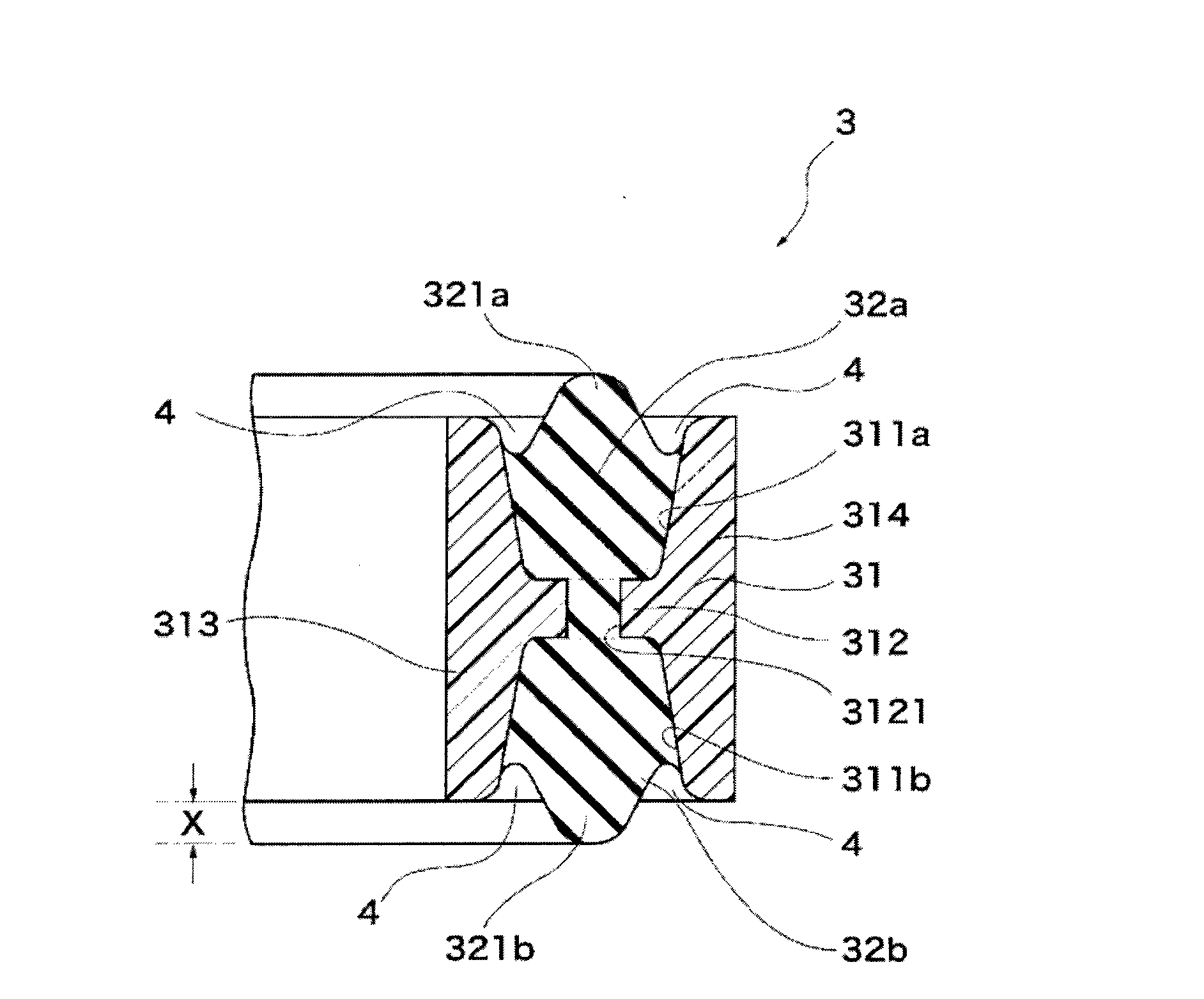

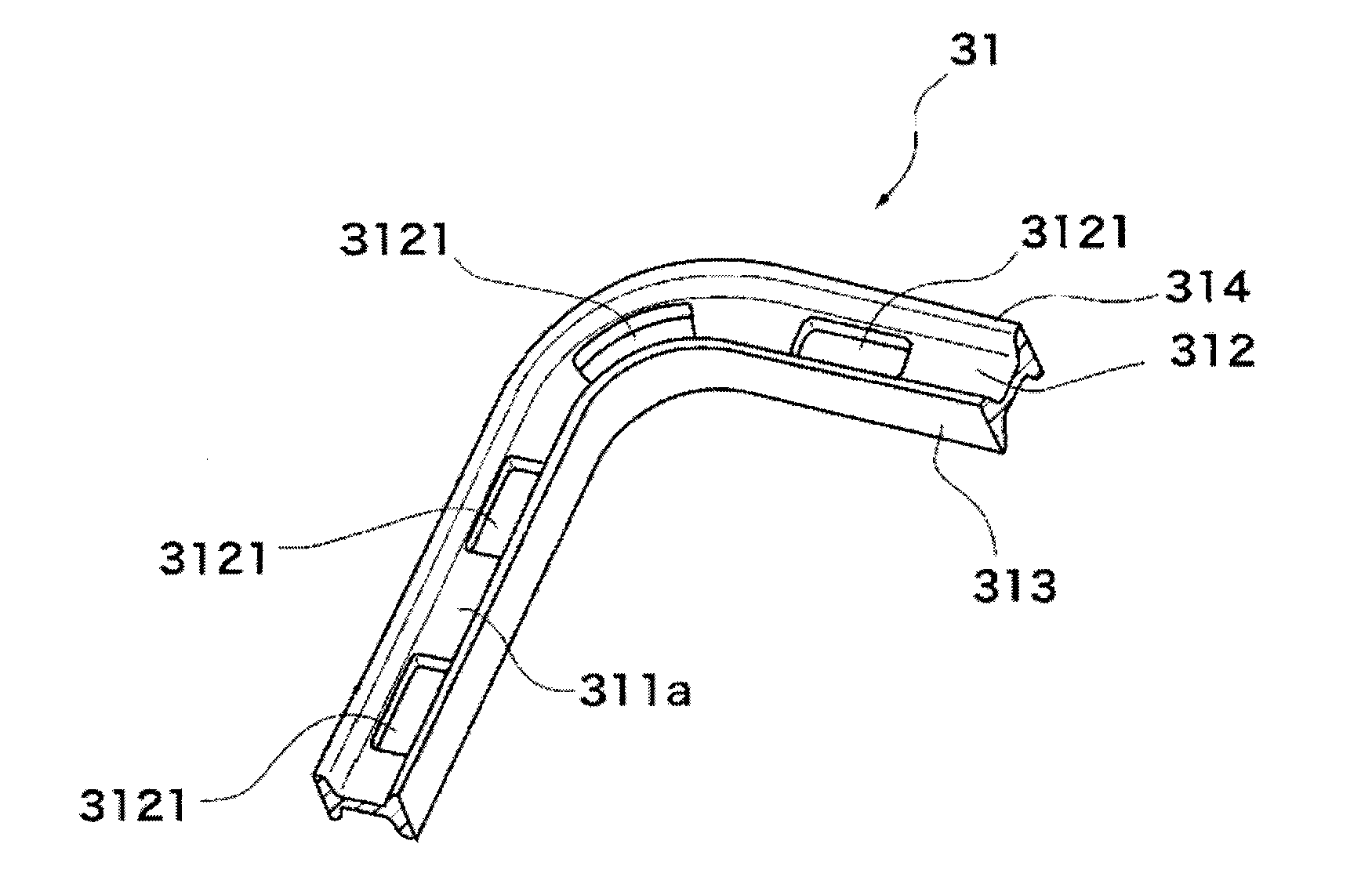

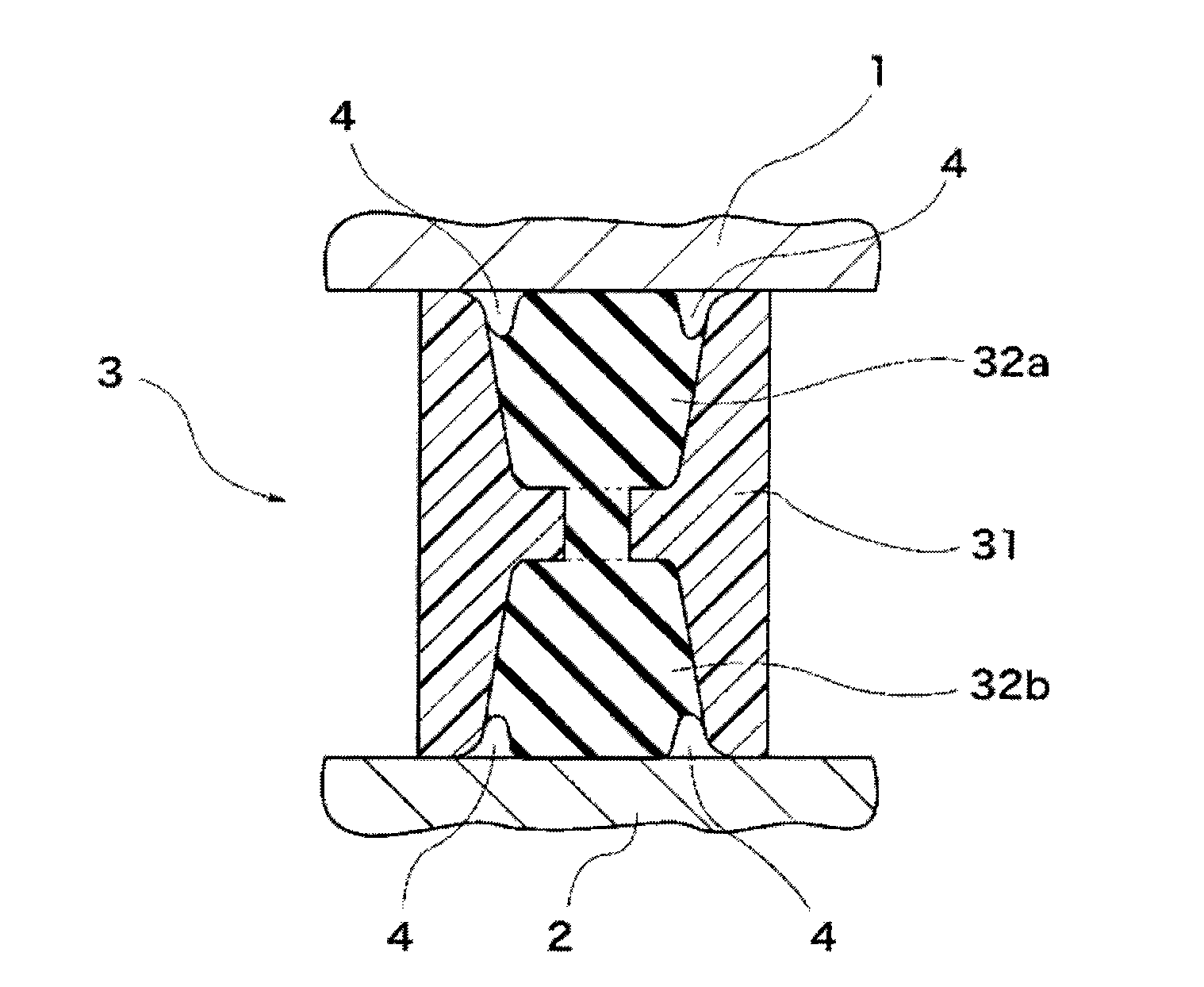

[0053] Such as Figure 1 to Figure 3 As shown, the sealing member involved in the present invention is a sealing member 3 located between one housing member 1 and another housing member 2 to seal the gap between the two members 1, 2, which is constituted as follows: The member 3 is composed of a holding member 31 made of a resin material having a substantially H-shaped cross section, and a pair of sealing members 32a and 32b made of a rubber material integrally provided on the two grooves 311a and 311b of the holding member 31. Lip portions 321a, 321b protruding from the two groove portions 311a, 311b are formed on the sealing members 32a, 32b.

[0054] In addition, if figure 2 As shown, the holding member 31 made of a resin material with a substantially H-shaped cross section is composed of an inner cylindrical portion 313, an outer cylindrical portion 314, and a connecting portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com