Multi-row thrust ball bearing

A ball bearing and thrust technology, applied in the directions of bearings, ball bearings, shafts and bearings, can solve the problem of non-existence and achieve the effect of increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, one embodiment of the multi-row thrust ball bearing according to the present invention will be described in detail based on the drawings.

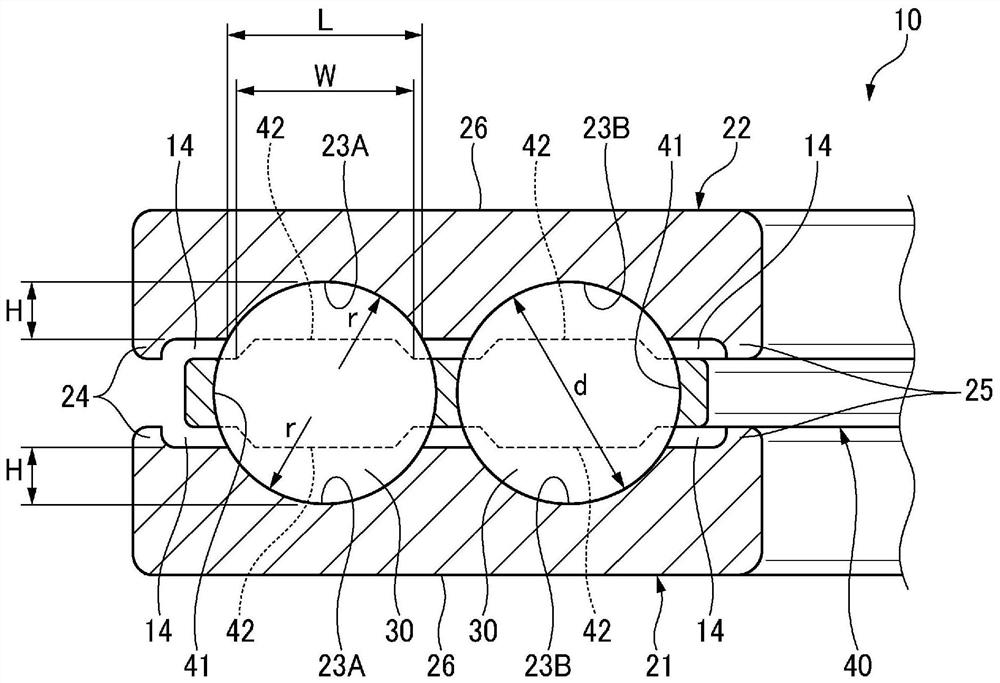

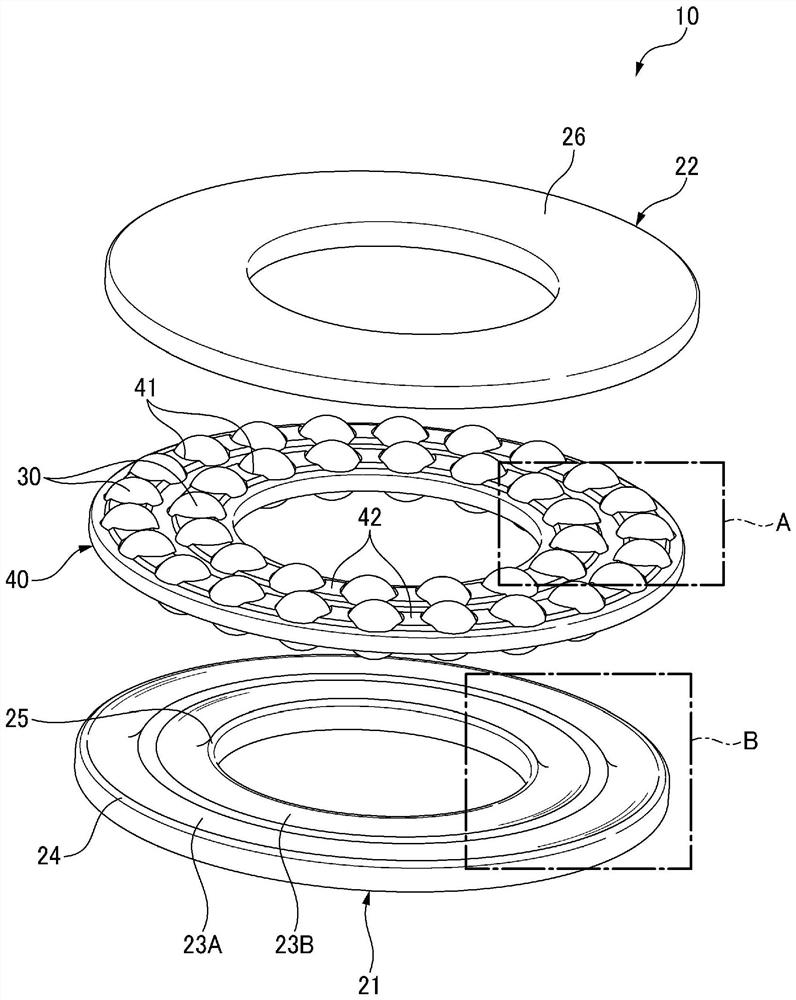

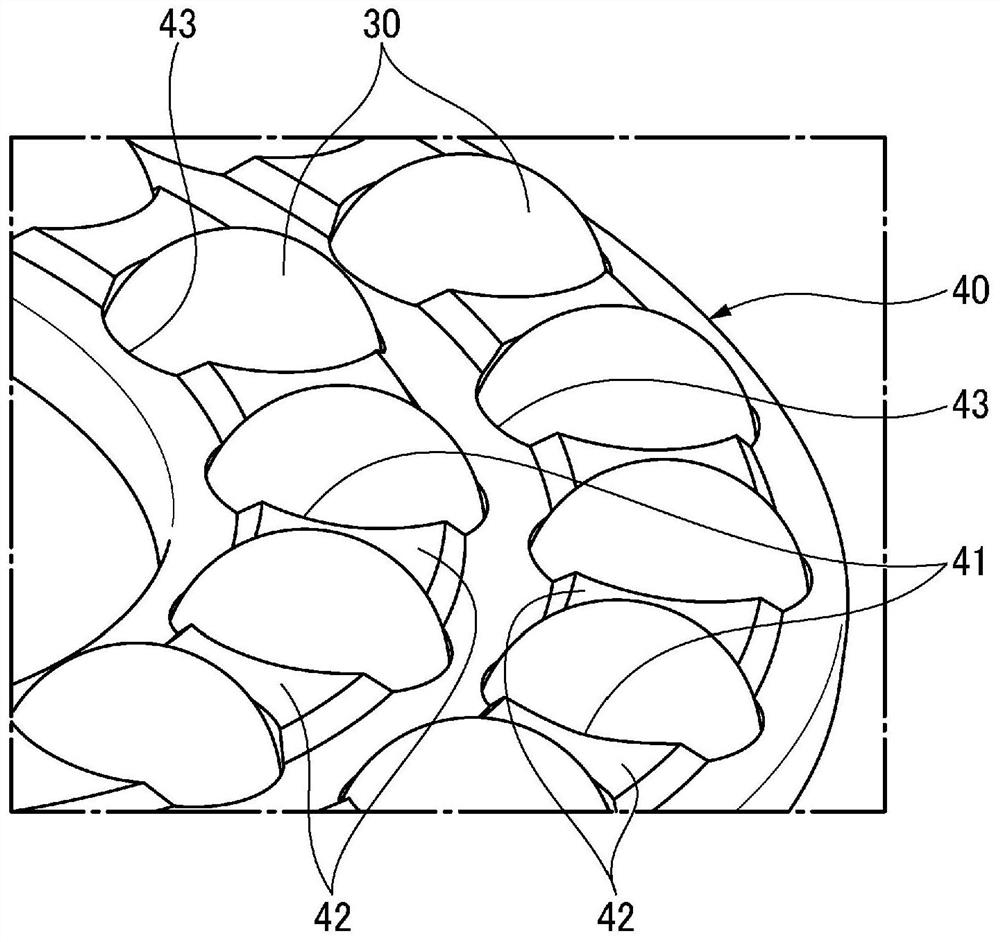

[0081] Such as figure 1 as well as figure 2 As shown, the multi-row thrust ball bearing 10 of this embodiment includes: a pair of raceway rings 21, 22 formed in an annular shape and arranged in parallel axially apart from each other; a plurality of balls (rolling elements) 30, which is rotatably arranged between the pair of raceway rings 21, 22; and a cage 40 which has a plurality of pockets 41 capable of rolling the plurality of balls 30 and holding the plurality of balls 30 in Keep at specified intervals.

[0082] Here, refer to Figure 4 A pair of raceway rings 21 and 22 are formed in an annular shape, and are provided with a plurality of rows of raceway grooves 23 on surfaces facing each other. In addition, the multi-row rolling groove 23 refers to the rolling groove 23 in two rows, and specifically includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com