Cantilever type digging and protecting integrated machine

A cantilever type, all-in-one machine technology, applied in the direction of cutting machinery, temporary shields, slitting machinery, etc., can solve the problems of limited area, difficult to permanently support construction operations, temporary safety protection, small structural volume, etc., to achieve The effect of large area and carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

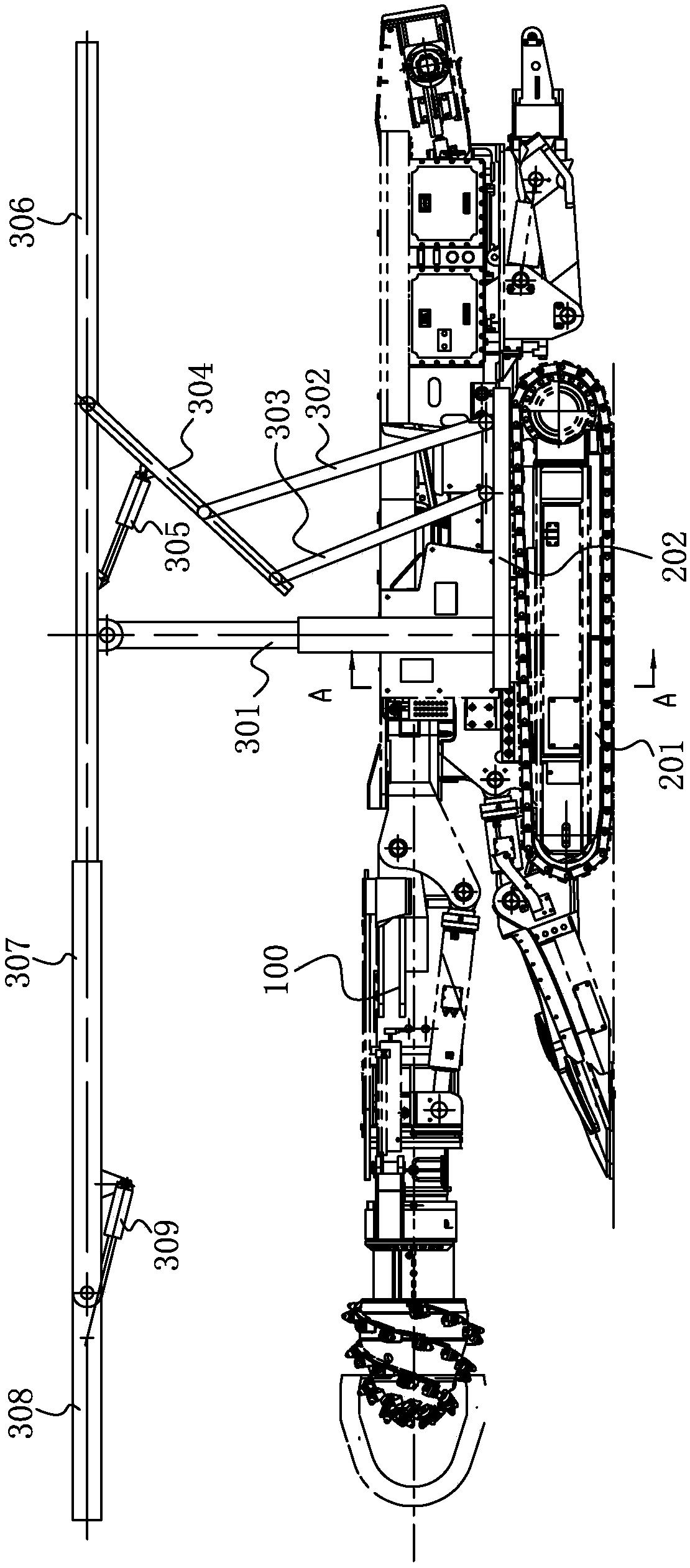

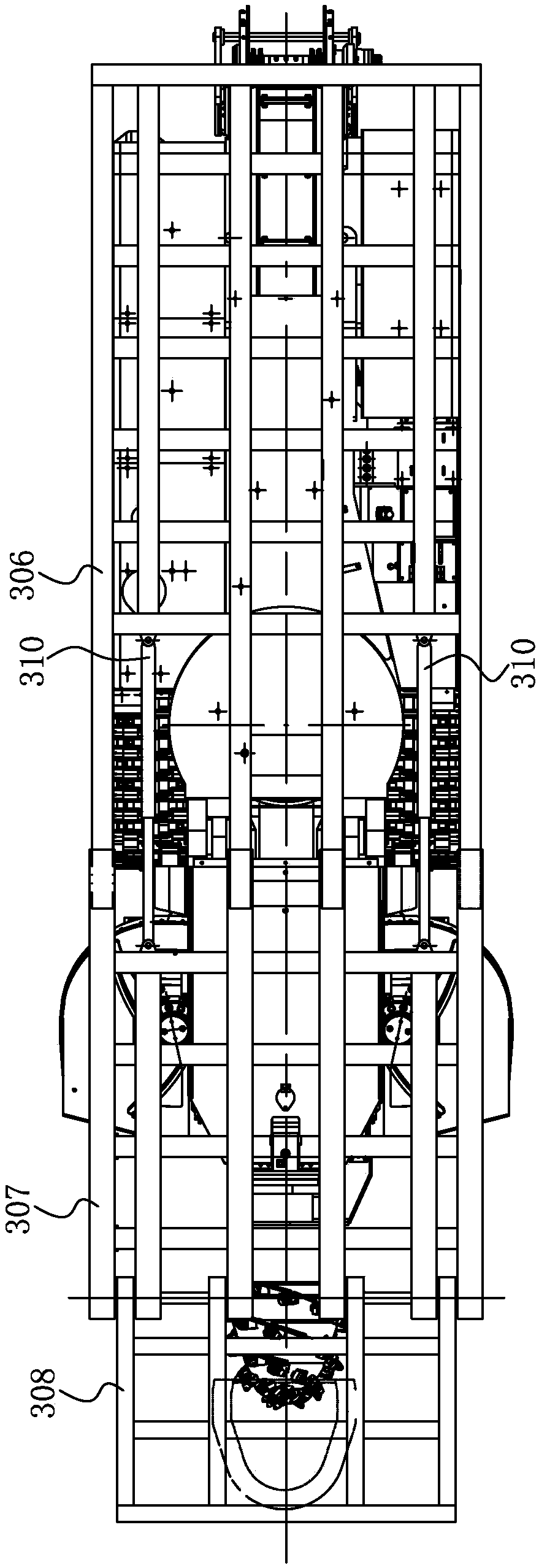

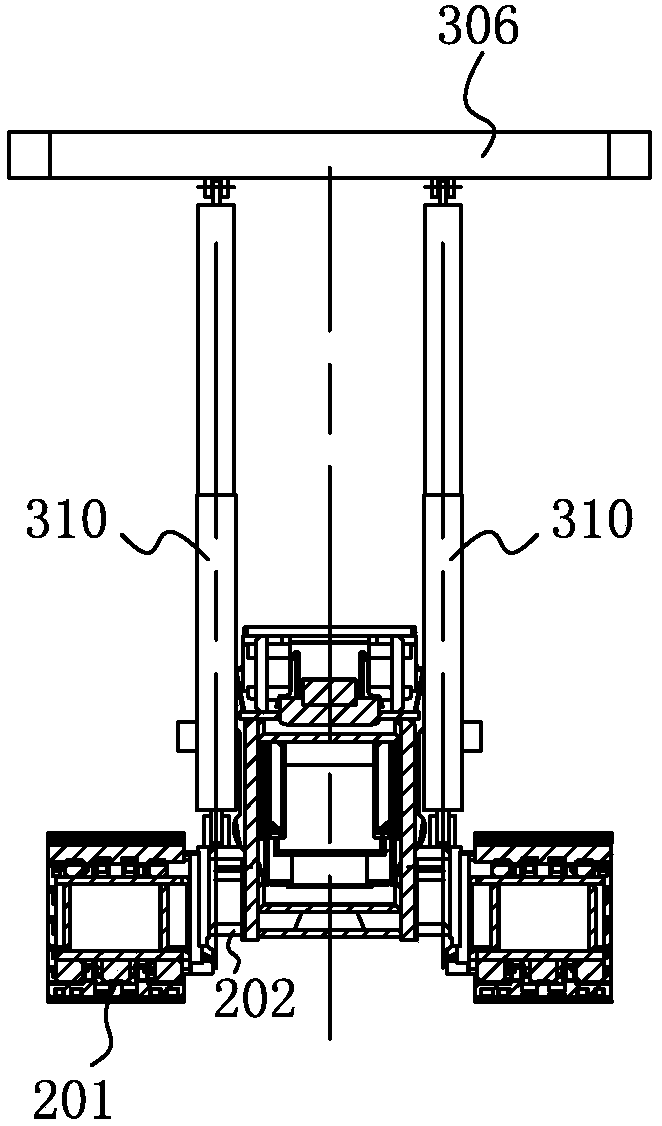

[0027] In this embodiment, the chassis of the cantilever-type longitudinal-axis roadheader is used as the chassis, and a telescopic shield and a rotary shield are arranged on the front and upper part of the chassis to provide a wider and longer protection range for personnel working in front of the roadheader chassis, and a higher carrying capacity. The large temporary safety protection ensures that the construction workers get reliable and safe protection for the construction work in front of the roadheader chassis. Such as figure 1 , figure 2 and image 3 Commonly shown is a cantilever type excavation and protection integrated machine, the frame body 202 is connected with the double crawler type running part 201, and the two together form a chassis. The cantilever type longitudinal axis cutting part 100 is arranged on the upper front of the chassis.

[0028] The base 306 is installed above the chassis through a carrying mechanism, which is a significant difference compar...

Embodiment 2

[0035] Such as Figure 4 As shown, this embodiment is a simplified version of Embodiment 1, which removes the swing shield 308 and the swing power device that drives the swing shield 308 to swing.

Embodiment 3

[0037] Such as Figure 5 As shown, this embodiment is another simplified version of Embodiment 1, which removes the telescopic shield 307 and the telescopic power device that drives the telescopic shield 307 to expand and contract in the longitudinal direction, and directly connects the swing shield 308 to the base through the transverse hinge shaft. Seat 306 is hinged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com