Electric valve

An electric valve, valve body technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inability to realize the miniaturization of electric valve, increase the height of electric valve, etc., and achieve easy welding and release the shortage of compressive strength. , to ensure the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

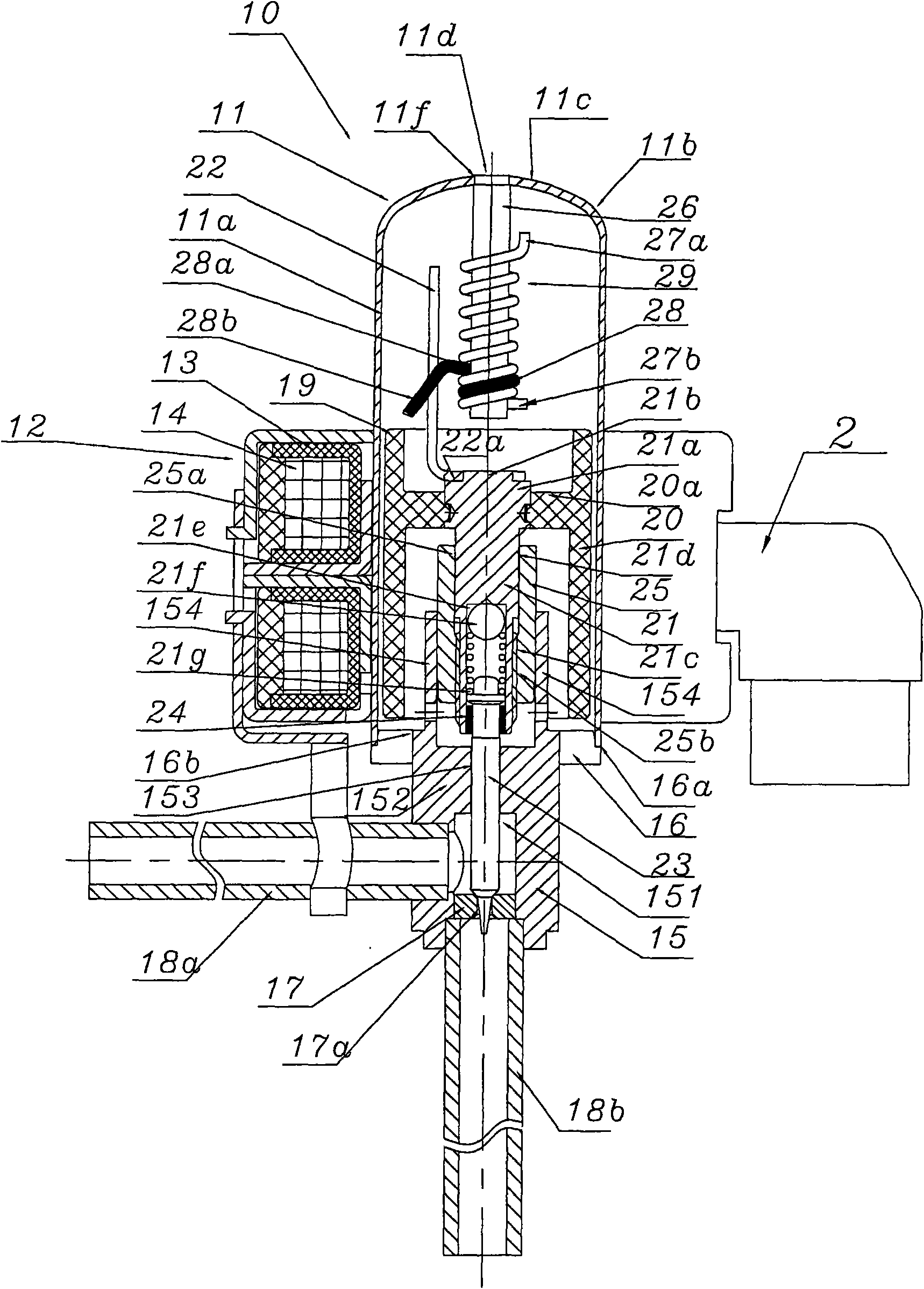

[0052] Below, refer to Figure 1a , Figure 1b , Figure 1c as well as Figure 1d , specifically explain the specific implementation of the electric valve of the present invention.

[0053] Such as Figure 1a As shown, the electric valve represented by the symbol 10 as a whole includes a cylindrical airtight cover 11 formed by stamping metal such as stainless steel, a stator part 12 installed on the outer periphery of the cover 11; a stator yoke 13 of the stator part 12 There is a stator coil 4 inside, and the electric valve is basically the same as the said existing electric valve, so the detailed description is omitted.

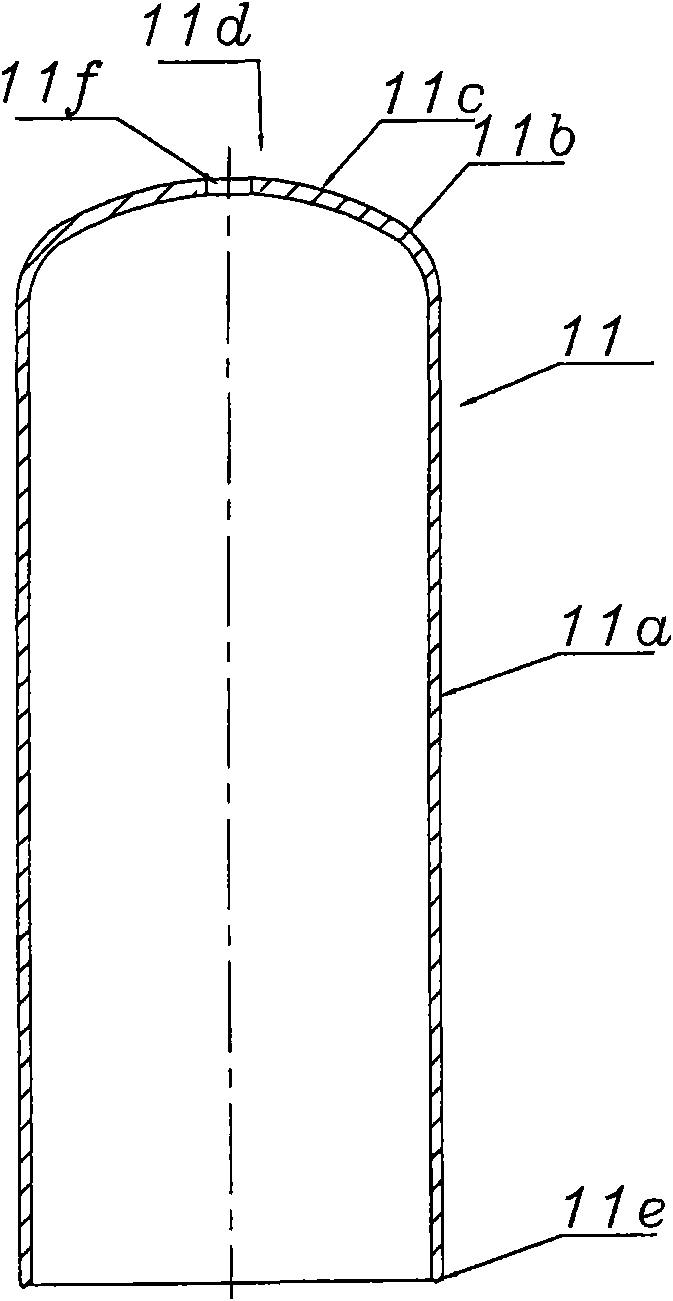

[0054] Such as Figure 1b As shown, the outer cover 11 forming the airtight space is generally composed of a cylindrical wall portion 11a of stainless steel material with a wall thickness of 1 mm, a curved portion 11b integrally connected with the cylindrical wall portion 11a, and an arc portion 11c. Moreover, the arc portion 11c is the top 11d correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com