Filter for extruder

A filter and extruder technology, applied in the field of filters, can solve the problems of difficult cleaning of rubber materials, low strength and deterioration of the porous plate 102, and achieve the effects of preventing the deterioration of cleaning performance, improving productivity and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

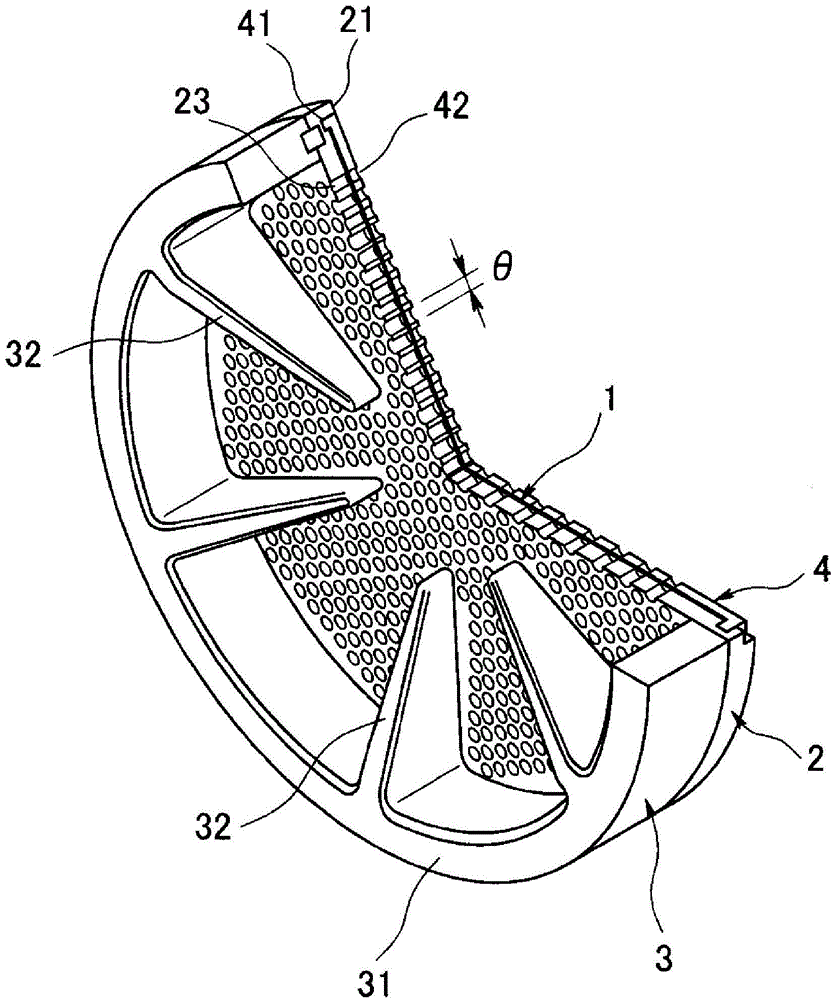

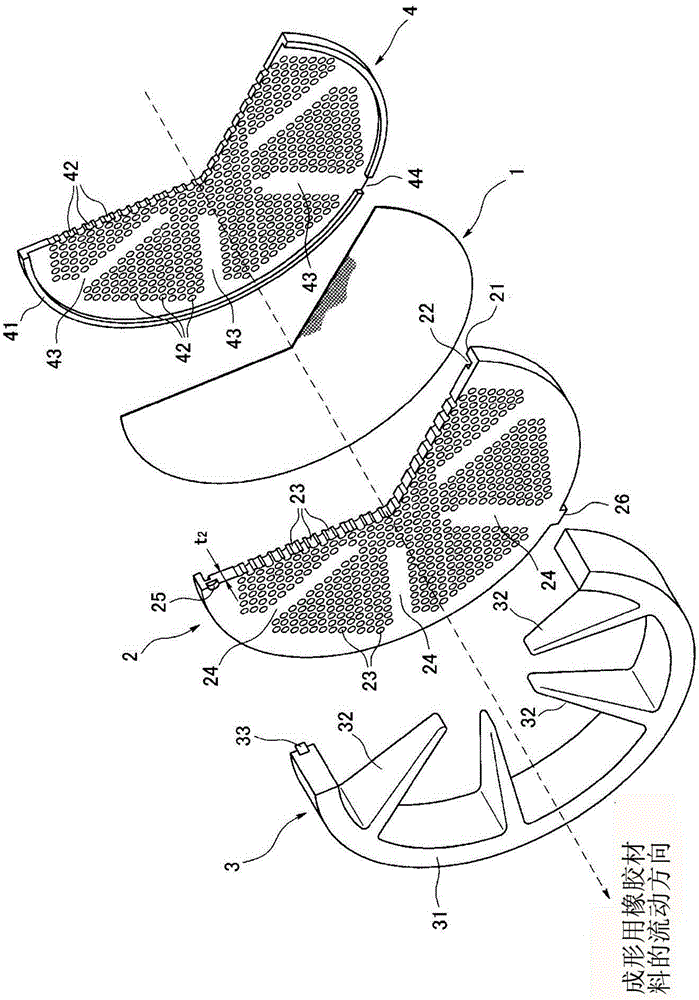

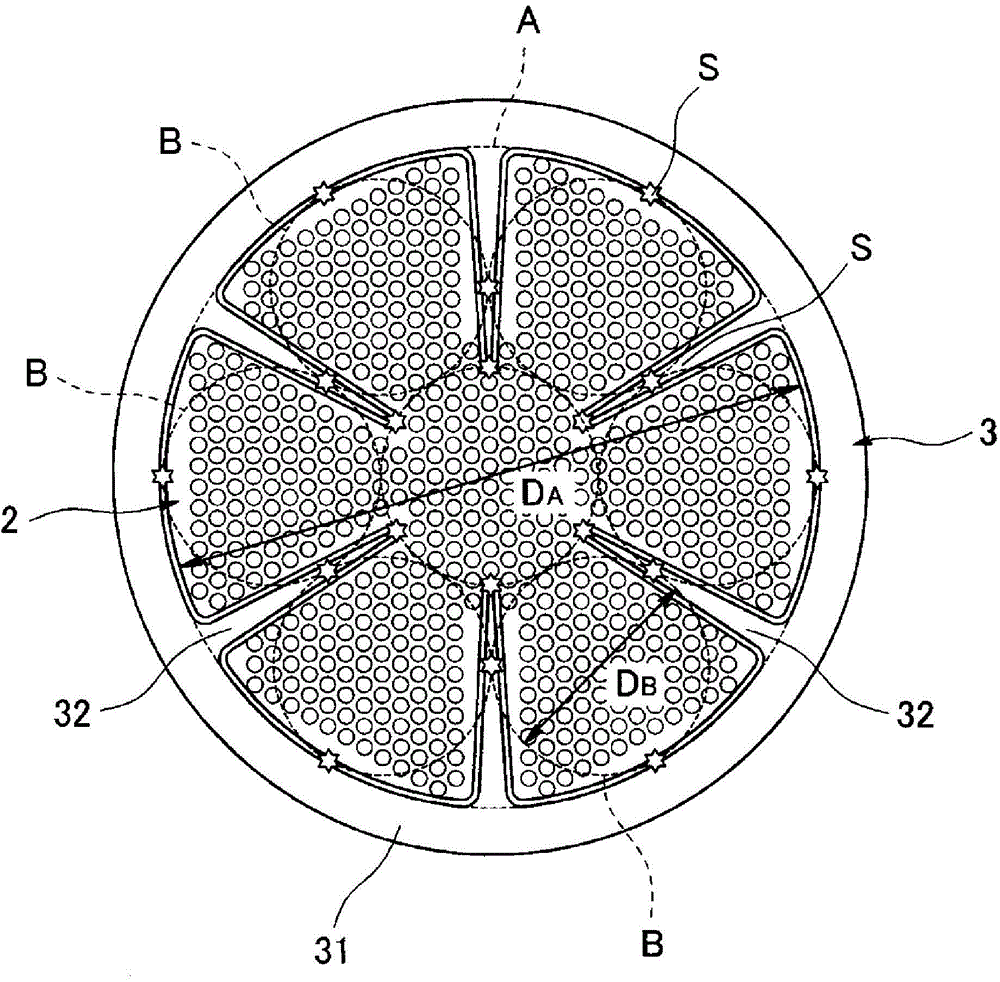

[0037] Hereinafter, preferred embodiments of the extruder filter according to the present invention will be described with reference to the drawings. first, Figure 1 to Figure 4 The first embodiment is shown.

[0038] The filter of the first embodiment is used in an extruder of a rubber material as a polymer material, such as figure 1 as well as figure 2 As shown, it has a filter main body 1, a porous plate (ブレーカープレート) 2 that supports the filter main body 1 from the downstream side in the flow of the rubber material, a support body 3 that further supports the porous plate 2 from the downstream side, The front plate 4 of the filter main body 1 is held between the porous plate 2 .

[0039] The filter main body 1 filters the rubber material for molding, and is constituted by overlapping, for example, several wire meshes of different mesh sizes and shapes, and has a disc shape.

[0040] The perforated plate 2 is made of steel such as chrome-molybdenum steel (SCM), and is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com