Manufacturing method of freeze-dried fruit slices

A production method and technology of fruit slices, which are applied in the fields of fruit and vegetable preservation, protection of fruits/vegetables with a coating protective layer, food drying, etc., can solve problems such as product safety hazards, loss of nutrients, and accelerated enzymatic reactions, etc., to achieve reduction Loss of nutrients and aroma, reduction of enzyme activity, and the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

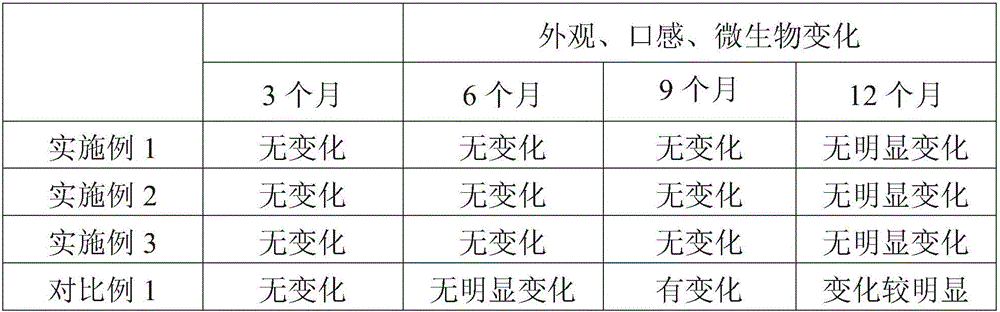

Examples

Embodiment 1

[0031] A method for making freeze-dried fruit slices, which includes the following steps:

[0032] 1) Selection of raw materials

[0033] Select C-grade lemon fruit with the largest inner cut surface diameter of 50-60mm;

[0034] 2) Cleaning

[0035] Put the selected lemons in hydrogen peroxide with a concentration of 5% by weight and ultrasonic treatment at a temperature of 10°C for 25 minutes, and an ultrasonic frequency of 35KHz;

[0036] The lemon washed with hydrogen peroxide was placed in tea water, and ultrasonic treatment was carried out for 30 minutes under a nitrogen atmosphere. The tea was Xinyang Maojian tea, and the tea was prepared with a weight ratio of tea leaves and water of 1:100 according to the conventional tea preparation process ; Among them, the ultrasonic frequency during the cleaning step ultrasonic treatment is 30KHz;

[0037] 3) One-time freeze drying

[0038] Put the cleaned fruit in the freezer compartment and freeze-dry it at -15℃ for 8 hours under sealed co...

Embodiment 2

[0049] A method for making freeze-dried fruit slices, which includes the following steps:

[0050] 1) Selection of raw materials

[0051] Select C grade apples with the largest internal cut surface diameter of 65-70mm;

[0052] 2) Cleaning

[0053] Place the selected apples in hydrogen peroxide with a concentration of 2% by weight, and ultrasonically treat them at a temperature of 5°C for 25 minutes, with an ultrasonic frequency of 40KHz;

[0054] 3) One-time freeze drying

[0055] Place the cleaned apples in the freezer compartment and freeze-dry at -20℃ for 12 hours under sealed conditions; then transfer the frozen apples from the freezer compartment to the working chamber of the vacuum freeze dryer, and set the temperature at a speed of 1.5℃ / min After raising to 65℃, keep it for 8 hours, the vacuum degree is 4Pa;

[0056] 4) De-core

[0057] Use a de-core machine to de-core the freeze-dried apple; keep the ambient temperature at the time of de-core not exceeding 10°C;

[0058] 5) Slice ...

Embodiment 3

[0068] A method for making freeze-dried fruit slices, which includes the following steps:

[0069] 1) Selection of raw materials

[0070] Select C-grade kiwi fruit with the largest inner cut surface diameter of 50-55mm;

[0071] 2) Cleaning

[0072] Place the selected kiwifruit in an ozone aqueous solution with a concentration of 5mg / L, and ultrasonically treat it at a temperature of 5°C for 25 minutes;

[0073] 3) One-time freeze drying

[0074] Put the cleaned kiwi fruit in the freezer and freeze-dried at -25°C for 6 hours under sealed conditions; then transfer the frozen fruit from the freezer to the working chamber of the vacuum freeze dryer, and set the temperature at a speed of 1°C / min After rising to 45℃, keep it for 7 hours, the vacuum degree is 5Pa;

[0075] 4) Peel

[0076] Use a peeling machine to peel the freeze-dried kiwi fruit; keep the environmental temperature at the time of peeling no more than 5℃;

[0077] 5) Slice

[0078] Cut the peeled kiwi fruit into slices with a thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com